Steel Angles: Equal & Unequal Sizes

RSA Steel Angles

What Are Steel Angles?

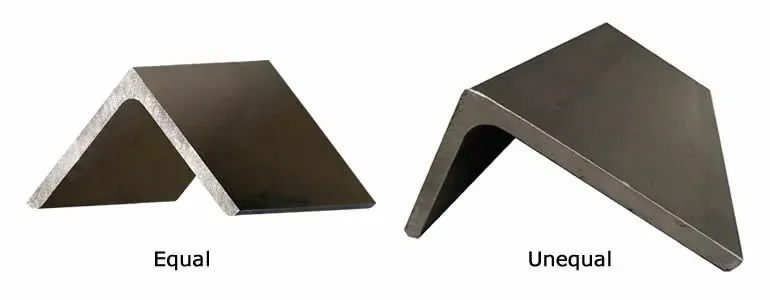

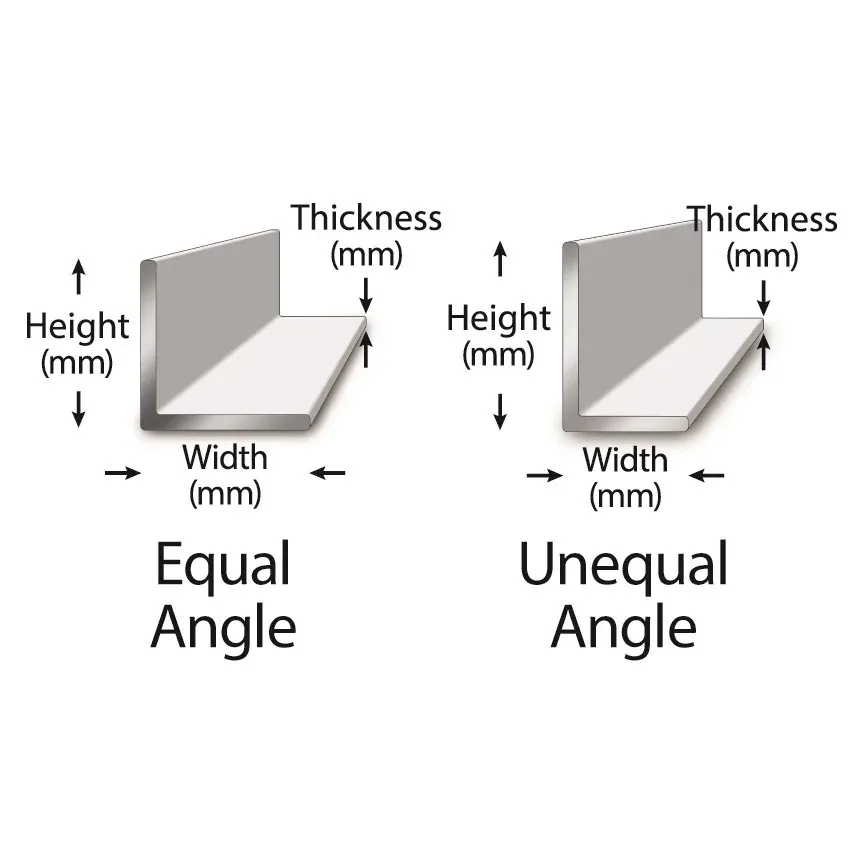

RSA (the acronym for “Rolled Steel Angle”) Steel angles are L-shaped cross-sections made by bending a single piece of steel (or, less often, by welding two steel plates) at a 90-degree angle.

These are fundamental structural elements in construction and engineering, routinely used for framing, bracing, and support. Steel angles come in various sizes and thicknesses and can be equal or unequal in leg length, covering everything from light architectural detailing to heavy industrial framing.

When ordering RSA steel angles, specify three parameters:

| Parameter | What to Specify |

|---|---|

| Dimensions | Leg length, width, and thickness determine load capacity and fit. The primary decision is whether an equal or unequal shape is needed. |

| Material Grade | The steel grade controls yield strength, tensile strength, and ductility. Common grades are S275 and S355 under EN 10025. |

| Surface Finish | Most structural RSAs are hot-rolled. Cold-rolled sections exist but are less common. Galvanizing or painting adds corrosion resistance where required. |

RSA Steel Angles Characteristics

Steel angles share several defining properties:

- The L-shaped cross-section gives two planes of support, adding both strength and stability to connected members.

- Equal angles have legs of the same length and suit applications requiring uniform strength along both axes. Unequal angles have legs of different lengths and handle asymmetric loading or fit constraints where one leg must be wider than the other.

- Sizes range from 16 mm equal legs up to 200 mm, and thicknesses from 3 mm to 24 mm (EN 10056), letting engineers match section properties to actual design loads.

- Properly treated or coated, steel angles resist corrosion and perform well in both indoor and outdoor environments.

- The simple L-profile is easy to cut, weld, and drill, which makes RSAs one of the most adaptable sections for custom fabrication.

RSA Applications

RSA steel angles appear across nearly every sector of construction and manufacturing:

| Sector | Typical Uses |

|---|---|

| Construction | Framing elements for buildings, bridges, towers, and other structures requiring rigidity |

| Infrastructure | Support and reinforcement in airports, stadiums, and railway structures |

| Manufacturing | Shelving, racks, benches, and frames that need strength with easy assembly |

| Architectural | Exposed structural members and decorative trim elements |

| Industrial | Brackets, frames, and supports for machinery and process equipment |

EU & US Specifications for RSA Angles

Both the European Union and the United States maintain detailed standards governing steel angle dimensions, tolerances, and mechanical properties. The EU follows EN (European Norm) standards; the US follows AISC specifications backed by ASTM material standards.

