Flow Meters: 8 Types for Oil & Gas Piping

Flow Meters in Oil & Gas

What Are Flow Meters?

A flow meter measures the rate at which fluid or gas moves through a pipeline, expressed as volume or mass per unit time (liters per minute, kilograms per second, etc.).

Industrial Flow Meter

Industrial Flow Meter

In oil and gas, flow meters serve two fundamental purposes: process control (you need to know what’s flowing where) and custody transfer (money changes hands based on these readings). Get the measurement wrong, and you either lose product or lose a client.

The main flow meter types (Coriolis, ultrasonic, electromagnetic, turbine, differential pressure, positive displacement, vortex, and thermal) each have distinct strengths. Which one you pick depends on the fluid (clean liquid? dirty slurry? wet gas?), the pipe size, the required accuracy, and whether particulates, temperature, or pressure will complicate things.

Key Takeaway: Flow meter selection in oil and gas depends on the application: Coriolis meters for high-accuracy mass flow and custody transfer, ultrasonic meters for non-intrusive measurement on large pipes, electromagnetic meters for conductive liquids and slurries, differential pressure meters for versatile and cost-effective service, and positive displacement meters for precise volumetric billing. Regular calibration against traceable standards is mandatory for all custody transfer applications.

Flow Meter Applications in Oil & Gas

In the field, flow meters handle four main jobs:

| Application | Purpose | Typical Meter Types |

|---|---|---|

| Custody transfer | Measuring volumes at buy/sell points where ownership changes | Coriolis, ultrasonic (multi-path), PD meters |

| Process control | Regulating flow within the plant to maintain setpoints | Vortex, DP, electromagnetic, turbine |

| Leak detection | Comparing upstream/downstream readings to spot pipeline losses | Ultrasonic (clamp-on), Coriolis |

| Emissions monitoring | Measuring flare gas, vent gas, and discharges for environmental compliance | Thermal, ultrasonic, vortex |

What Is Custody Transfer?

Custody transfer is the point where ownership of a commodity (crude oil, natural gas, refined products, LNG) changes hands between buyer and seller. Every barrel or cubic meter at that point has a dollar value attached, so measurement accuracy is not optional. A 0.25% error on a 100,000 bbl/day transfer point costs someone real money, every single day.

Electromagnetic flow meter for custody transfer

Electromagnetic flow meter for custody transfer

Custody transfer metering stations typically use Coriolis or positive displacement meters for liquids and multi-path ultrasonic meters for gas, backed by quality analyzers, provers, and third-party verification. The documentation (quantity, quality, time, conditions) must be bulletproof, because it is the first thing auditors and lawyers pull during a dispute.

The 8 Types of Flow Meters

- Coriolis: Direct mass flow, highest accuracy. The standard for custody transfer and multi-parameter measurement (mass, density, temperature).

- Ultrasonic: Non-intrusive, no pressure drop. Transit-time for clean fluids, Doppler for dirty fluids. Dominates large-diameter pipelines.

- Electromagnetic: Handles conductive liquids including slurries, corrosive fluids, and wastewater. No moving parts, no pressure drop.

- Thermal: Direct gas mass flow without pressure/temperature compensation. Excellent at low flow rates and for emissions monitoring.

- Turbine: High accuracy on clean, steady liquid flows. Linear output and fast response, but moving parts wear over time.

- Differential Pressure: The oldest technology, still the most widely installed. Orifice plates, venturi tubes, pitot tubes.

- Positive Displacement: Traps and counts discrete volumes. Best accuracy on viscous fluids and low-flow custody transfer.

- Vortex: No moving parts, handles liquids, gases, and steam. The default choice for steam metering in process plants.

Coriolis Flow Meters

The Coriolis flow meter is the benchmark for mass flow measurement. One or more tubes vibrate at their natural frequency, and as fluid flows through, the Coriolis forces create a phase shift in the vibration pattern that is directly proportional to mass flow rate. Measuring the vibration frequency also gives you fluid density, so from a single instrument you get mass flow, volumetric flow, density, and temperature.

Coriolis flowmeter

Coriolis flowmeter

What makes the Coriolis meter so valued in custody transfer is that it measures mass directly, with no need to calculate density separately and multiply. Changes in temperature, pressure, or viscosity do not affect the reading. There are no moving parts in the flow path, so maintenance is minimal.

The downside? Cost. A 6-inch Coriolis meter can run 3-5x the price of an equivalent orifice plate installation. Size is also a practical limit; Coriolis meters above 12 inches become heavy, expensive, and introduce significant pressure drop. But on a custody transfer station moving $50M/year in product, the payback on that accuracy is measured in weeks, not years. Coriolis meters dominate in petrochemical batching, oil and gas custody transfer, and pharmaceutical dosing, anywhere the cost of inaccuracy exceeds the cost of the instrument.

Ultrasonic Flow Meters

Ultrasonic flow meters measure fluid velocity using sound waves, then calculate flow rate from the velocity and pipe cross-section. Their biggest advantage is that clamp-on models require no pipe penetration: no process shutdown, no pressure drop, no contamination risk. You bolt transducers to the outside of the pipe and start measuring.

