Plug Valve: Types & Working Principle

Plug Valve

What Is a Plug Valve?

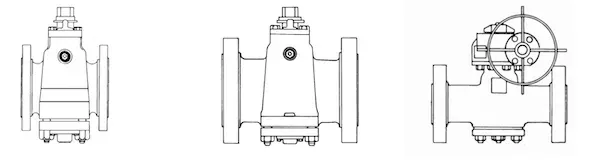

Definition: A plug valve is a quarter-turn valve that uses a cylindrical or tapered plug with a hollow passageway to control flow. Plug valves handle fluids with solids in suspension effectively and offer tight shut-off with a simple, durable design.

A plug valve controls fluid flow through a pipeline using a cylindrical or tapered plug with one or more hollow passageways oriented sideways through the plug body. When the passageway aligns with the pipeline bore, fluid flows freely. Rotating the plug 90 degrees blocks the flow path completely. This straightforward mechanism gives plug valves their reputation for reliable on/off service and moderate throttling duty.

Key Features

| Feature | Description |

|---|---|

| Quarter-Turn Operation | A single 90-degree rotation opens or closes the valve, giving operators fast, positive shut-off comparable to ball valves. |

| Solids Tolerance | The straight-through flow path and absence of cavities allow plug valves to pass fluids carrying suspended solids without clogging. |

| Durability | Few moving parts and a simple flow geometry translate to long service life with minimal wear. |

| Sealing | Depending on the design, sealing relies on an elastomeric sleeve pressed against the plug or on sealant injected into the seat area. |

Plug valves can be ordered with flanged, hub, or butt weld ends and in cast (bore size >2 inches) or a forged body material (for bore sizes < 2 inches).

The two key reference specifications covering plug valves, for petrochemical applications, are the API 6D (downstream) and API 6A (upstream).

Plug valves may be manually operated, with a wrench or a gear, or actuated with Electric, Electro-Hydraulic, Pneumatic-Hydraulic, and Gas Over Oil Actuators.

Types of Plug Valves

| Type | Description |

|---|---|

| Lubricated | A cavity in the body holds sealant that reduces plug-to-body friction and reinforces the seal. Sealant is replenished through fittings on the valve body. |

| Non-Lubricated | A non-metallic sleeve (typically PTFE) or a coated plug provides low-friction sealing without external lubricant. |

| Eccentric | The plug sits off-center, reducing seat contact during rotation and minimizing wear. Well-proven in slurry, sewage, and high-velocity services. |

| Expanding | A segmented plug expands radially against the body seats when closed, delivering true double block and bleed (DBB) isolation. |

| Multi-Port | Three or more ports allow flow diverting or combining, replacing multiple valves and tees in a single body. |

Applications

Plug valves appear across oil and gas pipelines (crude, natural gas, refined products), chemical plants (corrosive and viscous fluids, slurries), water and wastewater treatment systems, and food and beverage processing lines that demand sanitary conditions.

They handle a broad range of media:

- Neutral liquids (oil, water)

- Acidic and alkaline (corrosive) liquids

- Slurry

- Neutral gases (steam, air)

- Corrosive gases (chlorine, acid vapors)

Choosing a Plug Valve

Selection starts with the fluid: its chemistry, temperature, pressure, and whether it carries solids. From there, match the body and plug material (carbon steel, stainless steel, ductile iron) and the seal material (PTFE, EPDM, metal-to-metal) to the service conditions. If the application demands zero-maintenance sealing, lean toward non-lubricated designs. For pipeline pigging, specify a full-bore Venturi pattern. For DBB isolation, specify the expanding type.

Well-established plug valve manufacturers are Galli & Cassina, Flowserve (Nordstrom and Durco), and Crane/Xomox.

(Source: CTE Skills Youtube Channel)

Types of Plug Valves

Each plug valve type addresses a different service challenge. The sections below cover their construction, behavior, and best-fit applications.

Lubricated Plug Valve

A lubricated plug valve incorporates a sealant cavity within the valve body. Grease or oil is injected through external fittings to form a thin film between the plug and body, reducing operating torque and reinforcing the pressure seal.

