BW Pipe Fittings Sizes (ASME B16.9)

Buttweld Fittings Size and Weight

ASME B16.9 BW Fittings Dimensions & Weights

The ASME B16.9 standard specifies dimensions and weights for factory-made wrought buttwelding fittings for sizes NPS ½ through NPS 48 (DN 15 through DN 1200).

These fittings include elbows, tees, reducers, caps, and more, each designed for specific applications within piping systems. Below is an overview of the general dimensions and weights for some common types of ASME B16.9 buttweld fittings.

Please note, that for precise dimensions and weights, especially for specific sizes and schedules, consulting the ASME B16.9 standard or manufacturer’s data is recommended.

Elbows (90° and 45°)

- Dimensions: Include the outside diameter at the bevel, center-to-end dimensions, and wall thickness. For a 90° elbow, the center-to-end dimension is typically 1.5 times the NPS for sizes up to NPS 24. For 45° elbows, it’s about the same as the NPS.

- Weights: Vary significantly based on the size and schedule (wall thickness) of the elbow. For example, a 90° elbow NPS 2 Schedule 40 might weigh around 0.9 kg (2 lbs), while an NPS 24 Schedule 40 could weigh about 160 kg (353 lbs).

Tees (Straight and Reducing)

- Dimensions: For straight tees, the run (main pipe size) and branch (outlet size) dimensions are critical, with the outside diameter and center-to-end dimensions being specified.

- Weights: Depend on the size and schedule, similar to elbows. A straight tee NPS 2 Schedule 40 might weigh about 1 kg (2.2 lbs), while an NPS 24 Schedule 40 could be around 275 kg (606 lbs).

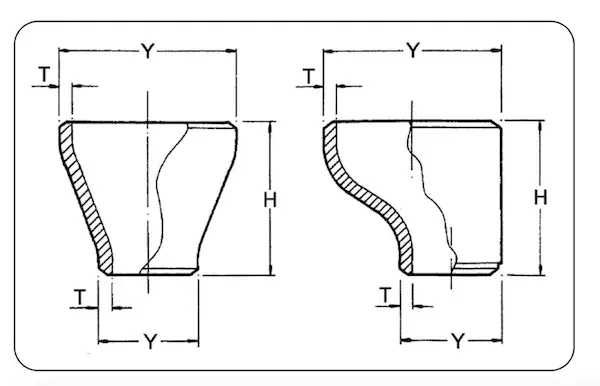

Reducers (Concentric and Eccentric)

- Dimensions: Include the larger and smaller outside diameters at the ends, the length (for concentric reducers), and the offset (for eccentric reducers).

- Weights: As with elbows and tees, weights vary. A concentric reducer NPS 6 x NPS 4 Schedule 40 might weigh around 3.6 kg (8 lbs), for instance.

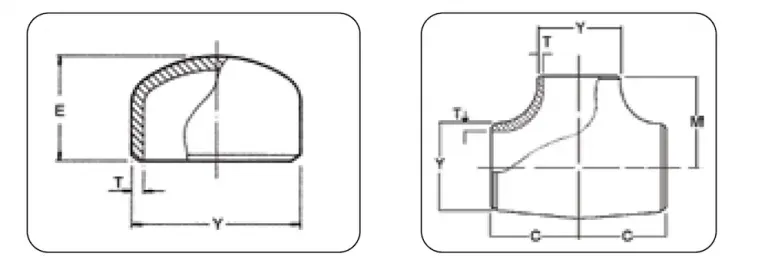

Caps

- Dimensions: Generally specified by the outside diameter, the height, and the wall thickness.

- Weights: A cap NPS 2 Schedule 40 might weigh approximately 0.4 kg (0.9 lbs), and an NPS 24 Schedule 40 cap could weigh about 75 kg (165 lbs).

General Considerations

- The dimensions and weights of buttweld fittings in ASME B16.9 can vary based on the nominal pipe size (NPS), the schedule (which dictates the wall thickness), and the material of the fitting.

- It’s key to select the appropriate schedule and material based on the fluid service, pressure, and temperature requirements of the piping system.

- For detailed engineering projects, always refer to the most current ASME B16.9 standard or consult with manufacturers for the exact dimensions and weights of the fittings required.

