Compression Fittings

Double Ferrule Compression Fittings

Definition

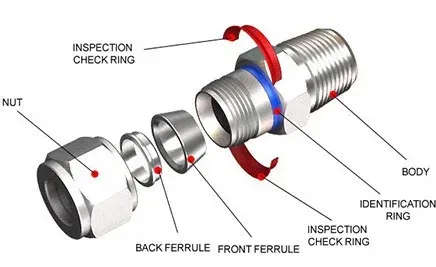

Double ferrule compression fittings are mechanical joints that connect tubing sections without welding or threading, producing a leak-proof seal. Four components make up the assembly: the fitting body, the front ferrule, the back ferrule, and the nut. The two-ferrule arrangement is what gives these fittings their sealing strength and mechanical reliability.

Double Ferrule Compression Fitting

Double Ferrule Compression Fitting

Double ferrule compression fittings join two tubes, whether imperial (also called “fractional tubes,” with outside diameters in inches) or metric (outside diameters in millimeters). A single fitting can even connect a fractional tube on one end to a metric tube on the other.

The typical size range spans from 1/16” to 2” for fractional tube sizes and from 2 mm to 50 mm for metric tube sizes.

These fittings accommodate the maximum working pressure of the tubing they connect, so the connection never becomes the weak point of the assembly.

Compression Fittings Components

A ferrule fitting has four key components:

| Component | Function |

|---|---|

| Nut | Threaded component that applies compressive force when tightened |

| Back Ferrule | Provides the primary sealing and grips the tube to prevent pull-out under pressure |

| Front Ferrule | Deforms under compressive force from the nut, creating a tight seal between the fitting body and the tube |

| Body | Main structural element that holds the tube and contains the threads that engage the nut |

When the nut is tightened onto the fitting body, it compresses both ferrules against the tube and the body simultaneously. The front ferrule is pushed into the tube, forming the seal, while the back ferrule grips the tube’s outer diameter. This dual action produces a leak-proof connection that withstands high pressure and vibration.

Key Advantages

Compression fittings dominate tubing systems because they deliver safe, reliable, reusable, and fast connections. The principal benefits are:

| Advantage | Details |

|---|---|

| Leak-proof sealing | Strong, gas-tight connections that hold up in high-pressure service |

| Versatility | Compatible with multiple tubing materials and diameters |

| Reliability | The two-ferrule design delivers both a seal and a mechanical hold, minimizing leak and disconnection risk |

| Simple installation | Assembled and disassembled without special tools or welding, so repairs and maintenance are fast |

| Durability | Available in stainless steel, brass, and specialty alloys that resist corrosion across a wide range of environments |

Sectors of Application

Double ferrule compression tube fittings are standard across downstream petrochemicals, pulp and paper, laboratory settings, aerospace and shipbuilding, defense, power generation, semiconductor production, and other heavy industries.

The most common fields of application include:

| Sector | Why compression fittings are used |

|---|---|

| Hydraulic and pneumatic systems | Fluid and air lines requiring precise flow and pressure control |

| Oil and gas | Harsh service conditions with demanding material requirements |

| Chemical processing | High chemical resistance and high-pressure capability are non-negotiable |

| Laboratories and analytical instrumentation | Leak-tight, reliable connections are critical for measurement accuracy |

Key Takeaway: Double ferrule compression fittings provide leak-free, gas-tight tubing connections without welding, using a front ferrule for sealing and a back ferrule for grip. Available in sizes from 1/16” to 2” (or 2-50mm metric) and pressure ratings up to 60,000 PSIG, they are the standard connection method for instrumentation tubing in oil and gas; with Swagelok and Parker Hannifin as the dominant suppliers. Never mix brands, as ferrule geometries are not interchangeable.

Are They Used for Tubing or Piping?

Double ferrule compression fittings are primarily used with tubing, not traditional piping. The distinction matters: tubing is specified by its outside diameter (OD) and is selected where precise diameters and wall thicknesses govern pressure calculations, flow rates, and structural integrity. Pipes, by contrast, are specified by nominal pipe size (NPS) and schedule number (wall thickness) and carry fluids and gases over longer distances at varying pressures and volumes.

Learn more about the key differences between pipes and tubes.