Ultrasonic flow meter

Ultrasonic flow meter

Two types exist, and choosing the wrong one is a common field mistake:

Transit-time ultrasonic flow meters send ultrasonic pulses both with and against the flow. The time difference between downstream and upstream pulses gives you the fluid velocity. These work well on clean, particulate-free liquids, but scatter and absorb badly if the fluid carries solids or gas bubbles.

Doppler ultrasonic flow meters rely on the frequency shift of ultrasonic signals bouncing off suspended particles or bubbles. They actually need particulates or aeration to function, the exact opposite of transit-time meters. If someone hands you a Doppler meter for clean demineralized water service, send it back.

Ultrasonic meters excel on large-diameter pipelines (24 inches and above) where other technologies become prohibitively expensive or impractical. Multi-path transit-time meters with 4+ paths now achieve custody-transfer accuracy on gas pipelines per AGA Report No. 9, and they are the standard choice for fiscal metering on large gas trunk lines.

Electromagnetic Flow Meters

Electromagnetic flow meters (mag meters) operate on Faraday’s law of electromagnetic induction: when a conductive fluid passes through a magnetic field, it generates a voltage proportional to its velocity. Two electrodes in the pipe wall pick up this voltage, and the meter calculates volumetric flow rate from the velocity and pipe cross-sectional area.

The critical requirement is that the fluid must be electrically conductive, with a minimum conductivity of about 5 µS/cm for most meters. This rules out hydrocarbons, pure water, and gases, but opens the door to a wide range of applications that other meters handle poorly: produced water, drilling mud, chemical injection, water treatment, and slurry service.

Electromagnetic meters have no moving parts and no obstructions in the flow path, which means zero pressure drop and nothing to wear or foul. The wetted parts can be lined with PTFE, rubber, or ceramic to handle corrosive and abrasive fluids. This makes them the go-to choice for:

- Produced water and injection water in oil and gas operations

- Slurry service (mining, dredging, cement) where particulates would destroy turbine or PD meters

- Corrosive chemicals (acids, caustics) where the liner protects the meter body

- Wastewater and effluent monitoring for environmental compliance

- Utility water metering in refineries and petrochemical plants

Accuracy is typically ±0.5% of reading for inline meters and ±2% for insertion types. The meters are available in sizes from ½ inch to 120 inches, covering everything from chemical dosing lines to large-diameter cooling water headers.

Thermal Flow Meters

Thermal flow meters (thermal mass flow meters) measure gas mass flow rate by quantifying heat transfer. They are the go-to choice for gas measurement (flare gas, vent gas, emissions monitoring, HVAC airflow, biogas), especially at low flow rates where other technologies lose sensitivity.

Thermal flow meter

Thermal flow meter

Two measurement methods are used. The constant temperature differential method maintains a fixed temperature difference between a heated sensor and a downstream reference; as flow increases, more heat is carried away, and the power required to hold that differential is proportional to mass flow. The constant power (hot-wire anemometer) method applies fixed power to a heated element and measures the cooling effect: faster flow, more cooling, lower element temperature.

The practical advantage: thermal meters give you mass flow directly without needing separate pressure and temperature compensation. They have no moving parts, handle very low flow rates well, and work on clean, dry gases. Their weakness is sensitivity to gas composition changes; if the thermal conductivity of the gas shifts (say, because the CO2/methane ratio changes in a biogas line), the reading drifts. For that reason, they need application-specific calibration and are not typically used for custody transfer.

Turbine Flow Meters

Turbine flow meters are straightforward: fluid spins a rotor, a magnetic pickup counts the blade passes, and each pulse corresponds to a known volume. The pulse frequency is linear with flow rate, which makes signal processing simple and response time fast.

Turbine flow meter

Turbine flow meter

Under optimal conditions (clean, steady flow, moderate viscosity), turbine meters achieve ±0.5% accuracy or better, with a wide turndown ratio. They have been a workhorse for petroleum product measurement and natural gas metering (per AGA Report No. 7) for decades.

The catch is that turbine meters have moving parts in the flow stream, and those parts wear. Particulates chew up the bearings and blade edges, viscous fluids drag on the rotor, and pulsating flow from reciprocating pumps can destroy accuracy and fatigue the blades. I have seen turbine meters in dirty crude service lose 2% accuracy in under six months. If your fluid is not clean and your flow is not steady, pick a different technology. When the application fits, though (clean refined products, aviation fuel, demineralized water), turbine meters deliver excellent performance at a reasonable cost.

Differential Pressure Flow Meters

Differential pressure (DP) flow meters are the oldest and most widely installed flow measurement technology in the world. The principle is Bernoulli’s equation in practice: put a restriction in the pipe (orifice plate, venturi tube, flow nozzle, or pitot tube), measure the pressure drop across it, and calculate the flow rate from the square root of that pressure difference.

