Weldolet & O-Let Branch Fittings

Branch Fittings (O’Lets)

Branch fittings, or O’lets, are forged fittings that create 45- or 90-degree reinforced branch connections from a header pipe to a smaller outlet pipe. They replace buttweld tees, reinforcing pads, and saddles, with fewer welds, less space, and lower installed cost.

Branch Fittings (Olets)Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques. They can be used as an alternative to buttweld tees, reinforcing pads, and saddles.

Branch Fittings (Olets)Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques. They can be used as an alternative to buttweld tees, reinforcing pads, and saddles.

O’lets come in size-on-size or reducing configurations, with buttweld, socket weld, or threaded end connections. Common materials:

| Material | Specification |

|---|---|

| Carbon steel (high temp) | ASTM A105 |

| Carbon steel (low temp) | ASTM A350 LF2, LF3 |

| Alloy steel | ASTM A182 F5, F9, F11, F22 |

| Stainless steel | ASTM A182 F304, F316, duplex, super duplex |

| Nickel alloys | Inconel, Hastelloy, Monel, Incoloy |

| Exotic | Titanium, Cupronickel |

Installation

Installation follows the same basic sequence regardless of O’let type:

- Mark and prepare the header pipe surface at the branch location. Clean the area back to bright metal.

- Cut the hole in the header. The bore should match the O’let’s ID (not the branch pipe OD). Bevel the hole edge for full weld penetration.

- Fit the O’let snugly against the header contour and align the outlet in the branch pipe direction.

- Weld the run-pipe side: for Weldolets, this is a full-penetration buttweld around the base. Sockolets and Threadolets also require a weld to the header.

- Connect the branch pipe: butt weld (Weldolet), insert and fillet weld (Sockolet), or thread on with sealant (Threadolet).

- Inspect: visual examination of all welds, followed by NDE per project spec (typically RT or UT on the header-side weld) and hydrostatic pressure testing.

Advantages over Conventional Fittings

Compared to buttweld tees, reinforcing pads, and saddles, O’lets win on several fronts:

| Factor | O’let | Buttweld Tee / Pad |

|---|---|---|

| Number of welds | 2 (header + branch) | 3 or more |

| Installation time | Faster; weld directly to header | Requires cut-out, fit-up, alignment |

| Space required | Compact; fits congested pipe racks | Tee needs full-bore branch length |

| Flow restriction | None (funnel-shaped bore) | Tee can restrict flow at small branch ratios |

| Material use | Less forging weight, especially on large headers | Full tee body uses more material |

| Field modifications | Weld on without cutting pipe | Must cut out pipe section to insert tee |

| Reinforcement | Integral; no separate pad needed | Pad must be calculated, fabricated, welded |

In practice, I have seen O’lets cut branch installation time nearly in half on congested offshore modules where every millimeter of clearance matters. The real payoff comes on large headers (20” and above) with small branches: a reducing tee in those sizes is expensive and heavy, while a Weldolet weighs a fraction and installs in an afternoon.

Key Specifications

| Standard | Scope |

|---|---|

| MSS SP-97 | The primary standard for O’lets. Covers types, dimensions, tolerances, material grades, and marking for Weldolets, Sockolets, Threadolets, Elbolets, Nipolets, and others |

| ASME B16.11 | Dimensions and pressure-temperature ratings for socket weld and threaded forged fittings (Sockolets, Threadolets) |

| ASME B16.25 | Buttweld end preparation (Weldolets, Sweepolets) |

| ASME B31.3 | Process piping code; governs design, fabrication, examination, and reinforcement calculations for branch connections |

| ASTM A105 | Carbon steel forgings (high temperature) |

| ASTM A182 | Alloy and stainless steel forgings (F304, F316, F11, F22, etc.) |

| ASTM A350 | Carbon/low-alloy forgings for low-temperature service (LF2, LF3) |

Buttweld O’lets (Weldolets, Sweepolets) follow the schedule/wall thickness of the branch pipe. Socket weld and threaded O’lets (Sockolets, Threadolets) are rated by class (3000#, 6000#, or 9000#) matching ASME B16.11 pressure-temperature tables.

Branch Fittings Types

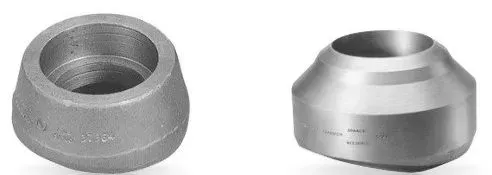

Weldolet

The Weldolet is the most widely used branch fitting. It creates a 90-degree buttweld branch connection from a header pipe to a smaller branch line. Both the header-side and branch-side connections are full-penetration butt welds, which is why Weldolets belong to the buttweld fittings family.