EU Specifications

EN 10056-1 defines the dimensions, tolerances, and designation system for RSA angles with equal and unequal legs for general structural use.

EN 10025 is a series of standards covering the technical delivery conditions for hot-rolled structural steels. It specifies the mechanical properties, chemical composition, and delivery conditions for the steel grades used to manufacture RSA sections.

AISC Specifications

ANSI/AISC 360, the Specification for Structural Steel Buildings, sets the design, fabrication, and erection requirements for structural steel in the US. It includes provisions for materials, design criteria, and workmanship applicable to steel angles.

ASTM standards referenced by AISC define the material properties: ASTM A36 covers carbon structural steel, ASTM A572 covers high-strength low-alloy structural steel, and several others address specific performance needs. These standards specify the chemical and mechanical requirements for each grade.

Key Differences and Considerations

The EU and US systems differ in several ways that affect cross-border projects:

| Aspect | EU (EN Standards) | US (AISC/ASTM Standards) |

|---|---|---|

| Grade designation | Alphanumeric codes such as S235, S275, S355 under EN 10025 | ASTM designations such as A36, A572, A588 |

| Dimensional tolerances | Defined in EN 10056-1 | Defined by ASTM A6/A6M, referenced in AISC |

| Mechanical properties | Yield, tensile, and impact values per EN 10025 sub-grades (JR, J0, J2, K2) | Values per individual ASTM specifications; grade variations by alloy content |

| Geographic adoption | EU member states and regions recognizing EN standards | United States and countries following American structural codes |

Engineers working on international projects should verify that material properties meet the governing code before substituting one standard for another.

Key Material Grades for RSA Angles

European Grades (EN 10025)

EN 10025 S235

Designated S235JR, S235J0, or S235J2. This grade offers good weldability, toughness, and moderate strength, making it a standard choice for general engineering and construction. The JR, J0, and J2 sub-grades reflect increasing impact toughness at progressively lower test temperatures.

EN 10025 S275

Designated S275JR, S275J0, or S275J2. Slightly higher in strength and hardness than S235, with similar weldability and toughness. S275 provides a practical balance between strength and ductility for many construction applications.

EN 10025 S355

Designated S355JR, S355J0, S355J2, or S355K2. This is the workhorse grade for applications demanding higher strength and better mechanical performance. The sub-grades (JR through K2) provide increasing impact toughness, with K2 offering the best notch performance at low temperatures.

EN 10025 S420 and S460

Designated S420N, S420NL, S460N, or S460NL. These high-strength grades serve heavily loaded welded structures such as bridges, storage tanks, and lifting equipment. The “N” suffix indicates normalized or normalized-rolled delivery; “NL” adds a low-temperature toughness requirement.

American Grades (AISC/ASTM)

In the United States, steel angles are specified according to ASTM standards referenced by AISC. The most common material grades for RSA angles are outlined below.

ASTM A36

Standard Specification for Carbon Structural Steel. A36 is the most widely used grade for structural angles. It welds readily, accepts surface hardening treatments, and suits a broad range of construction and architectural applications.

ASTM A572

Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel. A572 delivers higher strength than A36 with improved corrosion resistance. Grade 50 is the most common variant for structural work, offering a better strength-to-weight ratio where lighter sections or longer spans are needed.

ASTM A588

Standard Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi [345 MPa] Minimum Yield Point, with Atmospheric Corrosion Resistance. A588 develops a protective oxide patina when exposed to weather, reducing long-term maintenance. It is widely used in bridge construction, building facades, and exposed outdoor structures.

ASTM A709

Standard Specification for Structural Steel for Bridges. A709 covers carbon and high-strength low-alloy shapes and plates for bridge construction. It includes multiple grades with varying strength, weldability, and toughness to match the specific demands of bridge engineering.

Dimensions and Weights of RSA Angles

European RSA Steel Angles (EN 10056)

Equal RSA Steel Angles

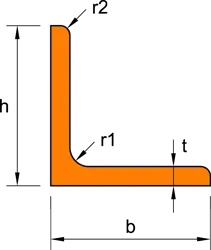

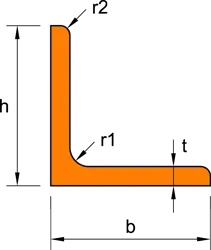

Dimensions of equal steel angles per EN 10056, with weight in kilograms per meter and surface area in square meters per meter length. Equal steel angles have legs of the same size.

| Equal Steel Angleh x b X t (in mm) | surface area in m2 per meter | weight in kg/meter |