Key Features

| Feature | Description |

|---|---|

| Sealant Cavity | A reservoir machined into the body stores lubricant accessible through external grease fittings, so operators can top up without removing the valve from line. |

| Low Operating Torque | The lubricant film prevents metal-to-metal contact between plug and body, keeping torque low even after years of service. |

| Reinforced Seal | Sealant fills micro-gaps at the plug-to-body interface, improving leak-tightness beyond what metal contact alone provides. |

| Scheduled Maintenance | Lubricant depletes over time and must be replenished on a defined schedule. Intervals depend on the sealant grade, operating temperature, and cycle frequency. |

Applications

Lubricated plug valves see heavy use in oil and gas pipeline isolation (crude, gas, refined products), chemical processing involving corrosive fluids that require tight shut-off, water and wastewater treatment for pipeline isolation and flow control, and petrochemical refining processes.

Selection Factors

| Factor | Guidance |

|---|---|

| Temperature and Pressure | Match body metallurgy and sealant grade to the service envelope; high temperatures degrade standard greases faster. |

| Maintenance Access | Plan for periodic sealant replenishment; remote or subsea installations need extended-life sealant or redundant injection points. |

| Sealant-Fluid Compatibility | The sealant must not dissolve in or contaminate the process fluid. Verify compatibility with the fluid data sheet before specifying. |

| Seal Reliability | Quality varies by manufacturer; evaluate fugitive-emission test certificates and API 641 compliance where applicable. |

Lubricated plug valves deliver smooth, repeatable operation and strong sealing performance, provided the lubrication program is maintained. Neglect the schedule, and the valve will either stick or leak.

Non-Lubricated Plug Valve

Non-lubricated plug valves eliminate the need for external sealant by relying on low-friction sleeve materials, typically PTFE or other fluoropolymers, pressed between the plug and body. This removes the ongoing maintenance burden of sealant injection while preserving tight shut-off.

Key Features

| Feature | Description |

|---|---|

| Self-Lubricating Sleeve | A PTFE or polymer sleeve lines the plug-to-body interface, giving inherently low friction without external lubrication. |

| Sleeved Construction | The plug is encapsulated in or seated against a non-metallic sleeve that absorbs minor surface irregularities and provides a resilient seal. |

| Spring-Assisted Sealing | Some designs use internal springs to press the plug against the sleeve, maintaining seal integrity across a range of pressures, particularly at low differential pressures where line pressure alone may not seat the plug. |

| Minimal Maintenance | With no sealant to replenish, non-lubricated plug valves reduce scheduled maintenance and associated downtime. |

Applications

Non-lubricated plug valves perform well in water and wastewater treatment, chemical processing (corrosive acids, aggressive solvents), oil and gas pipeline isolation, and power plant auxiliary systems (steam, cooling water, boiler feedwater).

Selection Factors

| Factor | Guidance |

|---|---|

| Material Compatibility | The sleeve polymer must resist the process fluid’s chemistry. PTFE handles most chemicals, but verify compatibility with strong oxidizers or exotic solvents. |

| Temperature Limits | Non-metallic sleeves impose upper temperature limits (typically 260 °C / 500 °F for PTFE). Above this, consider lubricated or metal-seated designs. |

| Sealing at Low ΔP | Spring-assisted designs perform better at low differential pressures. Confirm the valve maintains bubble-tight shut-off at your minimum operating pressure. |

| Inspection Intervals | Though maintenance is lower than lubricated types, periodic inspection of the sleeve for wear, extrusion, or chemical attack is still necessary. |

Non-lubricated valves are preferred over the lubricated type when low maintenance is required, like in services for sulfur, hydrogen fluoride, or in cases where the fluids could solidify and block the valve.

The downside of non-lubricated valves is that they suit only specific applications in terms of temperature, pressure and type fo conveyed fluids (chemical resistance) due to the non-metallic seat they use.