The contoured body sits flush against the header pipe curvature and provides integral reinforcement, so no separate reinforcing pad is needed. The branch-side bevel matches the branch pipe schedule, which can equal or exceed the header schedule. Weldolets are available in a wide range of dimensions.

Of all O’let types, the Weldolet handles the broadest size and pressure range. On any project I have worked on, if the branch-to-header ratio is below 0.5 and the line is NPS 2 or larger, the Weldolet is the default choice. It gives you a fully radiographable weld, unrestricted bore, and the strongest joint of all O’let variants.

How to install a Weldolet: Bonney Forge

Sockolet

A Sockolet works like a Weldolet but uses a socket weld connection on the branch side instead of a butt weld. The branch pipe inserts into the socket and is secured with a fillet weld per ASME B16.11. The header side is still welded to the run pipe.

Sockolets are available in size-on-size or reducing configurations, in classes 3000#, 6000#, and 9000#. They work well for small-bore, high-pressure branch connections (typically NPS 2 and below) where the compact socket joint is easier to fabricate than a buttweld in tight spaces.

Sockolet vs. Weldolet

| Criterion | Sockolet | Weldolet |

|---|---|---|

| Branch-side joint | Socket weld (fillet weld) | Butt weld (full penetration) |

| Classification | Forged fitting per ASME B16.11 | Buttweld fitting |

| Ratings | Class 3000#, 6000#, 9000# | Matches branch pipe schedule |

| Typical branch size | Up to NPS 2 | NPS 2 and above (no practical upper limit) |

| NDE | Fillet weld, limited to MT/PT | Butt weld, fully radiographable (RT/UT) |

| Fatigue resistance | Lower (fillet weld root is a stress riser) | Higher (full-penetration weld) |

| Best use | Small instrument taps, drains, vents, tight spaces | Process branches, high-cycle thermal services |

Thredolet

A Thredolet (also spelled Threadolet) creates a 90-degree branch with female NPT threads per ASME B1.20.1. The body is welded to the header pipe; the branch pipe simply screws in. Available in classes 3000# and 6000#.

Threadolets are the go-to fitting for low-pressure instrument taps, pressure gauge connections, drain points, and any branch where you need a removable connection without hot work on the branch side. They also see use where welding is restricted, such as live plant tie-ins or areas classified as hazardous where hot-work permits are difficult to obtain.

Latrolet

A Latrolet creates a 45-degree lateral branch from a header pipe, the only standard O’let that does so. Available with butt weld, socket weld, or threaded ends (classes 3000# or 6000# for SW/threaded).

Latrolets are commonly used for drain connections, instrument taps, and auxiliary tie-ins where a 45-degree take-off improves flow dynamics or gravity drainage. They are also useful during retrofits when a 90-degree branch would interfere with adjacent piping or steel.

Elbolet

An Elbolet is the O’let you reach for when you need a branch connection directly on the curved surface of a pipe elbow. The body is contoured to match the elbow’s curvature (long-radius or short-radius), so a standard Weldolet or Threadolet, shaped for straight pipe, cannot substitute.

Available with butt weld, socket weld, or threaded ends (classes 3000# or 6000# for SW/threaded). Typical uses include instrument taps, vent lines, and sampling ports on elbows where there is no straight run nearby.

Nipolet

A Nipolet combines an O’let body with an integral nipple extension. The header side welds to the run pipe; the branch end has external (male) threads or a plain end, so instrumentation, valves, or small-bore piping can connect directly without a separate nipple piece.

This makes the Nipolet a one-piece solution for instrument taps, thermowell connections, drains, and vents. It saves a threaded joint (and a potential leak point) compared to a Threadolet plus a separate nipple.

Sweepolet

A Sweepolet has a gradually curved, swept profile that provides the smoothest flow transition of any branch fitting. Where a standard Weldolet creates an abrupt 90-degree turn into the branch, the Sweepolet’s radius guides flow with less turbulence, lower pressure drop, and reduced erosion at the branch entry.

Both ends are butt-welded (header and branch), and the header-side weld is fully accessible for radiographic (RT) or ultrasonic (UT) non-destructive testing.

Sweepolets are specified on critical process lines, high-velocity services, erosive slurries, and high-temperature steam systems, anywhere that flow-induced vibration or erosion is a concern. They cost more than a standard Weldolet but pay for themselves in reduced maintenance on aggressive services.

Coupolet

Coupolet Branch FittingA Coupolet is a half-coupling style branch fitting with a contoured base that welds to the header pipe, providing a full-penetration connection with integral reinforcement. The branch side accepts a threaded or socket weld connection, similar to a half coupling, hence the name.

Coupolet Branch FittingA Coupolet is a half-coupling style branch fitting with a contoured base that welds to the header pipe, providing a full-penetration connection with integral reinforcement. The branch side accepts a threaded or socket weld connection, similar to a half coupling, hence the name.

