Oil & Gas: Upstream to Downstream

The Upstream, Midstream, and Downstream Oil & Gas Sectors

The Oil & Gas Industry

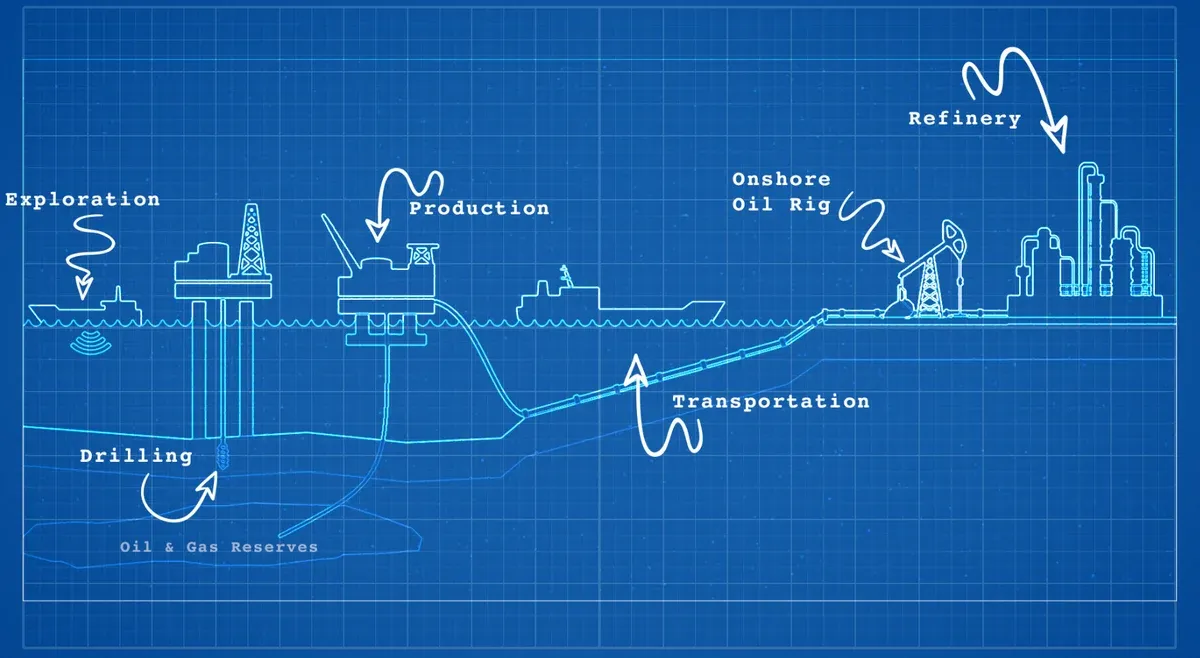

The oil and gas industry covers every step from finding hydrocarbons underground to putting refined fuel in a car’s tank. It splits into three segments: upstream, midstream, and downstream, and the equipment, risks, and economics differ wildly between them.

Upstream, Midstream, and Downstream O&G

Upstream, Midstream, and Downstream O&G

Upstream activities focus on the exploration and production (E&P) of oil and natural gas resources.

This means geological surveys, seismic analysis, and drilling exploratory wells. When viable reserves are confirmed, development drilling begins to extract hydrocarbons from beneath the earth’s surface or seabed. It is the highest-risk, highest-investment segment, and where value first enters the supply chain.

OCTG drill pipes for Upstream Oil & Gas

OCTG drill pipes for Upstream Oil & Gas

The midstream sector bridges production sites and processing facilities. It covers the transportation of crude oil, natural gas, and refined products via pipeline, ship, rail, and truck, as well as the storage of these products in tank farms or underground facilities. Midstream also includes initial processing of raw natural gas to strip out impurities and extract liquid hydrocarbons.

Gas Pipeline Construction Project: Midstream Oil & Gas

Gas Pipeline Construction Project: Midstream Oil & Gas

Downstream operations handle refining crude oil into petroleum products such as gasoline, diesel, jet fuel, heating oil, and petrochemicals, which are then marketed and distributed to end users. This is where the industry meets fluctuating consumer demand, tightening environmental regulation, and the ongoing push toward cleaner energy.

Oil & Gas Refinery: Downstream Operations

Oil & Gas Refinery: Downstream Operations

Key Takeaway: The oil and gas industry is structured into three interconnected segments (upstream (exploration and production), midstream (transportation and storage), and downstream (refining and distribution)) each relying on specialized equipment and infrastructure to deliver energy products from subsurface reservoirs to end consumers.

The industry remains a massive economic engine: it drives employment, funds technological innovation, and underpins energy security worldwide, even as it adapts to competition from renewables and stricter emissions standards.