Let’s now show the dimensions and weights of the most common buttweld fittings, 45/90 degrees elbows (SR/LR), tees, caps, and reducers (concentric/eccentric). Please note that weights refer to carbon/alloy steel grades.

45/90° Buttweld Elbow (CS)

Dimensions and weights of buttweld 45/90 degree elbows short and long radius (NPS 1/2 to 24, schedule STD/XS) - ASME B16.9

| NPS (mm) | NPS (in) | Y - OD (mm) | T - Wall (mm) | Sch | 45° LR B (mm) | 45° LR (kg) | 90° LR A (mm) | 90° LR (kg) | 90° SR A (mm) | 90° SR (kg) |

|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 1/2” | 21.3 | 2.78 | STD | 15.9 | 0.04 | 38.1 | 0.08 | - | - |

| 3.73 | X.S | 15.9 | 0.05 | 38.1 | 0.10 | - | - | |||

| 20 | 3/4” | 26.7 | 2.87 | STD | 11.1 | 0.04 | 28.6 | 0.08 | - | - |

| 3.91 | X.S | 11.1 | 0.05 | 28.6 | 0.11 | - | - | |||

| 25 | 1” | 33.4 | 3.38 | STD | 22.2 | 0.09 | 38.1 | 0.15 | 25.4 | 0.11 |

| 4.55 | X.S | 22.2 | 0.11 | 38.1 | 0.19 | 25.4 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 25.4 | 0.14 | 47.6 | 0.28 | 31.75 | 0.18 |

| 4.85 | X.S | 25.4 | 0.2 | 47.6 | 0.39 | 31.75 | 0.24 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 28.6 | 0.2 | 57.1 | 0.4 | 38.1 | 0.26 |

| 5.08 | X.S | 28.6 | 0.25 | 57.1 | 0.5 | 38.1 | 0.35 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 34.9 | 0.36 | 76.2 | 0.72 | 50.8 | 0.5 |

| 5.54 | X.S | 34.9 | 0.5 | 76.2 | 1.0 | 50.8 | 0.68 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 44.4 | 0.73 | 95.2 | 1.46 | 63.5 | 0.95 |

| 7.01 | X.S | 44.4 | 0.91 | 95.2 | 1.82 | 63.5 | 1.27 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 50.8 | 1.1 | 114.3 | 2.18 | 76.2 | 1.45 |

| 7.62 | X.S | 50.8 | 1.45 | 114.3 | 2.86 | 76.2 | 1.95 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 63.5 | 2.1 | 152.4 | 4.2 | 101.6 | 2.8 |

| 8.56 | X.S | 63.5 | 2.9 | 152.4 | 5.7 | 101.6 | 3.9 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 79.4 | 3.4 | 190.0 | 6.8 | 127.0 | 4.8 |

| 9.5 | X.S | 79.4 | 5.0 | 190.0 | 10.0 | 127.0 | 6.5 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 95.2 | 5.1 | 229.0 | 10.1 | 152.4 | 6.8 |

| 10.97 | X.S | 95.2 | 7.7 | 229.0 | 15.3 | 152.4 | 10.2 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 127.0 | 10.2 | 305.0 | 20.4 | 203.0 | 13.6 |

| 12.7 | X.S | 127.0 | 15.5 | 305.0 | 30.9 | 203.0 | 20.9 | |||

| 250 | 10” | 273.9 | 9.27 | STD | 159.0 | 18.1 | 381.0 | 36.1 | 254.0 | 24.1 |

| 12.7 | X.S | 159.0 | 24.4 | 381.0 | 48.8 | 254.0 | 32.5 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 190.0 | 26.6 | 457.0 | 53.1 | 305.0 | 35.4 |

| 12.7 | X.S | 190.0 | 35.0 | 457.0 | 70.0 | 305.0 | 46.7 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 222.0 | 34.1 | 533.0 | 68.1 | 356.0 | 45.4 |

| 12.7 | X.S | 222.0 | 45.0 | 533.0 | 90.0 | 356.0 | 60.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 254.0 | 45.0 | 610.0 | 89.3 | 406.0 | 59.5 |

