A HEM steel beam is a type of wide flange beam or an “I” beam with significantly deeper and heavier sections than those found in standard I beams or even wide flange beams like the HEB series. The acronym “HEM” stands for “H-Europäische Breitflanschträger mit breiten Flanschen und großen Flanschdicken,” which is German for “European-wide flange beams with wide flanges and large flange thicknesses,” but in practice, it is simply referred to as “HEM.” These beams are part of the European standard structural steel section known as IPE, HEA, HEB, and HEM sections.

HEM Steel Beams (“M” Sections)

WHAT ARE HEM STEEL BEAMS?

HEM steel beams are a type of structural steel beam used primarily in construction and civil engineering. They are part of the European wide flange beam family (“I” family as their shape resembles the I letter), which includes HEA (High Elastic modulus A) and HEB (High Elastic modulus B) beams, with HEM beams being the largest and heaviest of the series. The acronym “HEM” stands for “Haute Efficacité Mécanique” in French, or “High Mechanical Efficiency” in English, indicating their superior load-bearing capabilities and structural efficiency.

M Steel beams HEA/HEB are a very commonly used type of steel profile. Beams, otherwise called “M” sections, HEM, are available in multiple material grades, the most common are EN 10025 S275, and S355.

Due to their large size and high load-bearing capacity, HEM beams are often used in heavy-duty construction projects, such as multi-story buildings, bridges, and large industrial facilities. Their robustness makes them an ideal choice for primary structural elements where strength and durability are paramount.

In some structural steel literature, HEM steel beams are also known as “Continental Web flanges,” but this term is simply another name for the same product.

HEM BEAMS FEATURES

HEM steel beams are structural products with distinct features and advantages over other types of beams:

Deeper Sections: HEM beams have deeper sections compared to other beam types, which allows them to carry larger loads over wider spans. This makes them especially suitable for applications requiring strong structural support without the use of intermediate columns or supports.

Higher Load Capacity: The increased depth and weight of HEM beams result in a higher load capacity, making them ideal for heavy-duty structural applications.

Construction and Engineering: HEM beams are widely used in the construction of buildings, bridges, and other structures where high structural integrity and load-bearing capacity are necessary. They are also used in civil engineering projects and heavy industrial construction.

Aesthetic and Functional Design: The unique proportions of HEM beams offer architects and engineers the flexibility to design structures with fewer visible supports, creating more open and aesthetically pleasing spaces.

SPECIFICATIONS FOR HEM STEEL BEAMS

The specifications of HEM steel beams are standardized according to European norms, ensuring consistent quality and performance across applications. Here’s a closer look at the specifications of HEM steel beams:

Dimensional Specifications (EN 10034)

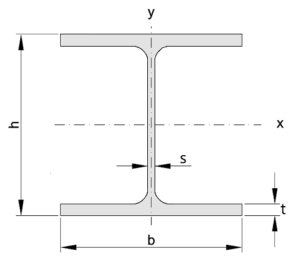

The dimensions of HEM steel beams include the depth of the section (height), the width of the flanges, the thickness of the web, and the thickness of the flanges. These dimensions significantly influence the beam’s structural properties, such as its load-bearing capacity and stiffness.

HEM steel beams are standardized under the EN 10034 standard, which defines the nominal dimensions, mass per meter, and geometrical properties. This European standard ensures that HEM beams meet specific criteria for shape, dimensions, and tolerances, making them suitable for high-demand structural applications.

While the specific dimensions can vary slightly between manufacturers and specific standards within the EN designation, HEM beams generally adhere to these specifications:

- Depth (Height): Ranges from about 100 mm for the smallest HEM beams to over 1000 mm for the largest.

- Flange Width: Typically very wide in comparison to other I-beam types, enhancing their structural stability.

- Web Thickness: The thickness of the vertical section (“web”) is greater than that in standard I-beams, contributing to their higher strength and stiffness.

- Weight per Meter: Due to their size, HEM beams are significantly heavier per unit length than other steel beams, which directly correlates with their ability to support large loads.

Material Grades (EN 10025)

The steel used in the manufacture of HEM beams typically conforms to specific European material standards, such as EN 10025. This standard specifies the technical delivery conditions for flat and long products of hot-rolled structural steels, including chemical composition and mechanical properties.