Key Oil & Gas Countries

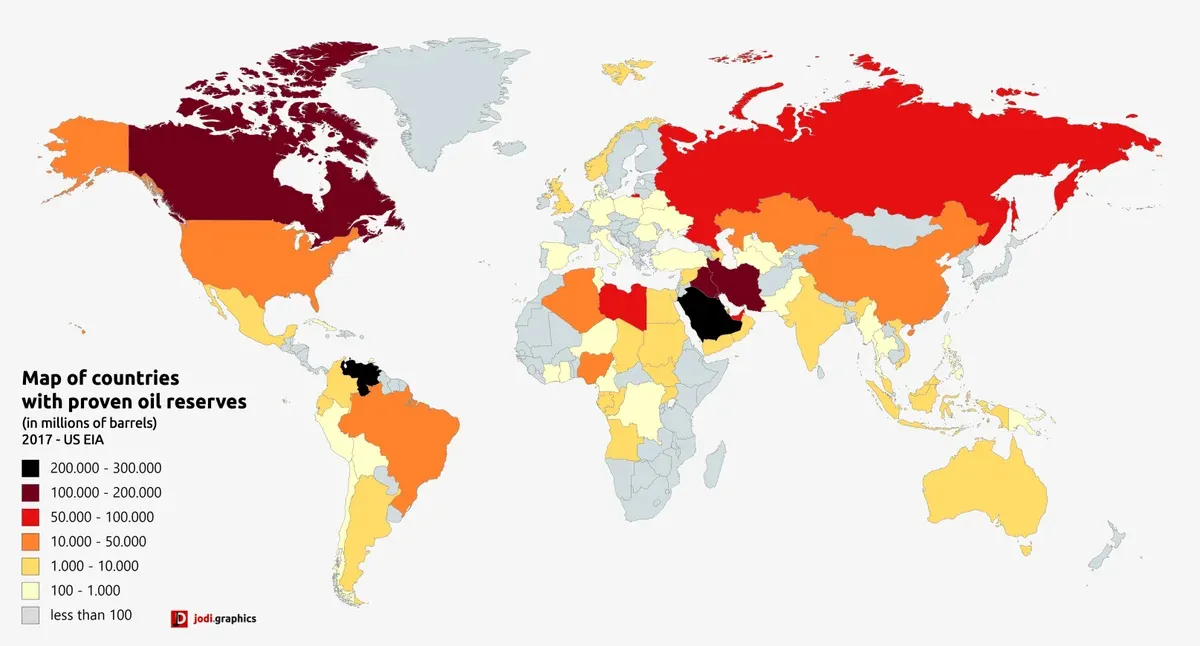

A handful of countries dominate global production, consumption, and reserves, and their policies ripple through energy markets and geopolitics alike.

Maps of oil & gas reserves by country

Maps of oil & gas reserves by country

| Country | Description |

|---|---|

| United States | One of the largest producers and consumers of oil and gas in the world. Innovations in hydraulic fracturing (fracking) and horizontal drilling have unlocked vast shale gas and oil reserves. |

| Saudi Arabia | Possesses the second-largest proven oil reserves and is the world’s largest exporter of oil. Heavily dependent on the oil and gas sector, with vast reserves located in the Ghawar Field, the world’s largest onshore oil field. |

| Russia | A leading oil and gas producer, with significant reserves of both resources. A major supplier of natural gas to Europe, primarily through its state-owned company Gazprom. |

| Canada | Holds the third-largest oil reserves in the world, much of it in the form of oil sands in Alberta. A top producer of natural gas and oil, exporting a significant portion of its production to the United States. |

| Iran | Has the world’s fourth-largest proven oil reserves and the second-largest natural gas reserves. The country’s oil and gas industry has been affected by international sanctions. |

| Iraq | Holds significant oil reserves, with major fields such as Rumaila contributing to its status as one of the top oil producers. The oil sector has been rebuilding after decades of conflict. |

| United Arab Emirates (UAE) | Particularly the emirate of Abu Dhabi, holds substantial oil and gas reserves, making it a critical player in the global energy market. Investing heavily in technology and infrastructure to maintain its position as a leading oil exporter. |

| China | One of the world’s largest oil producers and the second-largest consumer of oil. Investing in domestic production and overseas assets to secure its growing energy needs. |

| Others (Venezuela, Kuwait, Nigeria) | Play key roles in influencing global oil prices, shaping energy policies, and driving innovation in the oil and gas industry. |

The Oil & Gas Industry in Numbers (2024)

Numbers shift with every OPEC meeting and geopolitical crisis, but the following snapshot (April 2024) gives a sense of scale:

| Category | Details |

|---|---|

| Global Oil Production | Approximately 100 million barrels of oil per day (bpd). |

| Global Oil Consumption | Also, around 100 million bpd, indicating a tightly balanced supply and demand. |

| Largest Oil Producers | The United States, Saudi Arabia, and Russia are the top three, with the U.S. leading with over 11 million bpd. |

| Largest Oil Consumers | The United States and China, with the U.S. consuming around 20 million bpd and China about 14 million bpd. |

| Proven Oil Reserves | Estimated to be around 1.7 trillion barrels, with Venezuela, Saudi Arabia, and Canada holding the top spots. |

| Global Natural Gas Production | Around 4 trillion cubic meters of natural gas are produced annually. |

| Proven Natural Gas Reserves | About 6.9 quadrillion cubic feet, with Russia, Iran, and Qatar leading in reserves. |

| Oil Prices | Fluctuates significantly; as of early 2024, Brent crude was in the range of to barrel. |

| Investment | Requires substantial investment, with annual investments in the hundreds of billions of dollars. |

| Employment | Employs approximately 200 million people worldwide in both direct operations and related services. |

| Carbon Emissions | A significant source of carbon dioxide emissions, contributing to global greenhouse gas emissions. |

Understanding the 3 Segments

Value Chain: Exploration → Drilling → Production (Upstream) → Transportation → Storage (Midstream) → Refining → Distribution → Consumers (Downstream)

- Upstream (“E&P”): Exploration, drilling, well development, production, and field enhancement of crude oil and natural gas resources.

- Midstream: Transportation (pipelines, ships, rail, trucks), storage (tank farms, salt caverns, LNG facilities), and wholesale marketing of hydrocarbons.

- Downstream: Refining crude oil into petroleum products, natural gas processing, petrochemical production, and distribution to consumers.

Upstream Oil & Gas (“E&P”)

Upstream (exploration and production, or E&P) covers everything from the search for hydrocarbon reserves to getting crude oil and natural gas out of the ground. It is where the supply side of the market begins.