| 12.7 | X.S | 254.0 | 59.0 | 610.0 | 118.0 | 406.0 | 78.7 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 286.0 | 56.5 | 686.0 | 113.0 | 457.0 | 75.6 |

| 12.7 | X.S | 286.0 | 75.0 | 686.0 | 150.0 | 457.0 | 100.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 318.0 | 85.0 | 762.0 | 140.0 | 508.0 | 93.5 |

| 12.7 | X.S | 318.0 | 112.5 | 762.0 | 186.0 | 508.0 | 124.0 | |||

| 600 | 24” | 610.00 | 9.52 | STD | 381.0 | 101.5 | 914.0 | 203.0 | 610.0 | 135.0 |

| 12.7 | X.S | 381.0 | 134.5 | 914.0 | 269.0 | 610.0 | 179.0 |

Buttweld Tee and Cap (CS)

Dimensions and weights of buttweld tee and cap (NPS 1/2 to 24, schedule STD/XS) - ASME B16.9

| NPS (mm) | NPS (in) | Y - OD (mm) | T - Wall (mm) | Sch | Tee C/M (mm) | Tee (kg) | Cap E (mm) | Cap (kg) |

|---|---|---|---|---|---|---|---|---|

| 15 | 1/2” | 21.3 | 2.78 | STD | 25.4 | 0.58 | ||

| 3.73 | X.S | 25.4 | 0.21 | |||||

| 20 | 3/4” | 26.7 | 2.87 | STD | 28.6 | 0.21 | ||

| 3.91 | X.S | 28.6 | 0.27 | |||||

| 25 | 1” | 33.4 | 3.38 | STD | 38.1 | 0.34 | 38.1 | 0.1 |

| 4.55 | X.S | 38.1 | 0.43 | 38.1 | 0.14 | |||

| 32 | 11/4” | 42.2 | 3.56 | STD | 47.6 | 0.64 | 38.1 | 0.14 |

| 4.85 | X.S | 47.6 | 0.75 | 38.1 | 0.18 | |||

| 40 | 11/2” | 48.3 | 3.68 | STD | 57.1 | 0.95 | 38.1 | 0.18 |

| 5.08 | X.S | 57.1 | 1.13 | 38.1 | 0.23 | |||

| 50 | 2” | 60.3 | 3.91 | STD | 63.5 | 1.45 | 38.1 | 0.27 |

| 5.54 | X.S | 63.5 | 1.72 | 38.1 | 0.32 | |||

| 65 | 21/2” | 73.0 | 5.16 | STD | 76.2 | 2.45 | 38.1 | 0.41 |

| 7.01 | X.S | 76.2 | 2.95 | 38.1 | 0.45 | |||

| 80 | 3” | 88.9 | 5.49 | STD | 85.7 | 3.45 | 50.8 | 0.64 |

| 7.62 | X.S | 85.7 | 4.3 | 50.8 | 0.82 | |||

| 100 | 4” | 114.3 | 6.02 | STD | 105.0 | 5.7 | 63.5 | 1.13 |

| 8.56 | X.S | 105.0 | 7.3 | 63.5 | 1.54 | |||

| 125 | 5” | 141.3 | 6.65 | STD | 124.0 | 9.1 | 76.2 | 1.91 |

| 9.5 | X.S | 124.0 | 11.8 | 76.2 | 2.59 | |||

| 150 | 6” | 168.3 | 7.11 | STD | 143.0 | 13.6 | 88.9 | 2.95 |

| 10.97 | X.S | 143.0 | 19.0 | 88.9 | 4.1 | |||

| 200 | 8” | 219.1 | 8.18 | STD | 178.0 | 25.0 | 101.6 | 5.0 |

| 12.7 | X.S | 178.0 | 33.5 | 101.6 | 7.3 | |||

| 250 | 10” | 273.0 | 9.27 | STD | 216.0 | 41.0 | 127.0 | 9.1 |

| 12.7 | X.S | 216.0 | 54.0 | 127.0 | 12.0 | |||

| 300 | 12” | 323.9 | 9.52 | STD | 254.0 | 57.0 | 152.4 | 13.6 |

