What is a gate valve? It is a shut-off device to open and close the flow of the fluid conveyed by a piping system (or a pipeline). A gate valve is a bi-directional valve, as the fluid may flow in either direction. The installation of this type of valve creates a modest pressure drop in the pipeline, lower than globe valves. Gate valves have forged bodies for bore sizes below 2 inches (API 602/BS 5352), and cast bodies for larger sizes (API 600, API 603, API 6D).

GATE VALVES

WHAT IS A GATE VALVE?

In the oil and gas industry, a gate valve is a crucial component used to control the flow of fluids through pipelines and equipment. Characterized by its ability to provide a straight-through, unrestricted flow path when fully open, a gate valve operates by lifting a gate (or wedge) out of the path of the fluid.

This type of valve is typically used for on/off control rather than flow regulation, making it ideal for applications where a minimal pressure drop and a full bore are required when the valve is in the open position.

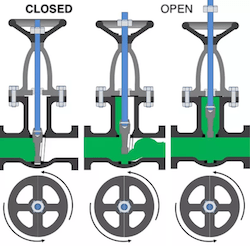

Gate valves are on-off valves to open and close the flow of the fluid in a pipeline. The valve is opened and/or closed by the vertical movement of a disc on the valve’s seat.

GATE VALVES ADVANTAGES & DISADVANTAGES

- Bi-Directional: Gate valves can control flow in both directions, offering versatility in installation and use.

- Minimal Pressure Drop: When fully open, gate valves provide a straight path for flow, resulting in a very low-pressure drop across the valve.

- Sealing Surface: Gate valves have two sealing surfaces between the gate and seats, providing a tight seal when the valve is closed.

- Operation: These valves are operated using a handwheel, gear, actuator, or motor, depending on the size, pressure rating, and application requirements. Manual operation is common for smaller sizes, while larger valves often require mechanical assistance.

- Easy to maintain and disassemble

- Low-cost option

- Can be used with slurries and viscous liquids

- Available in large sizes

- Inherently fire-safe (when used with a metal sheet)

The disadvantages of gate valves are:

- Slow open and close time

- Low-pressure limitations

- Erosion of the seat and disk can occur

- Poor throttling characteristics

- May be difficult to repair in case of failure (it is easier and cheaper to replace a broken cast valve in most cases)

TYPICAL APPLICATIONS IN THE OIL&GAS INDUSTRY

Gate valves are largely used in the oil & gas, petrochemicals, and general manufacturing industries. The most common tasks assigned to this type of valve are:

- Isolation Tasks: Gate valves are widely used for isolation purposes in oil and gas pipelines, storage tanks, and processing equipment, allowing sections of a system to be shut down for maintenance or in an emergency without affecting the rest of the operation.

- High-Pressure Environments: Their robust design makes them suitable for high-pressure and high-temperature applications commonly found in upstream exploration and production, as well as in downstream processing.

- Underground Installations: Due to their full-bore design and minimal pressure drop, gate valves are also preferred for underground gas storage and control applications.

SELECTION CRITERIA

When selecting a gate valve for oil and gas applications, several factors should be considered:

- Material: The choice of material depends on the type of fluid, operating temperatures, and pressures. Common materials include carbon steel, stainless steel, and alloy steel designed to withstand corrosive environments.

- Size and Pressure Rating: Proper sizing and selection of pressure ratings are essential to match the pipeline specifications and operational conditions.

- Maintenance: While gate valves are known for their durability, they are not ideally suited for throttling applications, as the vibration and rapid flow changes can cause wear to the gate and seats, leading to leakage. Regular maintenance is required to ensure long-term reliability and performance.

APPLICABLE SPECIFICATIONS (API, ASME)

API SPECS FOR GATE VALVES

API (American Petroleum Institute) specifications provide comprehensive standards and technical requirements for the design, manufacturing, and testing of gate valves used in the oil and gas industry. These specifications ensure the reliability, safety, and efficiency of gate valves under various operational conditions.

Below are some key API specifications applicable to gate valves:

API 600: applies to carbon/alloy steel gate valves

“Steel Gate Valves – Flanged and Butt-Welding Ends, Bolted Bonnets” This specification covers the design, manufacturing, and testing of bolted bonnet steel gate valves for petroleum and natural gas industries. It includes detailed requirements for gate valves with flanged or butt-welding ends and bolted bonnets, focusing on sizes and pressure classes specified for use in pipeline and piping systems.

API 603: applies to stainless steel gate valves

“Corrosion-Resistant, Bolted Bonnet Gate Valves – Flanged and Butt-Welding Ends” This standard covers corrosion-resistant bolted bonnet gate valves with flanged or butt-welding ends. API 603 focuses on valves made from stainless steel and other alloys intended for corrosion resistance, detailing requirements for various design features, pressure classes, and sizes.

API 602/BS 5352: applies to forged steel gate valves

“Compact Steel Gate Valves – Flanged, Threaded, Welding, and Extended-Body Ends” API 602 specifies the requirements for compact steel gate valves with a variety of end connections, including flanged, threaded, and welding ends. It is intended for smaller-sized valves (NPS 4 and smaller) used in high-pressure applications, offering guidance on materials, design, and testing criteria.

API 6D: applies to slab and through conduit valves for pipelines

“Pipeline and Piping Valves” API 6D is a broad specification that covers the design, manufacturing, and testing of valves for pipeline applications, including gate valves. It encompasses aspects such as end-to-end dimensions, pressure testing, and marking for valves intended to be used in pipeline systems for transporting petroleum and natural gas.

API 6FA

“Specification for Fire Test for Valves” While not exclusively for gate valves, API 6FA specifies fire test requirements for valves used in petroleum and natural gas industries. It provides a method for testing valve performance when exposed to fire, ensuring that valves can maintain structural integrity and leak tightness during and after a fire incident.

API 624

“Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions” API 624 addresses the testing of rising stem gate valves equipped with graphite packing, focusing on their performance regarding fugitive emissions. This specification ensures that valves meet environmental and safety standards by limiting emissions of volatile organic compounds (VOCs).

API-598: valves testing

ASME/ANSI SPECS FOR GATE VALVES

ASME (American Society of Mechanical Engineers) and ANSI (American National Standards Institute) specifications play critical roles in standardizing the design, manufacturing, and testing of gate valves, ensuring their safety, reliability, and efficiency across various industries. Here are some key ASME/ANSI specifications applicable to gate valves:

ASME B16.34 – Valves – Flanged, Threaded, and Welding End

This standard provides requirements for materials, pressure-temperature ratings, dimensions, tolerances, marking, and testing for flanged, threaded, and welding end steel valves. It includes gate valves among other valve types and serves as a fundamental reference for valve specifications in terms of pressure class ratings, material groups, and appropriate service conditions.

ASME B16.10 – Face-to-Face and End-to-End Dimensions of Valves

ASME B16.10 specifies the standard face-to-face and end-to-end dimensions for flanged, threaded-end, welding-end, and wafer-type valves, including gate valves. This standard is crucial for ensuring the interchangeability and proper fit of valves within piping systems.

ASME B16.5 – Pipe Flanges and Flanged Fittings

Although not exclusively for valves, ASME B16.5 establishes dimensions, tolerances, and material specifications for pipe flanges and flanged fittings in sizes from NPS 1/2 through NPS 24. Gate valves with flanged ends must comply with this specification to ensure compatibility with flanged piping connections.

ASME B16.25 – Buttwelding Ends

This specification outlines the dimensions, tolerances, and finishing for buttwelding ends of piping components, including gate valves. It ensures the proper fit and sealing capability for welded connections in piping systems.