Upstream Oil & Gas

Upstream Oil & Gas

Upstream Flow: Exploration → Drilling → Well Development → Production → Field Enhancement (with feedback loop to optimize production)

Exploration

Exploration means identifying areas that may contain hydrocarbon reserves. Geologists run seismic surveys (bouncing sound waves off subsurface rock layers) to build 3-D images of potential reservoirs. Those images drive decisions on where (and whether) to drill.

Seismic Surveys

Seismic Surveys

Drilling

Once a potential reservoir is identified, exploratory wells (wildcat wells) are drilled to confirm hydrocarbons exist. If results look promising, appraisal drilling follows to gauge reservoir size and commercial potential. Rigs can operate onshore or offshore, in shallow or deep waters.

Well Development

After a discovery is deemed commercial, development wells are drilled to begin production. Well design is tailored to reservoir characteristics: formation pressure, permeability, and fluid type. Infrastructure goes in at this stage: platforms for offshore fields, well pads and gathering lines for onshore.

Production

Production is about bringing oil or gas to the surface and preparing it for transport. That typically means separating water, gas, and solids from the crude, or scrubbing impurities from natural gas. A productive field can run for decades with the right reservoir management.

Oil & Gas Production

Oil & Gas Production

Field Enhancement

Secondary and tertiary recovery techniques boost a field’s productivity after natural reservoir pressure declines. Common methods include water flooding, gas injection, and chemical EOR, all aimed at maintaining pressure and sweeping more oil toward the wellbore.

Economic and Technological Aspects

Upstream is high risk, high investment, and (when it works) high reward. Wildcat wells are speculative; plenty come up dry. Technologies like 3D seismic imaging, horizontal drilling, and hydraulic fracturing (fracking) have dramatically improved hit rates and opened up reserves that were uneconomic a generation ago.

Environmental and Regulatory Considerations

Upstream operations sit under heavy regulatory scrutiny, especially in offshore and environmentally sensitive areas. Operators must navigate overlapping local, national, and international regulations covering environmental protection, well integrity, and community impact.

Midstream Oil & Gas

Midstream is the link between the wellhead and the refinery gate. It covers the transportation, storage, and wholesale marketing of crude oil, natural gas, and refined petroleum products, getting hydrocarbons from production sites to where they will be processed or consumed.

Transportation

Midstream transportation moves crude oil, natural gas, and refined products from extraction points to refineries, storage, or distribution. The main modes:

- Pipelines: The most common and cost-effective method for transporting oil and gas over land. Pipelines are used for both crude oil and natural gas and are required for moving large volumes across continents.

- Rail: Rail transport is often used when pipelines are not available or feasible. It offers flexibility but is generally more expensive than pipeline transport.

- Shipping: Oil tankers and liquefied natural gas (LNG) carriers are used for overseas transportation. This method connects global markets but is subject to geopolitical and environmental considerations.

- Trucking: Trucks can provide direct transport to and from storage and retail outlets, offering flexibility for smaller volumes or areas not serviced by pipelines.

Oil Pipeline

Oil Pipeline

Storage

Midstream storage holds crude oil, natural gas, and petroleum products until the market needs them:

- Tank Farms: Large storage facilities that hold crude oil or refined products before they are transported to refineries or sold to consumers.

- Underground Storage: Used primarily for natural gas, these facilities can include depleted reservoirs, salt caverns, or aquifers, offering large-volume storage options to manage supply and demand fluctuations.

- LNG Storage: Refrigerated tanks that hold natural gas in liquefied form at around -162 deg C (-260 deg F).

LNG Vessel

LNG Vessel

Wholesale Marketing

Midstream companies also engage in the wholesale marketing of crude oil, natural gas, and refined products. This involves the sale of bulk quantities to customers in the downstream sector, such as refineries and large industrial users, often involving commodity trading markets.

Oil Tanker

Oil Tanker

Key Challenges

Midstream operators deal with regulatory hurdles, right-of-way disputes, massive capital requirements, and the political sensitivity of pipeline projects. On top of that, they must handle supply/demand swings, geopolitical risk, and the energy transition away from fossil fuels.

That said, the midstream sector is the backbone of the energy supply chain. Without reliable pipelines, terminals, and storage, oil prices spike, gas stations run dry, and entire economies grind to a halt.

Loading Arms in Oil & Gas Midstream

Loading Arms in Oil & Gas Midstream

Downstream Oil & Gas

Downstream is the final step in the value chain: refining crude oil, processing natural gas, and distributing finished products (gasoline, diesel, jet fuel, petrochemicals) to end users.

Refining

Refining converts crude oil into usable products through physical and chemical processes. The main outputs: gasoline, diesel, jet fuel, heating oil, and asphalt. A refinery’s “complexity,” measured by its Nelson Complexity Index, determines the range and value of products it can produce from a given crude slate.

Oil Refinery

Oil Refinery

Natural Gas Processing

Natural gas processing involves removing impurities and separating gas liquids from natural gas to make it suitable for consumer and industrial use.

The purified gas is then transported through pipelines to distribution companies, power plants, and other end-users. Natural gas liquids (NGLs), such as propane and butane, are separated and sold for various uses, including heating, cooking, and as feedstock for petrochemical manufacturing.

Petrochemicals

The downstream sector also includes the petrochemical industry, which uses various components of crude oil and natural gas as raw materials to produce chemicals. These petrochemicals are the building blocks for a vast array of products, from plastics and fertilizers to pharmaceuticals and industrial chemicals.