Differential flow meter

Differential flow meter

Orifice plates are by far the most common primary element: a flat plate with a precision-bored hole, sandwiched between flanges. They are cheap, well-understood, and covered by extensive standards (ISO 5167, AGA Report No. 3). Venturi meters recover more pressure (lower permanent pressure loss) but cost more and take up more space. Flow nozzles sit between the two in terms of cost and pressure recovery. Pitot tubes (and averaging pitot tubes like Annubar) are insertion devices that measure velocity at a point or across the pipe, useful for large ducts and stacks where installing an orifice plate is impractical.

DP meters handle liquids, gases, and steam across a wide range of temperatures and pressures. They have no moving parts and, with a quality DP transmitter, can deliver ±1% accuracy on well-characterized flows. The trade-off is a permanent pressure drop (energy lost to the restriction) and a square-root relationship that limits the useful turndown ratio to about 4:1 or 5:1 with a single transmitter. For wider rangeability, you need stacked transmitters or a different technology.

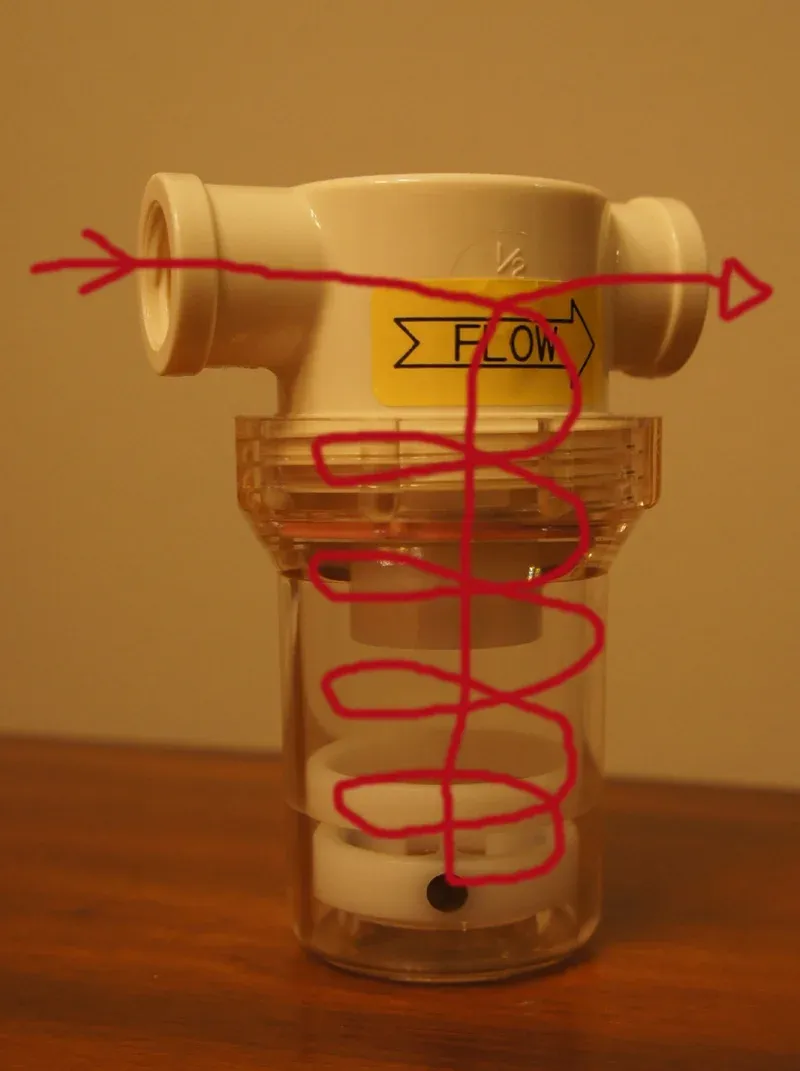

Positive Displacement Flow Meters

Positive displacement (PD) flow meters trap a fixed volume of fluid, transfer it through a chamber, and count the cycles. Each cycle equals a known volume, so the total flow is simply the number of cycles multiplied by the chamber volume. No inference, no calculation from velocity profiles, just direct volumetric measurement.

Positive displacement flow meters

Positive displacement flow meters

Common PD meter types include rotary vane, oval gear, piston, and diaphragm designs. The choice depends on the fluid: oval gear meters handle viscous liquids well (heavy fuel oil, lubricants), diaphragm meters dominate residential gas metering, and piston meters are common in chemical dosing.

PD meters shine on viscous fluids and at low flow rates, conditions where turbine meters and DP meters lose accuracy. In fact, higher viscosity actually improves PD meter performance by reducing slippage past the sealing surfaces. This makes them a natural fit for crude oil custody transfer and heavy fuel oil billing.

The trade-off is mechanical complexity. Moving parts wear, especially with abrasive or dirty fluids. PD meters also impose a pressure drop on the system. Calibration drift from wear is a real concern on high-value custody transfer points; budget for regular proving and do not assume the factory calibration will hold indefinitely.

