Pipe Color Codes: ASME A13.1, ISO 14726 & BS 1710

Why pipe color coding matters: Correct pipe identification prevents injuries, chemical exposures, and fatalities. Emergency responders, maintenance crews, and operators rely on visual pipe markings to identify contents instantly, without consulting drawings. OSHA recognizes ASME A13.1 as the consensus standard for pipe marking in the United States.

ASME A13.1: The US Standard for Pipe Identification

The ANSI/ASME A13.1 standard, titled Scheme for the Identification of Piping Systems, defines the pipe color coding and labeling requirements used throughout industrial facilities in North America. Originally published in 1928 and last revised in 2020, this standard establishes how to identify pipe contents and functions using color-coded labels with text and flow direction arrows.

ASME A13.1 classifies piped substances into hazard-based categories, each assigned a specific color combination. This approach differs from European and international standards that assign colors based on the specific substance rather than the hazard category.

According to the ASME A13.1 specification, fluids are classified into:

- Flammable: fluids and vapors that may ignite and burn in the air

- Oxidizing: gases or liquids that may contribute to the combustion of other materials when combined with oxygen

- Toxic and corrosive: media that are corrosive or toxic to personnel

- Fire-quenching: water, foam, and CO2 used in sprinkler systems and firefighting systems

- Compressed air: non-hazardous pressurized gases

- Combustible: substances that can burn but are not classified as flammable (higher flash point)

ASME A13.1 Color Code Chart

The background color indicates the general hazard category of the fluid or gas within the pipe. The label text color provides contrast for legibility.

| Category | Background Color | Text Color | Pantone Ref. | Examples |

|---|---|---|---|---|

| Flammable fluids | Brown | White | 4515 | Natural gas, diesel, crude oil, LPG, gasoline |

| Oxidizing fluids | Yellow | Black | 109 | Oxygen, hydrogen peroxide, ozone |

| Toxic/corrosive fluids | Orange | Black | 151 | H2S, sulfuric acid, caustic soda, ammonia, chlorine |

| Fire suppression | Red | White | 186 | Fire water, deluge systems, sprinkler, foam, CO2 |

| Compressed air | Blue | White | 540 | Instrument air, plant air, nitrogen |

| Non-hazardous water | Green | White | 335 | Potable water, cooling water, condensate |

| User-defined | Per facility | Per facility | Per facility | Steam, specialty chemicals, custom services |

ASME A13.1 pipe color marking

ASME A13.1 pipe color marking

Label Sizing Requirements

ASME A13.1 specifies minimum letter height and label length based on the pipe outside diameter (including insulation). Labels that are too small to read defeat the purpose of the marking system.

| Pipe OD Range | Min. Letter Height | Min. Label Length | Min. Arrow Size |

|---|---|---|---|

| 3/4” to 1-1/4” (19-32 mm) | 1/2” (13 mm) | 8” (200 mm) | 3” (75 mm) |

| 1-1/2” to 2” (38-50 mm) | 3/4” (19 mm) | 8” (200 mm) | 4” (100 mm) |

| 2-1/2” to 6” (65-150 mm) | 1-1/4” (32 mm) | 12” (300 mm) | 6” (150 mm) |

| 8” to 10” (200-250 mm) | 2-1/2” (64 mm) | 24” (600 mm) | 8” (200 mm) |

| Over 10” (over 250 mm) | 3-1/2” (89 mm) | 32” (800 mm) | 12” (300 mm) |

Label Placement Rules and Flow Direction Arrows

Proper placement is as important as correct color selection. A label on a pipe is useless if workers cannot see it from their normal working position.