ASME ANSI B16.47: flanged ends for bore sizes above 24 inches

ASME B31.4 – Pipeline Transportation Systems for Liquids and Slurries

While ASME B31.4 is a piping code rather than a specific valve standard, it includes requirements that affect the selection and application of gate valves in pipeline systems transporting liquids and slurries. It provides guidelines for materials, design, construction, and testing of pipeline components.

ASME B31.8 – Gas Transmission and Distribution Piping Systems

Similar to ASME B31.4 but focused on gas transmission and distribution, ASME B31.8 also impacts the use of gate valves in gas pipelines, specifying criteria for material selection, design, construction, and testing to ensure safety and integrity in gas piping systems.

Compliance with these ASME/ANSI specifications is essential for gate valve manufacturers and users, as it guarantees that valves meet established industry standards for performance, durability, and safety. These standards help guide engineers and project managers in selecting the appropriate gate valves for their specific applications, whether for water treatment, oil and gas, chemical processing, or other industrial systems.

Understanding Gate Valve (source: Milwaukee Valve)

GATE VALVE TYPES

CAST STEEL GATE VALVES

This is the most common type, covered by the API 600 (carbon and alloy steel) and API 603 (stainless steel and higher grades) specifications. Cast steel gate valves are available in sizes above 2 inches, and up to 80 inches.

Cast steel gate valves are essential components in various industrial applications, including oil and gas, power generation, and water treatment systems. These valves are designed for on/off control of fluids and are particularly favored for their capability to provide a minimal pressure drop when fully open. Cast steel, used in the construction of these valves, offers a robust and durable solution suitable for high-pressure and high-temperature environments.

Construction and Operation

Cast steel gate valves consist of a valve body, bonnet, stem, gate (or wedge), and sealing elements. The body and bonnet are typically made from cast steel through a casting process where molten steel is poured into a mold and allowed to solidify. This method provides the flexibility to create complex shapes and sizes, making it possible to tailor the valve design to specific application requirements.

The gate, manipulated by the stem, moves vertically within the valve body to open or close the flow path. When raised, the gate allows for an unrestricted flow, and when lowered, it sits tightly against the valve seat to block the flow, ensuring a tight seal.

Key Features

- Durability: Cast steel provides excellent strength and toughness, making these valves suitable for high-pressure and temperature applications.

- Leakage Prevention: Properly designed and maintained cast steel gate valves offer excellent sealing capabilities, minimizing the risk of leakage.

- Versatility: Available in various sizes and pressure ratings, cast steel gate valves can accommodate a wide range of fluids and service conditions.

- Maintenance: While generally reliable, these valves require regular inspection and maintenance to ensure optimal performance, particularly in applications involving suspended solids that might cause wear or obstruction.

Applications

Cast steel gate valves are widely used across multiple industries for their ability to control the flow of liquids, gases, and vapors. Some common applications include:

- Oil & Gas: For controlling the flow in pipelines and processing facilities.

- Power Generation: In steam and water systems where high pressure and temperature are common.

- Water Treatment and Distribution: For isolating sections of the system for maintenance or in response to system demands.

Selection Considerations

When selecting a cast steel gate valve, several factors should be considered to ensure it meets the operational requirements effectively:

- Size and Pressure Rating: Match the valve size and pressure rating with the pipeline specifications and operational pressures.

- Material Compatibility: Ensure the cast steel material is compatible with the fluid medium, considering factors like corrosion resistance and material strength at operating temperatures.

- Operation Type: Choose between manual, electric, pneumatic, or hydraulic actuation based on the application and accessibility.

- Standards and Certifications: Valves should meet relevant industry standards and certifications to ensure quality and safety in operation.

In summary, cast steel gate valves are a reliable choice for managing fluid flow in industrial systems, offering durability and versatility for a broad range of applications. Proper selection, based on the specific requirements of the application, ensures their effective and safe operation.

FORGED STEEL GATE VALVES

Forged steel valves are used for small bore piping, generally below 2 inches in diameter. The API 602 and BS 5352 specifications cover this type of gate valve.

Forged steel gate valves are integral components in a wide array of industrial systems where robust control of fluid flow is required. These valves utilize a gate mechanism to allow or block the flow of fluids, making them suitable for on/off service rather than flow regulation. Forged steel, as the material of choice for these valves, offers superior strength, durability, and resistance to high pressures and temperatures compared to cast steel counterparts. This makes forged steel gate valves especially valuable in high-demand environments such as the oil and gas, chemical processing, and power generation industries.

Construction and Features

Forged steel gate valves are constructed from steel that has been forged under high pressure to enhance its mechanical properties. The forging process aligns the grain structure of the steel, making it denser and more uniform. This results in a valve body with exceptional strength, improved impact toughness, and greater resistance to fatigue and thermal stresses.

Key features of forged steel gate valves include:

- Enhanced Durability: The forging process gives the steel enhanced strength and toughness, enabling the valve to withstand high pressures and temperatures.

- Tight Seal: When closed, the gate or wedge of the valve fits snugly against the valve seats, providing a tight seal that prevents fluid leakage.

- Low Flow Resistance: In the fully open position, the valve provides a straight path for the flow, resulting in minimal pressure drop.

- Versatility: Forged steel gate valves are available in various sizes, pressure classes, and end connection types, making them suitable for a broad range of applications.

Applications

Forged steel gate valves are used in demanding applications where high strength and durability are paramount. Typical applications include:

- High-Pressure Systems: Such as those found in oil and gas production, where the valves must handle high-pressure and corrosive fluids.

- Steam Services: In power plants and other settings where steam is used for power generation or heating, requiring valves that can withstand high temperatures and pressures.

- Process Industries: Chemical manufacturing and processing plants use these valves to control the flow of aggressive and hazardous chemicals.

- General Industrial Applications: Anywhere that requires reliable isolation of fluid flow under high pressure or temperature conditions.

Selection Considerations

Selecting the right forged steel gate valve involves several considerations:

- Pressure and Temperature Ratings: Choose a valve that meets or exceeds the maximum expected system pressure and temperature.

- Material Compatibility: The material of the valve should be compatible with the fluid it will control, considering factors such as corrosion and chemical reactivity.

- Size and End Connections: The valve size should match the pipeline specifications, and the end connections (flanged, threaded, butt weld, etc.) should be compatible with the existing piping.

- Standards and Certifications: Ensure the valve meets relevant industry standards and certifications for safety and performance.

Conclusion

Forged steel gate valves offer a reliable solution for high-pressure and high-temperature applications across various industries. Their construction from forged steel ensures superior strength, durability, and performance in challenging environments. When selecting a valve, it’s crucial to consider the specific requirements of the application to ensure optimal performance and safety.

API 6D GATE VALVES FOR PIPELINES (THROUGH-CONDUIT)

API 6D gate valves are specialized valves designed to meet the rigorous standards set by the American Petroleum Institute (API) for use in pipeline applications.

The API 6D specification covers the design, manufacturing, and testing of gate valves, as well as other pipeline valves such as ball, check, and plug valves, intended primarily for the oil and gas industry. These valves play a crucial role in controlling the flow of oil, gas, and other hydrocarbon products within pipeline systems, offering reliable operation in on/off service.

Key Features of API 6D Gate Valves

- Design and Construction: API 6D gate valves are designed to withstand the operational pressures and temperatures encountered in oil and gas pipelines. They feature robust construction and can be made from various materials to suit different environmental conditions and fluid properties.

- Double Block and Bleed (DBB) Capability: Many API 6D gate valves offer double block and bleed functionality, allowing for the isolation of a section of the pipeline and the draining or venting of the space between the two sealing surfaces (gates), enhancing operational safety and maintenance procedures.