Fertilizers

Fertilizers

Marketing, Distribution, and Retail

Finished products reach consumers through an extensive distribution network: pipeline terminals, wholesale distributors, gas stations, and direct industrial sales. Pricing tracks crude benchmarks, regional supply/demand balances, and seasonal patterns (gasoline demand peaks in summer, heating oil in winter). Service stations are the most visible face of the downstream sector, and the point where barrel economics finally translate into pump prices.

Environmental and Regulatory Considerations

Downstream is heavily regulated. Rules cover stack emissions, product quality standards (sulfur limits in fuels, for example), and safety procedures for workers and surrounding communities. Compliance costs are significant, but the alternative (fines, shutdowns, and reputational damage) is far worse.

Key Equipment in Upstream, Midstream, Downstream

Each segment of the oil and gas value chain depends on specialized equipment. Below is a walkthrough of the major hardware, from the drill bit to the loading rack.

Equipment in Upstream O&G

Drilling Equipment

Drill Rigs

Drill rigs bore holes into the earth to reach hydrocarbon reservoirs. They fall into two broad categories:

- Land rigs: mobile structures transported overland between well sites.

- Offshore rigs: jack-up rigs, semi-submersibles, and drillships, each suited to different water depths and sea conditions.

Every rig includes a derrick or mast (holds the drill string), a mud system (circulates drilling fluid to cool the bit, clear cuttings, and maintain wellbore pressure), a power system, and a hoisting system for raising and lowering the drill string.

Land Drilling Rigs for Exploration

Land Drilling Rigs for Exploration

Drill Bits

The drill bit sits at the bottom of the drill string and does the actual rock cutting. Two main types:

- Roller cone (tricone) bits: rotating cones with teeth or tungsten carbide inserts that crush and grind rock. Good for hard formations.

- Fixed cutter (PDC) bits: no moving parts; synthetic diamond cutters shear through rock. Faster in softer to medium formations and now the dominant bit type in most drilling programs.

Bit selection depends on formation hardness, wellbore diameter, depth, and budget. The right bit can slash days off a drilling campaign; the wrong one burns money.

Drilling Bits for Rock Cutting

Drilling Bits for Rock Cutting

Drill Pipes

Tubular steel pipes used to connect the surface equipment with the bottom hole assembly and the drill bit, facilitating the drilling fluid’s flow to the bit and back to the surface. Learn more about API 5CT OCTG drill pipes.

OCTG Drill Pipes for Upstream Oil & Gas Operations

OCTG Drill Pipes for Upstream Oil & Gas Operations

Production Equipment

Wellhead Systems

The wellhead is the surface assembly that seals the wellbore, supports the casing strings, and provides the pressure-control interface between the subsurface reservoir and surface equipment. Components include casing heads, casing spools, tubing heads, valves, chokes, and seals.

Skid-Mounted Wellhead Equipment

Skid-Mounted Wellhead Equipment

During drilling, the wellhead accepts blowout preventers (BOPs). During production, it manages well pressure and flow. It also serves as the entry point for intervention operations: acid stimulation, fracturing, wireline runs, and maintenance tools. Wellheads must handle extreme pressures and temperatures, and they are configured to each well’s specific conditions.

Christmas Trees

A Christmas tree is an assembly of valves, spools, and fittings installed on the wellhead after drilling is complete. It controls the flow of hydrocarbons from the well and can shut the well in completely when needed.

Christmas Tree for Upstream Ops

Christmas Tree for Upstream Ops

The tree includes master valves, wing valves, and choke valves that regulate pressure, control flow rate, and provide access for well interventions, testing, and emergency shutdowns. Trees are rated for the specific pressure and temperature conditions of each well and reservoir.

Pumps and Compressors

Pumps move liquids (crude oil, produced water, drilling fluids) through the upstream system. Common types include centrifugal, positive displacement, and electric submersible pumps (ESPs), each chosen based on fluid properties, pressure requirements, and flow rate.

Upstream Skid Mounted Pump

Upstream Skid Mounted Pump

Compressors handle gas. They boost natural gas pressure for pipeline transport, storage, or processing. Reciprocating compressors suit high-pressure/low-volume applications; centrifugal compressors handle high-volume throughput; rotary screw compressors fill the gap. Both pumps and compressors run continuously from wellhead to initial processing, and their reliability directly affects production uptime.

Logging and Monitoring Equipment

Wireline Logging Tools

Wireline tools are lowered into the wellbore on a cable to measure formation properties: electrical resistivity, porosity, density, hydrocarbon saturation, and formation pressure. This data drives decisions about well viability, completion design, and production optimization.

Wireline logging equipment

Wireline logging equipment

Logging can run during or after drilling. The data feeds directly into reservoir models, and better models mean better recovery. In my experience, skipping or skimping on logging almost always costs more in the long run than the logging itself.

Drilling Monitoring Systems

Modern rigs are instrumented wall-to-wall. Drilling monitoring systems collect real-time data on bit performance, downhole pressure and temperature, mud weight, and flow rates. Sensors sit both in the drill string (MWD/LWD tools) and on the rig floor.

The payoff: operators can optimize drilling speed, spot hazardous conditions early, and reduce non-productive time (NPT) from stuck pipe, kicks, or wellbore instability. On a deepwater well costing a million dollars a day in rig time, good monitoring pays for itself many times over.

Well Completion Equipment

Casing and Cementing Equipment

Casing (a series of concentric steel pipes) is run into the wellbore in stages as the well deepens. It prevents the hole from collapsing, isolates formation zones, protects freshwater aquifers, and provides the foundation for production equipment.