|---|---|---|

| 16 x 16 x3 | 0.061 | 0.704 |

| 20 x 20 x3 | 0.077 | 0.902 |

| 20 x 20 x4 | 0.077 | 1.16 |

| 25 x 25 x3 | 0.097 | 1.14 |

| 25 x 25 x4 | 0.097 | 1.49 |

| 25 x 25 x5 | 0.097 | 1.81 |

| 30 x 30 x3 | 0.116 | 1.39 |

| 30 x 30 x4 | 0.116 | 1.81 |

| 30 x 30 x5 | 0.116 | 2.22 |

| 35 x 35 x3 | 0.136 | 1.63 |

| 35 x 35 x4 | 0.136 | 2.13 |

| 35 x 35 x5 | 0.136 | 2.62 |

| 35 x 35 x6 | 0.136 | 3.09 |

| 40 x 40 x3 | 0.155 | 1.88 |

| 40 x 40 x4 | 0.155 | 2.46 |

| 40 x 40 x5 | 0.155 | 3.03 |

| 40 x 40 x6 | 0.155 | 3.58 |

| 45 x 45 x5 | 0.174 | 3.44 |

| 45 x 45 x6 | 0.174 | 4.07 |

| 50 x 50 x4 | 0.194 | 3.11 |

| 50 x 50 x5 | 0.194 | 3.84 |

| 50 x 50 x6 | 0.194 | 4.55 |

| 50 x 50 x7 | 0.194 | 5.25 |

| 50 x 50 x8 | 0.194 | 5.93 |

| 50 x 50 x9 | 0.194 | 6.6 |

| 55 x 55 x6 | 0.213 | 5.05 |

| 55 x 55 x8 | 0.213 | 6.58 |

| 60 x 60 x 6 | 0.233 | 5.53 |

| 60 x 60 x 7 | 0.233 | 6.38 |

| 60 x 60 x 8 | 0.233 | 7.22 |

| 60 x 60 x 10 | 0.233 | 8.85 |

| 65 x 65 x 6 | 0.252 | 6.02 |

| 65 x 65 x 7 | 0.252 | 6.96 |

| 65 x 65 x 8 | 0.252 | 7.88 |

| 65 x 65 x 9 | 0.252 | 8.8 |

| 70 x 70 x 7 | 0.272 | 7.52 |

| 70 x 70 x 8 | 0.272 | 8.56 |

| 70 x 70 x 9 | 0.272 | 9.5 |

| 70 x 70 x 10 | 0.272 | 10.5 |

| 75 x 75 x 6 | 0.29 | 6.98 |

| 75 x 75 x 7 | 0.291 | 8.09 |

| 75 x 75 x 8 | 0.291 | 9.17 |

| 75 x 75 x 10 | 0.291 | 11.3 |

| 75 x 75 x 12 | 0.291 | 13.3 |

| 80 x 80 x 8 | 0.311 | 9.81 |

| 80 x 80 x 10 | 0.311 | 12.1 |

| 80 x 80 x 12 | 0.311 | 14.3 |

| 90 x 90 x 8 | 0.351 | 11.1 |

| 90 x 90 x 9 | 0.351 | 12.4 |

| 90 x 90 x 10 | 0.351 | 13.7 |

| 90 x 90 x 12 | 0.351 | 16.2 |

| 100 x 100 x 8 | 0.39 | 12.4 |

| 100 x 100 x 10 | 0.39 | 15.3 |

| 100 x 100 x 12 | 0.39 | 18.2 |

| 100 x 100 x 14 | 0.39 | 21 |

| 100 x 100 x 15 | 0.39 | 22.3 |

| 110 x 110 x 10 | 0.43 | 16.9 |

| 110 x 110 x 12 | 0.43 | 20.1 |

| 110 x 110 x 14 | 0.43 | 23.2 |

| 120 x 120 x 10 | 0.469 | 18.5 |

| 120 x 120 x 11 | 0.469 | 20.3 |

| 120 x 120 x 12 | 0.469 | 22 |

| 120 x 120 x 15 | 0.469 | 27.1 |

| 130 x 130 x 12 | 0.508 | 24 |

| 130 x 130 x 14 | 0.508 | 27.8 |

| 140 x 140 x 13 | 0.547 | 28 |

| 140 x 140 x 15 | 0.547 | 32 |

| 150 x 150 x 12 | 0.586 | 27.9 |

| 150 x 150 x 14 | 0.586 | 32.2 |

| 150 x 150 x 15 | 0.586 | 34.4 |

| 150 x 150 x 18 | 0.586 | 40.8 |

| 160 x 160 x 15 | 0.625 | 36.8 |

| 180 x 180 x 16 | 0.705 | 44.3 |

| 180 x 180 x 18 | 0.705 | 49.5 |

| 200 x 200 x 16 | 0.785 | 49.4 |

| 200 x 200 x 18 | 0.785 | 55.3 |

| 200 x 200 x 20 | 0.785 | 61.1 |

| 200 x 200 x 24 | 0.785 | 72.5 |

Unequal RSA Steel Angles

Dimensions of unequal steel angles per EN 10056, with weight in kilograms per meter and surface area in square meters per meter length. Unequal steel angles have two legs of different sizes (one shorter, one longer).

| Unequal Steel Angle Dimensionsh x b x t (in mm) | surface area in m2 per meter | weight in kg/meter |