- Sealing and Seat Design: These valves typically include soft or metal-to-metal sealing mechanisms to ensure tight shut-off and minimize leakage. The seat design is critical for ensuring the valve’s reliability and performance under high pressure.

- Emergency Sealant Injection: Some API 6D gate valves are equipped with an emergency sealant injection feature, which allows for the injection of a sealant into the seating area in case of leakage, providing a temporary or emergency seal.

- Full Bore Design: API 6D gate valves often feature a full bore design, meaning the diameter of the valve opening matches the diameter of the pipeline. This design minimizes pressure drop and allows for the easy passage of pipeline inspection gauges (pigs).

Applications

API 6D gate valves are extensively used in the oil and gas industry, particularly in pipeline systems for:

- Transmission Pipelines: Controlling the flow and providing isolation capabilities in long-distance pipelines transporting oil and gas from production sites to refineries or storage facilities.

- Distribution Networks: Managing the distribution of gas to residential, commercial, and industrial end-users.

- Offshore Platforms and Processing Plants: Offering reliable isolation in the challenging conditions of offshore oil and gas extraction and processing.

Selection Considerations

When selecting an API 6D gate valve for a pipeline application, it’s important to consider:

- Pressure Class and Size: The valve must be suitable for the pipeline’s operating pressure and diameter.

- Material Compatibility: The valve material should be compatible with the fluid being transported, considering factors like corrosion resistance and temperature tolerance.

- Operational Requirements: Consider whether manual, electric, pneumatic, or hydraulic actuation is needed based on the valve’s location and the system’s operational demands.

Types of API 6D Gate Valves

PRESSURE SEAL API 6D TYPE

Pressure seal gate valves are used for high-pressure applications. The most common types of valves for high-pressure applications are the flexible wedge and the parallel slide pressure seal valve. They are generally available with cast or forged bodies, in dimensions from 2 to 24 inches, and pressure ratings from 600# to 4500#, with socket weld or buttweld, ends to ensure tight flanged joint connections (but flanged ends are also possible).

KNIFE TYPE API 6D Gate Valve

Knife gate valves were originally introduced within the pulp and paper industry, where standard shut-off valves could not properly operate due to the nature of the fluids conveyed during the paper production process.

Knife valves should never be used as modulating valves (to regulate the flow) as the fluid flowing through a partly closed valve would generate vibration and erode both the disk and the seat.

Therefore, knife valves should be used completely closed or opened like any other type of gate valve (globe valves are recommended to regulate the flow).

Lastly, to protect the valve against the impact of the water hammer effect, knife valves feature a very slow opening and closing speed.

A Knife valve can be manufactured in materials from ductile iron to stainless steel and in sizes between 2 and 24 inches (generally with cast bodies) with low-pressure ratings (< 300 lbs).

There are many different variants of knife valves, such as the soft-seated (resilient type, with elastomer seats) the metal seated (the seat and the disc generate a metal-to-metal seal), the slide gate, and bonneted types.

Soft seat knife gate valve.

A metal seated knife gate valve (left) and resilient, a soft-seated valve (right side).

The differences with standard design are:

- A standard valve is available with flanged, butt weld, and socket weld connections (knives have lugged or wafer connections mainly)

- A standard valve has a V-ring packing set that seals the shaft that is attached to the gate. Knife valves feature instead of a packing gland area that seals around the gate

- Gate valves are bidirectional, whereas the knife type is generally uni-directional

- A knife valve has a smaller profile than the ANSI gate valve, which is more bulky and refined

- Knife gate valves are lighter and cheaper than API and ASME types

Conclusion API 6D Gate Valves

API 6D gate valves are essential components in the oil and gas industry, providing critical control and isolation functions within pipeline systems. Their design and construction adhere to stringent standards, ensuring reliability, safety, and efficiency in the transportation of hydrocarbon products. When selecting these valves, it’s crucial to match the valve’s specifications with the specific requirements of the pipeline system to ensure optimal performance.

GATE VALVE vs. OTHER TYPES OF VALVES

GATE VALVE VS. BALL VALVE

What is the difference between a gate and a ball valve?

Gate valves and ball valves are two of the most commonly used types of valves in various piping systems. Each has its own unique design, operation method, and advantages, making them suitable for specific applications.

Understanding the differences between these two valve types is crucial for selecting the right valve for a given system.

Design and Operation

Gate Valve: A gate valve features a flat gate or wedge that moves perpendicularly to the direction of flow. To open or close the valve, the gate is raised or lowered by turning a handwheel or actuator. When fully open, gate valves offer a straight-through flow path with minimal resistance, making them ideal for on/off control rather than flow regulation.

Ball Valve: A ball valve uses a spherical ball with a hole (bore) through its center. Rotating the ball 90 degrees around its axis opens or closes the flow path. In the open position, fluid flows through the bore. Ball valves provide excellent sealing and are used for both on/off control and throttling.

Applications

Gate Valves: Due to their ability to provide minimal flow restriction when fully open, gate valves are often used in applications where a free flow of fluid is necessary and where the valve will remain either fully open or fully closed most of the time. They are commonly found in water and wastewater treatment, oil and gas pipelines, and other situations where fluid must be moved in large volumes.

Ball Valves: Ball valves are versatile and can be used in a wide range of applications, including residential plumbing, industrial processes, and gas handling systems. They are particularly valued for their quick operation, durability, and tight sealing capabilities, making them suitable for applications requiring reliable on/off control and system isolation.

Advantages and Disadvantages

Gate Valves:

- Advantages: Full bore design resulting in minimal pressure drop; suitable for both slurries and viscous fluids; good for high temperature and pressure applications.

- Disadvantages: Prone to wear and leakage across the seats and gate; slower to operate; not suitable for throttling purposes due to potential seat and gate damage.

Ball Valves:

- Advantages: Quick and easy to operate with a quarter-turn; excellent sealing capabilities with low torque; durable with a long service life; suitable for throttling applications with proper design.

- Disadvantages: Potential for cavitation and flow turbulence at partial open conditions; the full bore models can be more expensive than reduced bore models.

Choosing between Gate and Ball Valves

The choice between a gate valve and a ball valve often comes down to the specific needs of the application, including the type of fluid, required flow rate, operating pressure, and temperature, and whether precise flow control or simple on/off functionality is needed. Cost, ease of maintenance, and space constraints may also influence the decision.

In summary, gate valves are best suited for applications requiring unobstructed flow and minimal pressure drop, while ball valves offer superior sealing and control, making them ideal for a broad range of on/off and throttling applications.

GATE VALVE VS. GLOBE VALVE

What is the difference between a gate and a globe valve?

Gate valves and globe valves are two fundamental types of valves used in piping systems to control the flow of liquids, gases, and slurries. While they share some similarities, they have distinct features, operating principles, and applications that make them suitable for different scenarios.

Understanding the differences between these two valve types is crucial for selecting the right valve for a specific application.

Design and Operation

Gate Valve: Utilizes a flat gate or wedge that moves vertically to the flow direction to open or close the valve. When open, the gate fully retracts into the valve body, allowing for a full, unobstructed flow path. Gate valves are primarily used for on/off control and are not suitable for throttling due to the potential for gate and seat damage.

Globe Valve: Features a movable disk-type element and a stationary ring seat in a generally spherical body. The disk moves perpendicularly to the seat, allowing for precise flow control. Globe valves are characterized by their spherical body shape, with the internal baffle that splits the inside space into two chambers. They are used for on/off control as well as for throttling flow, offering better control over flow rates.

Applications

Gate Valves: Ideal for applications where a straight-line flow of fluid and minimum restriction is desired. Commonly used in water supply, natural gas pipelines, and in applications where the valve will remain either fully open or fully closed for long periods.

