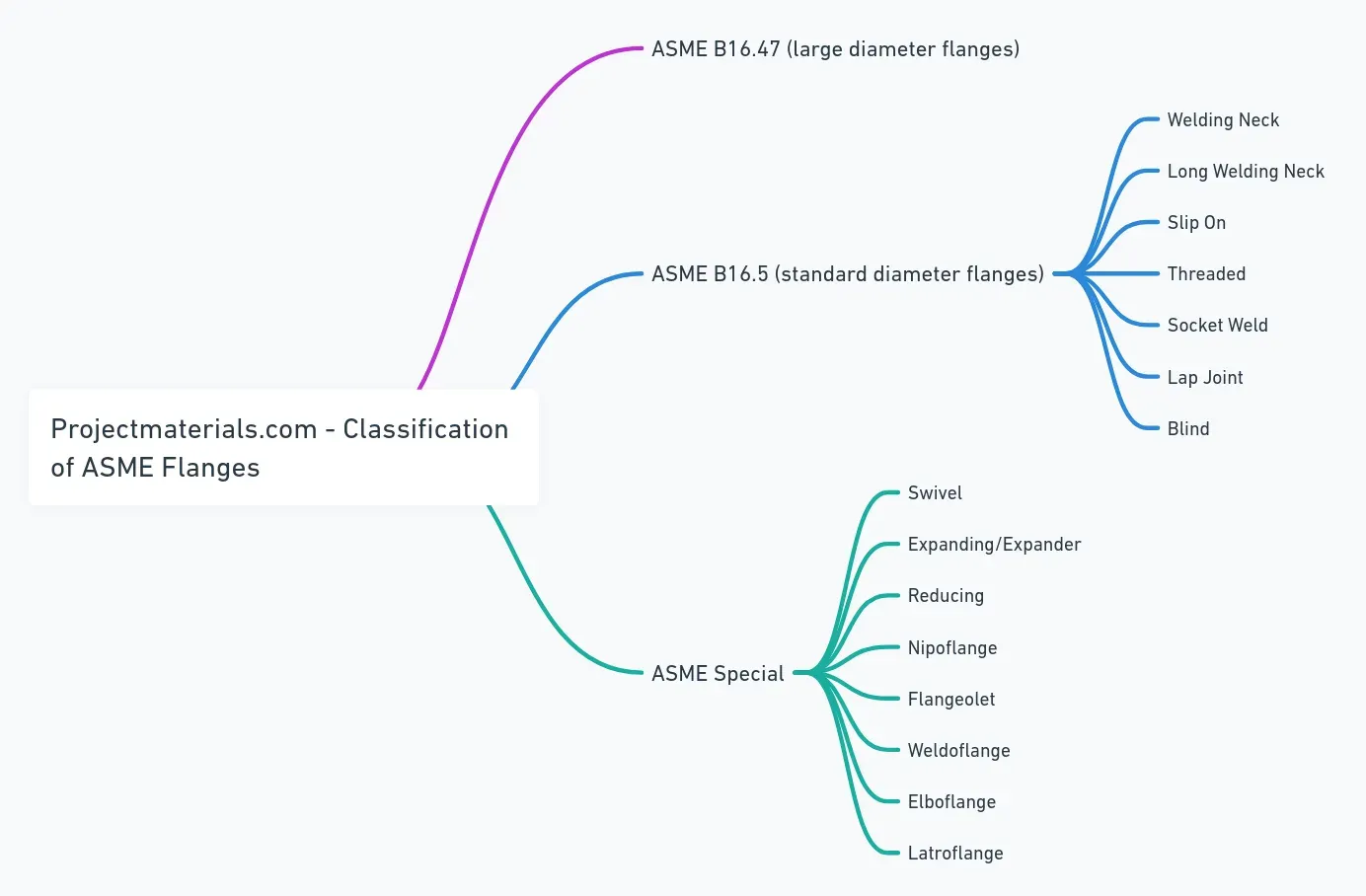

13 Flange Types (ASME B16.5)

Types of Flanges

Standard Types (ASME)