The mechanical properties of HEM beams, such as yield strength, tensile strength, and elongation, are crucial for determining the beam’s ability to bear loads without deforming or failing. These properties depend on the steel grade used and are specified in the material standards.

Size Range

HEM beams come in a wide range of sizes to suit various applications, with depth sizes typically ranging from 100 mm to 1000 mm. The larger sizes of HEM beams are particularly suited for applications requiring long spans and high load-bearing capabilities, such as in industrial buildings, bridges, and large structural frames.

Design Considerations

Engineers and designers select HEM beams based on the structural requirements of the project, considering factors such as the type of load (static or dynamic), the span length, the connection details, and the overall design aesthetic.

EN10025 1-2 MATERIAL GRADES

HEM steel beams, known for their wide flange and significant depth, are typically manufactured from structural steel grades that ensure their strength, durability, and weldability. T The material grades used for HEM beams are defined by European standards, particularly EN 10025, which covers several grades of structural steel. Here are some of the common material grades used for HEM steel beams:

EN 10025 S235JR

- Standard: EN 10025-2

- Features: S235JR is a non-alloy structural steel grade with good weldability. It offers an optimal balance of strength and ductility, making it suitable for general structural purposes.

EN 10025 S275JR

- Standard: EN 10025-2

- Features: Providing a bit more strength than S235JR, S275JR steel is also a non-alloy structural grade that is known for its excellent weldability. It’s commonly used in structural applications requiring higher strength.

EN 10025 S355J2

- Standard: EN 10025-2

- Features: A high-strength, low-alloy structural steel grade, S355J2 offers superior mechanical properties, including high strength and toughness, even at sub-zero temperatures. It also has good weldability and enhanced resistance to atmospheric corrosion, making it suitable for demanding structural applications.

EN 10025 S355K2

- Standard: EN 10025-2

- Features: Similar to S355J2, S355K2 is a high-strength, low-alloy structural steel grade but with improved impact strength at lower temperatures, which makes it particularly suitable for structural applications in colder climates.

EN 10025 S460M

- Standard: EN 10025-4

- Features: Part of the thermomechanical rolled weldable fine grain structural steels, S460M offers high strength and good weldability. It’s used in heavily loaded parts of welded structures such as bridges, storage tanks, and cranes.

Choosing the Right Material Grade

The selection of a specific steel grade for HEM beams depends on various factors, including the mechanical properties required for the project, the environmental conditions to which the steel will be exposed, and the specific application’s needs. Higher grades like S355J2 and S355K2 are chosen for their superior strength and toughness, which are essential in large-scale construction projects and in areas with challenging environmental conditions.

DIFFERENCE HEM VS. HEA/HEB STEEL BEAMS

The HEM, HEA, and HEB steel beams are all types of European wide flange beams, each with distinct characteristics and applications. These beams are part of the wider family of I-beams used in construction and engineering for their ability to provide efficient structural support. Here’s a breakdown of the differences among HEM, HEA, and HEB steel beams:

HEM Steel Beams

- Profile: HEM (Heavy Extra M) beams have the largest dimensions among the three types, including wider flanges and greater depth.

- Characteristics: They feature thicker flanges and webs compared to HEA and HEB beams, making them extremely strong and capable of supporting large loads over wide spans.

- Applications: Due to their significant size and weight, HEM beams are typically used in heavy construction projects, large buildings, bridges, and other structures requiring a high degree of structural support.

HEA Steel Beams

- Profile: HEA (High Euronorm A) beams are lighter than HEB and HEM beams, with thinner flanges and webs.

- Characteristics: These beams offer a good balance of strength and flexibility, making them suitable for a wide range of structural applications.

- Applications: HEA beams are commonly used in residential and commercial construction, framework, and support structures where the load requirements are moderate.

HEB Steel Beams

- Profile: HEB (High Euronorm B) beams sit between HEA and HEM beams in terms of dimensions and weight. They have wider flanges than HEA beams but are not as large as HEM beams.

- Characteristics: HEB beams provide a higher load capacity than HEA beams due to their greater flange width and depth.

- Applications: These beams are suited for medium to heavy construction projects, including commercial and industrial buildings, bridges, and other structures requiring substantial support.