Coupolets are typically used where the branch is less than half the header size. They follow MSS SP-97 and are available in the same materials and classes as other O’lets. Common applications include instrument connections (pressure gauges, thermowells), small drain and vent branches, and auxiliary system tie-ins on process piping in oil and gas, petrochemical, and power generation plants.

How to Order Branch Fittings

Suppliers of Weldolets, Thredolets, Sockolets, and other branch fittings need the following information to identify the needed product:

- Header run pipe size (which is generally expressed as a range of possible sizes, for example, 36-22)

- Branch pipe size (the NPS of the connecting pipe to the run pipe, for example, 6 inches)

- Branch pipe schedule (which can be STD, XS, 160, XXS) for buttweld types of connections (rating shall be provided for socket weld and NPT threaded Olets)

- Style of branch fitting (Weldolet, Thredolet, Nipolet, Sockolet, etc)

- Material Grade (example A105, A350 LF2, A182 F304)

EXAMPLE: 36-22 | 6 INCH Sch. STD | Weldolet | ASTM A105***

Conventional Reinforced Branch Connections

While O-lets provide integral reinforcement, traditional branch connections often use reinforcing pads (also called pad-type reinforcement or saddle reinforcement) to strengthen the branch-to-header junction. Understanding both methods helps engineers select the most appropriate solution for each application.

Reinforcing Pads (Pad-Type Reinforcement)

A reinforcing pad is a circular or oval plate welded around a branch connection to compensate for the material removed when cutting the hole in the header pipe. The pad restores the structural integrity lost due to the opening and distributes stress over a larger area.

| Feature | Description |

|---|---|

| Shape | Circular or elliptical plate with center hole matching branch OD |

| Material | Same as header pipe (or compatible material with equivalent strength) |

| Thickness | Typically equal to or greater than header pipe wall thickness |

| Vent hole | Small drilled hole (typically 1/4” or 6mm) for leak detection and venting during welding |

| Welds | Fillet welds at outer edge and around branch pipe |

Set-On vs. Set-In Connections

Branch connections are classified by how the branch pipe meets the header:

| Type | Description | Application |

|---|---|---|

| Set-on | Branch pipe sits on top of header; hole equals branch ID | Most common; simpler fabrication |

| Set-in (set-through) | Branch pipe penetrates through header; hole equals branch OD | Better flow characteristics; requires more precise fit-up |

Both set-on and set-in connections may require reinforcement depending on the pressure-area calculation per ASME B31.3 or other applicable codes.

O-Lets vs. Reinforcing Pads: Selection Criteria

| Factor | O-Lets (Integrally Reinforced) | Reinforcing Pads |

|---|---|---|

| Branch/header ratio | Best for ratios below 0.5 | Any ratio; required calculation per code |

| Cost (small quantities) | Higher unit cost | Lower material cost, higher labor |

| Cost (large quantities) | Economical at scale | Labor-intensive |

| Inspection | Simple; fewer welds | More welds to inspect |

| Fabrication time | Faster installation | Requires pad cutting, fit-up, multiple weld passes |

| Code compliance | Pre-engineered per MSS SP-97 | Requires reinforcement calculation per ASME B31 |

| Availability | Standard sizes readily available | Custom pads easily fabricated on-site |

| Large branches | Limited by size ratio | Preferred for branch/header ratios > 0.5 |

When to Use Reinforcing Pads

Reinforcing pads remain the preferred choice in several scenarios:

- Large branch-to-header ratios (above 0.5) where O-lets provide insufficient reinforcement

- Field modifications where standard O-let sizes are not available

- Cost-sensitive projects with sufficient fabrication capacity

- Non-standard angles (other than 45° or 90°) where O-lets are not manufactured

- Existing systems where pad reinforcement can be added without removing branch pipes

Reinforcement Calculation

Per ASME B31.3 (and similar codes), the required reinforcement area must equal or exceed the area removed from the header pipe. The calculation considers:

- Header pipe diameter and wall thickness

- Branch pipe diameter and wall thickness

- Design pressure and allowable stress

- Weld strength reduction factors

- Credit for excess wall thickness in header and branch

When the inherent reinforcement (from excess wall thickness) is insufficient, external reinforcement via pads or integrally reinforced fittings (O-lets) is required.

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

please i need proforma for sockolet 10 x3/4″

Please quote your best price and delivery (AIR FREIGHT) for the item below : 1. CAP 12″ S60 A234 WP11 – 1 PC 2. FLAT WELDOLET 1.1/2” X 12”-36”, A182 F11 CL2 – 1 PC

You have high / low pressure mixed up regarding your 3000# and 6000# fittings. Those are for high pressure applications, as is implied by them having a higher pound rating literally within their name.