Vortex Flow Meters

Vortex flow meters use the von Karman vortex street principle: a bluff body in the flow path sheds alternating vortices, and the shedding frequency is proportional to fluid velocity. A piezoelectric or capacitive sensor downstream picks up the vortices and converts the frequency into a flow signal.

Vortex flow meters

Vortex flow meters

No moving parts, minimal pressure drop, and they handle liquids, gases, and steam; vortex meters are among the most versatile options in process flow measurement. Steam metering in particular is where vortex meters have carved out a dominant position, because they tolerate the high temperatures and pressures that would destroy turbine meter bearings.

The limitations are real, though. Vortex meters need a minimum Reynolds number to generate stable vortex shedding, so they lose accuracy at low flow rates and with high-viscosity fluids. They are also sensitive to flow disturbances; an elbow or control valve too close upstream produces asymmetric vortex shedding and measurement errors. Budget for proper straight runs (typically 15-20D upstream, 5D downstream) or install flow conditioners. For general process monitoring, utility steam, and compressed air measurement, vortex meters are hard to beat on a cost-per-point basis.

Flow Meter Comparison Table

| Type | Accuracy | Turndown | Pressure Drop | Moving Parts | Best Application | Relative Cost |

|---|---|---|---|---|---|---|

| Coriolis | ±0.1-0.2% | 80:1 to 100:1 | Moderate | None | Custody transfer, mass flow | High |

| Ultrasonic | ±0.5-1% (±0.1% multi-path) | 50:1 to 100:1 | None (clamp-on) | None | Large pipes, gas fiscal metering | Medium-High |

| Electromagnetic | ±0.5% | 30:1 to 100:1 | None | None | Conductive liquids, slurries | Medium |

| Thermal | ±1-2% | 100:1 | Low | None | Gas mass flow, low flow rates | Medium |

| Turbine | ±0.5% | 10:1 to 20:1 | Moderate | Rotor, bearings | Clean liquids, petroleum products | Low-Medium |

| Differential Pressure | ±1-2% | 4:1 to 5:1 | High (orifice) | None | General purpose, established plants | Low |

| Positive Displacement | ±0.5% | 10:1 to 20:1 | High | Gears, vanes | Viscous fluids, liquid billing | Medium |

| Vortex | ±0.75-1% | 20:1 to 40:1 | Low-Moderate | None | Steam, general process | Low-Medium |

How to Select a Flow Meter

Selecting the right flow meter starts with the fluid and the application, not the technology. Work through these questions in order:

Step 1: What is the fluid?

- Gas → Consider thermal (low flow), ultrasonic, vortex, or DP (orifice/venturi)

- Clean liquid → Coriolis, ultrasonic (transit-time), turbine, vortex, or DP

- Conductive liquid or slurry → Electromagnetic

- Viscous liquid (>10 cP) → Positive displacement or Coriolis

- Steam → Vortex (first choice), DP (orifice or nozzle)

Step 2: What accuracy do you need?

- Custody transfer (±0.1-0.5%) → Coriolis, PD, or multi-path ultrasonic

- Process control (±1-2%) → Almost any technology works; optimize on cost and maintenance

- Indication only (±2-5%) → Clamp-on ultrasonic, rotameter, or variable area

Step 3: What is the pipe size?

- Small bore (½” to 2”) → Coriolis, turbine, PD, electromagnetic

- Medium (3” to 12”) → All types viable; select based on fluid and accuracy

- Large (>12”) → Ultrasonic, electromagnetic, DP (venturi/pitot), or insertion vortex

Step 4: What are the constraints?

- No shutdown allowed → Clamp-on ultrasonic or insertion meters

- Zero pressure drop required → Clamp-on ultrasonic or electromagnetic

- Minimal maintenance → Electromagnetic, ultrasonic, vortex (no moving parts)

- Limited straight run → Coriolis (0-5D) or conditioning orifice plate (2D)

- Hazardous area → Verify meter has appropriate ATEX/IECEx certification

Flow Meter Selection Guide by Fluid Type

| Fluid | First Choice | Second Choice | Avoid |

|---|---|---|---|

| Crude oil | Coriolis | PD (oval gear) | Electromagnetic |

| Refined products | Turbine | Coriolis | - |

| Natural gas (fiscal) | Ultrasonic (multi-path) | DP (orifice, AGA 3) | PD |

| Process gas | Vortex | Thermal | Turbine |

| Steam | Vortex | DP (orifice/nozzle) | Coriolis, electromagnetic |

| Produced water | Electromagnetic | Ultrasonic | Turbine |

| Slurry / drilling mud | Electromagnetic | Doppler ultrasonic | Turbine, PD |

| Chemical injection | Coriolis | PD (piston) | DP |

| Flare gas | Thermal | Ultrasonic | DP (low-pressure issues) |

| LNG / cryogenic | Coriolis | Turbine | Electromagnetic, vortex |

Installation Guidelines

Every flow meter has straight-run requirements, meaning the length of undisturbed pipe needed upstream and downstream to develop a proper velocity profile. Violating these requirements is the single most common cause of flow measurement error in the field.

