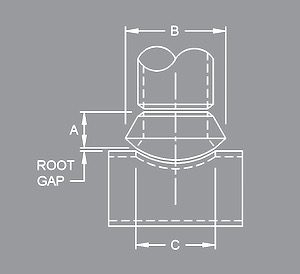

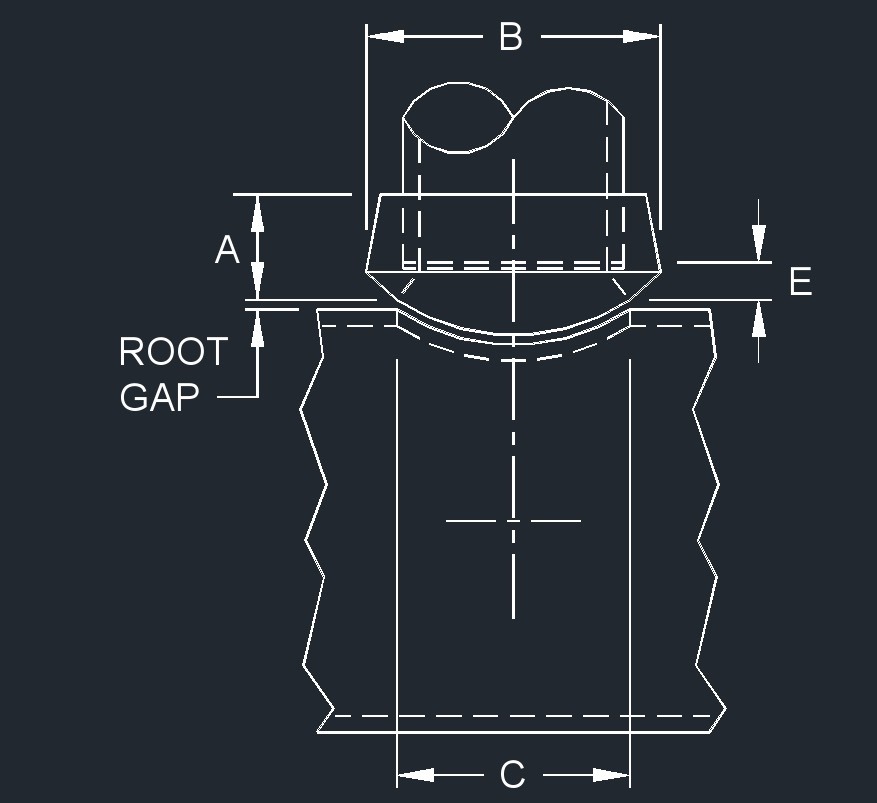

Weldolet dimensions and weights charts (showing “center of the run to Weldolet face”, “size-on-size” and “reducing” Weldolets sizes by NPS and schedule, and “run sizes combinations”), as well as the sizes of Sockolets.

WELDOLET DIMENSIONS & WEIGHTS

CENTER OF RUN-TO-FACE SIZES

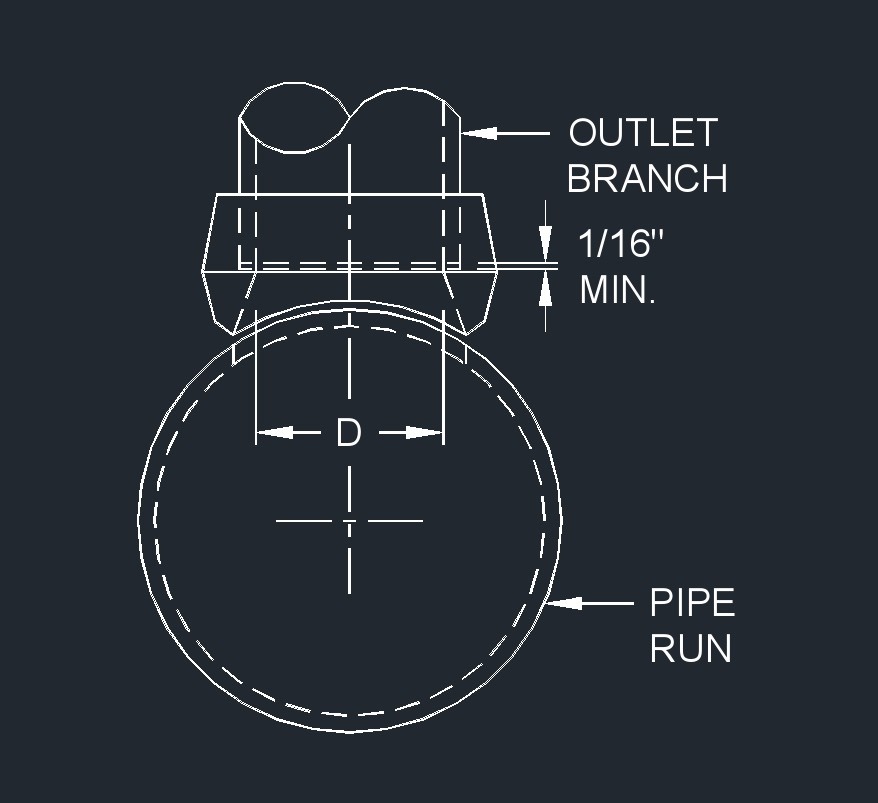

The distance between the run pipe center line and the Weldolet top-bore in mm (by pipe NPS/Schedule and Weldolet size):