Globe Valves: Suited for applications requiring flow regulation and frequent operation. Their ability to adjust the flow with precision makes them popular in cooling systems, fuel oil systems, marine applications, and where pressure drop is not a significant concern.

Advantages and Disadvantages

Gate Valves:

- Advantages: Minimal pressure drop when fully open; suitable for both slurries and viscous fluids; provides a tight seal when closed.

- Disadvantages: Slow to open and close; not suitable for throttling; can be prone to gate and seat damage from vibration if partially opened.

Globe Valves:

- Advantages: Good for throttling and regulating flow; faster to open and close compared to gate valves; provides better sealing.

- Disadvantages: Higher pressure drop across the valve; not ideal for applications requiring full, unobstructed flow.

Choosing between Gate and Globe Valves

Choosing between a gate valve and a globe valve often depends on the specific requirements of the system, including:

- Purpose: Gate valves are preferred for on/off control where the flow rate is not adjusted frequently. Globe valves are chosen for applications where flow needs to be regulated or adjusted regularly.

- Flow Characteristics: If minimal pressure drop and full flow are required, gate valves are more suitable. For precise flow control, even at lower flow rates, globe valves are preferred.

- Space and Orientation: Globe valves, due to their design, may require more space in a piping system and are sensitive to flow direction. Gate valves are less restrictive in terms of space and flow direction.

In summary, the choice between gate and globe valves hinges on the need for either unobstructed flow and infrequent operation or the need for flow regulation and frequent adjustments. Both valves serve critical roles in controlling system flow, and their selection should align with the operational needs and constraints of the application.

GATE VALVE VS. CHECK VALVE

Gate valves and check valves are two distinct types of valves used across various industries for controlling fluid flow in piping systems. Each serves a different primary function and operates based on different principles.

Gate Valve

Design and Function: A gate valve features a movable gate or wedge that slides vertically to control the flow of fluid. It is operated manually, typically using a handwheel or an actuator for larger sizes. The primary function of a gate valve is to start or stop the flow, providing a clear and unobstructed path when fully open, and a tight seal when fully closed.

Applications: Gate valves are widely used in applications where a full, unrestricted flow of fluid is necessary. They are ideal for on/off control but are not suitable for throttling purposes, as partial opening can cause vibration and damage to the gate and seats. Common uses include water supply, oil and gas pipelines, and other systems where flow needs to be completely shut off or allowed freely.

Advantages:

- Minimal pressure drop when fully open.

- Suitable for both liquid and gas applications.

- Provides a tight seal when closed.

Disadvantages:

- Slow to open and close.

- Not suitable for throttling.

- Prone to wear and corrosion, which can affect sealing over time.

Check Valve

Design and Function: A check valve, also known as a non-return valve, allows fluid to flow in one direction and automatically prevents backflow when the fluid in the line reverses direction. It operates based on the flow pressure and does not require manual operation. The internal mechanism varies by design, including ball, swing, and lift check valves.

Applications: Check valves are essential in preventing backflow, protecting equipment, and ensuring the safety of the system. They are used in a wide variety of applications, including water and wastewater treatment, chemical processing, and residential plumbing systems. Any system where backflow could cause problems or where fluid needs to be maintained in a single direction benefits from the use of a check valve.

Advantages:

- Prevents backflow automatically.

- Can be used in a wide range of pressures and temperatures.

- Available in various designs to suit specific flow characteristics.

Disadvantages:

- Cannot be used to regulate or stop flow.

- Some designs may cause a significant pressure drop.

- Requires careful selection and installation to function correctly.

Key Differences between Gate and Check Valves

- Primary Function: Gate valves are used to start or stop the flow, while check valves are designed to prevent backflow and allow flow in only one direction.

- Operation: Gate valves require manual or actuator operation to open or close, whereas check valves operate automatically based on flow conditions.

- Application Use: Gate valves are chosen for system isolation or where full flow is necessary. Check valves are selected to prevent backflow and protect against reverse flow conditions.

Understanding these differences is crucial when designing or maintaining a piping system, ensuring that the right type of valve is used for its intended function, thereby optimizing system performance and safety.

GATE VALVE VS. BUTTERFLY VALVE

Gate valves and butterfly valves are widely utilized in various industrial and domestic piping systems for fluid control. Despite serving the purpose of regulating flow, they exhibit distinct differences in design, operation, maintenance, and application suitability.

Gate Valve

Design and Operation: A gate valve features a flat gate that moves up and down in a linear motion perpendicular to the direction of flow. The valve operates by a handwheel or an actuator, and it is primarily used for starting or stopping the flow, allowing for a full, unrestricted flow path when fully open.

Advantages:

- Provides minimal pressure drop when fully open.

- Suitable for both on/off and isolation applications.

- Can handle thick fluids, as the gate can cut through viscous flow.

Disadvantages:

- Slow to open and close due to the multiple turns required on the handwheel.

- Not suitable for throttling applications, as partial opening can cause seat and gate damage.

- Larger size compared to butterfly valves, requiring more space for installation and operation.

Butterfly Valve

Design and Operation: A butterfly valve consists of a disc that rotates around a central axis within the body of the valve, allowing for quick and efficient flow control. Operated by a handle, gear, or actuator, butterfly valves can be used for both on/off control and throttling.

Advantages:

- Compact and lightweight design, requiring less space and support.

- Quick to open and close, offering good control over the flow rate.

- Generally more cost-effective than gate valves, especially in larger sizes.

Disadvantages:

- The presence of the disc in the flow path can cause a pressure drop, even when fully open.

- Not ideal for applications with particulate-laden fluids, as particles can accumulate around the disc and stem, potentially leading to wear or operational issues.

- Sealing performance might not be as effective as gate valves for high-pressure applications.

Key Differences between Gate and Butterfly Valves

- Flow Control: Gate valves are best suited for on/off applications with minimal pressure drop, while butterfly valves offer superior functionality in throttling and quick operation scenarios.

- Design and Space Requirements: Gate valves require more space due to their linear operation and larger size, making butterfly valves more suitable for compact or limited-space environments.

- Cost and Maintenance: Butterfly valves are generally more cost-effective and easier to maintain due to their simpler design and fewer moving parts. Gate valves, on the other hand, may require more maintenance, especially in systems with solid or viscous fluids.

Application Suitability of these two types of Valves

- Gate Valves: Preferred in applications where an unobstructed flow and tight shutoff are required, such as in water and wastewater treatment, oil and gas pipelines, and other high-pressure systems.

- Butterfly Valves: Ideal for applications requiring flow regulation and where space and cost are concerns, including HVAC systems, pharmaceutical processing, and food and beverage industries.

Selecting between a gate valve and a butterfly valve depends on the specific requirements of the application, including flow control needs, system pressure, space constraints, and budget considerations. Each valve type offers unique advantages that make it suitable for particular scenarios, ensuring efficient and reliable fluid control in diverse settings.

GATE VALVE VS. PLUG VALVE

Gate valves and plug valves are both commonly used in piping systems for controlling the flow of fluids, but they have distinct differences in design, operation, and application suitability. Understanding these differences is essential for selecting the appropriate valve type for specific system requirements.

Gate Valve

Design and Operation: A gate valve controls flow by raising or lowering a metal gate, usually via a handwheel or an actuator. The gate moves perpendicularly to the fluid flow, offering minimal resistance when fully open, which makes it well-suited for applications requiring unobstructed flow or full isolation.

Advantages:

- Provides a full-bore flow path when open, resulting in minimal pressure drop.

- Suitable for both on/off services and isolation.