Straight Run Requirements by Meter Type

| Meter Type | Upstream (pipe diameters) | Downstream (pipe diameters) | Notes |

|---|---|---|---|

| Coriolis | 0-5D | 0-3D | Least sensitive; some manufacturers specify zero straight run |

| Electromagnetic | 5-10D | 3-5D | More tolerant than most; 5D upstream sufficient for most disturbances |

| Ultrasonic (transit-time) | 10-20D | 5D | Multi-path designs are more tolerant; single-path needs full 20D |

| Ultrasonic (clamp-on) | 10-20D | 5D | Same as inline; pipe condition and wall thickness matter more |

| Turbine | 10-15D | 5D | Very sensitive to swirl; use straightening vanes after two elbows in different planes |

| DP (orifice plate) | 20-40D | 5-7D | Depends on beta ratio and upstream fitting; ISO 5167 has detailed tables |

| DP (venturi) | 5-20D | 4D | Better than orifice; gradual convergence is less profile-sensitive |

| Vortex | 15-20D | 5D | Sensitive to asymmetric flow; a control valve upstream needs 30D+ |

| Thermal | 15-20D | 10D | Insertion types are very profile-sensitive |

| PD | 0D | 0D | No straight run needed; PD meters are immune to flow profile disturbances |

General Installation Rules

- Orientation: Mount Coriolis meters vertically (flow up) for liquids with entrained gas. Mount electromagnetic meters with electrodes horizontal to avoid air bubble or sediment contact. Mount vortex meters in any orientation, but vertical with flow up is best for liquids.

- Grounding: Electromagnetic meters require proper grounding rings or grounding electrodes. Poor grounding causes erratic readings and is the #1 installation error with mag meters.

- Isolation valves: Always install isolation valves upstream and downstream of inline meters for maintenance access. Budget for a bypass line on critical custody transfer meters.

- Impulse tubing (DP meters): Keep impulse lines short, sloped properly (down for liquids, up for gas), and free of air traps (liquids) or condensate traps (gas). Use seal pots and condensate pots where needed. A badly run impulse line causes more measurement errors than a bad transmitter.

Flowmeter Calibration

All flow meters drift over time. Wear on moving parts, fouling of sensors, changes in fluid properties, electronic drift: the question is not if a meter will lose accuracy, but when and how much. Calibration compares the meter’s reading against a known reference and corrects the output.

When and How Often

Calibration frequency depends on the application. Custody transfer meters on high-value product lines may need proving monthly or even weekly. Process control meters in benign service might go 12-24 months between calibrations. Harsh service (abrasive slurries, corrosive chemicals, high-temperature steam) accelerates drift and demands shorter intervals. Always start with the manufacturer’s recommendation, then adjust based on operating experience and historical drift data.

Calibration Methods

| Method | Description | Best For |

|---|---|---|

| In-situ proving | A pipe prover or master meter installed in the line; calibrate without removal | Custody transfer stations, large meters |

| Off-site laboratory | Meter removed and sent to an accredited flow lab | High-accuracy verification, periodic recertification |

| Master meter comparison | A calibrated reference meter installed in series | Process meters, spot-checks |

All reference standards must be traceable to national metrology institutes (NIST, PTB, etc.). A calibration against an untraced reference is worthless.

The Calibration Sequence

The process is straightforward: pre-test to document as-found condition, adjust until readings match the reference, verify across the operating range, and document everything. That documentation (as-found data, as-left data, adjustments made, reference standard traceability) is not paperwork for its own sake. It is your evidence trail for audits, disputes, and regulatory inspections.

Standards and Codes Reference

Flow meter selection, installation, and operation in oil and gas are governed by an extensive set of standards. The table below lists the key references every instrument engineer should know:

| Standard | Title / Scope | Applies To |

|---|---|---|

| ISO 5167 (Parts 1-4) | Measurement of fluid flow - Pressure differential devices | Orifice plates, nozzles, venturi tubes |

| AGA Report No. 3 | Orifice Metering of Natural Gas | Natural gas orifice metering (custody transfer) |

| AGA Report No. 7 | Measurement of Natural Gas by Turbine Meters | Turbine meters for gas fiscal metering |

| AGA Report No. 9 | Measurement of Gas by Multipath Ultrasonic Meters | Ultrasonic meters for gas custody transfer |

| AGA Report No. 11 | Measurement of Natural Gas by Coriolis Meter | Coriolis meters for gas fiscal metering |

| API MPMS Ch. 5 | Metering (Manual of Petroleum Measurement Standards) | Liquid petroleum metering |

| API MPMS Ch. 6 | Metering Assemblies | Prover design and operation |

| API MPMS Ch. 7 | Temperature Determination | Temperature measurement at metering points |

| API MPMS Ch. 8 | Sampling | Representative sampling at custody transfer |

| IEC 61511 | Functional safety - Safety instrumented systems | Flow meters in SIS/SIF applications |

| ISO 10790 | Measurement of fluid flow - Coriolis meters | Coriolis meter specifications and testing |

| OIML R 117 | Dynamic measuring systems for liquids other than water | Legal metrology (weights and measures) |