The precise engineering and sealing mechanism of double ferrule compression fittings make them well-suited for tubing applications demanding leak-tight seals, particularly in high-pressure, high-vibration, and critical systems such as hydraulic lines, pneumatic circuits, and laboratory equipment. The ferrules compress against the tube to create both a seal and a grip that prevent leaks and pull-out.

While compression fittings that work on pipe do exist, they are uncommon and generally not called “double ferrule” fittings. Pipe connections in larger diameters and long-distance service rely on threaded, welded, flanged, or grooved joints, which handle the size and pressure demands of piping systems more effectively.

Single vs. Double Ferrule Compression Fittings

Single and double ferrule compression fittings both connect tubing with a leak-tight seal and no welding. They differ in construction and performance, and the right choice depends on pressure requirements, vibration exposure, and assembly conditions.

Single Ferrule Compression Fittings

Single ferrule fittings consist of a body, one ferrule, and a nut. The single ferrule handles both sealing and gripping. Assembly is faster because there are fewer parts, which can be an advantage in non-critical applications or tight spaces. These fittings are typically found in low- to medium-pressure systems such as residential water lines, pneumatic circuits, and light industrial service.

Double Ferrule Compression Fittings

Double ferrule fittings add a second ferrule: one ferrule seals, the other grips. This separation of functions provides stronger security and better leak protection. Assembly requires more care since correct sequencing and tightening are critical to achieving a proper seal without damaging the tubing. Double ferrule fittings are the standard in high-pressure, high-vibration, and safety-critical applications across petrochemicals, power generation, aerospace, defense, and semiconductor manufacturing.

Single vs. Double: Key Differences

| Factor | Single Ferrule | Double Ferrule |

|---|---|---|

| Pressure and vibration resistance | Adequate for low-medium duty | Superior in high-pressure and high-vibration environments |

| Leak integrity | Acceptable for general service | Better sealing reliability; preferred for critical and hazardous fluids |

| Ease of use | Simpler and faster to assemble | Requires careful assembly but delivers more reliable results |

The choice between single and double ferrule fittings comes down to the application: operating pressure, leak prevention criticality, and environmental conditions. Double ferrule fittings dominate in demanding service, while single ferrule fittings fill the role in simpler, lower-pressure systems.

How to Install Ferrule Compression Fittings

Ferrule fittings are easy to assemble and disassembly, as shown in this online tutorial from Swagelok tube fittings:

Installing compression fittings requires no special tools or welding, which is why they are so widely used for connecting tubing in plumbing, instrumentation, and industrial systems.

The installation process follows these steps:

1. Prepare the Tubing:

Cut the tubing with a tube cutter to produce a clean, square end. A straight cut is required to prevent leaks. Deburr the cut end with a deburring tool or file to remove sharp edges that could damage the ferrules. Wipe the tubing end clean of any debris or contaminants.

2. Assemble the Fitting:

Slide the compression nut onto the tubing with the threads facing the tube end where the fitting body will connect. Then place the ferrules onto the tubing: for double ferrule fittings, the front (conical) ferrule goes on first, followed by the back (ring-shaped) ferrule. Verify correct orientation before proceeding.

3. Insert the Tubing:

Push the tubing with the nut and ferrules into the fitting body until it bottoms out or reaches the depth specified by the manufacturer.

4. Tighten the Nut:

Start by hand-tightening the nut to confirm proper thread engagement. Then use a wrench to tighten to the manufacturer’s recommended torque. For most fittings, this means 1-1/4 to 1-1/2 turns past finger tight. Always follow the specific manufacturer’s instructions: over-tightening damages the ferrule, and under-tightening causes leaks.

5. Inspect and Test:

Visually inspect the completed connection for gaps between the nut and fitting body. Pressure-test the system before placing it in service, using leak detection fluid or another method appropriate for the application.

Installation tips:

| Concern | Guidance |

|---|---|

| Sizing | Tubing and fitting sizes must match exactly. Mismatched sizes cause leaks or fitting failure. |

| Ferrule reuse | Ferrules deform during initial makeup to create their seal. When disassembling a connection, replace ferrules with new ones of the same material before reassembling. |

| Over-tightening | Follow the manufacturer’s torque specifications precisely to avoid damaging tubing or fittings. |

Proper tubing preparation, correct component assembly, and adherence to manufacturer tightening specifications are the three things that determine whether a compression fitting connection holds or leaks. Regular inspection and maintenance extend the service life of every connection.