Key Differences HEM/HEA/HEB Beams

- Size and Weight: HEM beams are the heaviest and provide the highest load capacity, suitable for heavy-duty applications. HEB beams are medium-sized, offering a balance between weight and structural support. HEA beams are the lightest, ideal for applications where weight saving is important alongside structural integrity.

- Flange and Web Thickness: HEM beams have the thickest flanges and webs, followed by HEB, and then HEA, which has the thinnest. This affects their strength, rigidity, and how they distribute loads.

- Applications: The choice between HEM, HEA, and HEB beams depends on the specific requirements of a project, including the needed strength, span length, and aesthetic considerations.

DIMENSIONS & WEIGHTS HEM STEEL BEAMS

The dimensions and weight of HEM steel beams vary significantly across the range, catering to a variety of structural needs. The HEM series offers some of the largest and heaviest H-sections available, making them suitable for major construction projects requiring high load-bearing capacity and long spans. The following table provides a generalized overview of the dimensions and weights for a selection of HEM steel beams. Please note, for precise specifications, always refer to the latest standards or manufacturer’s details.

HEM Dimensions & Weights by Size

| Beam Size | Depth (mm) | Width of Flange (mm) | Thickness of Web (mm) | Thickness of Flange (mm) | Weight (kg/m) |

|---|---|---|---|---|---|

| HEM 100 | 120 | 106 | 12 | 20 | 41.8 |

| HEM 120 | 140 | 126 | 12.5 | 21 | 52.1 |

| HEM 140 | 160 | 146 | 13 | 22 | 63.2 |

| HEM 160 | 180 | 166 | 14 | 23 | 76.2 |

| HEM 180 | 200 | 186 | 14.5 | 24 | 88.9 |

| HEM 200 | 220 | 206 | 15 | 25 | 103 |

| HEM 220 | 240 | 226 | 15.5 | 26 | 117 |

| HEM 240 | 270 | 248 | 18 | 32 | 167 |

| HEM 260 | 290 | 268 | 18 | 32.5 | 172 |

| HEM 280 | 310 | 288 | 18.5 | 33 | 177 |

| HEM 300 | 340 | 310 | 21 | 39 | 244 |

| HEM 320 | 359 | 309 | 21 | 40 | 251 |

| HEM 340 | 377 | 309 | 21 | 40 | 256 |

| HEM 360 | 395 | 308 | 21 | 40 | 262 |

| HEM 400 | 432 | 307 | 21 | 40 | 291 |

| HEM 450 | 478 | 307 | 21 | 40 | 320 |

| HEM 500 | 524 | 306 | 21 | 40 | 349 |

| HEM 550 | 572 | 306 | 21 | 40 | 377 |

| HEM 600 | 620 | 305 | 21 | 40 | 405 |

| HEM 650 | 668 | 305 | 21 | 40 | 434 |

| HEM 700 | 716 | 304 | 21 | 40 | 461 |

| HEM 800 | 814 | 303 | 21 | 40 | 520 |

| HEM 900 | 910 | 302 | 21 | 40 | 582 |

| HEM 1000 | 1008 | 302 | 21 | 40 | 642 |

HEM Size Chart (EN 10034/10025): Mechanical Properties by Size

| HEM Sizes EN 10034/10025 1/2 | Sizes in mm | Cross Section cm² | Modulus Section cm³ | ||||