|---|---|---|

| 30 x 20 x 3 | 0.097 | 1.14 |

| 30 x 20 x 4 | 0.097 | 1.49 |

| 40 x 20 x 3 | 0.117 | 1.38 |

| 40 x 20 x 4 | 0.117 | 1.8 |

| 40 x 25 x 4 | 0.127 | 1.97 |

| 45 x 30 x 4 | 0.146 | 2.3 |

| 45 x 30 x 5 | 0.146 | 2.82 |

| 50 x 30 x 5 | 0.156 | 3.02 |

| 50 x 30 x 6 | 0.156 | 3.58 |

| 50 x 40 x 4 | 0.177 | 2.77 |

| 50 x 40 x 5 | 0.177 | 3.42 |

| 50 x 40 x 6 | 0.177 | 4.03 |

| 60 x 30 x 5 | 0.175 | 3.43 |

| 60 x 30 x 6 | 0.175 | 4.06 |

| 60 x 30 x 7 | 0.175 | 4.68 |

| 60 x 40 x 5 | 0.195 | 3.83 |

| 60 x 40 x 6 | 0.195 | 4.54 |

| 60 x 40 x 7 | 0.195 | 5.24 |

| 65 x 50 x 5 | 0.224 | 4.43 |

| 65 x 50 x 6 | 0.224 | 5.26 |

| 65 x 50 x 7 | 0.224 | 6.08 |

| 65 x 50 x 8 | 0.224 | 6.88 |

| 75 x 50 x 5 | 0.244 | 4.83 |

| 75 x 50 x 6 | 0.244 | 5.75 |

| 75 x 50 x 7 | 0.244 | 6.65 |

| 75 x 50 x 8 | 0.244 | 7.53 |

| 75 x 50 x 9 | 0.244 | 8.4 |

| 75 x 55 x 5 | 0.254 | 5.04 |

| 75 x 55 x 7 | 0.254 | 6.93 |

| 75 x 65 x 6 | 0.273 | 6.49 |

| 75 x 65 x 8 | 0.273 | 8.48 |

| 75 x 65 x 10 | 0.273 | 10.5 |

| 80 x 40 x 6 | 0.234 | 5.51 |

| 80 x 40 x 8 | 0.234 | 7.21 |

| 80 x 60 x 6 | 0.273 | 6.49 |

| 80 x 60 x 7 | 0.273 | 7.5 |

| 80 x 60 x 8 | 0.273 | 8.48 |

| 80 x 65 x 6 | 0.283 | 6.73 |

| 80 x 65 x 8 | 0.283 | 8.82 |

| 80 x 65 x 10 | 0.283 | 10.9 |

| 90 x 65 x 6 | 0.303 | 7.22 |

| 90 x 65 x 7 | 0.303 | 8.32 |

| 90 x 65 x 8 | 0.303 | 9.44 |

| 90 x 65 x 10 | 0.303 | 11.7 |

| 100 x 50 x 6 | 0.292 | 6.98 |

| 100 x 50 x 8 | 0.292 | 9.16 |

| 100 x 50 x 10 | 0.292 | 11.3 |

| 100 x 65 x 7 | 0.321 | 8.96 |

| 100 x 65 x 8 | 0.321 | 10.2 |

| 100 x 65 x 9 | 0.321 | 11.3 |

| 100 x 65 x 10 | 0.321 | 12.5 |

| 100 x 75 x 7 | 0.341 | 9.52 |

| 100 x 75 x 8 | 0.341 | 10.8 |

| 100 x 75 x 9 | 0.341 | 12.1 |

| 100 x 75 x 10 | 0.341 | 13.3 |

| 100 x 75 x 11 | 0.341 | 14.6 |

| 100 x 75 x 12 | 0.341 | 15.8 |

| 120 x 80 x 8 | 0.391 | 12.4 |

| 120 x 80 x 10 | 0.391 | 15.3 |

| 120 x 80 x 12 | 0.391 | 18.2 |

| 130 x 65 x 8 | 0.381 | 12.1 |

| 130 x 65 x 10 | 0.381 | 14.9 |

| 130 x 65 x 12 | 0.381 | 17.7 |

| 130 x 75 x 8 | 0.401 | 12.7 |

| 130 x 75 x 10 | 0.401 | 15.7 |

| 130 x 75 x 12 | 0.401 | 18.6 |

| 130 x 90 x 10 | 0.43 | 17 |

| 130 x 90 x 12 | 0.43 | 20.1 |

| 150 x 75 x 9 | 0.441 | 15.7 |

| 150 x 75 x 10 | 0.441 | 17.4 |

| 150 x 75 x 11 | 0.441 | 18.9 |

| 150 x 75 x 12 | 0.441 | 20.6 |

| 150 x 90 x 10 | 0.47 | 18.6 |

| 150 x 90 x 12 | 0.47 | 22 |

| 150 x 90 x 15 | 0.47 | 27.1 |

| 150 x100 x 10 | 0.489 | 19.3 |

| 150 x100 x 12 | 0.489 | 23 |

| 150 x100 x 14 | 0.489 | 26.6 |

| 160 x 80 x 10 | 0.469 | 18.5 |

| 160 x 80 x 12 | 0.469 | 22 |

| 160 x 80 x 14 | 0.469 | 25.4 |

| 200 x100 x 10 | 0.587 | 23.4 |

| 200 x100 x 12 | 0.587 | 27.8 |

| 200 x100 x 15 | 0.587 | 34.4 |

American RSA Steel Angles (AISC)

Equal RSA Steel Angles

Dimensions of RSA equal steel angles per AISC 360/A6 (dimensions in inches):