Compression Fittings Types

Classification by Fitting Shape

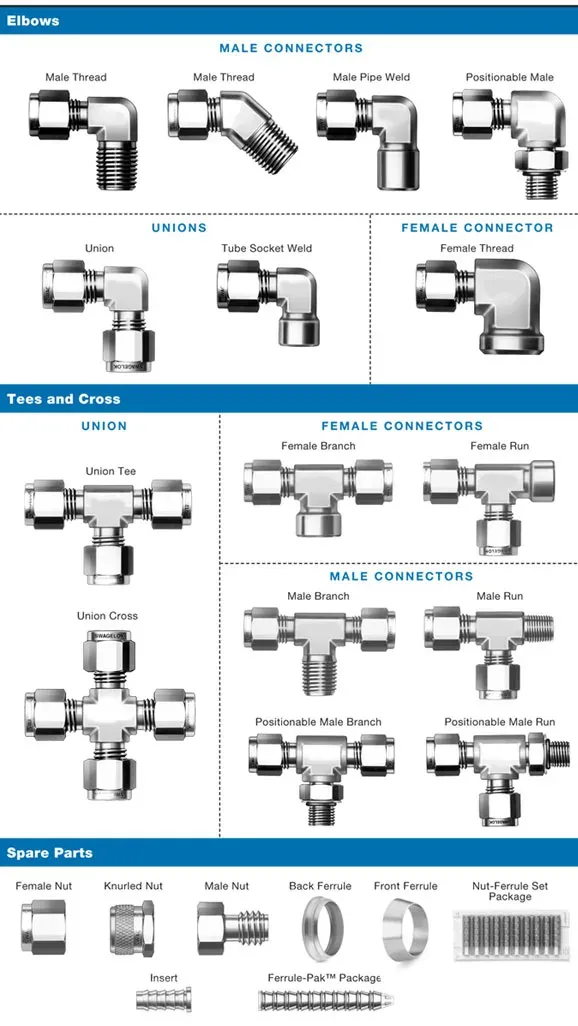

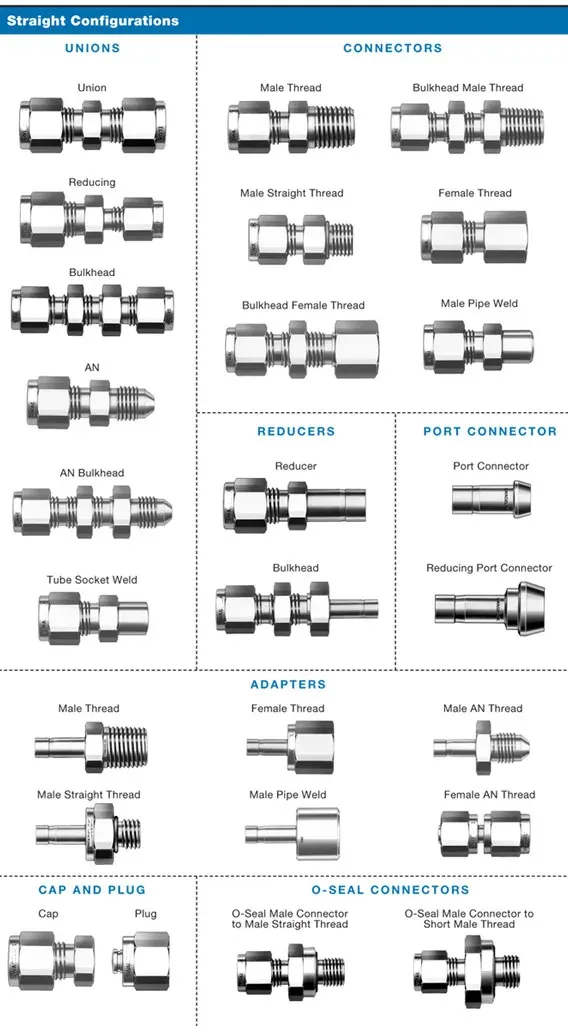

Double ferrule compression fittings are classified by shape according to their routing and connection function in tubing systems. The shape dictates whether the fitting connects straight runs, changes direction, branches flow, or adapts between sizes or thread types.