| RUN PIPE NPS | RUN PIPE SCHEDULE | WELDOLET DIMENSIONS | |||||||||||

| SIZE | SCH. | 2″ | 3″ | 4″ | 6″ | 8″ | 10″ | 12″ | 14″ | 16″ | 18″ | 20″ | 24″ |

| 2″ | STD-40 XS-80 | 70 | |||||||||||

| XXS-160 | 87 | ||||||||||||

| 3″ | STD-40 XS-80 | 84 | 91 | ||||||||||

| XXS-160 | 101 | 119 | |||||||||||

| 4″ | STD-40 XS-80 | 97 | 103 | 111 | |||||||||

| XXS-160 | 114 | 132 | 144 | ||||||||||

| STD-40 | 124 | 130 | 138 | 148 | |||||||||

| 6″ | XS-80 | 124 | 130 | 138 | 165 | ||||||||

| XXS-160 | 141 | 159 | 171 | 192 | |||||||||

| STD-40 | 149 | 156 | 164 | 176 | 183 | ||||||||

| 8″ | XS-80 | 149 | 156 | 164 | 191 | 197 | |||||||

| XXS-160 | 167 | 184 | 197 | 218 | 224 | ||||||||

| STD-40 | 176 | 183 | 191 | 205 | 210 | 218 | |||||||

| 10″ | XS-80 | 176 | 183 | 191 | 218 | 238 | 235 | ||||||

| XXS-160 | 194 | 211 | 224 | 245 | 251 | 265 | |||||||

| STD | 202 | 208 | 216 | 228 | 255 | 245 | 251 | ||||||

| 12″ | XS | 202 | 208 | 216 | 243 | 264 | 267 | 265 | |||||

| XXS-160 | 219 | 237 | 249 | 270 | 276 | 291 | 324 | ||||||

| 14″ | STD | 218 | 224 | 232 | 245 | 251 | 259 | 267 | 270 | ||||

| XS | 218 | 224 | 231 | 239 | 279 | 270 | 278 | 286 | |||||

| 16″ | STD | 243 | 249 | 257 | 270 | 276 | 284 | 292 | 295 | 300 | |||

| XS | 243 | 249 | 257 | 284 | 305 | 293 | 303 | 306 | 319 | ||||

| 18″ | STD | 268 | 275 | 283 | 295 | 302 | 310 | 318 | 321 | 325 | 335 | ||

| XS | 268 | 275 | 283 | 310 | 330 | 321 | 329 | 332 | 338 | 352 | |||

| 20″ | STD | 294 | 300 | 308 | 321 | 327 | 335 | 343 | 346 | 351 | 356 | 376 | |

| XS | 294 | 300 | 308 | 335 | 356 | 346 | 354 | 557 | 364 | 370 | 386 | ||

| 24″ | STD | 345 | 351 | 359 | 372 | 378 | 386 | 394 | 397 | 402 | 406 | 411 | 446 |

| XS | 345 | 351 | 359 | 386 | 406 | 397 | 405 | 408 | 414 | 421 | 429 | 449 | |

WELDOLET DIMENSIONS & WEIGTHS

Size-on-Size Weldolet Schedule 40

Sizes in inches, weights in pounds

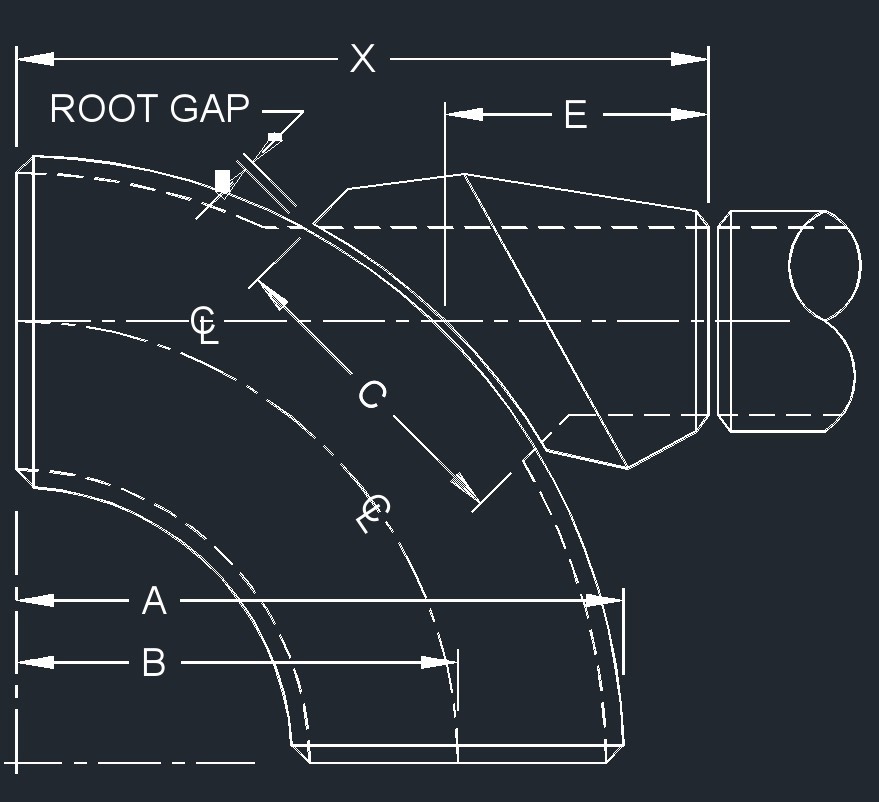

| Weldolet Size (inches) | A | B | C | D | Weldolet weight in lbs |

| 1/2 | 3/4 | 1 3/8 | 15/16 | 5/8 | 0.15 |

| 3/4 | 7/8 | 1 5/8 | 1 3/16 | 13/16 | 0.25 |

| 1 | 1 1/16 | 2 | 1 7/16 | 1 1/32 | 0.4 |

| 1 1/4 | 1 1/4 | 2 3/8 | 1 3/4 | 1 3/8 | 0.7 |

| 1 1/2 | 1 5/16 | 2 7/8 | 2 | 1 5/8 | 0.8 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 2 1/16 | 1.5 |

| 2 1/2 | 1 5/8 | 4 1/6 | 3 | 2 7/16 | 2.25 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 3 1/16 | 3.75 |