- Can handle a wide range of fluids, temperatures, and pressures.

Disadvantages:

- Not suitable for throttling applications, as partial openings can cause gate and seat damage.

- Typically slower to operate due to the multiple turns required to open or close.

- Larger and heavier than plug valves, requiring more space and support.

Plug Valve

Design and Operation: Plug valves control flow through a cylindrical or tapered plug with one or more hollow passageways. By rotating the plug 90 degrees, the flow can be allowed, blocked, or partially passed through the valve. Plug valves are known for their quick operation and are used for on/off control as well as throttling.

Advantages:

- Quick to operate with a simple quarter-turn to open or close.

- Compact and generally lighter than gate valves, making them suitable for tight spaces.

- Good for applications requiring frequent operation and where flow regulation is needed.

Disadvantages:

- The presence of the plug in the flow path can cause a pressure drop, even when fully open.

- May not be suitable for high-pressure applications as sealing performance can be affected by high pressures.

- Requires lubrication for smooth operation, which may not be ideal for some types of fluids.

Key Differences

- Flow Control and Operation: Gate valves are best for on/off control where full flow is needed without obstruction. Plug valves offer rapid operation and are versatile for both on/off control and throttling.

- Design and Space Requirements: Gate valves have a larger size and require more space, while plug valves are compact and suitable for limited-space applications.

- Application Suitability: Gate valves are preferred in applications that demand minimal pressure drop and where valve operation is infrequent. Plug valves are favored for their quick operation, flow regulation capabilities, and when space constraints exist.

Application Suitability

- Gate Valves: Ideal for larger-diameter pipelines, water treatment plants, and other settings where unobstructed flow and tight sealing are crucial.

- Plug Valves: Commonly used in chemical and petrochemical industries, gas utilities, and where rapid or frequent operation is required.

In summary, the choice between a gate valve and a plug valve largely depends on the specific operational needs, including the desired control type (on/off or throttling), system pressure, space availability, and the frequency of valve operation. Each valve type offers distinct benefits and limitations, making them suitable for different applications.

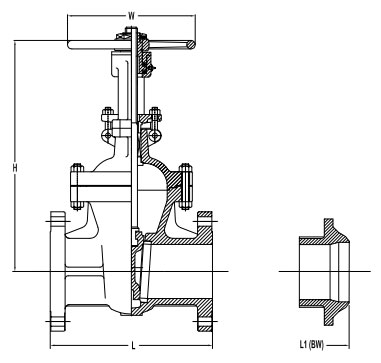

GATE VALVE DIAGRAM

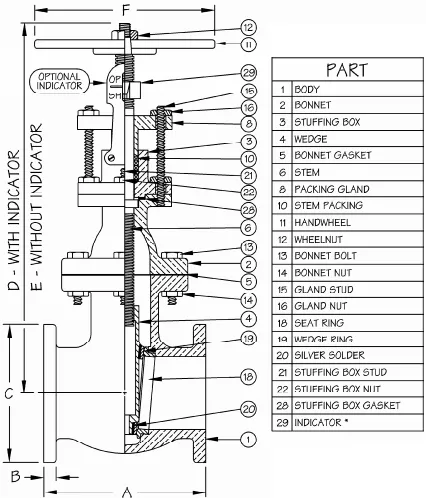

The gate valve diagram shows the standard assembly drawing of a gate valve.

Many design variations are possible, depending on the gate valve parts configuration:

- Body material construction: forged or cast

- Bonnet design and connection: can be standard BB or pressure seal (high-pressure gate valves), bolted/welded bonnet, etc.

- Valve ends connection: gate valves are available with multiple valve ends designs (socket weld and threaded for forged gate valves and butt weld for cast body gate valves)

- Wedge type (solid/flexible/split/parallel slide): see details below in this article

- Stem type (rising/ non-rising): see details below

- Manufacturing norm: API vs EN gate valves have slightly different designs

- Type of valve operation: manual, gear, or pneumatic/hydraulic/electric actuation

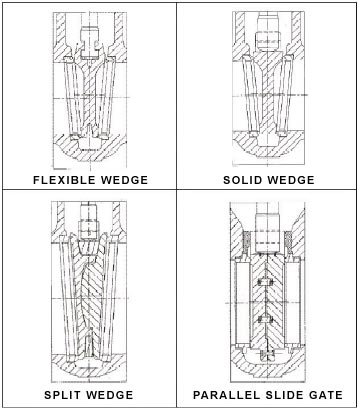

In gate valves, the wedge is the movable part that seals against seats to stop the flow or opens to allow flow. The design of the wedge is crucial for the valve’s performance, especially in terms of sealing capability, ease of operation, and durability. There are several types of wedges used in gate valves, each suited to different applications and operating conditions:

1. Solid Wedge

The solid wedge is the simplest and most robust type, made from a single piece of metal. Its simplicity makes it highly reliable and suitable for a wide range of conditions, including high-temperature and pressure environments. However, its rigidity means it may not always compensate for seat misalignments or changes in temperature that affect the valve body and seating surfaces.

2. Flexible Wedge

A flexible wedge is designed with a cut around its perimeter or a special shape that allows the wedge to flex as it seats. This design helps accommodate changes in valve body dimensions due to thermal expansion or contraction, improving the seal in varying temperature conditions. Flexible wedges are particularly useful in steam systems where temperature fluctuations are common. However, they can be less suitable for applications involving high vibration or thermal cycling, which may lead to fatigue cracks.

3. Split Wedge or Parallel Disks

The split wedge, or parallel disk design, consists of two solid pieces that are hinged together or use a mechanism to keep them in alignment. This design allows the wedge to adjust to variations in the angle between the seats and the wedge surfaces, enhancing sealing effectiveness. Split wedges are advantageous in applications where thermal binding (sticking due to differential thermal expansion) is a concern.

4. Slab Gate

Slab gate valves use a flat gate that slides between two parallel seats, providing a tight seal. While not a wedge in the traditional sense, the slab gate functions similarly by blocking or allowing flow. This design is particularly favored in the oil and gas industry for pipeline valves because it provides a full-bore, low-friction path for the fluid, making it ideal for transporting viscous fluids like oil.

Wedge Selection Considerations

Choosing the appropriate wedge type depends on several factors:

- Operating Conditions: Temperature fluctuations, pressure range, and the presence of vibrations can affect wedge selection.

- Fluid Characteristics: Slurry services may require a specific wedge type to prevent particle trapping.

- Sealing Requirements: Some applications demand tighter seals, influencing the choice of wedge design.

Understanding the different types of wedges in gate valves and their respective advantages and limitations is essential for selecting the right valve for a specific application, ensuring optimal performance and longevity.

The image below shows how the gate valve wedge opens and closes the flow of the fluid by application of a vertical movement (which can be manual or operated by an actuator).

The wedge is positioned between two parallel (or oblique) seats that are perpendicular to the flow. The fluid flows horizontally through gate valves and is not subject to pressure drops.