| Fitting Shape | Description |

|---|---|

| Straight | Simplest type; connects two pieces of tubing in a straight line. Includes tube-to-tube unions, tube-to-male/female threads, and tube-to-weld fittings. |

| Elbows | Change tubing direction; available in 45-degree and 90-degree angles. Connect tubing-to-tubing, tubing-to-threads, or combine with other fittings. |

| Tees | Branch tubing into two directions (T-shape). Distribute fluid/gas from one source to two outlets, or combine two sources into one outlet. |

| Crosses | Four openings (cross shape); branch or combine flow in four directions. Useful for multiple inputs/outputs from a central point. |

| Reducers | Connect tubing sections with different diameters; smooth transition between sizes. Adapt systems to varying flow rates or component connection sizes. |

| Caps and Plugs | Caps seal tube ends; plugs insert into fitting ends. Used for maintenance, pressure testing, or terminating unused ports. |

| Bulkhead | Pass through panels or walls while maintaining barrier integrity. Ensure secure traversal between compartments or enclosures. |

| Union | Quick disassembly and reassembly for easy maintenance. Securely connect two tubing pieces; removable without disturbing the entire system. |

These common tube fitting types are shown in the images below. For each type, the key sub-categorization is: male, female, and union type.

Classification by End-Type

Double ferrule compression fittings accommodate different connection requirements through a range of end-type configurations:

| Connection Type | Description |

|---|---|

| Tube-to-Tube | Most common application; secure, leak-tight seal between tubing sections of same or different diameters |

| Tube-to-Male Threads | Attaches tubing to male threaded components (valves, instruments, equipment); interfaces tubing with threaded systems |

| Tube-to-Female Threads | Connects tubing to female threaded ports; secure connection to internal threads of a receiving port |

| Tube-to-Welded Systems | Connects tubing to welded components; useful where welding is preferred but flexibility is needed for service/maintenance |

| Tube-to-Flange | Adapts tubing to flanged components via a compatible flange adapter; suited for frequent disassembly |

| Bulkhead | Passes tubing through panels or enclosures; maintains barrier integrity while securing the connection |

| Angle and Tee | Elbows (90-degree) and tees for branching or direction changes; maintains leak-tight integrity during routing |

Double ferrule compression fittings provide a highly adaptable solution for tubing system connections. Their two-ferrule seal mechanism delivers reliable, leak-tight performance across industries. Selecting the right connection type depends on flow direction, system pressure, and compatibility with existing components.

Compression Fittings Sizes & Rating

Dimensions

Ferrule compression fittings come in a range of sizes to match different tubing outside diameters, with sizes expressed in imperial (inches) or metric (millimeters). The choice between the two depends on regional standards, the industry, and the equipment in use.

Imperial or Fractional Sizes (USA)

Imperial sizes, commonly called fractional sizes, are measured in inches and widely used in the United States and in industries following U.S. standards. Standard imperial sizes for ferrule compression fittings:

- 1/16”

- 1/8”

- 3/16”

- 1/4″

- 3/8”

- 1/2″

- 5/8”

- 3/4″

- 1”

- 1 1/4″

- 1 1/2″

- 2”

These sizes refer to the outside diameter (OD) of the tubing the fitting accommodates.

Metric Sizes (EU)

Metric sizes, measured in millimeters, are the international standard outside the United States. Available metric sizes include:

- 2 mm

- 3 mm

- 4 mm

- 6 mm

- 8 mm

- 10 mm

- 12 mm

- 16 mm

- 18 mm

- 20 mm

- 25 mm

- 32 mm

- 38 mm

- 50 mm

As with imperial sizes, these metric values correspond to the tubing’s outside diameter.

Selection Considerations

| Factor | Impact on selection |

|---|---|

| Tubing material | Wall thickness and material type (stainless steel, copper, nylon) influence which fitting size and grade to specify |

| Pressure ratings | Both fitting and tubing must have compatible pressure ratings to maintain connection integrity |

| Application requirements | Temperature, fluid type, and environmental conditions all affect size and material selection |

Correct sizing is required for a secure, leak-tight connection. Always consult the manufacturer’s specifications to match fitting size to the tubing’s outside diameter and material.

More detailed dimensional data for compression fittings, organized by shape, is available from the major manufacturers:

Pressure Rating

The pressure rating of a double ferrule compression fitting depends on the fitting material, design, size, and tubing type.