| 3 1/2 | 2 | 5 3/8 | 3 7/8 | 3 9/16 | 5 |

| 4 | 2 | 6 | 4 3/4 | 4 | 6.7 |

| 5 | 2 1/4 | 7 1/8 | 5 9/16 | 5 1/16 | 8.5 |

| 6 | 2 3/8 | 8 1/2 | 6 11/16 | 6 1/16 | 14 |

| 8 | 2 3/4 | 10 3/8 | 8 11/16 | 7 15/16 | 28 |

| 10 | 3 1/16 | 12 9/16 | 10 13/16 | 10 | 39 |

| 12 | 3 3/8 | 14 7/8 | 12 13/16 | 12 | 65 |

| 14 | 3 1/2 | 16 1/8 | 14 1/16 | 13 1/4 | 70 |

| 16 | 3 11/16 | 18 1/4 | 16 1/16 | 15 1/4 | 92 |

| 18 | 4 1/16 | 20 3/4 | 18 5/8 | 17 1/4 | 125 |

| 20 | 4 5/8 | 23 1/16 | 20 1/16 | 19 1/4 | 175 |

| 24 | 5 3/8 | 27 7/8 | 25 1/8 | 23 1/4 | 280 |

| 30 | 5 3/8 | 34 1/16 | 30 7/16 | 29 1/4 | 440 |

| 36 | 5 3/8 | 34 1/16 | 36 1/2 | 35 1/4 | 1180 |

Size-on-Size Weldolet Schedule XS

Sizes in inches, weights in pounds

| Weldolet Size (inches) | A | B | C | D | Weldolet weight in lbs |

| 1/2 | 3/4 | 1.375 | 15/16 | 5/8 | 0.15 |

| 3/4 | 7/8 | 1.625 | 1.1875 | 13/16 | 0.25 |

| 1 | 1.0625 | 2 | 1.4375 | 1.03125 | 0.4 |

| 1 1/14 | 1.25 | 2.4375 | 1.75 | 1.375 | 0.7 |

| 1.5 | 1.3125 | 2.875 | 2 | 1.625 | 0.9 |

| 2 | 1.5 | 3.5 | 2.5625 | 2.0625 | 1.6 |

| 2 1/2 | 1.625 | 4.0625 | 3 | 2.4375 | 2.5 |

| 3 | 1.75 | 4.8125 | 3.6875 | 3.0625 | 4.1 |

| 3 1/2 | 2 | 5.375 | 3.875 | 3.5625 | 5.1 |

| 4 | 2 | 6 | 4.75 | 4 | 7.5 |

| 5 | 2.25 | 7.125 | 5.5625 | 5.0625 | 9.5 |

| 6 | 3.0625 | 8.875 | 6.6875 | 6.0625 | 15 |

| 8 | 3.875 | 10.625 | 8.6875 | 7.625 | 32 |

| 10 | 3.5 | 12.875 | 10.4375 | 9.75 | 46 |

| 12 | 3.9375 | 15.1875 | 13 | 11.75 | 61 |

| 14 | 4.125 | 16.6875 | 14.3125 | 13 | 75 |

| 16 | 4.4375 | 18.875 | 16.5 | 15 | 115 |

| 18 | 4.6875 | 21.125 | 18.625 | 17 | 130 |

| 20 | 5 | 23.375 | 20.8125 | 19 | 187 |

| 24 | 5.5 | 27.875 | 25.125 | 23 | 316 |

| 26 | 5.75 | 30.125 | 27.25 | 25 | 370 |

Size-on-Size Weldolet Schedule 160/XXS

Sizes in inches, weights in pounds

| Weldolet Size (inches) | A | B | C | Weldolet weight in lbs |

| 1/2 | 1 1/8 | 1 3/8 | 9/16 | 0.25 |

| 3/4 | 1 1/4 | 1 3/4 | 3/4 | 0.70 |

| 1 | 1 1/2 | 2 | 1 | 0.80 |

| 1 1/4 | 1 3/4 | 2 7/16 | 1 5/16 | 1.25 |

| 1 1/2 | 2 | 2 3/4 | 1 1/2 | 1.75 |