The image below shows the different types of wedges used in gate valves:

- “solid wedge” (in this case, the wedge is manufactured with a solid piece of steel)

- “flexible-wedge” (in this case the disc features cuts around its perimeter to enhance the ability of the valve to correct changes in the angle between the seats)

- “split-wedge” (two pieces construction disc, to enforce self-alignment of the wedge on the seats)

- “parallel-slide wedge“

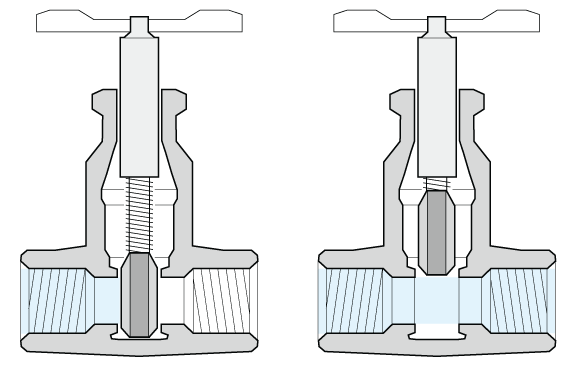

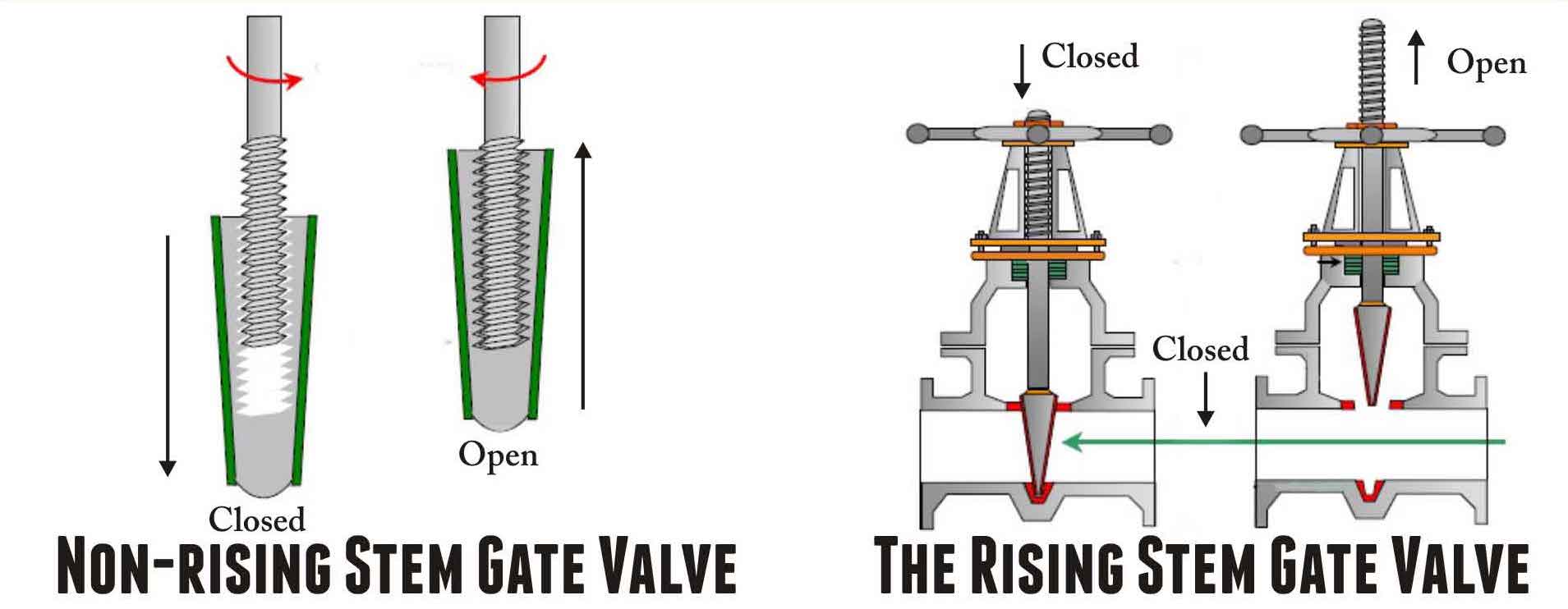

GATE VALVE STEM TYPES

Gate valves control fluid flow by lifting a barrier (gate) out of the fluid path, and this operation is facilitated by the valve’s stem. The stem, which connects the actuator (e.g., handwheel, lever, or electric motor) to the gate, is a critical component in translating the actuator’s motion into the opening or closing of the valve. There are several types of stems used in gate valves, each with its specific design and operational characteristics:

1. Rising Stem (OS&Y – Outside Screw and Yoke)

The rising stem design features a stem that moves up and down along with the gate, providing a visual indication of the valve’s position (open or closed). In this configuration, the stem’s threads are external, located outside the valve body, and interact with the yoke, which is part of the actuator assembly. The rising stem design is advantageous for visual inspection and understanding the valve’s status, but it requires more vertical space for operation.

- Advantages: Visible indication of valve position; reduced risk of thread contamination by the fluid.

- Applications: Widely used in applications where valve status indication is important and where there is sufficient space for stem movement.

2. Non-Rising Stem (NRS)

In a non-rising stem design, the stem remains stationary in the vertical direction while the gate moves up and down. This is achieved by having the stem threads inside the valve body, engaging directly with the gate. Non-rising stem valves are compact and suitable for applications with limited vertical space.

- Advantages: Requires less vertical space; suitable for underground installations or tight spaces.

- Applications: Common in water, wastewater, and gas services where space constraints exist.

Rising and non rising stem of gate valves

3. Sliding Stem

Though not as common in gate valves, a sliding stem design can be found in some specialized gate valves where the stem slides in and out of the valve body without rotating. This design is similar in principle to the non-rising stem but is distinguished by the mechanism of stem movement.

4. Rotating Rising Stem

A rotating rising stem combines the visual position indication of a rising stem with a rotation mechanism. As the valve is opened or closed, the stem not only rises or lowers but also rotates. This rotation can help reduce the wear on the seating surfaces, extending the valve’s service life.

- Advantages: Visual position indication and reduced seat wear due to rotation.

- Applications: Useful in applications requiring durability and clear valve position indication.

Stem Selection Considerations

Choosing the right stem type for a gate valve involves several factors:

- Space Availability: Non-rising stems are preferred in limited vertical space applications while rising stems are chosen when visual position indication is crucial and space permits.

- Environment: External stem threads (rising stems) are less prone to contamination in clean environments, whereas internal threads (non-rising stems) are protected from the external environment but can be exposed to the process fluid.

- Operation and Maintenance: Considerations include ease of operation, maintenance requirements, and the need for clear valve position indication.

Understanding the different types of stems and their operational characteristics is essential for selecting the appropriate gate valve for a specific application, ensuring optimal performance and longevity.

OS&Y VS. IS&Y DESIGN

It is very frequent to see the term “OS&Y” associated with gate valves.

This term means that when the handle of a gate valve is rotated to open or close the valve, it directly raises and lowers the disc by interacting with the stem of the valve.

In an “OS&Y gate valve”, the stem of the valve itself raises and lowers outside the body of the valve in a very visible way, while the handle remains in a fixed position.

When the stem raises, the disc inside the body of the valve rises from the seat letting the fluid flow through the valve (valve in open position).

Therefore with an OS&Y gate valve, the actual position of a valve (closed or open) is always evident to the operators.

Differently, the valve position is not immediately visible for “IS&Y gate valves” (inside screw and yoke), as the stem of the valve does not raise or lowers outside the valve when the handle is rotated.

GATE VALVE MATERIALS

BODY

TRIM

The removable and replaceable parts of the valve are collectively defined as “trim” (for a gate valve: seat, disc, backseat, and, stem).