Exceeding the pressure rating risks fitting failure, which can result in leaks, blowouts, or hazardous conditions. Always select fittings with pressure ratings appropriate for the specific application, and account for temperature fluctuations and potential pressure spikes in the system.

As a general classification, compression fittings fall into three pressure classes: “standard” (up to 11 kPSIG), “medium” (11 to 20 kPSIG), and “high-pressure” (up to 60 kPSIG). See the tables below for details on each class.

Standard Tube Fittings (< 11 Kpsig)

| Pressure Ratings | Up to 11.000 PSIG (760 bar) |

|---|---|

| Materials | Stainless steel |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts, and ferrules Chromatograph and Column End |

Medium Pressure Tube Fittings (11 to 20kpsig)

| Pressure Ratings | Up to 20.000 PSIG (1378 bar) |

|---|---|

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless Steel or Alloy 625 |

| End Connections | Unions, NPT, medium-pressure cone, and thread adapters, male SAE/MS, reducers, port connectors, tube adapters, caps, plugs |

| Dimensional Range | 1/4, 3/8, 1/2, 9/16, 3/4 in.; 6, 10, 12 mm |

| Configurations | Straights, elbow, tees, cross |

| Other medium-pressure products available | Medium-pressure ball valves, medium-pressure tubing |

Cone and Thread Tube Fittings (Medium Pressure)

Cone and thread connection types are suited for medium and high-pressure performance and can be equipped with antivibration components. They can meet NACE MR0175/ISO 15156.

| Pressure Ratings | Up to 20.000 PSIG (1378 bar) |

|---|---|

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless SteelAlloy 2507Alloy 625 |

| End Connections | 1/4 to 1-1/2 in. |

| Configurations | Straights, elbow, tees |

Cone and Thread Tube Fittings (High Pressure)

| Pressure Ratings | Up to 60.000 PSIG (4134 bar) |

|---|---|

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless SteelAlloy 2507Alloy 625 |

| End Connections | 1/4 to 9/16 in. |

| Configurations | Straights, elbow, tees |

Compression Fittings Materials

Fitting Body Material

Compression fittings are manufactured from a range of materials to handle everything from general water supply to high-pressure, corrosive, or sanitary environments. The material determines the fitting’s durability, corrosion resistance, pressure rating, and compatibility with both the tubing and the transported medium.

Typical material grades used for compression fittings are described below.

Stainless Steel

304 Stainless Steel provides good corrosion resistance across many environments and is one of the most widely used grades for fittings. 316 Stainless Steel contains molybdenum for enhanced corrosion resistance, particularly against chlorides and marine exposure. It is the preferred choice for corrosive service and sees heavy use in chemical, food processing, and maritime industries.

Brass

CW617N (Leaded Brass) machines well and is common in lower-pressure water and gas fittings, though it is not recommended for corrosive fluids. DZR Brass (Dezincification-resistant Brass) resists dezincification and works well in water supply systems where corrosion is a concern.

Carbon Steel

A105 Carbon Steel delivers good mechanical properties for high-pressure, high-temperature applications. It requires protective coatings or treatments because it is susceptible to corrosion.

Alloy Steel

Chrome-Molybdenum Steel (e.g., F11, F22) provides excellent strength at elevated temperatures and pressures, and is widely specified in power plants and petrochemical facilities.

Copper and Copper Alloys

Copper has excellent thermal conductivity and resists corrosion in water service; it is used for medical gases and potable water. Copper-Nickel Alloys (e.g., CuNi 70/30) resist marine biofouling and are the standard choice for seawater applications.

Nickel-Alloys

Hastelloy provides exceptional resistance to strong acids and serves in highly corrosive environments. Inconel combines high strength with oxidation and corrosion resistance at elevated temperatures, performing well in extreme service. Monel resists seawater and steam and is common in marine and chemical processing.

Plastic

PVC and CPVC handle low-pressure, non-corrosive applications, with CPVC tolerating higher temperatures. Polypropylene (PP) and Polyethylene (PE) offer good chemical resistance for chemical processing and water treatment. PTFE (Polytetrafluoroethylene) combines high chemical resistance with temperature tolerance for highly corrosive and high-purity applications.

The right material depends on the medium being transported, environmental conditions, pressure and temperature ranges, and applicable regulatory standards. Each grade has distinct strengths, and the selection should follow a thorough evaluation of all application requirements.