| 2 | 2 3/16 | 3 3/16 | 1 11/16 | 2.15 |

| 2 1/2 | 2 7/16 | 3 13/16 | 2 1/8 | 3.40 |

| 3 | 2 7/8 | 4 3/4 | 2 7/8 | 6.35 |

| 4 | 3 5/16 | 6 | 3 7/8 | 10.50 |

| 5 | 3 11/16 | 7 3/8 | 4 13/16 | 14.25 |

| 6 | 4 1/8 | 8 11/16 | 5 3/4 | 30.25 |

Reducing Weldolet Schedule 40

Sizes in inches, weights in pounds

| Weldolet Size (inches) | A | B | C | Weldolet weight in lbs |

| 1/8 | 5/8 | 1 | 5/8 | 0.10 |

| 1/4 | 5/8 | 1 | 5/8 | 0.10 |

| 3/8 | 3/4 | 1 1/4 | 3/4 | 0.15 |

| 1/2 | 3/4 | 1 3/8 | 15/16 | 0.20 |

| 3/4 | 7/8 | 1 3/4 | 1 3/16 | 0.25 |

| 1 | 1 1/16 | 2 1/8 | 1 7/16 | 0.50 |

| 1 1/4 | 1 1/4 | 2 9/16 | 1 3/4 | 0.80 |

| 1 1/2 | 1 5/16 | 2 7/8 | 2 | 1.00 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 1.75 |

| 2 1/2 | 1 5/8 | 4 1/16 | 3 | 2.50 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 4.00 |

| 3 1/2 | 1 7/8 | 5 1/4 | 4 | 5.50 |

| 4 | 2 | 6 | 4 3/4 | 6.30 |

| 5 | 2 1/4 | 7 1/16 | 5 9/16 | 10.25 |

| 6 | 2 3/8 | 8 3/16 | 6 11/16 | 12.00 |

| 8 | 2 3/4 | 10 1/4 | 8 11/16 | 23.00 |

| 10 | 3 1/16 | 12 11/16 | 10 13/16 | 36.00 |

| 12 | 3 3/8 | 14 7/8 | 12 13/16 | 59.00 |

| 14 | 3 1/2 | 16 9/16 | 14 1/16 | 66.00 |

| 16 | 3 11/16 | 18 1/4 | 16 1/16 | 75.00 |

| 18 | 3 13/16 | 21 1/16 | 18 1/16 | 97.00 |

| 20 | 4 | 23 3/16 | 20 | 118.00 |

| 24 | 4 9/16 | 27 3/4 | 24 3/16 | 220.00 |

| 26 | 4 11/16 | 29 7/8 | 26 1/4 | 265.00 |

| 30 | 5 3/8 | 34 1/2 | 30 7/16 | 430.00 |

| 36 | 5 3/8 | 40 1/2 | 36 1/2 | 900.00 |

Reducing Weldolet Schedule XS

Sizes in inches, weights in pounds

| Weldolet Size (inches) | A | B | C | Weldolet weight in lbs |

| 1/8 | 5/8 | 1 | 5/8 | 0.10 |

| 1/4 | 5/8 | 1 | 5/8 | 0.10 |

| 3/8 | 3/4 | 1 1/4 | 3/4 | 0.15 |

| 1/2 | 3/4 | 1 3/8 | 15/16 | 0.20 |

| 3/4 | 7/8 | 1 3/4 | 1 3/16 | 0.30 |

| 1 | 1 1/16 | 2 1/8 | 1 7/16 | 0.50 |

| 1 1/4 | 1 1/4 | 2 9/16 | 1 3/4 | 0.90 |

| 1 1/2 | 1 5/16 | 2 7/8 | 2 | 1.10 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 1.75 |

| 2 1/2 | 1 5/8 | 4 1/16 | 3 | 2.60 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 4.10 |