Casing Pipes for Weelbore Stabilization

Casing Pipes for Weelbore Stabilization

After each casing string is set, cement is pumped down the casing and back up the annulus to lock everything in place and seal off formation fluids. Cementing equipment includes mixers, pumps, and blenders; monitoring systems track slurry flow rates, pressures, and densities in real time. A bad cement job can lead to sustained casing pressure, zonal communication, or, in the worst case, a blowout. There is no cutting corners here.

Fracturing Equipment

Hydraulic fracturing (“fracking”) pumps high-pressure fluid (water, sand (proppant), and chemical additives) into low-permeability rock to crack it open and allow hydrocarbons to flow to the wellbore. The sand props the fractures open once pumping stops.

High pressure fracturing pump

High pressure fracturing pump

A frac spread includes high-pressure pumps (often 20+ units on a single job), blending units, proppant storage and conveyors, chemical mixing systems, and real-time monitoring and control. The pumps must survive extreme pressures; treating pressures of 10,000+ psi are routine in deeper shale plays. Fracking has unlocked vast unconventional reserves (Permian, Marcellus, Eagle Ford) and fundamentally reshaped global energy supply.

Offshore Specific Equipment

Subsea Production Systems

Subsea production systems sit on the ocean floor and allow drilling, completion, and hydrocarbon processing at the seabed, reducing or eliminating the need for fixed surface platforms. Major components:

subsea production systems

subsea production systems

- Subsea trees: control well flow with valves and sensors.

- Manifolds: distribute flow between multiple wells and the host facility.

- Flowlines: transport hydrocarbons from subsea wells to processing.

- Umbilicals: deliver hydraulic power, electrical signals, and injection chemicals from the surface.

- Risers: convey fluids from the seabed up to the platform or FPSO.

These systems must endure extreme deepwater pressures, low temperatures, and corrosive fluids. They have made it economically viable to develop fields in water depths exceeding 2,000 meters.

Floating Production, Storage, and Offloading (FPSO) Units

An FPSO is a vessel (often a converted tanker or a purpose-built hull) that produces, processes, stores, and offloads petroleum directly at sea. Topsides equipment separates oil, gas, and water; processed oil is stored in the hull and periodically offloaded to shuttle tankers.

FPSO

FPSO

FPSOs shine in remote or deep-water locations where laying a pipeline to shore is uneconomic. They can be redeployed to a new field once the current one is exhausted, and they use dynamic positioning or spread mooring to stay on station in harsh weather. For many deepwater developments (offshore Brazil, West Africa, Southeast Asia), FPSOs are the only practical production solution.

Safety and Environmental Protection Equipment

Blowout Preventers (BOPs)

BOPs are the last line of defense against an uncontrolled well release (a blowout). Mounted on the wellhead, they seal the well and can be activated manually, remotely, or automatically when pressure spikes unexpectedly.

BOP Blow Out Preventers

BOP Blow Out Preventers

Two main types: annular BOPs seal around the drill string, casing, or open hole with a flexible element; ram BOPs use steel rams to either close around a specific pipe diameter (pipe rams) or shear through the drill string and seal the well completely (shear rams). After the Deepwater Horizon disaster, BOP testing and maintenance requirements tightened considerably, and rightly so.

Oil Spill Equipment

Oil spill response gear includes booms (floating barriers to contain the slick), skimmers (mechanical devices that separate oil from water), absorbents (pads, granules, sorbent booms), and dispersants (chemicals that break oil into droplets for faster natural degradation).

Oil Boom Example

Oil Boom Example

Equipment selection depends on the type of oil, sea state, weather, and proximity to sensitive shoreline. Rapid deployment is everything: a spill that is contained in the first hours is manageable; one that spreads for days becomes an environmental catastrophe.

Equipment in Midstream O&G

Transportation Equipment

Pipelines

The backbone of the midstream sector, pipelines are used to transport crude oil, refined products, and natural gas from production sites to refineries and then to distribution centers or storage facilities. They include long-distance trunk lines and shorter gathering systems. A common type of pype specification for pipelines is API 5L (Gr. B to X80). Learn more about API 5L pipes for pipelines.

ASTM A333 Pipe for Low Temperature Service

ASTM A333 Pipe for Low Temperature Service

Pumping Stations

Pumping stations are spaced along pipeline routes to maintain pressure and flow rate over long distances. For liquids (crude, refined products), they use high-capacity centrifugal or positive-displacement pumps. For natural gas, compressor stations do the equivalent job, boosting gas pressure to keep it moving.

pumping station

pumping station

Each station includes safety devices, SCADA-connected control systems, and monitoring equipment to detect anomalies and regulate operation. Station spacing depends on terrain, pipeline diameter, product viscosity, and target throughput.

Rail Tank Cars

Rail tank cars transport crude oil, refined products, and LPGs across rail networks. Built from steel or aluminum depending on cargo hazard class, they feature reinforced shells, pressure management systems, and protective coatings.

Rail Tank Cars

Rail Tank Cars

Rail is the go-to when pipeline capacity is unavailable or the route does not justify building one. Unit trains of 100+ cars can move substantial volumes. After a series of high-profile derailments, DOT-117 tank car standards significantly upgraded shell thickness and thermal protection.

Tanker Trucks

Tanker trucks handle short- to medium-distance transport of crude oil, refined products, and liquefied gases. Tanks are built from aluminum, stainless steel, or carbon steel, often compartmentalized to carry different products in one haul.

Tanker Trucks

Tanker Trucks

Safety features include reinforced shells, pressure relief valves, and grounding systems for static electricity. Trucks fill the last-mile gap, connecting pipeline terminals, rail depots, or marine terminals to storage facilities, refineries, and retail outlets that pipelines do not reach directly.