The API 600 specification foresees several standard trim combinations, as illustrated below

| API TRIM # | BASE MATERIAL | MATERIAL FOR SEAT | MATERIAL FOR DISC | BACKSEAT MATERIAL | MATERIAL FOR STEM |

|---|---|---|---|---|---|

| 1 | 410 | 410 | 410 | 410 | 410 |

| 2 | 304 | 304 | 304 | 304 | 304 |

| 3 | F310 | 310 | 310 | 310 | 310 |

| 4 | Hard 410 | Hard 410 | 410 | 410 | 410 |

| 5 | Hard faced | Stellite | Stellite | 410 | 410 |

| 5A | Hard faced | Ni-Cr | Ni-Cr | 410 | 410 |

| 6 | 410 and Cu-Ni | Cu-Ni | Cu-Ni | 410 | 410 |

| 7 | 410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 |

| 8 | 410 and Hardfaced | Stellite | 410 | 410 | 410 |

| 8A | 410 and Hardfaced | Ni-Cr | 410 | 410 | 410 |

| 9 | Monel | Monel | Monel | Monel | Monel |

| 10 | 316 | 316 | 316 | 316 | 316 |

| 11 | Monel | Stellite | Monel | Monel | Monel |

| 12 | 316 and Hardfaced | Stellite | 316 | 316 | 316 |

| 13 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 |

| 14 | Alloy 20 and Hardfaced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 |

| 15 | 304 and Hardfaced | Stellite | Stellite | 304 | 304 |

| 16 | 316 and Hardfaced | Stellite | Stellite | 316 | 316 |

| 17 | 347 and Hardfaced | Stellite | Stellite | 347 | 347 |

| 18 | Alloy 20 and Hardfaced | Stellite | Stellite | Alloy 20 | Alloy 20 |

MATERIAL SELECTION

| TRIM | RECOMMENDED SERVICE |

|---|---|

| 13% Cr, Type 410 Stainless Steel | For oil and oil vapors and general services with heat treated seats and wedges. |

| 13% Cr, Type 410 plus Hardfacing | Universal trim for general service requiring long service life up to 1100°F (593°C).* |

| Type 316 Stainless | For liquids and gases that are corrosive to 410 Stainless Steel, up to 1000°F (537°C).* |

| Monel | For corrosive service to 842°F (450°C) such as acids, alkalies, salt solutions, etc. |

| Alloy 20 | For corrosive service such as hot acids -49°F to 608oF (-45°C to 320°C). |

| NACE | Specially treated 316 or 410 trim combined optionally with B7M Bolts and 2HM nuts to meet NACE MR-01-75 requirements. |

| Full Stellite | Full hard-faced trim, suitable for abrasive & severe services up to 1200°F (650°C). |

GATE VALVE DIMENSIONS

The tables show the dimensions and weights of API 600 gate valves (bolted bonnet / rising stem)

CLASS 150

Dimensions in inches (millimeters)

| Sizes | L | L1 (BW) | H (Open) | W |

|---|---|---|---|---|

| 2″ | 7 (180) | 8-1/2 (216) | 14-1/2 (368) | 8 (200) |

| 2-1/2″ | 7-1/2 (190) | 9-1/2 (241) | 17 (432) | 8 (200) |

| 3″ | 8 (200) | 11-1/8 (283) | 18 (457) | 8-7/8 (225) |

| 4″ | 9 (230) | 12 (305) | 22 (559) | 11 (279) |

| 5″ | 10 (254) | 15 (381) | 26 (660) | 12-3/4 (325) |

| 6″ | 10-1/2 (266) | 15-7/8 (403) | 30 (762) | 14 (356) |

| 8″ | 11-1/2 (290) | 16-1/2 (420) | 38-1/2 (978) | 14 (356) |

| 10″ | 13 (330) | 18 (457) | 46 (1168) | 18 (457) |

| 12″ | 14 (356) | 19 (502) | 55-1/4 (1403) | 20 (508) |

| 14″ | 15 (381) | 22 (559) | 60 (1524) | 21-1/2 (546) |

| 16″ | 16 (407) | 24 (610) | 74-7/8 (1902) | 24 (610) |

| 18″ | 17 (432) | 26 (660) | 79 (2007) | 27 (686) |

| 20″ | 18 (457) | 28 (711) | 87-1/2 (2223) | 28 (711) |

| 24″ | 20 (508) | 32 (813) | 105 (2667) | 31-1/2 (800) |

| 30″ | 24 (610) | 38 (965) | 130 (3302) | 43 (1092) |

| 36″ | 28 (711) | 44 (1118) | 162 (4115) | 51 (1295) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 10″ AND ABOVE | ||||

CLASS 300

Dimensions in inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2″ | 8-1/2 (216) | 16 (407) | 7-7/8 (200) | |

| 2-1/2″ | 9-1/2 (241) | 17-3/8 (442) | 7-7/8 (200) | |

| 3″ | 11-1/8 (283) | 19-3/4 (501) | 8-7/8 (225) | |

| 4″ | 12 (305) | 23-3/8 (594) | 9-7/8 (251) | |

| 5″ | 15 (381) | 23-3/4 (603) | 12-1/2 (318) | |

| 6″ | 15-7/8 (403) | 32-1/8 (816) | 14 (356) | |

| 8″ | 16-1/2 (420) | 41 (1041) | 15-3/4 (400) | |

| 10″ | 18 (457) | 48-3/8 (1229) | 17-3/4 (451) | |

| 12″ | 19-3/4 (501) | 57 (1448) | 20 (508) | |

| 14″ | 30 (762) | 62-1/2 (1588) | 22 (559) | |

| 16″ | 33 (838) | 69 (1753) | 25 (635) | |

| 18″ | 36 (914) | 80-1/2 (2045) | 28 (711) | |

| 20″ | 39 (991) | 91 (2311) | 35-1/2 (902) | |

| 24″ | 45 (1143) | 120-1/2 (3061) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | ||||

CLASS 600

Dimensions in inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2″ | 11-1/2 (290) | 16-1/2 (420) | 7-7/8 (200) | |

| 2-1/2″ | 13 (330) | 18 (457) | 8-7/8 (225) | |

| 3″ | 14 (356) | 20-1/8 (511) | 9-7/8 (251) | |

| 4″ | 17 (432) | 25 (635) | 14 (356) | |

| 5″ | 20 (508) | 30-1/2 (775) | 15-3/4 (400) | |

| 6″ | 22 (559) | 33-5/8 (854) | 17-3/4 (451) | |

| 8″ | 26 (660) | 42-3/8 (1076) | 20 (508) | |

| 10″ | 31 (787) | 49 (1245) | 25 (635) | |

| 12″ | 33 (838) | 68-1/2 (1740) | 27 (686) | |

| 14″ | 35 (889) | 69 (1753) | 31-1/2 (800) | |

| 16″ | 39 (991) | 74 (1880) | 35-1/2 (902) | |

| 18″ | 43 (1092) | 84-1/4 (2140) | 43 (1092) | |

| 20″ | 47 (1194) | 93-1/2 (2375) | 51 (1295) | |

| 24″ | 55 (1397) | 110 (2794) | 51 (1295) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | ||||

CLASS 900

Dimensions in inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2″ | 14-1/2 (368) | 26 (660) | 10-1/4 (260) | |

| 3″ | 15 (381) | 26-3/8 (670) | 11-1/2 (292) | |

| 4″ | 18 (457) | 30 (762) | 14 (356) | |

| 6″ | 24 (610) | 40-3/4 (1035) | 20 (508) | |

| 8″ | 29 (737) | 51 (1295) | 24 (610) | |

| 10″ | 33 (838) | 61 (1549) | 27 (686) | |

| 12″ | 38 (965) | 69-1/2 (1765) | 31-1/2 (800) | |

| 14″ | 40-1/2 (1029) | 77 (1956) | 35-1/2 (902) | |

| 16″ | 44-1/2 (1130) | 82-3/4 (2102) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | ||||