Types of non-lubricated plug valves

The three main types of non-lubricated valves are: fully lined, elastomer sleeve and, lift-type plug valve.

Each addresses a different combination of chemical resistance, sealing resilience, and ease of operation. Many commercial valves combine two or all three of these features in a single unit.

Fully Lined

“Fully lined” means the body interior and wetted components are coated with a corrosion-resistant fluoropolymer, typically PTFE or PFA. The lining prevents the process fluid from ever contacting the metal body, protecting against corrosion and extending service life in aggressive chemical duties.

Elastomer Sleeve

An elastomer sleeve (EPDM, NBR, or FKM) surrounds the plug, creating a flexible, resilient seal against the body bore. The sleeve conforms to minor surface imperfections and maintains sealing even at low pressures or partial vacuum. It also reduces plug-to-body friction, contributing to smooth operation without external lubricant.

Lift-Type Design

In lift-type plug valves, the plug rises vertically off the seat before rotating, then drops back down to re-engage the seal. This eliminates sliding contact between the plug and sleeve during rotation, dramatically reducing wear and preventing the trapping of solids or debris at the seating surfaces. The result is longer seal life and lower operating torque.

Non-lubricated plug valves offer cost-effective, low-maintenance flow control with tight shut-off and long-term durability across diverse process conditions.

Eccentric Plug Valve

An eccentric plug valve positions its plug off-center, typically 30 degrees or more from the valve centerline. This offset geometry changes the way the plug engages the seat and delivers specific performance advantages over concentric designs.

The half-plug configuration generates stronger seating force with less friction during the open-to-close stroke. Eccentric valves also achieve tighter shut-off than their concentric counterparts.

Typical services include dirty water, sewage, sludge, slurries, compressed air, and other applications that demand tight shut-off despite abrasive or fouling media.

Key Features

| Feature | Description |

|---|---|

| Off-Center Plug | The plug contacts the seat only at the final moment of closure, producing a non-slam, quick-closing action that minimizes wear on both plug and seat. |

| Low Turbulence | The asymmetric flow path reduces turbulence and pressure drop compared to concentric plug valves, improving flow efficiency. |

| Self-Cleaning Action | As the plug rotates, its eccentric path wipes the seat surface clean, preventing buildup of solids or deposits that could impair sealing. |

| Bidirectional Sealing | Eccentric plug valves seal in both flow directions, handling flow reversal without requiring a specific installation orientation. |

| Flexible Seat Options | Seat materials range from elastomers (EPDM, NBR) to metal-to-metal and ceramic, matching the valve to the abrasiveness and temperature of the service fluid. |

Applications

Eccentric plug valves are common in oil and gas pipeline isolation, chemical plants handling corrosive fluids and abrasive slurries, water and wastewater treatment systems, and power generation facilities (steam, cooling water, boiler feedwater circuits).

Selection Factors

Match the seat material to the fluid’s abrasiveness and temperature. For slurries with sharp particles, ceramic or hardened metal seats outlast elastomers. Verify that the eccentric offset angle and seating force are adequate for the required shut-off class. In bidirectional service, confirm the valve’s rated differential pressure applies in both directions.

Eccentric plug valves combine low-wear operation with strong shut-off, and the self-cleaning seat action makes them a practical choice for fouling or abrasive media.

Expanding Plug Valve (Double Block and Bleed - DBB)

An expanding plug valve uses a segmented or sleeved plug that expands radially when the valve closes, pressing outward against both upstream and downstream body seats. This mechanical expansion creates two independent seals with a vented cavity between them, providing a true double block and bleed configuration.

Key Features

| Feature | Description |

|---|---|

| Radially Expanding Plug | The plug consists of multiple segments or sleeves that spread outward on closure, contacting the full circumference of both body seats simultaneously. |

| Segmented Construction | Independent plug segments compensate for minor variations in the body bore, ensuring uniform seal pressure around the entire circumference. |

| Actuation | Operated by handwheel, gear, pneumatic, electric, or hydraulic actuators. The actuation mechanism controls plug expansion and retraction for precise positioning. |

| Bidirectional Sealing | Both upstream and downstream seats seal independently, providing full isolation from either direction. |

| Heavy-Duty Build | Bodies and plugs are manufactured from carbon steel, stainless steel, or alloy materials rated for high-pressure, high-temperature pipeline service. |

Applications

Expanding plug valves are found in oil and gas transmission pipelines, refinery and petrochemical process isolation, water treatment pipeline sectioning, and power plant main-line isolation where true DBB is required.