| 3 1/2 | 1 7/8 | 5 1/4 | 4 | 5.60 |

| 4 | 2 | 6 | 4 3/4 | 6.40 |

| 5 | 2 1/4 | 7 1/16 | 5 9/16 | 10.40 |

| 6 | 3 1/16 | 8 5/16 | 6 11/16 | 23.00 |

| 8 | 3 7/8 | 11 1/2 | 8 11/16 | 37.00 |

| 10 | 3 11/16 | 13 3/16 | 10 7/16 | 46.00 |

| 12 | 4 1/16 | 15 5/8 | 12 1/2 | 61.00 |

| 14 | 3 15/16 | 16 | 13 13/16 | 70.00 |

| 16 | 4 3/16 | 18 3/8 | 15 7/8 | 102.00 |

| 18 | 4 3/8 | 20 3/8 | 17 15/16 | 130.00 |

| 20 | 4 11/16 | 22 15/16 | 20 1/16 | 158.00 |

| 24 | 5 1/2 | 28 1/2 | 24 3/16 | 290.00 |

| 26 | 5 3/4 | 30 1/8 | 27 1/4 | 350.00 |

Reducing Weldolet Schedule 160/XXS

Sizes in inches, weights in pounds

| Weldolet Size (inches) | A | B | C | Weldolet weight in lbs |

| 1/2 | 1 1/8 | 1 3/8 | 9/16 | 0.25 |

| 3/4 | 1 1/4 | 1 3/4 | 3/4 | 0.70 |

| 1 | 1 1/2 | 2 | 1 | 0.85 |

| 1 1/4 | 1 3/4 | 2 7/16 | 1 5/16 | 1.25 |

| 1 1/2 | 2 | 2 3/4 | 1 1/2 | 1.75 |

| 2 | 2 3/16 | 3 3/16 | 1 11/16 | 2.15 |

| 2 1/2 | 2 7/16 | 3 13/16 | 2 1/8 | 3.40 |

| 3 | 2 7/8 | 4 3/4 | 2 7/8 | 6.30 |

| 4 | 3 5/16 | 6 | 3 7/8 | 10.50 |

| 5 | 3 11/16 | 7 3/8 | 4 13/16 | 14.25 |

| 6 | 4 1/8 | 9 5/16 | 5 3/4 | 28.00 |

HEAVY-WALL WELDOLETS SIZES

| Run WT | 3/4 | 1 | 1 1/4 | 1 1/2 | 1 3/4 | 2 | 2 1/4 | 2 3/4 | 3 | |||||||||

| Run Size | A | C | A | C | A | C | A | C | A | C | A | C | A | C | A | C | A | C |

| 3 | 2 7/8 | 2.906 | 3 7/32 | 2.900 | 3 3/8 | 2.906 | 3 5/8 | 2.900 | 4 1/8 | 2.900 | 4 9/16 | 2.900 | 5 | 2.900 | 5 7/8 | 2.900 | 6 1/16 | 2.900 |

| 3 1/2 | 3 1/8 | 3.359 | 3 1/4 | 3.359 | 3 7/16 | 3 359 | 3 3/4 | 3.359 | 4 3/16 | 3.359 | 4 5/8 | 3.359 | 5 1/16 | 3.359 | 6 | 3.359 | 6 5/16 | 3.359 |

| 4 | 3 5/16 | 3.843 | 3 3/8 | 3.826 | 3 1/2 | 3.828 | 3 7/8 | 3.826 | 4 3/4 | 3.826 | 4 3/4 | 3.826 | 5 3/16 | 3.826 | 6 1/8 | 3.826 | 6 9/16 | 3.826 |

| 5 | 3 3/4 | 4.812 | 3 3/4 | 4.812 | 4 | 4.812 | 4 1/4 | 4.812 | 4 3/4 | 4.812 | 5 1/4 | 4.812 | 5 3/4 | 4.812 | 6 5/8 | 4.812 | 7 3/16 | 4.812 |

| 6 | 4 1/8 | 5.750 | 4 11/32 | 5.761 | 4 1/2 | 5.760 | 4 11/16 | 5.760 | 5 1/4 | 5.760 | 5 3/4 | 5.760 | 6 1/4 | 5.760 | 7 1/4 | 5.760 | 7 13/16 | 5.760 |

| 8 | 4 3/16 | 7.625 | 4 5/8 | 7.625 | 4 7/8 | 7.625 | 5 5/32 | 7.625 | 5 3/4 | 7.625 | 6 11/32 | 7.625 | 6 15/16 | 7.625 | 8 3/32 | 7.625 | 8 11/16 | 7.625 |

| 10 | 4 1/4 | 9.750 | 4 27/32 | 9.750 | 5 | 9.562 | 5 5/16 | 9.562 | 5 15/16 | 9.562 | 6 9/16 | 9.562 | 7 3/16 | 9.562 | 8 7/16 | 9.562 | 9 1/16 | 9.562 |

| 12 | 4 3/8 | 11.750 | 5 3/32 | 11.750 | 5 3/8 | 11.375 | 5 11/16 | 11.375 | 6 5/16 | 11.375 | 6 15/16 | 11.375 | 7 9/16 | 11.375 | 8 13/16 | 11.375 | 9 7/16 | 11.375 |

| 14 | 4 1/2 | 13 | 5 1/4 | 13 | 5 1/2 | 12.500 | 5 13/16 | 12.500 | 6 5/16 | 12.500 | 6 15/16 | 12.500 | 7 9/16 | 12.500 | 8 13/16 | 12.500 | 9 7/16 | 12.500 |

| 16 | 4 11/16 | 15 | 5 7/8 | 15 | 6 | 14.312 | 6 7/16 | 14.310 | 6 5/8 | 14.310 | 7 1/4 | 14.310 | 7 7/8 | 14.310 | 9 1/8 | 14.310 | 9 3/4 | 14.310 |

| 18 | 5 1/8 | 17 | 6 1/2 | 17 | 6 1/2 | 16.125 | 6 1/2 | 16.126 | 6 13/16 | 16.126 | 7 7/16 | 16.126 | 8 7/32 | 16.126 | 9 13/32 | 16.126 | 10 1/32 | 16.126 |

| 20 | 5 5/8 | 19 | 6 3/4 | 19 | 7 | 17.937 | 7 9/16 | 17.938 | 7 25/32 | 17.938 | 8 3/32 | 17.938 | 8 21/32 | 17.938 | 9 29/32 | 17.938 | 10 15/32 | 17.938 |

| 24 | 6 1/2 | 23 | 7 5/8 | 23 | 8 | 21.564 | 8 23/32 | 21.564 | 8 31/32 | 21.564 | 9 13/16 | 21.568 | 10 1/2 | 21.568 | 12 9/16 | 21.564 | 10 21/32 | 21.564 |