Where to Place Pipe Labels

ASME A13.1 requires labels at the following locations:

- At all valves (on both sides if accessible from two directions)

- At branch connections and tees, on each branch leg near the junction

- On both sides of wall, floor, and ceiling penetrations, so the pipe is identified in each room or area

- At direction changes such as elbows, bends, and offsets

- Near equipment connections including pumps, heat exchangers, vessels, and tanks

- On straight runs at intervals not exceeding 25 feet (7.6 m)

Flow Direction Arrows

Flow direction arrows are a mandatory element of every pipe label under ASME A13.1. The arrow indicates the direction of normal flow or the direction of pressure source in static systems.

| Situation | Arrow Requirement |

|---|---|

| Single-direction flow | One arrow pointing in the direction of flow |

| Bidirectional flow (e.g., utility headers) | Two arrows pointing in opposite directions |

| Dead-end or static lines | Arrow pointing toward the pressure source |

| Vertical risers/drops | Arrow pointing up or down, visible from the access level |

Identification at Valves, Walls, and Floor Penetrations

Pipes passing through walls or floors are particularly critical marking points. Workers on one side of a wall have no visibility of where the pipe goes or what it carries on the other side. ASME A13.1 requires labels on both sides of every penetration.

At valves, the label should be placed near (but not on) the valve body, positioned so it remains visible whether the valve is open or closed. For valve stations with multiple valves in a manifold, each pipe entering and leaving the manifold must be individually labeled.

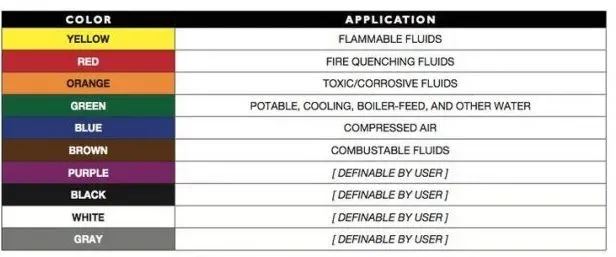

EN 13480: European Pipe Color Coding

The European Standard EN 13480 (Metallic Industrial Piping) addresses pipe color coding in European countries. While similar to ASME standards in principle, EN 13480 incorporates the content-based identification approach that is common in European practice.

| Color | Contents / Category |

|---|---|

| Yellow | Flammable fluids or gases |

| Red | Fire protection systems |

| Blue | Compressed air |

| Green | Potable water |

| Brown | Combustible fluids |

| White | Steam |

| Gray | Non-potable water |

| Orange | Toxic or corrosive fluids |

ISO 14726: International Pipe Color Coding

ISO 14726 (Pipelines: Identification of pipelines and associated services) is the International Organization for Standardization’s standard for pipe identification. It provides a globally recognized framework for color-coding pipelines in industrial and commercial applications. ISO 14726 uses a content-based identification system, assigning colors to specific substances rather than hazard categories.

Key Features of ISO 14726

| Feature | Description |

|---|---|

| Color Bands | Specifies color bands or stripes on pipes to indicate the specific type of fluid or gas carried. Each color represents a particular substance category: water, steam, compressed air, hazardous chemicals, oils, or fire protection. |

| Base and Identification Colors | Defines a base color for the general fluid group and an identification color for the specific substance. For example, all water services share a green base, with secondary bands differentiating potable from cooling water. |

| Text and Labels | Recommends text or labels alongside color bands for additional information about pipe contents, operating conditions, or safety precautions. |

| Size and Placement | Includes guidelines for the size, placement, and spacing of pipe markings so they remain visible and legible under various lighting and environmental conditions. |

| Compliance and Maintenance | Covers ongoing maintenance and inspection of pipe markings to keep them visible, intact, and compliant with regulatory requirements. |

ISO 14726 Color Assignments

| Color | Substance |

|---|---|

| Green | Water (all types) |

| Silver-gray | Steam |

| Light blue | Air and compressed gases (non-flammable) |

| Yellow | Flammable gases |

| Brown | Flammable liquids (oils, fuels) |

| Violet | Acids and alkalis |

| Red | Fire protection |

| Orange | Toxic and harmful substances |

Although ISO 14726 provides international guidance, regional standards and regulations may also apply. Always confirm which standards govern your project location before implementing pipe markings.

BS 1710: British Standard for Pipe Identification

BS 1710 (Specification for identification of pipelines and services) is the British Standard widely used in the United Kingdom, Ireland, and many Commonwealth countries. Like ISO 14726, BS 1710 uses a content-based identification system.