Tanker Ships

Tanker ships range from small coastal vessels to ultra-large crude carriers (ULCCs) hauling over 2 million barrels. They move oil and LNG across oceans, connecting production regions with refining centers worldwide.

Modern tankers have double hulls (mandatory under MARPOL regulations), segregated cargo tanks for different grades, and sophisticated pumping and tank-cleaning systems. LNG carriers use specialized containment systems (membrane or Moss-type spherical tanks) to keep cargo at -162 deg C.

Tanker Ships

Tanker Ships

Freight rates, insurance, and scheduling all respond to geopolitical events; a Suez Canal blockage or sanctions on a producing nation can reshape tanker economics overnight.

Storage Equipment

Storage Tanks

Midstream storage tanks hold crude oil, refined products, and NGLs at tank farms, terminals, and refineries. Types range from large cylindrical above-ground tanks (ASTs) to spherical pressure vessels for LPG.

Above-ground tanks typically use floating roofs to cut vapor losses and fire risk. Underground storage tanks (USTs) are used where space is tight or extra protection is needed. All tanks follow strict standards (API 650 for atmospheric tanks, API 620 for low-pressure) with secondary containment, corrosion protection, and regular inspections.

Storage Tanks

Storage Tanks

LNG Storage Facilities

LNG storage facilities hold natural gas cooled to about -162 deg C (-260 deg F), which reduces its volume roughly 600 times. Two main tank types exist: full containment (inner tank plus outer tank with insulation between) and membrane (a thin, cryogenic-resistant membrane inside a concrete structure).

LNG Storage Facilities

LNG Storage Facilities

Materials must withstand extreme cold and thermal cycling. Safety systems include leak detection, pressure relief, and fire protection. Most LNG terminals also have regasification capacity to warm the liquid back to gas before sending it into the pipeline grid. These facilities are the enablers of the global LNG trade; without them, gas-exporting nations could not reach distant markets.

Salt Caverns

Salt caverns are underground voids created by solution mining (pumping water into a salt formation, dissolving it, and extracting the brine). The resulting cavern stores natural gas, crude oil, or LPGs.

The attraction is simple: salt is impermeable, so caverns provide a natural seal with minimal leak risk. They handle high pressures and allow rapid injection and withdrawal, which makes them ideal for managing supply swings and strategic reserves. The U.S. Strategic Petroleum Reserve, for instance, stores hundreds of millions of barrels in Gulf Coast salt caverns.

Processing Equipment

Natural Gas Processing Plants

Raw natural gas from the wellhead contains methane, heavier alkanes (ethane, propane, butane, pentane), water vapor, H2S, CO2, and sometimes helium or nitrogen. Gas processing plants clean it up to pipeline-quality specs.

Natural Gas Processing unit

Natural Gas Processing unit

The main stages: dehydration (removes water to prevent hydrate formation and corrosion), sweetening (strips H2S and CO2, both toxic and corrosive), and fractionation (separates NGLs, specifically ethane, propane, and butane, from the methane stream). The NGLs have significant standalone value as petrochemical feedstocks and heating fuels.

Fractionation Plants

Fractionation plants split the mixed NGL stream into individual products (ethane, propane, butane, and natural gasoline), each with different market uses and values.

Fractionation Plants

Fractionation Plants

The process uses a series of distillation towers, each targeting a specific component based on boiling point. The lightest component (ethane) comes off first; heavier fractions follow in sequence. Mont Belvieu, Texas, is the pricing hub for U.S. NGLs, and most of the country’s fractionation capacity sits along the Gulf Coast.

LNG Liquefaction Plants

LNG liquefaction plants cool natural gas to -162 deg C (-260 deg F), shrinking its volume ~600x for ocean transport. The process starts with purification (removing water, CO2, and sulfur compounds that would freeze or corrode equipment) followed by staged refrigeration using mixed-refrigerant or cascade cycles.

LNG Liquefaction Plants

LNG Liquefaction Plants

Major equipment includes cryogenic heat exchangers (often the single most expensive item), large-frame compressors, and expanders. These plants are hugely capital-intensive (a greenfield LNG train can cost $5-10 billion), but they connect stranded gas reserves to premium markets in Asia, Europe, and the Americas.

Loading and Unloading Equipment

Dock Loading Facilities

Dock loading facilities transfer crude oil, LNG, and refined products between tanker ships and onshore storage. They use marine loading arms or flexible hoses, along with pumping systems that control flow rate during loading and unloading.

Rail and Truck Loading:Unloading Facilities

Rail and Truck Loading:Unloading Facilities

Key components include berthing infrastructure, vapor recovery units (to capture emissions during transfer), spill containment systems, and emergency shutdown (ESD) systems. A mishap at the dock can shut down an entire terminal, so safety protocols here are stringent.

Rail and Truck Loading/Unloading Facilities

Specialized stations equipped with pumps, meters, and loading arms to transfer hydrocarbons to and from rail cars and tanker trucks efficiently and safely.