Ferrule Materials

The ferrules in double ferrule compression fittings are critical to achieving a secure, leak-tight connection. These components must deform under compression to create a seal and grip without compromising tubing integrity. Ferrule material selection directly affects performance in terms of corrosion resistance, durability, and compatibility with the tubing and fluid.

When a connection is disassembled, ferrules should generally be replaced with new ones to maintain leak-proof performance.

Common ferrule materials include:

Stainless Steel

The most widely used ferrule material due to its corrosion resistance, durability, and strength. 316 stainless steel ferrules perform well across a broad range of applications, including harsh environments and corrosive fluid service.

Brass

Brass ferrules serve applications where corrosion is less of a concern. They offer good thermal conductivity and pair with brass fittings in water, gas, and air systems.

Carbon Steel

Carbon steel ferrules are selected where mechanical strength matters more than corrosion resistance. They are common in hydraulic and pneumatic systems operating at high pressure.

Monel

Monel ferrules deliver excellent resistance to seawater and corrosive conditions, making them the standard for marine and chemical processing applications.

Hastelloy

Hastelloy ferrules provide exceptional resistance to strong acids and serve in the most aggressively corrosive environments, handling concentrated chemical exposure that other alloys cannot.

Titanium

Titanium ferrules offer outstanding corrosion resistance combined with high strength and low weight. They serve in corrosive environments and applications where strength-to-weight ratio is a priority.

Alloy 400 (Monel) and Alloy C-276 (Hastelloy)

These specialty alloys address specific corrosion challenges. Alloy 400 targets marine environments, while Alloy C-276 handles highly corrosive acid service.

Plastic (e.g., PTFE, PEEK)

PTFE and PEEK ferrules provide excellent chemical resistance and are selected where metal ferrules might react with the process fluid. They also serve in high-purity applications where metal contamination must be avoided.

Ferrule material selection depends on chemical compatibility, temperature range, pressure conditions, and corrosion potential. Stainless steel and brass cover most general applications, while Monel, Hastelloy, titanium, and engineering plastics address specialized service where higher corrosion resistance or specific material properties are required.

Need More Info?

For more information about compression tube fittings, we suggest the Swagelok Essential Guide or the Parker Instrumentation Products.

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

Fsinox provide stainless steel railing tube and component fitting manufacturer in Foshan, which is specializing in the delivery of base cover, bar holder, elbow, end cap, glass clamp, handrail bracket, wall bracket, 25x21mm/ 42.4mm/48.3mm slotted tube fitting and LED Handrail to Europe, South American, and Australia Market. Visit Website

We are in need of Union Assly of carbon steel zinc plated and chrome passivated Nut and body of straight fittings with SS 316 Quality double ferrule size. (1) 1/4″ inches Qty 120 Nos. (2) 3/8″ inches Qty 120 Nos. (3) 1/2″ inches Qty 120 Nos.

You have a picture of the make-up of a Superlok fitting with a built-in gap gauge, but no link to that particular fitting. Check out Superlok World, https://superlokworld.com/ to source the i-Fitting tube fittings from the first picture in the article and watch this Tube Fitting Basics video on How to Properly Install Tube Fittings: https://www.youtube.com/watch?v=HwmkNiTNGeU

Dear sir good afternoon myself from Danish Engineers . We are manufacturer of instrumentation valves and fittings upto 15,000 psi . located in navi mumbai . please revert your requirement on [email protected].

Nice summary, we are in Australia and have used all 3 of the brands mentioned (Swage-lok, Parker, and DK-Lok) and never had an issue with these top 3 quality wise or even mixing on selected parts. We did find the service from Valve and Flow Control Specialists on the DK-Lok to be better although Swagelok seemed to have a better availability when it came to above 1″ (25mm). The larger sizes though are not as easy to install.

DEAR SIR WE HAVE HUGE NUMBER OF SS316 GRADE PARKER AND MARIOFF HI FOG FITTINGS IN STOCK COMPLETE LOT FOR SALE. More details please send Email: [email protected]

Your blog so good and also helpful for me.keep it up

visit proflow.co.in

Dear R.K.Gadia: We are a manufacturer of instrumentation tube fittings in stainless steel, brass, and carbon steel materials. Contact me at [email protected] Best Regards Yolanda

Hello! Today I read your blog, and I found it very informative and helpful. It also provided valuable information about compression fittings. Thank you for sharing such useful content!