BS 1710 Color Scheme

| Color (BS 4800 Ref.) | Substance |

|---|---|

| Green (12-D-45) | Water |

| Silver-gray (10-A-03) | Steam |

| Light blue (20-E-51) | Air |

| Yellow ochre (08-C-35) | Flammable gas |

| Brown (06-C-37) | Oils and combustible liquids |

| Violet (22-C-37) | Acids and alkalis |

| Red (04-E-53) | Fire protection |

| Orange (06-E-51) | Electrical services and conduits |

| Black | Drainage and waste |

| Cream (10-C-31) | Non-combustible gases (nitrogen, CO2) |

BS 1710 Key Differences from ASME A13.1

| Feature | ASME A13.1 | BS 1710 |

|---|---|---|

| Classification approach | Hazard-based categories | Content-based assignments |

| Steam | User-defined (commonly gray) | Silver-gray (dedicated) |

| Acids/chemicals | All grouped under orange (toxic/corrosive) | Violet for acids and alkalis specifically |

| Natural gas | Brown (flammable category) | Yellow ochre |

| Color reference system | Pantone | BS 4800 |

| Number of standard colors | 6 + user-defined | 10+ content-specific |

Standards Comparison: ASME A13.1 vs ISO 14726 vs BS 1710

The following table compares how the three major pipe color standards identify common industrial pipe services. This is essential knowledge for engineers working on international EPC projects.

| Pipe Service | ASME A13.1 (USA) | ISO 14726 (International) | BS 1710 (UK) |

|---|---|---|---|

| Fire water | Red | Red | Red |

| Potable water | Green | Green | Green |

| Cooling water | Green | Green (with secondary band) | Green (with secondary band) |

| Compressed air | Blue | Light blue | Light blue |

| Instrument air | Blue | Light blue | Light blue |

| Steam | User-defined (gray) | Silver-gray | Silver-gray |

| Natural gas | Brown | Yellow | Yellow ochre |

| Crude oil | Brown | Brown | Brown |

| Diesel fuel | Brown | Brown | Brown |

| Sulfuric acid | Orange | Violet | Violet |

| Caustic soda (NaOH) | Orange | Violet | Violet |

| Ammonia | Orange | Orange | Yellow (as toxic gas) |

| Oxygen | Yellow | Light blue (with “O2” label) | Light blue (with “O2” label) |

| Nitrogen | Blue | Light blue | Light blue |

| Hydrogen | Brown | Yellow | Yellow ochre |

PFI ES-22: Color Coding by Material Grade

PFI ES-22 stands for the “Pipe Fabrication Institute Engineering Standard No. 22.” This standard is published by the Pipe Fabrication Institute (PFI), an organization focused on pipe fabrication and installation quality in industrial construction.

PFI ES-22 addresses “Color Coding Recommendations for Process Piping.” Unlike ASME A13.1, which identifies pipe contents, PFI ES-22 identifies the pipe material grade using color bands painted on the pipe end or body. This is used in fabrication shops, laydown yards, and during construction to prevent material mix-ups.

Note that, in addition to the colors specified in the table, welded pipes shall show an additional white stripe.

PFI Standard ES-22: Pipe Color Coding Recommendations

Carbon Steel Pipes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| Carbon Steel, Electric Resistance Welded Pipe | A53 Gr. B/API | 1 solid white |

| Carbon Steel, Smls, specified tensile strength under 70,000 psi (483 MPA) | A53 Gr. B | No Marking |

| Carbon Steel killed steel | A106 Gr. B | 1 solid green |

| Carbon Steel, specified tensile strength 70,000 psi (483 MPA) and over | A106 Gr. C | 2 solid green |

| Carbon Steel, low temperature (impact tested) | A333 Gr. 6 | 1 solid red |

High Yield Carbon Steel Pipes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| 52,000 min. yield | API 5L X-52 | 1 solid yellow, 1 solid green |

| 60,000 min. yield | API 5L X-60 | 1 solid yellow, 1 solid pink |

| 65,000 min. yield | API 5L X-65 | 2 solid yellow |

| 70,000 min. yield | API 5L X-70 | 1 solid yellow, 1 solid orange |

Low Alloy Pipes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| C-Mo steel | A335 Gr. P1 | 1 solid orange |