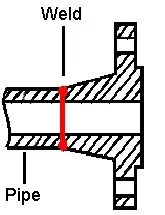

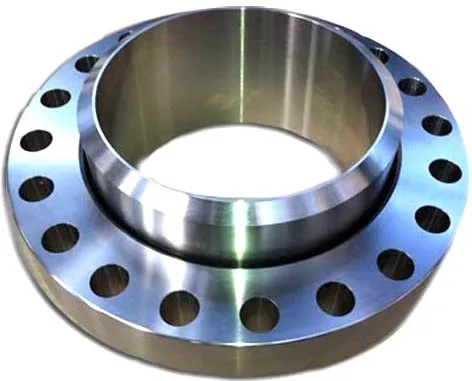

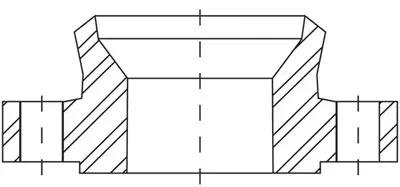

Welding Neck Flange (“WNF”)

The weld neck flange features a tapered hub that provides stress distribution and reinforcement for high-pressure and high/low-temperature applications. The bore matches the pipe ID for unrestricted flow.

| Feature | Description |

|---|---|

| Connection | Single full-penetration V-shaped butt weld |

| Bore | Machined to match pipe ID (smooth flow, no turbulence) |

| Standards | ASME B16.5 (≤24”), B16.47 (>24”) |

| Applications | High P/T, fluctuating conditions, critical services |

Advantages: Strong welded joint; tapered hub reduces stress concentration; allows radiographic inspection; no pressure drops at joint.

Long Welding Neck (“LWNF”)

The Long Welding Neck Flange has an extended neck for additional reinforcement in high-stress applications. Used to connect piping to pressure vessels, boilers, and heat exchangers where clearance for insulation is needed.

| Feature | Description |

|---|---|

| Connection | Butt-weld (same as WNF) |

| Variants | Heavy Barrel (HB), Equal Barrel (E) |

| Applications | Vessels, columns, barrels; thermal expansion/contraction zones |

Advantages: Better stress distribution along extended neck; handles piping misalignment; resists vibration and thermal cycling.

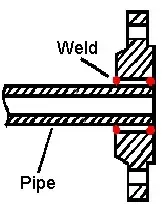

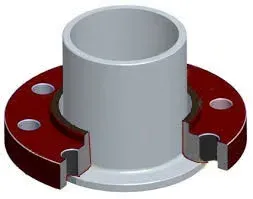

Slip-On Flange

The slip-on flange slides over the pipe and is connected by two fillet welds (inside and outside). Also called “Hubbed Flanges” due to their slim, compact shape. The bore is larger than the pipe OD to allow insertion.

| Feature | Description |

|---|---|

| Connection | Two fillet welds (inside + outside) |

| Bore | Larger than pipe OD (pipe slides in) |

| Applications | Lower P/T, non-critical services (water, HVAC) |

Advantages: Lower cost; easier alignment than WNF; suitable for tight spaces.

Limitations: Lower strength than WNF; not for high P/T or fatigue conditions.

Weld Neck vs. Slip-On

| Aspect | Weld Neck | Slip-On |

|---|---|---|

| Strength | Higher (tapered hub) | Lower |

| Welds | 1 butt weld | 2 fillet welds |

| Cost | Higher | Lower |

| Connection | Pipes + fittings | Pipes only |

| Application | High P/T, critical | Low P/T, non-critical |

Threaded Flange

The pipe screws directly into the flange (NPT threads per ASME B1.20.1) without welding. Small seal welds may be added for extra strength.

Sizes: Up to 4” typically. Applications: Low P/T utility services (water, air); mandatory in explosive areas where welding is prohibited.

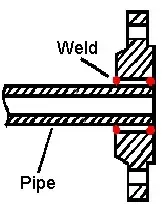

Socket Weld Flange

The pipe inserts into the socket and is secured by a single fillet weld on the outside. Per ASME B31.1, insert pipe to bottom of socket, then lift 1.6 mm before welding (allows for weld solidification positioning).

Applications: Small-size, high-pressure piping. Not for corrosive fluids-the gap between pipe end and socket shoulder is prone to crevice corrosion.

Strength: Similar static strength to slip-on, but higher fatigue strength (single weld vs. double).

Lap Joint Flange

Lap joint flanges are always used with a stub end. The flange slips over the pipe and seats on the stub end’s flanged portion; bolts hold the assembly together.