| Size | Leg (in) | Thickness (in) | Area (in²) | Weight (lb/ft) | Ix (in⁴) |

|---|---|---|---|---|---|

| 12 x 12 | 12 | 1 3/8 | 30.9 | 105 | 410.0 |

| 12 x 12 | 12 | 1 1/4 | 28.3 | 96.4 | 377.5 |

| 12 x 12 | 12 | 1 1/8 | 25.6 | 87.2 | 344.1 |

| 12 x 12 | 12 | 1 | 22.9 | 77.8 | 310.4 |

| 10 x 10 | 10 | 1 3/8 | 25.6 | 87.1 | 232.1 |

| 10 x 10 | 10 | 1 1/4 | 23.5 | 79.9 | 215.1 |

| 10 x 10 | 10 | 1 1/8 | 21.2 | 72.3 | 196.2 |

| 10 x 10 | 10 | 1 | 19.0 | 64.7 | 177.3 |

| 10 x 10 | 10 | 7/8 | 16.7 | 56.9 | 157.6 |

| 10 x 10 | 10 | 3/4 | 14.4 | 49.1 | 137.2 |

| 8 x 8 | 8 | 1 1/8 | 16.7 | 56.9 | 98.0 |

| 8 x 8 | 8 | 1 | 15.0 | 51.0 | 89.0 |

| 8 x 8 | 8 | 7/8 | 13.2 | 45.0 | 79.6 |

| 8 x 8 | 8 | 3/4 | 11.4 | 38.9 | 69.7 |

| 8 x 8 | 8 | 5/8 | 9.6 | 32.7 | 59.4 |

| 8 x 8 | 8 | 9/16 | 8.7 | 29.6 | 54.1 |

| 8 x 8 | 8 | 1/2 | 7.8 | 26.4 | 48.6 |

| 6 x 6 | 6 | 1 | 11.0 | 37.4 | 35.5 |

| 6 x 6 | 6 | 7/8 | 9.7 | 33.1 | 31.9 |

| 6 x 6 | 6 | 3/4 | 8.4 | 28.7 | 28.2 |

| 6 x 6 | 6 | 5/8 | 7.1 | 24.2 | 24.2 |

| 6 x 6 | 6 | 9/16 | 6.4 | 21.9 | 22.1 |

| 6 x 6 | 6 | 1/2 | 5.8 | 19.6 | 19.9 |

| 6 x 6 | 6 | 7/16 | 5.1 | 17.2 | 17.7 |

| 6 x 6 | 6 | 3/8 | 4.4 | 14.9 | 15.4 |

| 6 x 6 | 6 | 5/16 | 3.7 | 12.4 | 13.0 |

| 5 x 5 | 5 | 7/8 | 8.0 | 27.2 | 17.8 |

| 5 x 5 | 5 | 3/4 | 6.9 | 23.6 | 15.7 |

| 5 x 5 | 5 | 5/8 | 5.9 | 20.0 | 13.6 |

| 5 x 5 | 5 | 1/2 | 4.8 | 16.2 | 11.3 |

| 5 x 5 | 5 | 7/16 | 4.2 | 14.3 | 10.0 |

| 5 x 5 | 5 | 3/8 | 3.6 | 12.3 | 8.74 |

| 5 x 5 | 5 | 5/16 | 3.0 | 10.3 | 7.42 |

| 4 x 4 | 4 | 3/4 | 5.4 | 18.5 | 7.67 |

| 4 x 4 | 4 | 5/8 | 4.6 | 15.7 | 6.66 |

| 4 x 4 | 4 | 1/2 | 3.8 | 12.8 | 5.56 |

| 4 x 4 | 4 | 7/16 | 3.3 | 11.3 | 4.97 |

| 4 x 4 | 4 | 3/8 | 2.9 | 9.8 | 4.36 |

| 4 x 4 | 4 | 5/16 | 2.4 | 8.2 | 3.71 |

| 4 x 4 | 4 | 1/4 | 1.9 | 6.6 | 3.04 |

| 3 1/2 x 3 1/2 | 3 1/2 | 1/2 | 3.3 | 11.1 | 3.64 |

| 3 1/2 x 3 1/2 | 3 1/2 | 7/16 | 2.9 | 9.8 | 3.26 |

| 3 1/2 x 3 1/2 | 3 1/2 | 3/8 | 2.5 | 8.5 | 2.87 |

| 3 1/2 x 3 1/2 | 3 1/2 | 5/16 | 2.1 | 7.2 | 2.45 |

| 3 1/2 x 3 1/2 | 3 1/2 | 1/4 | 1.7 | 5.8 | 2.01 |

| 3 x 3 | 3 | 1/2 | 2.75 | 9.4 | 2.22 |

| 3 x 3 | 3 | 7/16 | 2.43 | 8.3 | 1.99 |

| 3 x 3 | 3 | 3/8 | 2.11 | 7.2 | 1.76 |

| 3 x 3 | 3 | 5/16 | 1.78 | 6.1 | 1.51 |

| 3 x 3 | 3 | 1/4 | 1.44 | 4.9 | 1.24 |

| 3 x 3 | 3 | 3/16 | 1.09 | 3.7 | 0.96 |

| 2 1/2 x 2 1/2 | 2 1/2 | 1/2 | 2.25 | 7.7 | 1.23 |

| 2 1/2 x 2 1/2 | 2 1/2 | 3/8 | 1.73 | 5.9 | 0.98 |

| 2 1/2 x 2 1/2 | 2 1/2 | 5/16 | 1.46 | 5.0 | 0.85 |

| 2 1/2 x 2 1/2 | 2 1/2 | 1/4 | 1.19 | 4.1 | 0.70 |

| 2 1/2 x 2 1/2 | 2 1/2 | 3/16 | 0.90 | 3.1 | 0.55 |

| 2 x 2 | 2 | 3/8 | 1.36 | 4.7 | 0.48 |

| 2 x 2 | 2 | 5/16 | 1.15 | 3.9 | 0.42 |

| 2 x 2 | 2 | 1/4 | 0.94 | 3.2 | 0.35 |

| 2 x 2 | 2 | 3/16 | 0.72 | 2.4 | 0.27 |

| 2 x 2 | 2 | 1/8 | 0.48 | 1.7 | 0.19 |

Unequal RSA Steel Angles

Dimensions of RSA unequal steel angles per AISC 360/A6 (dimensions in inches):

| RSA Size | Depth (in) | Width (in) | Thickness (in) | Sectional Area (in) | Weight (lb/ft) | Moment of Inertia - I (in4) | Section of Modulus - Sx (in3) |