| 1 Cr-1/2 Mo Steel | A335 Gr. P12 | 1 solid orange, 1 solid blue |

| 1 1/4 Cr-1/2 Mo Steel | A335 Gr. P11 | 1 solid yellow |

| 2 1/4 Cr-1 Mo Steel | A335 Gr. P22 | 1 solid blue |

| 5 Cr-1/2 Mo Steel | A335 Gr. P5 | 1 solid blue, 1 solid yellow |

| 9 Cr-1/2 Mo Steel | A335 Gr. P9 | 2 solid orange |

Ferritic and Martensitic Pipes and Tubes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| Type 405 | A268 TP405 | 1 solid green, 1 solid black |

| Type 410 | A268 TP410 | 1 solid green, 1 solid red |

Austenitic Stainless Steel Pipes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| Type 304 | A312 TP304 | 1 solid black |

| Type 304L | A312 TP304L | 2 solid black |

| Type 304H | A312 TP304H | 1 intermittent black |

| Type 309 | A358 Gr309 | 1 solid black, 1 solid brown |

| Type 310 | A358 Gr310 | 1 solid green, 1 solid orange |

| Type 316 | A312 TP316 | 1 solid gray |

| Type 316L | A312 TP316L | 2 solid gray |

| Type 316H | A312 TP316H | 1 intermittent gray |

| Type 317 | A312 TP317 | 1 solid brown, 1 solid green |

| Type 317L | A312 TP317L | 1 solid brown, 1 solid red |

| Type 321 | A312 TP321 | 1 solid pink |

| Type 321H | A312 TP321H | 2 solid pink |

| Type 347 | A312 TP347 | 1 solid brown |

| Type 347H | A312 TP347H | 2 solid brown |

Nickel-Alloy Pipes

| Material | Material Grade | Band / Strip Color |

|---|---|---|

| Nickel 200 | — | 1 solid black, 1 solid pink |

| Incoloy 800 | — | 1 solid black, 1 solid orange |

| Incoloy 800H | — | 1 solid gray, 1 solid red |

| Incoloy 825 | — | 1 solid gray, 1 solid blue |

| Inconel 600 | — | 2 solid blue |

| Inconel 625 | — | 1 solid blue, 1 solid pink |

| Hastelloy Alloy 8-2 | — | 1 solid red, 1 solid orange |

| Hastelloy Alloy C-276 | — | 1 solid red, 1 solid blue |

| Hastelloy Alloy C-22 | — | 2 solid red |

| Hastelloy Alloy G | — | 1 solid red, 1 solid yellow |

| Carpenter Alloy 20 C 8-3 | — | 1 solid black, 1 solid blue |

| Monel 400 | — | 1 solid black, 1 solid yellow |

Practical Implementation Guide

Implementing a pipe color coding system across a facility requires planning, coordination, and sustained maintenance. The following steps outline a practical approach for new facilities and retrofits.

Step 1: Select the Applicable Standard

The standard depends on the project location, owner requirements, and local regulations:

| Location / Context | Primary Standard | Notes |

|---|---|---|

| United States | ASME A13.1 | OSHA-recognized consensus standard |

| United Kingdom | BS 1710 | Widely adopted; may be supplemented by owner specs |

| European Union | ISO 14726 or EN 13480 | Country-specific codes may also apply |

| Middle East (EPC) | ASME A13.1 or project-specific | Many operators specify ASME A13.1 |

| International projects | ISO 14726 | Used as a neutral baseline when standards conflict |

Step 2: Develop a Pipe Marking Specification

Create a project-specific document that defines:

- The color code for every service in the facility (referencing the applicable standard)

- Label format: text content, font, size, and arrow style

- Placement rules: spacing, locations, and orientation

- Label materials: vinyl, snap-around, stenciled paint, or metal tags

- Responsibility for initial application and ongoing maintenance

- User-defined colors for services not covered by the standard (e.g., steam under ASME A13.1)