| 12.7 | X.S | 254.0 | 77.0 | 152.4 | 17.0 | |||

| 350 | 14” | 355.6 | 9.52 | STD | 279.0 | 73.0 | 165.1 | 15.9 |

| 12.7 | X.S | 279.0 | 93.0 | 165.1 | 21.0 | |||

| 400 | 16” | 406.4 | 9.52 | STD | 305.0 | 91.0 | 178.8 | 20.0 |

| 12.7 | X.S | 305.0 | 120.0 | 178.8 | 26.0 | |||

| 450 | 18” | 457.0 | 9.52 | STD | 343.0 | 127.0 | 203.2 | 26.0 |

| 12.7 | X.S | 343.0 | 165.0 | 203.2 | 34.0 | |||

| 500 | 20” | 508.0 | 9.52 | STD | 381.0 | 227.0 | 228.6 | 33.0 |

| 12.7 | X.S | 381.0 | 270.0 | 228.6 | 43.0 | |||

| 600 | 24” | 610.0 | 9.52 | STD | 432.0 | 345.0 | 266.7 | 46.0 |

| 12.7 | X.S | 432.0 | 430.0 | 266.7 | 61.0 |

Buttweld Reducers (CS)

Dimensions and weights of buttweld reducers concentric and eccentric (NPS 1/2 to 24, schedule STD/XS) - ASME B16.9

| NPS (mm) | NPS (in) | Length H (mm) | Sch | Weight (kg) |

|---|---|---|---|---|

| 20×15 | 3/4” x 1/2” | 38.1 | STD | 0.07 |

| XS | 0.1 | |||

| 25×15 | 1” x 1/2” | 50.8 | STD | 0.14 |

| X.S | 0.18 | |||

| 25×20 | 1” x 3/4” | 50.8 | STD | 0.14 |

| X.S | 0.18 | |||

| 32×15 | 11/4” x 1/2” | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 32×20 | 11/4” x 3/4“ | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 32×25 | 11/4” x 1” | 50.8 | STD | 0.18 |

| X.S | 0.23 | |||

| 40×15 | 11/2” x 1/2” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×20 | 11/2” x 3/4” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×25 | 11/2” x 1” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 40×32 | 11/2” x 11/4” | 63.5 | STD | 0.27 |

| X.S | 0.32 | |||

| 50×15 | 2” x 1/2” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×20 | 2” x 3/4” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×25 | 2”x1” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×32 | 2” x 11/4” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 50×40 | 2” x 11/2” | 76.2 | STD | 0.41 |

| X.S | 0.54 | |||

| 65×25 | 21/2” x 1” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 65×32 | 21/2” x 11/4” | 88.9 | STD | 0.68 |

| X.S | 0.91 |

| NPS (mm) | NPS (in) | Length H (mm) | Sch | Weight (kg) |

|---|---|---|---|---|

| 65×40 | 21/2” x 11/2” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 65×50 | 21/2” x 2” | 88.9 | STD | 0.68 |