Safety and Monitoring Equipment

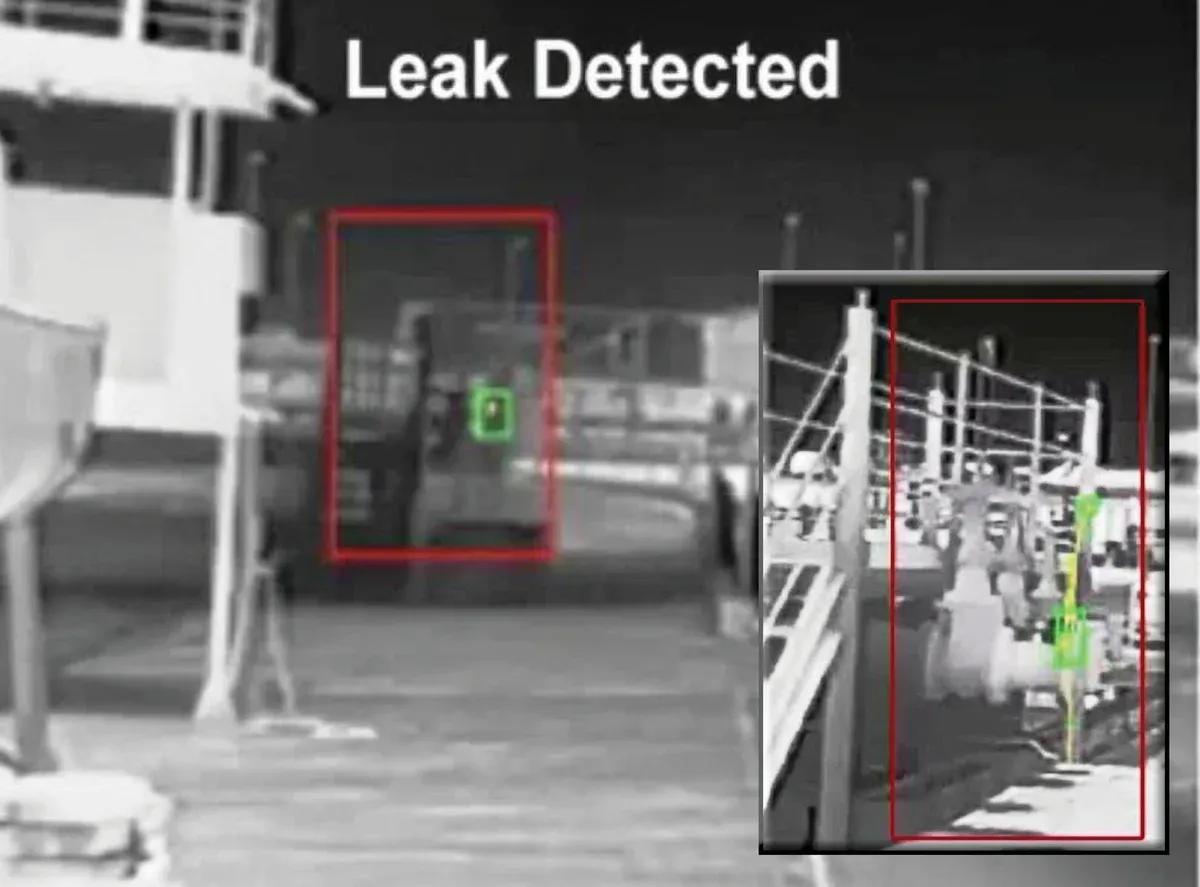

Leak Detection Systems

Leak detection systems find and locate leaks in pipelines and storage before they become major incidents. Technologies include acoustic sensors, fiber optics (which detect temperature anomalies along a pipeline), vapor sensing tubes, infrared cameras, and computational flow monitoring (comparing what enters a pipeline with what exits).

Leak Detection Systems

Leak Detection Systems

Speed matters: a system that identifies a leak in minutes lets operators isolate the section and limit the spill. One that takes hours means thousands of barrels on the ground. Regulators worldwide now mandate pipeline leak detection, and the technology keeps getting faster and more sensitive.

Control Systems

SCADA (Supervisory Control and Data Acquisition) and DCS (Distributed Control System) platforms monitor pipelines, processing plants, and storage facilities in real time. They allow remote control and automation of valves, pumps, compressors, and other critical equipment across hundreds of kilometers of infrastructure.

Equipment in Downstream O&G

Downstream covers refining, gas processing, petrochemical production, and product distribution. The equipment is specialized and often operates at extreme temperatures and pressures.

Refining Equipment

Crude Oil Distillation Units

The CDU (crude distillation unit) is the first and most fundamental process unit in any refinery. Crude oil is preheated and fed into a distillation column, where it vaporizes and separates into fractions based on boiling point.

Crude Oil Distillation Units Refinery

Crude Oil Distillation Units Refinery

Lighter products (naphtha, gasoline) condense at the top of the column; heavier cuts (diesel, atmospheric gas oil, residue) are drawn from progressively lower trays. Everything that follows in a refinery depends on what comes out of the CDU, so its throughput and cut-point accuracy directly drive refinery economics.

Catalytic Crackers

Fluid catalytic cracking (FCC) units break heavy gas oil into lighter, more valuable products: gasoline, diesel, and propylene. A zeolite catalyst contacts hot heavy hydrocarbons in the riser reactor; the heavy molecules crack into lighter ones in seconds.

Catalytic Crackers

Catalytic Crackers

Coke deposits on the spent catalyst, which is then regenerated in a separate vessel by burning the coke off, which conveniently provides heat for the process. The FCC is typically the single biggest profit driver in a conversion refinery, and catalyst selection has a huge impact on product yields.

Hydrocrackers

Hydrocrackers combine high pressure, hydrogen, and a catalyst to break heavy petroleum fractions into jet fuel, diesel, and gasoline. Unlike catalytic cracking, hydrocracking saturates the products with hydrogen and strips out sulfur and nitrogen, producing cleaner fuels that meet modern emission specs.

Hydrocrackers

Hydrocrackers

Key advantages:

- Flexibility: operators can shift product yields (more diesel vs. more jet fuel) by adjusting severity.

- Sulfur removal: products come out low-sulfur, reducing the load on downstream hydrotreaters.

- Bottom-of-the-barrel conversion: hydrocrackers handle the heavy fractions other units cannot process efficiently.

Hydrocracking units are expensive to build and operate (hydrogen costs are significant), but they maximize the value extracted from every barrel of crude.