Cost-saving design: Use carbon steel lap joint flange with stainless/nickel alloy stub end-only the stub end (in contact with fluid) needs high-grade material. The flange can rotate freely for easy bolt alignment.

Blind Flange

Blind flanges have no center hole-used to seal pipeline ends, valves, or pressure vessels. Must withstand full system pressure plus bolting forces. Easy to unbolt for pipeline access (also used as pressure vessel manholes).

Special Types (ASME)

Nipoflange

A Nipoflange creates 90° branch connections-a single forged piece combining a weld neck flange and a Nipolet. Weld the Nipolet portion to the run pipe; bolt the flange to the branch pipe. Available in reinforced variants for higher strength.

Materials: A105, A350, A182 (stainless, duplex), nickel alloys.

Weldoflange

A Weldoflange combines a weld neck flange with a branch fitting-weld directly to the run pipe for a reinforced branch connection. Eliminates separate tee + flange combinations; space-saving for congested areas.

Applications: High P/T branch connections in oil & gas, petrochemical, power generation.

Elboflange

An Elboflange integrates an elbow + flange into one piece-changes flow direction while providing a flanged connection. Reduces fittings and welds; ideal for tight spaces.

Applications: Connecting piping to compressors, reactors, tanks, boilers, turbines where direction change + flange connection is needed.

Latroflange

A Latroflange combines a lateral tee + flange-creates angled branch connections (typically 45°) with a flanged outlet. Reduces turbulence vs. 90° branches; easier equipment attachment.

Applications: Process instrumentation connections, bypass lines, flow distribution systems.

Swivel Flange

Swivel flanges rotate freely on the pipe for bolt hole alignment-required for large-diameter pipelines, subsea/offshore installations, and shallow water pipe works.

Availability: All standard flange shapes (WN, SO, LJ, SW); sizes 3/8” to 60”; Classes 150-2500. Materials: A105, A182 F1/F5/F9/F91, A182 F304/F304L/F316/F316L.

Expanding and Reducing Flanges

Expander flanges increase pipe bore; reducer flanges decrease pipe bore. Both limited to 1-2 size changes maximum-for larger changes, use buttweld reducer + standard flange.

Materials: A105, A350, A182. Faces: RF, FF per ASME B16.5.

European Types of Flanges (EN/DIN/ISO)

European flanges follow EN 1092-1 (superseding older DIN standards) with pressure ratings in PN (Pressure Nominale, bars) vs. ASME Class system.

| Standard | Flange Types |

|---|---|

| EN 1092-1 | Type 01 (plate), Type 02 (loose plate), Type 05 (blind), Type 11 (weld neck), Type 13 (threaded) |

| DIN | DIN 2501 (bolt/face dimensions), DIN 2631-2638 (weld neck), DIN 2576 (slip-on) |

| ISO 7005-1 | Mirrors EN 1092-1 for global compatibility |

Dimensions: DN 10 to DN 4000. Materials: Carbon steel, stainless steel, alloys.

See also:

- EN 1092 Weld Neck Flange Sizes

- EN 1092 Blind Flange Sizes

- EN 1092 Threaded Flange Sizes

- EN 1092 Plate Flange Sizes

Flange Selection Criteria

| Factor | Considerations |

|---|---|

| Pressure/Temperature | WNF for high P/T; SO for moderate conditions |

| Fluid properties | Corrosive → stainless/alloy; crevice-sensitive → avoid SW |

| Assembly/Maintenance | LJ for frequent disassembly; threaded for no-weld zones |

| Space/Weight | Threaded or SW for compact installations |

| Cost | SO < WNF; LJ + stub end reduces high-grade material use |

| Safety | WNF for critical services; verify correct P/T rating |

| Installation | Threaded where welding prohibited; swivel for alignment |

| Standards | ASME B16.5/B16.47 (US), EN 1092-1 (Europe) |

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

Such a great blog and I really appreciate to read this blog.

informative blog, can you make a blog on its application of carbon flanges. ms flanges

Thank you very much. Your blog helped me a lot during my research!

a very good and informative blog thanks for this blog waiting for you to make a blog on different types of fittings .

Good knowledge

This blog is very useful specifically for giving the complete details and explanation.