WELDOLET RUN SIZES COMBINATIONS

Weldolet Size Sch. STD/XS

| Pipe Run Sizes | Branch Pipe Size (inches) | ||||||||||||||

| 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 | 6 | |

| 3/8 | 3/8 | 1/2 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 | 6 | |

| 1/2 | 1/2 | 1-3/4 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 | 6 | 8 | |

| 1-3/4 | 1-3/4 | 21/2-11/4 | 1 | 1 1/2 – 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 | 6 | 8 | 10 | |

| 2 1/2 – 1 1/4 | 21/2-11/4 | 36-3 | 1 1/2 – 1 1/4 | 2 1/2 – 2 | 2 | 2 1/2 | 3 | 4 – 3 1/2 | 4 | 5 | 6 | 8 | 10 | 14-12 | |

| 36-3 | 36-3 | flat | 2 1/2 – 2 | 5-3 | 2 1/2 | 3 1/2 – 3 | 4 – 3 1/2 | 5 | 5 | 6 | 8 | 10 | 12 | 16 | |

| flat | flat | 8-3 | 12-6 | 3 1/2 – 3 | 5-4 | 6-5 | 6 | 6 | 8 | 10 | 14-12 | 14 | 18 | ||

| 36-10 | 36-14 | 5 – 4 | 8-6 | 12-8 | 10-8 | 8 | 10 | 14-12 | 20-16 | 18-16 | 22-20 | ||||

| flat | flat | 10 – 6 | 18-10 | 24-14 | 18-12 | 12-10 | 14-12 | 20-16 | 22 | 22-20 | 28-24 | ||||

| 3/4 – 1/2 | 36 – 12 | 36-20 | 36-26 | 36-20 | 18-14 | 20-16 | 36-24 | 36-24 | 28-24 | 36-30 | |||||

| 36 – 1 | flat | flat | flat | flat | 36-20 | 36-24 | flat | flat | 36-30 | flat | |||||

| flat | flat | flat | flat | ||||||||||||

| Outlet sizes 8, 10, 12, 14, 16. 18, 24, 26. 20 orders to specific size combinations. | Size consolidation for Weldolets only | ||||||||||||||

Weldolet Size Sch. XXS/160

| Pipe Run Sizes | Branch Pipe Size (inches) | ||||||||

| 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| 1/2 | 1 3/4 | 1 | 1 1/2 – 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| 1 1/4 – 3/4 | 2 – 1 1/4 | 2 1/2 -1 1/4 | 2 1/2 -2 | 2 1/2 – 2 | 2 1/2 | 3 | 3 1/2 | 6 | |

| 36 – 1 1/2 | 6 – 2 1/2 | 10-3 | 10-3 | 3 1/2 -3 | 3 1/2 -3 | 3 1/2 | 4 | 8 | |

| flat | 36-8 | 36-12 | 36-12 | 8-4 | 5-4 | 4 | 5 | 10 | |

| flat | flat | flat | 20-10 | 8-6 | 5 | 6 | 12 | ||

| 22 | 18-10 | 8-6 | 8 | 14 | |||||

| 36-24 | 36-20 | 12-10 | 10 | 16 | |||||

| flat | flat | 18-14 | 12 | 18 | |||||

| 36-20 | 14 | 20 | |||||||

| flat | 16 | 22 | |||||||

| 18 | 24 | ||||||||

| 20 | |||||||||

| 22 | |||||||||

| 24 | |||||||||

| flat | |||||||||

(Source: Bonney Forge)

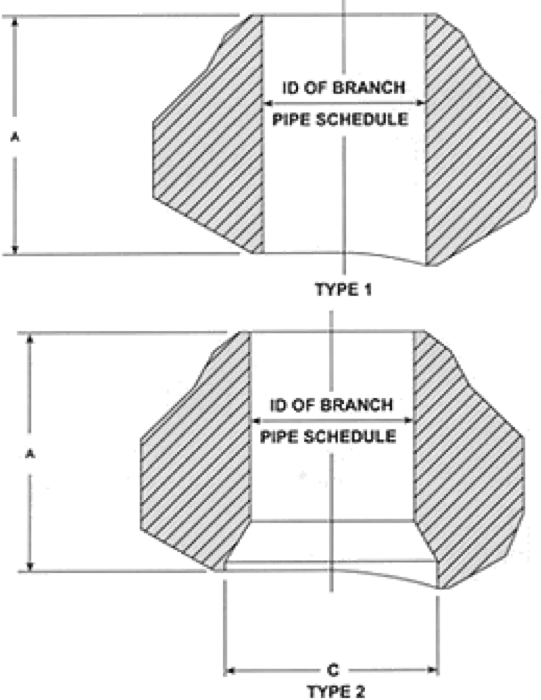

SOCKOLETS DIMENSIONS & WEIGTHS

Sockolet class 3000 “Size on Size”