|---|---|---|---|---|---|---|---|

| L9 x 4 x 5/8 | 9 | 4 | 0.625 | 7.73 | 26.3 | 64.9 | 11.5 |

| L9 x 4 x 9/16 | 9 | 4 | 0.563 | 7 | 23.8 | 59.1 | 10.4 |

| L9 x 4 x 1/2 | 9 | 4 | 0.5 | 6.25 | 21.3 | 53.2 | 9.34 |

| L8 x 6 x 1 | 8 | 6 | 1 | 13 | 44.2 | 80.8 | 15.1 |

| L8 x 6 x 7/8 | 8 | 6 | 0.875 | 11.5 | 39.1 | 72.3 | 13.4 |

| L8 x 6 x 3/4 | 8 | 6 | 0.75 | 9.94 | 33.8 | 63.4 | 11.7 |

| L8 x 6 x 5/8 | 8 | 6 | 0.625 | 8.36 | 28.5 | 54.1 | 9.87 |

| L8 x 6 x 9/16 | 8 | 6 | 0.563 | 7.56 | 25.76 | 49.3 | 8.95 |

| L8 x 6 x 1/2 | 8 | 6 | 0.5 | 6.75 | 23 | 44.3 | 8.02 |

| L8 x 6 x 7/16 | 8 | 6 | 0.438 | 5.93 | 20.2 | 39.2 | 7.1 |

| L8 x 4 x 1 | 8 | 4 | 1 | 11 | 37.4 | 69.6 | 14.1 |

| L8 x 4 x 3/4 | 8 | 4 | 0.75 | 8.44 | 28.7 | 54.9 | 10.9 |

| L8 x 4 x 9/16 | 8 | 4 | 0.563 | 6.43 | 21.9 | 42.8 | 8.35 |

| L8 x 4 x 1/2 | 8 | 4 | 0.5 | 5.75 | 19.6 | 38.5 | 7.49 |

| L7 x 4 x 3/4 | 7 | 4 | 0.75 | 7.69 | 26.2 | 37.8 | 8.42 |

| L7 x 4 x 5/8 | 7 | 4 | 0.625 | 6.48 | 22.1 | 32.4 | 7.14 |

| L7 x 4 x 1/2 | 7 | 4 | 0.5 | 5.25 | 17.9 | 26.7 | 5.81 |

| L7 x 4 x 3/8 | 7 | 4 | 0.375 | 3.98 | 13.6 | 20.6 | 4.44 |

| L6 x 4 x 7/8 | 6 | 4 | 0.875 | 7.98 | 27.2 | 27.7 | 7.15 |

| L6 x 4 x 3/4 | 6 | 4 | 0.75 | 6.94 | 23.6 | 24.5 | 6.25 |

| L6 x 4 x 5/8 | 6 | 4 | 0.625 | 5.86 | 20 | 21.1 | 5.31 |

| L6 x 4 x 9/16 | 6 | 4 | 0.563 | 5.31 | 18.1 | 19.3 | 4.83 |

| L6 x 4 x 1/2 | 6 | 4 | 0.5 | 4.75 | 16.2 | 17.4 | 4.33 |

| L6 x 4 x 7/16 | 6 | 4 | 0.368 | 4.18 | 14.3 | 15.5 | 3.83 |

| L6 x 4 x 3/8 | 6 | 4 | 0.375 | 3.61 | 12.3 | 13.5 | 3.32 |

| L6 x 4 x 5/16 | 6 | 4 | 0.313 | 3.03 | 10.3 | 11.4 | 2.79 |

| L6 x 3 1/2 x 1/2 | 6 | 3.5 | 0.5 | 4.5 | 15.3 | 16.6 | 4.24 |

| L6 x 3 1/2 x 3/8 | 6 | 3.5 | 0.375 | 3.42 | 11.7 | 12.9 | 3.24 |

| L6 x 3 1/2 x 5/16 | 6 | 3.5 | 0.313 | 2.87 | 9.8 | 10.9 | 2.73 |

| L5 x 3 1/2 x 3/4 | 5 | 3.5 | 0.75 | 5.81 | 19.8 | 13.9 | 4.28 |

| L5 x 3 1/2 x 5/8 | 5 | 3.5 | 0.625 | 4.92 | 16.8 | 12 | 3.65 |

| L5 x 3 1/2 x 1/2 | 5 | 3.5 | 0.5 | 4 | 13.6 | 10 | 2.99 |

| L5 x 3 1/2 x 7/16 | 5 | 3.5 | 0.438 | 3.53 | 12 | 8.9 | 2.64 |

| L5 x 3 1/2 x 3/8 | 5 | 3.5 | 0.375 | 3.05 | 10.4 | 7.78 | 2.29 |

| L5 x 3 1/2 x 5/16 | 5 | 3.5 | 0.313 | 2.56 | 8.7 | 6.6 | 1.94 |

| L5 x 3 1/2 x 1/4 | 5 | 3.5 | 0.25 | 2.06 | 7 | 5.39 | 1.57 |

| L5 x 3 x 5/8 | 5 | 3 | 0.625 | 4.61 | 15.7 | 11.4 | 3.55 |

| L5 x 3 x 1/2 | 5 | 3 | 0.5 | 3.75 | 12.8 | 9.45 | 2.91 |

| L5 x 3 x 7/16 | 5 | 3 | 0.438 | 3.31 | 11.3 | 8.43 | 2.58 |

| L5 x 3 x 3/8 | 5 | 3 | 0.375 | 2.86 | 9.8 | 7.37 | 2.24 |

| L5 x 3 x 5/16 | 5 | 3 | 0.313 | 2.4 | 8.2 | 6.26 | 1.89 |

| L5 x 3 x 1/4 | 5 | 3 | 0.25 | 1.94 | 6.6 | 5.11 | 1.53 |

| L4 x 3 1/2 x 5/8 | 4 | 3 | 0.625 | 4.3 | 14.7 | 6.37 | 2.35 |

| L4 x 3 1/2 x 1/2 | 4 | 3 | 0.5 | 3.5 | 11.9 | 5.32 | 1.94 |

| L4 x 3 1/2 x 7/16 | 4 | 3 | 0.438 | 3.09 | 10.6 | 4.76 | 1.72 |

| L4 x 3 1/2 x 3/8 | 4 | 3 | 0.375 | 2.67 | 9.1 | 4.18 | 1.49 |

| L4 x 3 1/2 x 5/16 | 4 | 3 | 0.313 | 2.25 | 7.7 | 3.56 | 1.26 |

| L4 x 3 1/2 x 1/4 | 4 | 3 | 0.25 | 1.81 | 6.2 | 2.91 | 1.03 |

| L4 x 3 x 5/8 | 4 | 3 | 0.625 | 3.98 | 13.6 | 6.03 | 2.3 |