Hi, I have purchased 10″-18″(Run size) x 2″ SCH 160 (Branch size) weldolet as per the CL 900 piping class. My question is does the header size pipe thickness matters? Currently my header size thickness is SCH 120 for 10″ pipe and SCH 100 for 16″ to 18″. The reason I am asking whether the header size pipe thickness matters is because, I have a requirement of wedloelt16″ (Run size) X 2″ SCH 160(Branch size) for pipe line whose thickness is 10.9 mm and 11.91 mm. Can I use the same weldolet mentioned in the first line (surpluss available) which was procured as per piping class to install on the 16″ pipe line with wall thickness 10.9 mm and 11.91 mm but having the branch size of 2″ with SCH 160.

Please below see the price CAP 12″ S60 A234 WP11 – 1 PC PRICE: 189.1/- $ PER EACH FLAT WELDOLET 1.1/2” X 12”-36”, A182 F11 CL2 – 1 PC PRICE: 59.5/- $ PER EACH THANKS AND REGARDS AMRUT MODI SAKSHI METAL INDUSTRIES EMAIL: [email protected] WHATSAPP: +91 9892802783

Thank you for sharing an informative blog. Also Visit- Trimac piping solutions Flanges Manufacturer in India Carbon Steel IS 2062 flange

Thank you for sharing an informative blog. Also Visit- Trimac piping solutions Flanges Manufacturer in India Flanges Supplier in dubai

Nice Info, also check on Titanium Vessel Manufacturer in India , Titanium Refineries Manufacturer in India and visit our website at Ladhani Metal Corporation.We also manufacture Titanium Butterfly Valve, and Titanium C Clamp.

PRICE QUOTATION Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY:2 Material PO Text: 20″ X 2″ WELDOLET, MSS-SP97, ASTM A 350 GR. LF3 CL.1 BWSCH 80 X SCH 160 QUANTITY:1 Material PO Text: 4″ X 2″ CONC REDUCER A234 WPB SCH 80 X SCH 40, BW QUANTITY:10 Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY: 10 Material PO Text: 4″ X 2″ CONC REDUCER A234 WPB SCH 80 X SCH 40, BW QUANTITY:5 Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY:5 Material PO Text: 3/4″ PIPE SCH 80 A106 – Gr. B SMLS BE QUANTITY:5 Material PO Text: 20″ X 2″ WELDOLET, MSS-SP97, ASTM A 350 GR. LF3 CL.1 BWSCH 80 X SCH 160 QUANTITY:1

Nice Info, also check wire mesh manufacturer in India and visit our website at Bhansali Steel.We Manufacture various types of steel products like Rectangular Wire Mesh and Hastelloy Wire Mesh.

Good Blog, was very helpful also if you want Round bar Kanak Metals is a good option to go with. We are Round Bar Manufacturer in India and the best Alloy Steel Round Bar Manufacturer in India.

Very Good information. For weldolet welding guidelines check it out: https://www.materialwelding.com/weldolet-welding-requirements-details-you-need-to-know/

Nice information i am also from the same industry and i have more information and product as well so kindly visit us https://goyalsteeltubes.com/

3 weldolet branch connections on pipe at the same heigth, is it possible?

Bonjour, Je recherche un latrolets ou threadolet taraudé dn 15 BSP . acier carbone proche A105N , P280GH/EN10222-2. Le collecteur est en DN300 , la connexion en DN 15 femelle Merci

Hello, here are European Origin Prices for your items SOCKOLET A105 2″ x 3/4″ 3000# SW 17pcs @ 7.50 EURO/ea, WEDOLET ASTM A350 LF2 20″ x 2″ S-80/160 2pcs @ 40 EURO/ea, CONCENTRIC REDUCER ASTM A234 WPB 4″ S-80 x 2″ S-40 15PCS @ 75 EURO/ea

Wonderful article. I became well-versed in it. Also visit Rajkrupa Metal Industries to know more about Round Bars Manufacturer in India.

Thank you for providing the European Origin Prices for the items mentioned in the previous conversation. It is helpful to have a clear understanding of the pricing for SOCKOLET, WELDOLET, and CONCENTRIC REDUCER. Based on your information, the SOCKOLET A105 2″ x 3/4″ 3000# SW is priced at 7.50 EURO/ea, with a quantity of 17 pieces. The WELDOLET ASTM A350 LF2 20″ x 2″ S-80/160 is priced at 40 EURO/ea, with a quantity of 2 pieces. Lastly, the CONCENTRIC REDUCER ASTM A234 WPB 4″ S-80 x 2″ S-40 is priced at 75 EURO/ea, with a quantity of 15 pieces. Having these specific prices allows us to make more informed decisions regarding the purchase of these items. It would be helpful to know if these prices are inclusive of any additional charges or if there are any terms and conditions associated with them. Thank you again for providing this information.