| Outlet Size (NPT) | A | B | C | D | E | Approx. Weight (lb) |

|---|---|---|---|---|---|---|

| 1/2 | 1 | 1 3/8 | 15/16 | 0.622 | 17/32 | 0.15 |

| 3/4 | 1 1/16 | 1 5/8 | 1 3/16 | 0.824 | 15/32 | 0.25 |

| 1 | 1 5/16 | 2 | 1 7/16 | 1.049 | 23/32 | 0.45 |

| 1 1/4 | 1 5/16 | 2 3/8 | 1 3/4 | 1.380 | 9/16 0.65 | |

| 1 1/2 | 1 3/8 | 2 7/8 | 2 | 1.610 | 21/32 | 0.85 |

| 2 | 1 1/2 | 3 1/2 | 2 9/16 | 2.067 | 15/16 | 1.40 |

| 2 1/2 | 1 9/16 | 4 1/16 | 3 | 2.469 | 3/4 | 2.25 |

| 3 | 1 3/4 | 4 13/16 | 3 11/16 | 3.068 | 15/16 | 3.75 |

| 3 1/2 | 1 11/16 | 5 3/8 | 4 7/16 | 3.548 | 11/16 | 4.30 |

| 4 | 1 7/8 | 6 1/16 | 4 3/4 | 4.026 | 1 1/16 | 6.60 |

| 5 | 2 7/16 | 7 1/4 | 5 1/4 | 5.047 | 1 | 9.00 |

| 6 | 2 11/16 | 8 11/16 | 6 1/16 | 6.065 | 1 3/16 | 15.50 |

Notes:

- Class 3000 is to be used with schedule 80 pipes

- Dimensions and tolerances by ASME B16.11 and MSS SP-97

- Flat Sockolets are used on welding caps, elliptical heads, and flat surfaces

- Each outlet size is available to fit any run curvature.

Sockolet class 6000 “Size on Size”

| Outlet Size (NPS) | A | B | C | D | E | Approx. Weight (lb) |

|---|---|---|---|---|---|---|

| 1/2 | 1 1/4 | 1 23/32 | 3/4 | 0.466 | 7/8 | 0.50 |

| 3/4 | 1 7/16 | 1 61/64 | 1 | 0.614 | 7/8 | 0.80 |

| 1 | 1 9/16 | 2 7/16 | 1 5/16 | 0.815 | 15/16 | 1.30 |

| 1 1/4 | 1 5/8 | 2 23/32 | 1 1/2 | 1.160 | 13/16 | 1.60 |

| 1 1/2 | 1 11/16 | 3 1/4 | 1 15/16 | 1.338 | 7/8 | 2.00 |

| 2 | 2 1/16 | 4 1/32 | 2 3/4 | 1.689 | 1 3/16 | 5.15 |

- Notes:

- Class 6000 is to be used with schedule 160 pipe.

- Dimensions and tolerances by ASME B16.11 and MSS SP-97

- Flat Sockolets are used on welding caps, elliptical heads, and flat surfaces.

- Outlet combinations fit many run pipe sizes, and fittings are marked accordingly

ELBOLET DIMENSIONS

| Nominal Size of Elbow (NPS) | Outlet Size (NPS) | CL 3000 Threaded and Socket Weld Sch. Standard and XS Buttweld | CL 6000 Threaded and Socket Weld Sch. 160 and XXS Buttweld | ||

|---|---|---|---|---|---|

| C | E | C | E | ||

| 36 – 3/4 | 1/4 | 1 1/2 | 1 19/32 | 1 1/2 | 1 19/32 |

| 36 – 3/4 | 3/8 | 1 1/2 | 1 19/32 | 1 1/2 | 1 19/32 |

| 36 – 3/4 | 1/2 | 1 1/2 | 1 19/32 | 1 23/32 | 1 7/8 |

| 36 – 1 | 3/4 | 1 23/32 | 1 7/8 | 2 1/4 | 2 1/4 |

| 36 – 2 | 1 | 2 1/4 | 2 1/4 | 2 7/8 | 2 1/2 |

| 36 – 2 | 1 1/4 | 2 7/8 | 2 1/2 | 3 1/8 | 2 11/16 |

| 36 – 2 | 1 1/2 | 3 1/8 | 2 11/16 | 4 3/16 | 3 1/4 |

| 36 – 3 | 2 | 4 3/16 | 3 1/4 | – | – |

| Order to Specific Elbow Sizes | |||||

| *2 1/2 | 4 3/16 | 3 1/4 | bw only | bw only | |

| *3 | 5 1/16 | 3 7/8 | bw only | bw only | |

| *4 | 6 5/8 | 4 13/16 | bw only | bw only | |

| *6 | 9 3/8 | 6 1/2 | bw only | bw only | |

| *8 | 13 5/16 | 8 1/16 | bw only | bw only | |

| *10 | 17 1/32 | 10 3/8 | bw only | bw only | |

| *12 | 19 5/8 | 11 1/8 | bw only | bw only | |

Notes:

- Class 3000 is to be used for Schedule 80 pipes

- Class 6000 is to be used for Schedule 160 pipes

- Dimensions and tolerances acc. to ASME B16.9, ASME B16.25, and, MSS SP-97.