Step 3: Label Materials and Durability

| Environment | Recommended Label Type | Expected Life |

|---|---|---|

| Indoor, ambient temperature | Self-adhesive vinyl or polyester | 3-5 years |

| Outdoor pipe racks | UV-resistant laminated polyester | 7-10 years |

| High vibration or thermal cycling | Snap-around or coiled markers | 5-10 years |

| Offshore or corrosive atmosphere | Stainless steel tags (SS 316) | 20+ years |

| Insulated pipes (steam, hot oil) | Applied on insulation jacket surface | Match insulation maintenance cycle |

Step 4: Verification and Maintenance

Pipe marking is not a one-time activity. Labels degrade from UV exposure, chemical splash, abrasion, and temperature cycling. Include pipe marking verification in:

- Annual facility safety inspections

- Management of Change (MOC) procedures, since any piping modification must trigger label review

- Pre-startup safety reviews (PSSRs) for new or modified piping

- Turnaround and shutdown planning checklists

Common Mistakes in Pipe Marking

Even facilities with well-intentioned marking programs make recurring errors. The following list covers the most frequent issues found during audits and inspections.

Facility-Specific and Industry Standards

Some industries or facilities maintain their own color coding standards based on internal policies, safety regulations, or industry practices. These may differ from ASME/ISO/BS standards but serve the same purpose: accurate identification of pipe contents and functions.

Examples include:

- Semiconductor manufacturing: specialized gas delivery systems use proprietary color codes for ultra-high-purity gases

- Pharmaceutical plants: GMP requirements may dictate additional markings for clean-in-place (CIP) and sterilize-in-place (SIP) lines

- Nuclear facilities: NRC regulations require specific identification for safety-related, non-safety-related, and seismic-qualified piping

- Food and beverage: 3-A Sanitary Standards may supplement ASME A13.1 with requirements for product contact vs. non-contact lines

Always check the applicable standards, regulations, and facility-specific guidelines before implementing pipe color coding.

Frequently Asked Questions

What color is used for flammable pipes under ASME A13.1?

Under ASME A13.1, flammable fluids and gases (such as natural gas, diesel, and crude oil) are identified with white text on a brown background (Pantone 4515). Oxidizing fluids use white text on a yellow background (Pantone 109). The label must include the specific fluid name and a flow direction arrow. Do not rely on the background color alone; always include written identification of the exact substance.

What is the difference between ASME A13.1, ISO 14726, and BS 1710?

ASME A13.1 (USA) classifies pipes by hazard category (flammable, toxic, fire suppression, etc.) using 6 standard colors plus user-defined. ISO 14726 (international) and BS 1710 (UK) assign colors based on specific pipe contents (water, steam, acids, oils) and use 10 or more content-specific colors. Fire water (red), potable water (green), and compressed air (blue) are consistent across all three standards. However, steam, chemicals, and hydrocarbons are assigned different colors depending on the standard. Always verify which standard applies to your project.

How often should pipe labels be placed?

ASME A13.1 requires pipe labels at intervals not exceeding 25 feet (7.6 m) on straight runs, plus at every valve, branch connection, direction change, and on both sides of wall, floor, and ceiling penetrations. Labels must be visible from the normal approach direction and include the fluid name and flow direction arrow. BS 1710 and ISO 14726 have similar placement requirements, typically specifying 6-8 meter intervals.

Does ASME A13.1 assign a color for steam pipes?

No. ASME A13.1 does not assign a dedicated color for steam piping; it falls under the user-defined category. Most North American facilities adopt gray or silver as the background color for steam. By contrast, BS 1710 and ISO 14726 specifically assign silver-gray to steam, and DIN 2403 (Germany) uses red, which can conflict with fire water markings in other systems. Always check the project-specific pipe marking specification for steam color assignments.

Is pipe color coding required by OSHA?

OSHA does not mandate a specific pipe color standard, but it requires employers to identify pipe contents under 29 CFR 1910.261 and the general duty clause (Section 5(a)(1)). ASME A13.1 is the recognized consensus standard for compliance in the United States. Failure to identify pipe contents can result in OSHA citations and fines. Many facility owners and insurance underwriters require ASME A13.1 compliance as part of their safety management system and process safety management (PSM) programs.

Leave a Comment

Have a question or feedback? Send us a message.