| L4 x 3 x 1/2 | 4 | 3 | 0.5 | 3.25 | 11.1 | 5.05 | 1.89 |

| L4 x 3 x 7/16 | 4 | 3 | 0.438 | 2.87 | 9.8 | 4.52 | 1.68 |

| L4 x 3 x 3/8 | 4 | 3 | 0.375 | 2.48 | 8.5 | 3.96 | 1.46 |

| L4 x 3 x 5/16 | 4 | 3 | 0.313 | 2.09 | 7.2 | 3.38 | 1.23 |

| L4 x 3 x 1/4 | 4 | 3 | 0.25 | 1.69 | 5.8 | 2.77 | 1 |

| L3 1/2 x 3 x 1/2 | 3.5 | 3 | 0.5 | 3 | 10.2 | 3.45 | 1.45 |

| L3 1/2 x 3 x 7/16 | 3.5 | 3 | 0.438 | 2.65 | 9.1 | 3.1 | 1.29 |

| L3 1/2 x 3 x 3/8 | 3.5 | 3 | 0.375 | 2.3 | 7.9 | 2.72 | 1.13 |

| L3 1/2 x 3 x 5/16 | 3.5 | 3 | 0.313 | 1.93 | 6.6 | 2.33 | 0.95 |

| L3 1/2 x 3 x 1/4 | 3.5 | 3 | 0.25 | 1.56 | 5.4 | 1.91 | 0.78 |

| L3 1/2 x 2 1/2 x 1/2 | 3.5 | 2.5 | 0.5 | 2.75 | 9.4 | 3.24 | 1.41 |

| L3 1/2 x 2 1/2 x 7/16 | 3.5 | 2.5 | 0.438 | 2.43 | 8.3 | 2.91 | 1.26 |

| L3 1/2 x 2 1/2 x 3/8 | 3.5 | 2.5 | 0.375 | 2.11 | 7.2 | 2.56 | 1.09 |

| L3 1/2 x 2 1/2 x 5/16 | 3.5 | 2.5 | 0.313 | 1.78 | 6.1 | 2.19 | 0.93 |

| L3 1/2 x 2 1/2 x 1/4 | 3.5 | 2.5 | 0.25 | 1.44 | 4.9 | 1.8 | 0.76 |

| L3 x 2 1/2 x 1/2 | 3 | 2.5 | 0.5 | 2.5 | 8.5 | 2.08 | 1.04 |

| L3 x 2 1/2 x 7/16 | 3 | 2.5 | 0.438 | 2.21 | 7.6 | 1.88 | 0.93 |

| L3 x 2 1/2 x 3/8 | 3 | 2.5 | 0.375 | 1.92 | 6.6 | 1.66 | 0.81 |

| L3 x 2 1/2 x 5/16 | 3 | 2.5 | 0.313 | 1.62 | 5.6 | 1.42 | 0.69 |

| L3 x 2 1/2 x 1/4 | 3 | 2.5 | 0.25 | 1.31 | 4.5 | 1.17 | 0.56 |

| L3 x 2 1/2 x 3/16 | 3 | 2.5 | 0.188 | 1 | 3.39 | 0.91 | 0.43 |

| L3 x 2 x 1/2 | 3 | 2 | 0.5 | 2.25 | 7.7 | 1.92 | 1 |

| L3 x 2 x 7/16 | 3 | 2 | 0.438 | 2 | 6.8 | 1.73 | 0.89 |

| L3 x 2 x 3/8 | 3 | 2 | 0.375 | 1.73 | 5.9 | 1.53 | 0.78 |

| L3 x 2 x 5/16 | 3 | 2 | 0.313 | 1.46 | 5 | 1.32 | 0.66 |

| L3 x 2 x 1/4 | 3 | 2 | 0.25 | 1.19 | 4.1 | 1.09 | 0.54 |

| L3 x 2 x 3/16 | 3 | 2 | 0.188 | 0.9 | 3.1 | 0.84 | 0.42 |

| L2 1/2 x 2 x 3/8 | 2.5 | 2 | 0.375 | 1.55 | 5.3 | 0.91 | 0.55 |

| L2 1/2 x 2 x 5/16 | 2.5 | 2 | 0.313 | 1.31 | 4.5 | 0.79 | 0.47 |

| L2 1/2 x 2 x 1/4 | 2.5 | 2 | 0.25 | 1.06 | 3.62 | 0.65 | 0.38 |

| L2 1/2 x 2 x 3/16 | 2.5 | 2 | 0.188 | 0.81 | 2.75 | 0.51 | 0.29 |

| L2 1/2 x 1 1/2 x 5/16 | 2.5 | 1.5 | 0.313 | 3.92 | |||

| L2 1/2 x 1 1/2 x 1/4 | 2.5 | 1.5 | 0.25 | 0.938 | 3.19 | ||

| L2 1/2 x 1 1/2 x 3/16 | 2.5 | 1.5 | 0.1875 | 0.715 | 2.44 | ||

| L2 x 1 1/2 x 1/4 | 2 | 1.5 | 0.25 | 0.813 | 2.77 | ||

| L2 x 1 1/2 x 3/16 | 2 | 1.5 | 0.1875 | 0.621 | 2.12 | ||

| L2 x 1 1/2 x 1/8 | 2 | 1.5 | 0.125 | 0.422 | 1.44 | ||

| L2 x 1 1/4 x 1/4 | 2 | 1.25 | 0.25 | 2.55 | |||

| L2 x 1 1/4 x 3/16 | 2 | 1.25 | 0.1875 | 1.96 | |||

| L1 3/4 x 1 1/4 x 1/4 | 1.75 | 1.25 | 0.25 | 2.34 | |||

| L1 3/4 x 1 1/4 x 3/16 | 1.75 | 1.25 | 0.1875 | 1.8 | |||

| L1 3/4 x 1 1/4 x 1/8 | 1.75 | 1.25 | 0.125 | 1.23 | |||

| L1 1/2 x 1 1/4 x 3/16 | 1.5 | 1.25 | 0.1875 | 1.64 | |||

| L1 3/8 x 7/8 x 3/16 | 1.375 | 0.875 | 0.1875 | 1.32 | |||

| L1 3/8 x 7/8 x 1/8 | 1.375 | 0.875 | 0.125 | 0.91 | |||

| L1 x 3/4 x 1/8 | 1 | 0.75 | 0.125 | 0.7 | |||

| L1 x 5/8 x 1/8 | 1 | 0.625 | 0.125 | 0.64 |

Leave a Comment

Have a question or feedback? Send us a message.

Previous Comments