Gas vs. Oil Flow Metering

Gas and oil behave so differently that the same meter technology often requires fundamentally different design choices for each service:

| Aspect | Gas Service | Oil Service |

|---|---|---|

| Compressibility | Gases are compressible; volume changes with pressure and temperature. Every measurement must be corrected to standard conditions (14.7 psia, 60°F or 1 atm, 15°C) | Oils are essentially incompressible; volume corrections are minor (thermal expansion only) |

| Density | Low density means low momentum; meters need higher sensitivity and may struggle at low velocities | Higher density provides strong signal; most meter types work well |

| Viscosity | Very low viscosity; Reynolds number is usually high, which helps DP and vortex meters | Viscosity varies widely with temperature and grade; high viscosity favors PD and Coriolis meters |

| Preferred meters | Ultrasonic (multi-path), DP (orifice per AGA 3), turbine (AGA 7), thermal, vortex | Coriolis, PD, turbine, ultrasonic (transit-time) |

| Custody transfer standard | Multi-path ultrasonic (AGA 9) or orifice (AGA 3) with online chromatograph | Coriolis or PD meter with pipe prover |

| P/T compensation | Always required; gas volume changes ~0.5% per 1 psi and ~0.2% per 1°F | Usually not required for process control; needed for custody transfer |

| Moisture/condensation | Wet gas and condensation cause errors in all meter types; use knock-out drums and trace heating | Water cut measurement is a separate discipline; requires multiphase meters or sampling |

| Safety | Leak prevention critical; must handle varying pressures; safety certification required | Corrosion and erosion are primary concerns; material compatibility essential |

The bottom line: do not assume a flow meter rated for oil service will work on gas, or vice versa, without checking the manufacturer’s specifications for that specific medium. The internals, calibration, and rangeability can be entirely different.

Frequently Asked Questions

What are the main types of flow meters used in oil and gas?

The 8 main flow meter types are: Coriolis (mass flow, custody transfer), Ultrasonic (non-intrusive, large pipes), Electromagnetic (conductive liquids, slurries), Turbine (clean liquids), Differential Pressure (orifice plates, venturi, pitot tubes), Positive Displacement (viscous fluids, billing), Vortex (steam, low maintenance), and Thermal (gas mass flow). Selection depends on fluid type, accuracy requirements, pipe size, and whether the application involves custody transfer.

Which flow meter is best for custody transfer in oil and gas?

Coriolis flow meters are the preferred choice for liquid custody transfer because they measure mass flow directly, unaffected by temperature, pressure, or viscosity changes. For large-diameter gas pipelines, multi-path ultrasonic meters (per AGA Report No. 9) are preferred. Positive displacement meters are also common for liquid custody transfer, especially with viscous products like crude oil and heavy fuel oil.

What is the difference between transit-time and Doppler ultrasonic flow meters?

Transit-time meters measure the time difference of ultrasonic pulses sent with and against the flow, requiring clean, particulate-free liquids. Doppler meters measure the frequency shift of signals bouncing off suspended particles or bubbles, requiring particulates or aeration to function. Using the wrong type is a common field mistake: transit-time on dirty fluids gives errors, and Doppler on clean fluids gives no signal at all.

How much straight pipe run do flow meters need?

Straight run requirements vary by meter type: Coriolis needs 0-5 diameters (least sensitive), Electromagnetic needs 5-10D upstream, Ultrasonic needs 10-20D upstream, Vortex needs 15-20D upstream, and Orifice plates need 20-40D upstream. Positive displacement meters need zero straight run. Flow conditioners can reduce requirements in tight installations, but always design piping for adequate straight runs from the start.

What standards govern flow meter installation in oil and gas?

Key standards include ISO 5167 (differential pressure devices), AGA Report No. 3 (orifice metering of natural gas), AGA Report No. 7 (turbine meters for gas), AGA Report No. 9 (ultrasonic meters for gas), API MPMS Chapters 5-8 (petroleum measurement), and IEC 61511 (safety instrumented systems). Custody transfer applications must also comply with local weights and measures regulations (OIML R 117).

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

Great Content! I find it very useful, you have explained everything in very simple manner. I was looking forward to this type of content.

Thank you very much indeed for sharing this important information with us. It helped to to know the information about flow meters.

I just loved your blog and thanks for publishing this about the flow meters oil gas. I am really happy to come across this exceptionally well written content. Thanks for sharing and look for more in future!! Keep doing this inspirational work and share with us.

I wish to show thanks to you just for bailing me out of this particular trouble.As a result of checking through the net and meeting techniques that were not productive, I thought my life was done.

I wish to show thanks to you just for bailing me out of this particular trouble.As a result of checking through the net and meeting techniques that were not productive, I thought my life was done.

best quality Graphene Material, Carbon NanoTubes, Carbon Fiber Powder, Electric PTC Heating Films

Great and simply explained in detail.