Alkylation Units

Alkylation units react isobutane with light olefins (butylenes, propylene) to produce alkylate, a premium, high-octane gasoline blending component with low vapor pressure and zero aromatics. The catalyst is either sulfuric acid or hydrofluoric acid, both of which demand careful handling.

Alkylate is one of the cleanest gasoline components a refinery can produce, and refiners increasingly value it as emission regulations tighten. Without an alky unit, light olefins from the FCC would go to lower-value uses.

Reformers

Catalytic reformers upgrade low-octane naphtha into high-octane reformate by rearranging hydrocarbon molecules (converting linear paraffins into branched-chain and aromatic compounds) over a platinum or platinum-rhenium catalyst at high temperature and moderate pressure.

Reformers

Reformers

A critical bonus: reformers produce hydrogen as a byproduct. That hydrogen feeds hydrocrackers and desulfurization units elsewhere in the refinery. In many facilities, the reformer is the primary source of on-site hydrogen, so its uptime directly affects the rest of the plant.

Processing Equipment for Natural Gas

Gas Processing Plants

Downstream gas processing plants condition natural gas for end-use, removing water vapor, H2S, CO2, and other contaminants while separating out NGLs (ethane, propane, butane). Technologies include amine treating (for acid gas removal), glycol dehydration, and cryogenic expansion (for NGL recovery).

The result: pipeline-quality methane plus marketable NGL streams. Without gas processing, the raw well gas would corrode pipelines and fail to meet consumer safety or quality specs.

Sulfur Recovery Units

SRUs convert hydrogen sulfide (H2S) stripped from sour gas and refinery streams into elemental sulfur using the Claus process. The thermal stage partially combusts H2S to produce SO2; the catalytic stage reacts SO2 with remaining H2S over a catalyst to yield liquid sulfur.

Sulfur Recovery Units

Sulfur Recovery Units

Recovery rates reach 95-98%, with tail-gas treatment pushing that higher. The sulfur is sold into the fertilizer and chemicals markets. Without SRUs, refineries and gas plants could not process sour crudes or sour gas and still meet SO2 emission limits.

Petrochemical Production Equipment

Crackers for Ethylene, Propylene

Steam crackers are the gateway to petrochemicals. They heat hydrocarbon feedstock (naphtha, ethane, propane, or butane) in furnace tubes at 800-900 deg C in the absence of oxygen (pyrolysis), breaking large molecules into ethylene and propylene plus various co-products.

Ethylene and propylene are the building blocks for plastics, synthetic rubber, solvents, and thousands of downstream chemical products. Steam crackers are energy-intensive and represent some of the largest single capital investments in the chemical industry. Feedstock flexibility (ethane-based in the U.S., naphtha-based in Europe and Asia) is a major driver of regional competitiveness.

Polymerization Units

Polymerization units bond monomers (ethylene, propylene, and others) into long-chain polymers: the plastics and synthetic materials used in packaging, automotive, construction, healthcare, and almost everything else.

Processes include chain-growth and step-growth polymerization, with catalyst type and reactor conditions (temperature, pressure, residence time) controlling polymer properties like density, melt flow, and tensile strength. Getting the recipe right is the difference between commodity film resin and high-value engineering plastic.

Product Handling and Distribution Equipment

Storage Tanks

Downstream storage tanks hold crude oil, refined products, and chemical intermediates at refineries, terminals, and distribution hubs. Most are above-ground vertical cylindrical tanks (API 650) with floating roofs to minimize vapor losses. Service stations typically use underground tanks.

Storage Tanks GAS

Storage Tanks GAS

Materials are carbon steel or stainless steel depending on the product stored. Maintenance (corrosion monitoring, floor inspections, seal replacement) is mandatory; a tank failure can mean millions of liters on the ground and a facility shutdown.

Loading Racks

Loading racks transfer petroleum products, chemicals, and liquefied gases from storage into tank trucks, railcars, or marine vessels. Multiple loading bays with articulated arms allow simultaneous loading of different products.

Safety features include spill containment, vapor recovery units, automatic shut-off, and precise metering and custody-transfer systems. A well-designed loading rack keeps trucks turning around quickly while preventing product contamination and spills, two things that eat into margins fast.

Safety and Environmental Protection Equipment

Flare Systems

Flare systems safely combust excess hydrocarbons and waste gases that cannot be recovered (the tall stacks with burning flames you see at every refinery and petrochemical plant). They handle gas released during upsets, start-ups, shutdowns, and emergency depressurizations.

Flare Systems Gas

Flare Systems Gas

Modern flares use steam-assist or air-assist to achieve smokeless combustion, high-efficiency burner tips, and continuous pilot monitoring. Regulators are increasingly restricting routine flaring, pushing operators toward flare gas recovery systems that capture and compress the gas for reuse instead of burning it.

Wastewater Treatment Plants

Refinery and petrochemical wastewater contains hydrocarbons, heavy metals, and chemical additives that must be treated before discharge or reuse. Treatment typically progresses through: preliminary (screening solids), primary (sedimentation), secondary (biological degradation of organics), and tertiary (polishing: membrane filtration, activated carbon, or advanced oxidation).

Water reuse within the facility is increasingly common, driven by both regulatory pressure and the rising cost of freshwater intake in many regions.

Quality Control and Testing Equipment

Laboratory Testing Equipment

Lab equipment analyzes crude oil, intermediate streams, and finished products against specifications: density, viscosity, sulfur content, octane number, flash point, and dozens of other parameters. Quality control catches off-spec product before it leaves the gate.

Leave a Comment

Have a question or feedback? Send us a message.