Selection Factors

Expanding plug valves are the most mechanically complex plug valve type, with more internal components than lubricated or non-lubricated designs. Specify them where the application genuinely requires DBB capability; using them where a simpler plug valve suffices adds unnecessary cost and maintenance complexity.

They are also used to prevent product contamination in applications that do not require double isolation.

The expanding valve uses a mechanism that rotates between the open and closed position and protects both seals from the flow path. During the rotation, the body and seals do not get in contact, and slips expand onto the body seat when the valve is closed to prevent wear or abrasion to the seals.

Expanding plug valves deliver reliable DBB isolation with bidirectional sealing and seal protection during operation.

Multiport Plug Valve

Multi-port plug valves have three or more ports arranged around the valve body, with a rotating plug that directs flow between different port combinations. A single multi-port valve can replace an assembly of two or three conventional valves and tees, simplifying the piping layout and reducing potential leak paths.

Key Features

| Feature | Description |

|---|---|

| Multiple Ports | Three or more ports allow straight-through, cross-flow, or combined flow configurations without additional piping. |

| Rotating Plug | The plug position determines which ports communicate. Operators select the flow path by rotating to predefined detent positions. |

| Solid Construction | Bodies in carbon steel, stainless steel, or alloy materials handle high pressures and temperatures consistent with other plug valve types. |

| Sealing | Standard plug valve sealing methods apply: elastomeric, metal-to-metal, or sealant-injected, depending on the service. |

| Actuation | Manual (wrench, gear) or automated (pneumatic, electric, hydraulic) operation. Automation is common where the valve switches flow paths frequently or remotely. |

Applications

Multi-port plug valves serve chemical blending and distribution manifolds, oil and gas metering stations and pipeline manifold systems, water treatment plants (switching between filtration, disinfection, and dosing stages), and food and beverage processing lines handling multiple product streams.

Selection Factors

Define the required port configuration (3-way L-port, 3-way T-port, 4-way, etc.) before selecting a valve. Verify that the plug’s flow passages match the required Cv for each operating position. In multi-product service, confirm that the dead volume between ports does not cause unacceptable cross-contamination.

Multi-port plug valves reduce valve count, simplify piping, and consolidate flow-switching functions into a single body, but only where the port configuration genuinely matches the process requirements.

Short vs. Long Pattern Plug Valve

Short and long pattern plug valves refer to variations in the overall length of the valve body.

Short, regular, and Venturi plug valve.

Short Pattern vs. Long Pattern Comparison

| Feature | Short Pattern | Long Pattern |

|---|---|---|

| Body Length | Compact face-to-face dimensions; fits tight piping layouts | Extended body; more material between inlet and outlet flanges |

| Weight | Lighter; easier to handle and install where weight is restricted | Heavier due to the longer body |

| Flow Capacity | Port area is 40-60% of full bore; adequate for most on/off duties | Larger internal passageways; lower pressure drop and higher flow capacity |

| Sealing | Standard sealing performance | Additional contact area between plug and body improves leak-tightness at higher pressures and temperatures |

Application Considerations

| Factor | Recommendation |

|---|---|

| Space Constraints | Short pattern valves fit where piping runs are tight or where compact face-to-face dimensions must match an existing spool piece. |

| Flow and Pressure Drop | Long pattern valves suit services that need higher Cv values or where minimizing pressure drop is a process requirement. |

| Pressure and Temperature | Both patterns are available across standard ASME pressure classes and temperature ratings. |

The choice between short and long pattern depends on the installed space, the required port area, and the acceptable pressure drop.