A turbine flowmeter will work either with water or clean Transmission oil without further ajustments or need to be specified as such? Thank's

Nice Info. also check Flange Manufacturer in India and visit Inco Special Alloys. We also deal with Slip on Flange and Ring Joint Flange.

Thank you for sharing an informative blog. Also Visit- Trimac piping solutions Flanges Manufacturer in India Carbon Steel IS 2062 flange

Thank you for sharing an informative blog. Also Visit- Single Piece Design Ball Valves two-piece Design Ball valve Three piece design Ball Valves Four Way Ball Valves

Thank you for sharing an informative blog. Also Visit- Single Piece Design Ball Valves two-piece Design Ball valve Three piece design Ball Valves Four Way Ball Valves khd avlves

Nice Blog! Also visit our website Inco Special Alloys and read on Flange Supplier in Dubai and Flange Manufacturer in India .We have many types of flanges, Slip on Flange,Threaded Flange and Ring Joint Flange and many more.

I feel good after reading your blog. Please look at gate valve suppliers in India & Gate Valves

Your Blog is amazing and knowledgeable.I always like to read your blog and helps me to keep aware. please visit Aluminium Bronze Bar Manufacturer and Dhanwant Metal Corporation

Nice Blog! Also Read on Flange Supplier in Dubai and visit our website Inco Special Alloys.We have many types of flanges, Slip on Flange,Threaded Flange and Ring Joint Flange and many more.

Thank you for sharing Website:Inox Steel India For more info visit us: SS 304 seamless pipe suppliers in Mumbai, SS 304 pipe manufacturers in India, 304 Stainless Steel Pipes Suppliers, SS 304 pipe manufacturers, Stainless Steel Pipes, 304/304L Seamless Pipes

Nice Info, also check on Titanium Vessel Manufacturer in India , Titanium Refineries Manufacturer in India and visit our website at Ladhani Metal Corporation.We also manufacture Titanium Butterfly Valve, and Titanium C Clamp.

Excellent Keep up the good work, you can also visit Riddhi Siddhi Metal Impex for India’s Top Quality Stainless Steel Flanges Manufacturers. We also Manufacturer EIL Approved Flanges & IBR Approved Flanges

Such an amazing content you have shared about the usage of flow meter in oil and gas agency. Thank you! Visit us to know more about flow meter at http://www.proteusind.com

Thank you for providing us with this important information and assisting us in reaching our goal. You can visit here.: Stainless Steel 316 Wire In India, Stainless Steel 316 Wire, Stainless Steel 316 Wire Manufacturers.

Excellent Post, Also read on Fasteners Manufacturers, High Tensile Fasteners Manufacturer and visit our website at Ananka Fasteners. We are the best Inconel Fasteners Manufacturer, Monel Fasteners Manufacturer.

Excellent blog, Learn a lot. Also if you interested in Flanges trimac piping solutions is the best flanges manufacturers in india with flanges manufacturers in mumbai & flange manufacturer in pune. We are one of the leading ss flanges manufacturers in india and stainless steel flanges manufacturers in india.

Excellent blog, Learn a lot. Also if you interested in Flanges trimac piping solutions is the best flanges manufacturers in india with ss flange manufacturer in ahmedabad & flange manufacturer in pune. We are one of the leading ss flanges manufacturers in india and stainless steel flanges manufacturers in india.

Thanks for the content and Hello to everybody. Which type of flow meter is best for measurement and local indication of flow in pulsating service (e.g. reciprocating pumps outlet). The line size is less than 2 in. and service is chemical injection package. Does utilizing rotameter face any problem?

Good Blog, was very helpful also if you want Nut and Bolt Aashish Steel is a good option to go with. We are a Bolt Manufacturer in India and the best nut and bolt manufacturer.

Good blog, Learnt a lot. Do visit Bhansali Wire Mesh we are one of the best Wire Mesh Manufacturer in India with inconel wire mesh and perforated pipe manufacturers in India

Thanks for sharing with us this valuable information and enabling us in achieving our goal. Also, visit us at Timex Metals and check out: Stainless Steel 316 Wire. We are a major Steel Wire Rod. Timex Metals is the top class SS Wire Manufacturers In Gujarat, SS Wire Manufacturers In Delhi, and SS Wire Manufacturers In Mumbai.

Thank you for this information, do visit our blog if you interested in knowing about WordPress Vs Shopify

Thank You for such an informative blog, you might also like Stainless Steel Pipe Fittings Manufacturers, Stainless Steel Pipe Fittings Manufacturers in India, SS Pipe Fittings Manufacturer, from Sanjay Metal India.

Excellent Blog! You may also check SS Flanges Manufacturer,Stainless Steel Flanges Manufacturers in India, Stainless Steel Flange Manufacturer, Stainless Steel Flanges Manufacturers, EIL Approved Flanges, IBR Approved Flanges, from Riddhi Siddhi Metal Impex.