| X.S | 0.91 | |||

| 80×40 | 3” x 11/2” | 88.9 | STD | 0.77 |

| X.S | 1.09 | |||

| 80×50 | 3”x2” | 88.9 | STD | 0.91 |

| X.S | 1.22 | |||

| 80×65 | 3” x 21/2” | 88.9 | STD | 0.91 |

| X.S | 1.27 | |||

| 100×40 | 4” x 11/2” | 101.6 | STD | 1.36 |

| X.S | 1.91 | |||

| 100×50 | 4”x2” | 101.6 | STD | 1.40 |

| X.S | 1.95 | |||

| 100×65 | 4” x 21/2” | 101.6 | STD | 1.45 |

| X.S | 2.04 | |||

| 100×80 | 4”x3” | 101.6 | STD | 1.59 |

| X.S | 2.08 | |||

| 125×80 | 5”x3” | 127.0 | STD | 2.5 |

| X.S | 3.4 | |||

| 125 x 100 | 5”x4” | 127.0 | STD | 2.7 |

| X.S | 3.8 | |||

| 150×50 | 6”x2” | 140.0 | STD | 3.4 |

| X.S | 4.3 | |||

| 150×65 | 6” x 21/2” | 140.0 | STD | 3.4 |

| X.S | 4.5 | |||

| 150×80 | 6”x3” | 140.0 | STD | 3.6 |

| X.S | 4.8 | |||

| 150 x 100 | 6”x4” | 140.0 | STD | 3.7 |

| X.S | 5.2 | |||

| 150 x 125 | 6”x5” | 140.0 | STD | 3.9 |

| X.S | 5.4 |

| NPS (mm) | NPS (in) | Length H (mm) | Sch | Weight (kg) |

|---|---|---|---|---|

| 200×80 | 8”x3” | 152.4 | STD | 4.5 |

| X.S | 7.2 | |||

| 200 x 100 | 8”x4” | 152.4 | STD | 5.0 |

| X.S | 7.7 | |||

| 200 x 125 | 8”x5” | 152.4 | STD | 5.4 |

| X.S | 8.2 | |||

| 200 x 150 | 8”x6” | 152.4 | STD | 5.9 |

| X.S | 8.6 | |||

| 250 x 100 | 10”x4” | 178.0 | STD | 9.1 |

| X.S | 11.8 | |||

| 250 x 125 | 10”x5” | 178.0 | STD | 9.5 |

| X.S | 13.6 | |||

| 250 x 150 | 10”x6” | 178.0 | STD | 9.5 |

| X.S | 13.6 | |||

| 250 x 200 | 10”x8” | 178.0 | STD | 10.0 |

| X.S | 14.0 | |||

| 300 x 150 | 12”x6” | 203.0 | STD | 14.1 |

| X.S | 18.1 | |||

| 300 x 200 | 12”x8” | 203.0 | STD | 14.5 |

| X.S | 19.1 | |||

| 300 x 250 | 12” x 10” | 203.0 | STD | 15.4 |

| X.S | 20.0 | |||

| 350 x 200 | 14”x8” | 330.0 | STD | 26.3 |

| X.S | 34.9 | |||

| 350 x 250 | 14” x 10” | 330.0 | STD | 27.2 |

| X.S | 36.3 | |||

| 350 x 300 | 14” x 12” | 330.0 | STD | 28.6 |

| X.S | 37.6 | |||

| 400 x 200 | 16”x8” | 356.0 | STD | 31.8 |

| X.S | 42.6 | |||

| 400 x 250 | 16” x 10” | 356.0 | STD | 33.1 |

| X.S | 43.5 | |||

| 400 x 300 | 16” x 12” | 356.0 | STD | 34.5 |

| X.S | 45.4 |

| NPS (mm) | NPS (in) | Length H (mm) | Sch | Weight (kg) |

|---|---|---|---|---|

| 400 x 350 | 16” x 14” | 356.0 | STD | 35.4 |

| X.S | 46.3 | |||

| 450 x 250 | 18” x 10” | 381.0 | STD | 38.0 |

| X.S | 52.1 | |||

| 450 x 300 | 18” x 12” | 381.0 | STD | 39.0 |

| X.S | 53.5 | |||

| 450 x 350 | 18” x 14” | 381.0 | STD | 40.0 |

| X.S | 54.9 | |||

| 450 x 400 | 18” x 16” | 381.0 | STD | 40.8 |

| X.S | 53.5 | |||

| 500 x 250 | 20” x 10” | 508.0 | STD | 53.0 |

| X.S | 79.9 | |||

| 500 x 300 | 20” x 12” | 508.0 | STD | 54.4 |

| X.S | 82.0 | |||

| 500 x 350 | 20” x 14” | 508.0 | STD | 57.6 |

| X.S | 80.2 | |||

| 500 x 400 | 20” x 16” | 508.0 | STD | 58.9 |

| X.S | 82.0 | |||

| 500 x 450 | 20” x 18” | 508.0 | STD | 61.7 |

| X.S | 82.0 | |||

| 600 x 300 | 24” x 12” | 508.0 | STD | 63.5 |

| X.S | 84.4 | |||

| 600 x 350 | 24” x 14” | 508.0 | STD | 65.3 |

| X.S | 86.8 | |||

| 600 x 400 | 24” x 16” | 508.0 | STD | 68.0 |

| X.S | 90.4 | |||

| 600 x 450 | 24” x 18” | 508.0 | STD | 72.6 |

| X.S | 96.5 | |||

| 600 x 500 | 24” x 20” | 508.0 | STD | 77.1 |

| X.S | 102.5 |

Buttweld Fittings Tolerance

ASME B16.9 specifies the dimensions, tolerances, and materials for factory-made wrought buttwelding fittings for sizes NPS 1/2 through NPS 48 (DN 15 through DN 1200). The standard covers various fittings, including elbows, tees, reducers, caps, and others. Tolerances in ASME B16.9 are key for ensuring proper fit and leak-proof connections in piping systems. Here’s an overview of the size tolerances for buttweld fittings as per ASME B16.9:

Outside Diameter (OD) at Bevel

- For fittings NPS 12 (DN 300) and smaller, the tolerance is ±1.5 mm.

- For fittings larger than NPS 12 (DN 300), it is +1.5 mm / -0.8 mm.

Inside Diameter (ID) of Fitting

- The tolerance for the ID of the fitting is not specified by ASME B16.9. The ID is determined by the schedule (thickness) of the pipe to which the fitting is to be matched.

Wall Thickness (t)

- The wall thickness at all points must be at least 87.5% of the nominal wall thickness specified for the scheduled wall thickness of the fitting.

Center-to-End Dimensions (C)

- For elbows, tees, and crosses up to NPS 24 (inclusive), the tolerance is ±1.5 mm.

- For lap joint stub ends, the tolerance varies with the nominal pipe size, ranging from +2.5 mm / -0 mm for smaller sizes to ±3 mm for larger sizes.

Angularity Tolerances

- For all fittings, there are angularity tolerances to ensure the fittings align properly when installed. These tolerances vary depending on the type of fitting and its size but are generally within a degree or two.

Overall Length (E)

- For fittings where the overall length is critical, such as caps and stub ends, the tolerance is generally ±3 mm for sizes up to NPS 24.

These tolerances are general guidelines. For specific applications, consult the ASME B16.9 standard directly or work with a piping specialist to confirm compliance.

ASME B16.9 Buttweld Fittings Tolerances (in inches)

| NPS | OD at Bevel | ID at End | Wall Thickness T | Center-to-End A, C, B | Length H | Length F |

|---|---|---|---|---|---|---|

| 1/2 to 2-1/2 | +0.06 / -0.03 | - | Min 87.5% of nominal | ±0.06 | ±0.06 | ±0.12 |

| 3 to 3-1/2 | ±0.06 | ±0.06 | Min 87.5% of nominal | ±0.06 | ±0.06 | ±0.12 |

| 4 | ±0.06 | ±0.06 | Min 87.5% of nominal | ±0.06 | ±0.06 | ±0.12 |

| 5 to 8 | ±0.06 | ±0.06 | Min 87.5% of nominal | ±0.06 | ±0.06 | ±0.25 |

| 10 to 18 | +0.16 / -0.12 | ±0.12 | Min 87.5% of nominal | ±0.09 | ±0.09 | ±0.25 |

| 20 to 24 | +0.25 / -0.19 | ±0.19 | Min 87.5% of nominal | ±0.09 | ±0.09 | ±0.25 |

| 26 to 30 | +0.25 / -0.19 | ±0.19 | Min 87.5% of nominal | ±0.12 | ±0.19 | ±0.38 |

| 32 to 48 | +0.25 / -0.19 | ±0.19 | Min 87.5% of nominal | ±0.19 | ±0.19 | ±0.38 |

Tolerances of butt weld fittings (in inches) according to ASME/ANSI B16.9 for all carbon alloy fittings except short radius elbows and returns (ASME/ANSI B16.28).

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

Thank you so much for taking the time to say that; it means so much to me. Website: Caliber Enterprises For me info visit us: Fasteners manufacturers in India Also visit: Fasteners Manufacturers in Mumbai

Thank you for taking the time to express that; it means a lot to me. Website: Caliber Enterprises For me info visit us: Fasteners manufacturers in India Also visit: Fasteners Manufacturers in Mumbai

Dear Sir, We can provide you products for all your requirements for Branch fittings, forged fittings, flanges, fasteners, pipes & tubes. Kindly contact us on +919867815181 for fastest response you can also email us on [email protected] RANDHIR METAL AND ALLOYS PVT LTD