- The short pattern design type has compact face-to-face dimensions and port areas accounting for 40% to 60% of a full-bore type

- The regular pattern has longer face-to-face dimensions and a port area of 50-70% of the full-bore plug valves, providing minimal loss of flow.

- Full bore design has long face-to-face dimensions and a round port (Venturi).

This last configuration provides unrestricted flow and allows pigging operations of the pipeline. Modern plug valves are an evolution of a basic design that was developed back in the Roman Empire.

Plug Valve vs. Other Types of Valve

Plug Valve vs. Ball Valve

Plug valves and ball valves are both quarter-turn shut-off devices, and they compete for many of the same line positions. Their internal geometry, however, gives each type distinct strengths.

Plug Valve

A plug valve uses a cylindrical or tapered plug with a through-port that rotates within the body. The plug seats against the body bore, either through direct metal contact, an elastomeric sleeve, or injected sealant. Rotating the plug 90 degrees moves between full open and full close.

Plug valves can deliver linear or equal-percentage flow characteristics depending on the plug and port geometry, so they handle moderate throttling as well as on/off duty. The wiping contact between plug and seat during rotation keeps the sealing surfaces clean, which matters in services carrying suspended solids.

Ball Valve

A ball valve uses a spherical closure element (the ball) with a through-port. The ball rotates within the body between two seat rings. Full-bore ball valves match the pipeline ID; reduced-bore versions trade flow area for a smaller, lighter body.

Ball valves provide quick, full-flow shut-off with low pressure drop and low operating torque. They are straightforward to automate with electric, pneumatic, or hydraulic actuators. However, the cavity between the ball and body can trap debris and process fluid, which creates maintenance issues after shutdowns.

Comparison

| Aspect | Plug Valve | Ball Valve |

|---|---|---|

| Best for | Frequent operation, tight shut-off, moderate flow control | Quick on/off operation, full-flow shut-off, minimal pressure drop |

| Cost | More economical due to simpler design | Generally more expensive |

| Contamination | Less prone to contamination by debris and dirt accumulation | Debris can accumulate in spaces between sphere and body |

| Maintenance | Lower maintenance requirements | Higher maintenance, especially after planned or unplanned plant shut-downs |

| Port design | Full port design without pressure drops | May be reduced or full port (full port ball valve is heavier and bulkier than a plug valve of the same size) |

Plug valves are a strong alternative to ball valves, though ball valves remain the default choice for shut-off service in the oil and gas industry.

Plug Valves Specifications (ASME/API)

ASME and API publish the governing standards for plug valve design, materials, dimensions, and testing. The tables below summarize the most relevant documents.

ASME Specifications

| Standard | Scope |

|---|---|

| ASME B16.34 - Valves Flanged, Threaded, and Welding End | Covers design, materials, dimensions, tolerances, and testing for plug valves (among other types). Defines pressure-temperature ratings, end connections, and valve marking requirements. |

| ASME B16.10 - Face-to-Face and End-to-End Dimensions of Valves | Specifies face-to-face and end-to-end dimensions and tolerances for plug valves, ensuring interchangeability within standardized piping systems. |

| ASME B16.11 - Forged Fittings, Socket-Welding and Threaded | Primarily covers forged fittings but includes provisions for plug valves with socket-welding or threaded ends. Addresses dimensions, materials, and pressure ratings. |

API Specifications

| Standard | Scope |

|---|---|

| API 6D - Specification for Pipeline Valves | The primary specification for pipeline plug valves in the petroleum and natural gas industries. Covers design, materials, manufacturing, testing, and inspection. |

| API 599 - Metal Plug Valves - Flanged and Welding Ends | Addresses metal plug valves specifically: design, materials, dimensions, pressure ratings, testing, and marking for flanged or welding end connections. |

| API 6A - Specification for Wellhead and Christmas Tree Equipment | Governs wellhead and Christmas tree equipment, including plug valves used in upstream oil and gas service. Covers design, materials, dimensions, and testing. |

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

How can you tell the preferred pressure side on a plug valve?