Excellent Blog! You may also checkSS Flanges Manufacturer,Stainless Steel Flanges Manufacturers in India, Stainless Steel Flange Manufacturer, Stainless Steel Flanges Manufacturers, EIL Approved Flanges, IBR Approved Flanges, fromRiddhi Siddhi Metal Impex.

Nice Post. Thank You Sharing, Do visit our blog Stainless Steel Round Bar, Mehran Metals & Alloys You May Also Like: EN31 Bright Steel Round Bar Manufacturer in India

such an amazing blog thank you for sharing this information our company also provides quality calibration services to produce effective output and Air Velocity Instruments such as Air Flow Meter , Gas flow meter , Hot-wire / Vane Anemometer . please visit our website http://www.leomi.in

such an amazing blog thank you for sharing this information our company also provides quality calibration services to produce effective output and Air Velocity Instruments such as Air Flow Meter , Gas flow meter , Hot-wire / Vane Anemometer . please visit our website http://www.leomi.in

Thank you for sharing this vital information. You might be interested in it as well. Stainless Steel Chequered Plate, Chequered Plates Manufacturer In India and you should also visit our website Maxgrow Corporation

That's very useful information, thanks for sharing. Also visit our site for more information – https://yugmet.com/astm-a312-stainless-steel-pipe-tube/

I read this post your post is so nice and very informative post thanks for sharing this post.

Hi very nice information you have shared we have information about the MS pipes and tubes if any one wants more details Kindly visit Goyal Steel tubes https://goyalsteeltubes.com/

Wonderful blog. incredibly informative Thank you for sharing that with me. Trimac Piping Solution thought it was fantastic.

Nice info, Goyal Steel Tubes, the oldest dealer of MS Pipes and Tubes in Delhi-NCR, deals in all sizes and variety of MS Pipes, stocked from reputed companies like APL Apollo, Jindal, Surya etc. Send your pipe related queries on 9650705448, call on 9910495448 or find us on google- Goyal Steel Tubes click on the first link.

the excellently written article also visit our useful products – Ferrule Fittings Manufacturer, Manifold Valves Manufacturer in India, Swagelok Tube Fitting Manufacturer, Instrumentation Fittings Manufacturer in India

The article "Flow Meters in Oil and Gas: Which One to Choose?" on projectmaterials.com is an informative guide for anyone who needs to select a flow meter for the oil and gas industry. The blog covers several types of flow meters commonly used in the industry and the applications they are best suited for, making it easy for readers to find the perfect flow meter for their needs. Additionally, the blog provides some key factors to consider when selecting a flow meter, such as accuracy, reliability, and cost.

Beautiful illustration on the tips that Flow Meters. So, happy that I found your blog. Thank you for posting this useful information over here. Appreciative content. I love reading this article. I would surely come again in this site to learn more.

This article discusses the history of flow meters and how they are used in the energy sector. The selection criteria and full descriptions of available flow meter types are quite helpful. Those working in the field who want to learn more about flow measurement will find this book quite helpful. Good job!

Great article! You've provided valuable insights and presented the information in a clear and concise manner. I appreciate how you've addressed the topic from different angles, making it easy for readers to grasp the concepts. The examples you've included also help in illustrating the key points effectively. Overall, it's an excellent piece that offers practical knowledge and leaves readers with a sense of inspiration. Thank you for sharing your expertise! We are also the best cloud-based ERP software in India.

Your writing not only informs but also evokes emotions and prompts introspection. Thank you for creating content that resonates deeply with your readers.

Your articles have the power to spark positive change and create a ripple effect in the world. Thank you for using your platform to make a difference and inspire others.

Great blog, buddy. My name is Jissa and I work at pipingprojects.ae Thank you for sharing this informative blog. Also,check out our. Steel Plate Weight Chart

Great blog, I appreciate you sharing that so much. Also, look into Manibhadra Fittings. We are a well-known producer of Medical Gas Copper Pipes in India.Visit us now at manibhadrafittings.com for the lowest rates on Medical Gas Copper Pipes Indigo Copper Pipes & other Copper Pipes and tubes.

Hi there to all of you. There is plenty of knowledge on this page that might help with understanding.You may also check out Rajkrupa Metal Industries or Round Bars Manufacturer in India.

Hello, I would like to reach the best point of contact to discuss buying ad space on projectmaterials.com. Please let me know if you want to talk about this further. Have a great day! Thanks, Mike Freides E: [email protected] P: 604-836-9491 Schedule a call: https://calendly.com/mike-freides-infolinks/30min

Hi Mike, Thank you for reaching out and expressing your interest in buying ad space on projectmaterials.com. I understand that you would like to discuss this further and I appreciate your proactive approach. To discuss advertising opportunities on our website, I recommend getting in touch with our advertising department. They will be able to provide you with the necessary information and guide you through the process. You can reach them at [[email protected]]. We value your interest in our platform and look forward to the possibility of collaborating with you. Should you have any further questions or require additional information, please feel free to reach out. Thank you once again, and have a great day! Best regards, Projectmaterials

Thank you very much indeed for sharing this important information with us.