| HEM Beam Size | h | b | s | t | F | Wx | Wy |

| HEM 100 | 120 | 106 | 12 | 20 | 53.2 | 190.4 | 75.31 |

| HEM 120 | 140 | 126 | 12.5 | 21 | 66.4 | 288.2 | 111.6 |

| HEM 140 | 160 | 146 | 13 | 22 | 80.6 | 411.4 | 156.8 |

| HEM 160 | 180 | 166 | 14 | 23 | 97.1 | 566.5 | 211.9 |

| HEM 180 | 200 | 186 | 14.5 | 24 | 113.3 | 748.3 | 277.4 |

| HEM 200 | 220 | 206 | 15 | 25 | 131.3 | 967.4 | 354.5 |

| HEM 220 | 240 | 226 | 15.5 | 26 | 149.4 | 1217 | 443.5 |

| HEM 240 | 270 | 248 | 18 | 32 | 199.6 | 1799 | 657.5 |

| HEM 260 | 290 | 268 | 18 | 32.5 | 219.6 | 2159 | 779.7 |

| HEM 280 | 310 | 288 | 18.5 | 33 | 240.2 | 2551 | 914.1 |

| HEM 300 | 340 | 310 | 21 | 39 | 303.1 | 3482 | 1252 |

| HEM 320 | 359 | 309 | 21 | 40 | 312 | 3796 | 1276 |

| HEM 340 | 377 | 309 | 21 | 40 | 315.8 | 4052 | 1276 |

| HEM 360 | 395 | 308 | 21 | 40 | 318.8 | 4297 | 1268 |

| HEM 400 | 432 | 307 | 21 | 40 | 325.8 | 4820 | 1260 |

| HEM 450 | 478 | 307 | 21 | 40 | 335.4 | 5501 | 1260 |

| HEM 500 | 524 | 306 | 21 | 40 | 344.3 | 6180 | 1252 |

| HEM 550 | 572 | 306 | 21 | 40 | 354.4 | 6923 | 1252 |

| HEM 600 | 620 | 305 | 21 | 40 | 363.7 | 7660 | 1244 |

| HEM 650 | 668 | 305 | 21 | 40 | 373.7 | 8433 | 1245 |

| HEM 700 | 716 | 304 | 21 | 40 | 383 | 9198 | 1240 |

| HEM 800 | 814 | 303 | 21 | 40 | 404.3 | 10870 | 1230 |

| HEM 900 | 910 | 302 | 21 | 40 | 423.6 | 12540 | 1220 |

| HEM 1000 | 1008 | 302 | 21 | 40 | 444.2 | 14330 | 1222 |

HEM BEAM SELECTION CRITERIA

Choosing HEM steel beams for a construction project involves considering several key factors that make these beams particularly suitable for certain applications. HEM beams, with their wide flanges and substantial depth, offer unique advantages:

1. High Load-Bearing Capacity (Strength)

HEM beams are designed to bear heavy loads, making them ideal for structures that require a high degree of load-bearing capacity without the need for additional support columns. This capability stems from their large cross-sectional area and robust structure.

2. Long Spans

The depth and strength of HEM beams allow for longer spans between supports compared to other beam types. This is particularly beneficial in large buildings or structures where open spaces without columns are desired, such as in auditoriums, warehouses, and industrial buildings.

3. Durability & Structural Integrity

The substantial material in the web and flanges of HEM beams not only provides strength but also contributes to the overall durability of the structure. They are capable of withstanding environmental stresses, vibrations, and other factors that might compromise the integrity of less robust beam types.

4. Design Flexibility

The size and strength of HEM beams make them versatile in their application, and suitable for both standard and innovative architectural designs. They can be used in a variety of structural systems, including frames for buildings and bridges, support for heavy machinery, and other critical structural components.

5. Aesthetic Appeal

For projects where the appearance of structural elements is a consideration, HEM beams offer a visually substantial and professional look. Their size and shape can contribute to the aesthetic appeal of the structure, aligning with modern design trends that favor clean lines and open spaces.

6. Cost-Efficiency

Despite their larger size, choosing HEM beams can lead to cost savings in the long term through reduced need for additional supports and maintenance. Their ability to cover long spans with fewer materials can also contribute to cost efficiency in terms of both materials and labor.

7. Structural Safety

The robustness of HEM beams contributes to the overall safety of the structure, providing reliable support against loads and reducing the risk of structural failure.

Conclusion

The decision to use HEM steel beams is driven by the need for high strength, long spans, durability, and versatility in construction projects. While the initial cost might be higher compared to other beam types, the long-term benefits of using HEM beams, including structural integrity, design flexibility, and cost savings, often justify the investment. Engineers and architects choose HEM beams for challenging projects where these factors are critical to the success and longevity of the structure.

One Response

Dear Sir/Madam.

Good day.I am a Ghana local agent.

I want to know if your company will bid in a tender to supply your product to Ghana if you are successful, However, We will like to see your company catalog/website to help select the Require items

If you are interested to participate then get back to enable us proceed.

Awaiting for your prompt response, and have a nice day.

In the mean time, I look forward to hearing from you by return of my mail & to developing a long term business partnership with you soon.

Best regards.