CLASS 1500

Dimensions in inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2″ | 14-1/2 (368) | 21-1/2 (546) | 11-1/2 (290) | |

| 3″ | 18-1/2 (470) | 27-1/8 (689) | 14 (356) | |

| 4″ | 21-1/2 (546) | 31-1/2 (800) | 20 (508) | |

| 6″ | 27-3/4 (705) | 45 (1143) | 24 (610) | |

| 8″ | 32-3/4 (832) | 53-1/2 (1359) | 27 (686) | |

| 10″ | 39 (991) | 65 (1651) | 35-1/2 (902) | |

| 12″ | 44-1/2 (1130) | 74 (1880) | 43 (1092) | |

| 14″ | 49-1/2 (1257) | 83-1/2 (2121) | 51 (1295) | |

| 16″ | 54-1/2 (1384) | 88 (2235) | 63 (1600) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | ||||

CLASS 2500

Dimensions in inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2″ | 17-3/4 (451) | 24-7/8 (632) | 12 (305) | |

| 3″ | 22-3/4 (578) | 36 (914) | 20 (508) | |

| 4″ | 26-1/2 (673) | 41-1/2 (1054) | 20 (508) | |

| 6″ | 36 (914) | 57 (1448) | 24 (610) | |

| 8″ | 40-1/4 (1022) | 63-3/8 (1610) | 24 (610) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | ||||

5 Responses

1. VALVE,GATE: SIZE: 2-1/2″ DESIGN RATING: 175 PSI (12.1 BAR) WWP CONNECTION: THD BODY MATERIAL: BRZ ASTM B62 TYPE: SOLID WEDGE STEM DESIGN: NON-RISING STEM OPERATED: HANDWHEEL STYLE: THD BONNET TRIM: BRZ ASTM B62 BONNET, SILICON BRZ ASTM B371 ALLOYC69430 SOFTGOODS: NON ASBESTOS ARAMID FIBERS W/GRAPHITE PACKINGTEXT:FIRE FITTING SYSTEM, HOSE MFG VINTAGE BRONZE POWHATAN RANSON W VAPART # 19-281

2. VALVE,GATE: SIZE: 3″ DESIGN RATING: 600 LB CONNECTION: RF FLG BODY MATERIAL: ASTM A217 WC6 – NORM.&TEMP. TYPE: FLEXIBLE WEDGE STEM DESIGN: RISING STEM, OUTSIDE SCREW PORT: FULL OPERATED: HANDWHEEL STYLE: BOLTED BONNET, OS&Y TRIM: 316L SS TRIM SOFTGOODS: 13-CR ASTM A182 GR F6 TRIM, STELLITED SEAT MANUFACTURING STANDARD: GRAPHITE GLAND PACKING MFG VITAS(S.P.A):00-GA-E-60146

Nice Information Regarding Gate Valve

Dear Sir

We are an official partner for Saudi Electricity Co.

So, We Need To know Price For one of your Company Product , Could You Send us an official Quotation with Price, Full DataSheets and Delivery Time about This Product with The Following Data ..

– Shipping and Deliver : Riyadh – Saudi Arabia

Kindly Reply us as soon as Possible that’s So urgent ..

==============

*PROUDCT DATA*

==============

Item No : 901415094

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSURE

VALVE WEDGE CLASS 150 GATE SW END MAT

ERIAL-: A217-CA15+STL USED IN SHUQAIQ S

TEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030DN40 SW,POS#3

Quantity : 1 EA

Item No : 901415107

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSURE

VALVE WEDGE CLASS 600 GATE SW END MAT

ERIAL-: A217-CA15+STL USED IN SHUQAIQ S

TEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030DN40 SWCLASS600,POS#3

Quantity : 1 EA

Item No : 901415120

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSUR

E VALVE WEDGE CLASS 600 GATE SW END MAT

ERIAL-: A217-CA15+STL USED IN SHUQAIQ S

TEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030DN25 SW,POS#3

Quantity : 1 EA

Item No : 901415133

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSUR

E VALVE WEDGE CLASS 600 GATE SW END MAT

ERIAL-: A217-CA15+STL USED IN SHUQAIQ S

TEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030WEDGEDN25,POS#3

Quantity : 1 EA

Item No : 901415209

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSUR

E VALVE WEDGE CLASS 1500 GATE SW END MA

TERIAL-: A217-CA15+STL USED IN SHUQAIQ

STEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030DN40,POS#3

Quantity : 1 EA

Item No : 901415222

WEDGE,BULK NOUN:

ADDITIONAL DATA:

PARENT EQUIPMENT FUNCTION-: LOW PRESSUR

E VALVE WEDGE CLASS 600 GATE SW END MAT

ERIAL-: A217-CA15+STL USED IN SHUQAIQ S

TEAM POWER PLANT

S & S VALVES:

P/N#SNSD-2013-1030DN25GATE,POS#3

Quantity : 1 EA

Item No : 901498938

CAPACITOR:FIXED,

2 MICRO F,6000 VDC,ALUM

CAPACITOR,FIXED:

CAPACITANCE: 2 MICRO F;

VOLTAGE:

6000 VDC;

STYLE:ALUM CANISTER;

TOLERANCE:MINUS/PLUS 10

SIZE:130 MM WD X 100 MM LG X 50 MM DP;

STANDARD/SPECIFICATION:IEC 60384-4

ADDITIONAL DATA:

ITEM ADDITIONAL DESCRIPTION: ; SYSTEM

PARENT EQUIPMENT INFORMATION: USED FOR

SHUQAIQ STEAM POWER PLANT.

VISHAY (FM):

P/N#ER60-205

Quantity : 1 EA

Item No : 901499024

AMMETER:ANALOG,PANEL MOUNT SQUARE FACE,0

AMMETER,ANALOG:

STYLE:

PANEL MOUNT SQUARE FACE;

RANGE: 0 TO 2000 A;

STANDARD/SPECIFICATION:

CE, UL LISTED;

ADDITIONAL DATA:

ITEM ADDITIONAL DATA: CLASS 1.5, CT RA

TING 2000:1 A; SYSTEM PARENT EQUIPMENT

DETAILS: USED FOR AL SHUQIQ POWER PLANT SUBSTATION.

GANZ:

P/N#72LA 2000A(AC

Quantity : 2 EA

Item No : 901499025

AMMETER:ANALOG,PANEL MOUNT SQUARE FACE,0

AMMETER,ANALOG:

STYLE:

PANEL MOUNT SQUARE FACE;

RANGE: 0 TO 400 A;

STANDARD/SPECIFICATION:

CE, UL LISTED;

ADDITIONAL DATA:

ITEM ADDITIONAL DATA: CLASS 1.5, CT RA

TING 400:1 A; SYSTEM PARENT EQUIPMENT

DETAILS: USED FOR AL SHUQIQ POWER PLANT SUBSTATION.

GANZ:

P/N#72LA 400A(AC)

Quantity : 2 EA

Item No : 4602BF661

METER:FREQUENCY,ANALOG READOUT,PANEL MOU

METER,FREQUENCY:

READOUT:

ANALOG;

STYLE:

PANEL MOUNT;

RANGE:

55 TO 60 TO 65 HZ;

ADDITIONAL DATA:

DOUBLE REED, WITH TWO INDEPENDENT VIBRA

TING REED MECHANISMS, 96 MM X 96 MM SIZ

E, 3240F, EH726, FZ16-2 ROWS OF 21, IL

731- 100- 120 VAC, LB1-CONDITIONALLY TROPIC PROOF, FQ1S5C.

UNIDENTIFIED MANUFACTURER – SOA:

ZF-96-2

Quantity : 4 EA

Dear Sir, please post your RFQ in the RFQ section of the site

REQUIRE 3′ &4″ CAST STEEL BALL VALVE URGENTLY NEED PRICE : FOB/C&F NIGERIA !!! PEASE