Thanks!;)

Thank you for your appreciated comment. Should you need further information on some specific topics, kindly send us an email to [email protected]. To submit an RFQ for piping materials, please visit this page: https://projectmaterials.com/submit-rfq-mto. Best regards, Projectmaterials

This blog is exceptionally valuable explicitly for giving the total subtleties and clarification.

What are the two welded dots on a slip on flange for?

we liked your blogs very much thanks for such good information for more Details On Example link

Thanks, what an informative post! Everything we need to know are found in this article. We hope you keep posting quality articles.

very nice post, I found something more interesting

I have a flange of 24″ 600 psi to match a pipe of 24″ sch 30 (0.532 inch), but the skirt of the flange is 0.602. Can I accept this kind of flange with that difference

Can you tell us more about this? I'd care to find out more details.

What's up, this weekend is good designed for me, because this point in time i am reading this impressive informative paragraph here at my home.

Thank you so much for writing such an informative blog. If you are looking for ms flange manufacturer then do consider Apex ms flange.

how we decide number of holes on a flange? Do we have any calculation? Please suggest any reference material to get to the answer of my question. thanks

Dear sir Can the outer rim of the 2” #150 be snip a of a bit to avoid touching another pipe

Dear Alex, may you please explain the question a bit more?

Great information shared. i want to get the customized flanges products as per my requirements so any one tell me the best place where i can buy it now.

Do you have a distributor in United Arab Emirates ? If so please let me know, Regards,

This blog post is full of great information! Thank you for sharing your knowledge.

Thank you so much for the pipe welding information. TIG welder is the best, durable, reliablle and affordable way to weld the pipes no matter what kind of including steel, copper, mild etc.

Very informative blog

Thanks for the info about pipes and flanges. I need to buy pipes. I'll consider this information as I look for steel pipes to purchase.

Your article answered all of the important points and seemed fantastic and helpful. Keep up the wonderful work!

Weld repairs to aircraft and component parts use such equipment as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), plasma arc welding, and oxyacetylene gas hobby tig welder welding. When repairs of hobby tig welder any of flight-critical parts are required,

Hi There, Thanks for sharing the blog and this great information which is definitely going to help us. Well done. https://dic-oiltools.com/flanges.php

This site is excellent.it has very nice look and perefect writing style. This information is better and very important for machinery/flanging-series It is maybe interesting to observe that, while this flanges type is easier to manufacture, they are sold at a premium average cost per kilogram compared to the other flange types. This is part important for mattress flanging machines

Thanks for posting this helpful blog and We are a HUSAIN S.S FABRICATION Company whose that fabrication work near me and S.S Steel Works in Gurgaon.Before More Information visit our website:- http://www.husainssfabriction.co.in

Great article! You have explained about the various kinds of flanges in great detail in this article. I have now understood the various kinds of flanges such as Inconel Flanges, Hastelloy Flanges, Monel Flanges and Nickel Flanges. Thank you for sharing all this information with us.

Top notched information available

A disadvantage of slip-on and socket weld flanges is that it is not possible to perform radiographic inspection on the weld. You imply this in the description of the weld neck flange, where you point out that radiographic examination is possible. Radiographic examination is generally possible on all butt welds and not possible on fillet welds – also not possible on nipoflanges and weldoflanges.

The details given about flanges are informative, crispy and handy. It is easy to read and understand for non technical person also. Looking forward for more read.

Tube Expander The Best Product More information is in the link in the website box

THAT IS PIPE TO FLANGE WELDING POINT

Great information. Nice Blog!! #asia129 https://top129.shop

such a great information for me i am researching for ms flange manufacturer in bhavnagar .

WHAT WE DO We are the Large diameter elbow stockist for seamless and welded,Size:8inch to 48inch Supply piping system products ,trying to be a good piping solution provider. Help customers solve their needs for Material. Butt Weld Pipe Fittings Products: Flanges Products: Piping Products: Supplier: CANGZHOU SIJIN INTERNATIONAL TRADING CO.,LTD Warehouse 1 :Zhenggang Industrial Zone, Yanshan County, Cangzhou City, Hebei Province, China Warehouse 2 :Guajialin Industrial Zone, Mengcun Hui Autonomous County, Cangzhou City, Hebei Province, China Head Office: [email protected] Sales Department:[email protected] / [email protected] TEL:15632773869 http://www.sijinpiping.com