RFQ# FW: GTG RFQ – TEC-25-004 -110608 S/N Item Description Qty Unit 1 650000300006 "Shape HEB-100; Material ASTM A36 Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 40 & 41 / Type-1 DETAIL B) & (SHEET: 44 & 45/ Type- 1)" 24 "Mètre linéaire linear meter" 2 650000300007 "Shape L-50 x 5 x 5; Material ASTM A36 Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 52 & 53 / Type-3)" 24 "Mètre linéaire linear meter" 3 650000300008 "Plate 10THK 10MM; Material ASTM A36, size (L2000x1000x10 mm) Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 44 & 45 / Type-1) & (SHEET: 52 & 53 / Type-3) & (SHEET: 07 / Type-3) & (SHEET: 99 / Type-2)" 4 "Mètre linéaire linear meter" 4 650000300009 "Plate THK 15MM; Material ASTM A36, (L2000x1000x15 mm); Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 104)" 2 "Mètre linéaire linear meter" 5 650000300010 "Plate THK 6MM; Material ASTM A36 , (L2000x1000x 6 mm); Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 99 / Type-2)" 2 "Mètre linéaire linear meter" 6 650000300011 "Flat Bare 60MM X 6MM; Material ASTM A36;Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 98)" 40 Mètre linéaire 7 650000300012 "Flat Bare – 60MM X 8MM; Material ASTM A36 Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 07 / Type-3)" 20 "Mètre linéaire linear meter" 8 650000300013 "Flat Bare 80MM X 10MM; Material ASTM A36; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 07 / Type-3)" 20 "Mètre linéaire linear meter" 9 650000300014 "Sheet Neoprene: Sheet THK 1MM; Material Neoprene; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 52 & 07 / Type-3)" 2 "Mètre linéaire linear meter" 10 650000300015 "Sheet Neoprene: Sheet THK 3MM; Material Neoprene; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 114 / Type-1 Detail-A) & (SHEET: 98)" 2 "Mètre linéaire linear meter" 11 235000100888 "Bolt: 6″" U-Bolt; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 114 / Type-1)" 10 "Mètre linéaire linear meter" 12 235000100889 "Bolt: 6″" U-Bolt Galvanized; Material CS; Ref: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 114 / Type-1 Detail-A)" 18 "Mètre linéaire linear meter" 13 235000100890 "Bolt: Welded Anchor Bolts 6 x 515MM; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 104);" 50 "Mètre linéaire linear meter" 14 235000100891 "Bolt: Fastening Bolt – M12 X 95MM; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 98); Remark: With 2 Nuts and 2 Washers" 100 "Mètre linéaire linear meter" 15 235000100892 "Bolt: Mechanical Bolts – M20 X 60MM;Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 07 / Type-3); Remark: With Nuts" 80 "Mètre linéaire linear meter" 16 235000100893 "Screw: Screw – M16 X 60MM; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 98); Remark: With Nuts and Locknut" 180 "Mètre linéaire linear meter" 17 235000100894 "Eye Nut: Eye Nut for M12 Rod; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 99 / Type-1)" 180 "Mètre linéaire linear meter" 18 235000100895 "Rod: M-12 Rod; Material CS; Ref Doc: FAC10005-TRE-000-PIP-STD-0200 (SHEET: 35 / Type-1)" 100 "Mètre linéaire linear meter"