- Dimensions and tolerances under ANSI/ASME B16.11

- Threaded ends per ANSI/ASME B1.20.1

16 Responses

We are manufacturer of Pipe Fittings and Flanges in Stainless Steel, Carbon Steel & Alloy Steel. Please send us all your inquiry for Fittings and Flanges at info@astralloyindia.com

Dear Sir,

We can provide you products for all your requirements for Branch fittings, forged fittings, flanges, fasteners, pipes & tubes.

Kindly contact us on +919867815181 for fastest response you can also email us on sales1@randhirmetal.com

Regards,

RANDHIR METAL AND ALLOYS PVT LTD

Bonjour,

Pourrions-nous avoir les articles ci-dessous:

-Weldolet 18″ – 10″ x 2″ Schedule 160

Piping class: B03S

Acier au carbone ASTM A105

ASME B16.25 & MSS SP 97

Service H2S niveau 1 selon NACE-MR-01-75/ISO 15156

Spécifications applicables GS EP PVV 144 et 612

Imposition technique: Ceq inférieur ou égal à 0,42

Certificats matières 3.1 suivant EN 10204

-Weldolet 20″ – 16″ x 3″ Sch 80

Acier carbone ASTM A234 WPB/ASME B 31.3

Piping class: D51C (Nkossa)

Service H2S niveau 1 selon nace-MR-01-75 / ISO 15156

Matériel conforme à la GS.EP.PVV 144 & GS EP PVV 612

Certificats matières: 3.1 suivant EN 10204.

Merci de nous faire parvenir un devis incoterm CIF Port autonome de Pointe-Noire République du Congo

Bonjour,

pourrions-nous avoir les articles ci-dessous:

-Weldolet 18″-10″ x 2″ Schedule 160

Piping class: B03S

Acier au carbone ASTM A105

ASME B16.25 & MSS SP 97

Service H2S niveau 1 selon NACE-MR-01-75/ISO 15156

Spécifications applicables GS EP PVV 144 et 612

Imposition technique: Ceq inférieur ou égal à 0,42

Certificats matières 3.1 suivant EN 10204

-Weldolet 20″-16″ x 3″ Sch 80

Acier carbone ASTM A234 WPB/ASME B 31.3

Piping class: D51C (Nkossa)

Service H2S niveau 1 selon nace-MR-01-75 / ISO 15156

Matériel conforme à la GS.EP.PVV 144 & GS EP PVV 612

Certificats matières: 3.1 suivant EN 10204.

Merci de nous faire parvenir un devis incoterm CIF Port autonome de Pointe-Noire République du Congo

Kindly mail all your requirements to sales@nufitpiping.com

Call or Whatsapp: 00919823458877

Please send all your inquires to sales@faridapiping.com

Contact: 00971545476126

Urgent requirements are responded on timely manner.

I need 170 pieces of steel 14″x3″ weldolet. Can you make it for me?

Best regards

Wira Sinto

Hello,

Kindly send the best price for the item below;

Weldolet, 10 In X 3/4 In, Schedule 160, CS, ASTM A105, MSS SP-97

QUANTITY: 25 pieces

Kindly treat as urgent, thank you.

We are manufacturer of Pipe Fittings and Flanges in Stainless Steel, Carbon Steel & Alloy Steel.

Please send us all your inquiry for Fittings and Flanges at info@astralloyindia.com

Dear Sir,

We are currently looking for the products in the list below.

Could you pls send us your offer below listed products?

These materials are required on a regular basis. Please send commercial offers with the best prices and prompt:

1. Availability

2. Terms of delivery to Kazakhstan. (Pls mention in your quote – delivery time)

№ Short Description Long Description Qty Unit

1 WELDOLET:PIPE WELDOLET:PIPE;SIZE:10 IN X 2 IN,WT 14,27 MM /SCH 160 A694 F60;RATING:;MATERIAL:IN ACCORDANCE WITH NACE MR0175. FORGED CARBON STEEL FOR LOW TEMP SERVICE. ASTM-A694 GRADE F60;TYPE:BRANCH FITTING BUTT-WELD;SPECIFICATION:IN ACCORDANCE WITH TCO SPEC. L-ST-2009 LATEST REVISION;GRADE:;STANDARDS:ASME B16.9/ASME B31.3/MS;SHORT RUSSIAN TRANSLATION:ОТВОДНОЙ ПАТРУБОК; 8 Ea

2 WELDOLET 8INX2IN WT 11.1MM/SCH 160 A694 F60 WELDOLET 8INX2IN WT 11.1MM/SCH 160 A694 F60 BRANCH FITTING BUTT-WELD, TYPE – WELDOLET, HEADER WEIGHT – 11.1MM WALL THICKNESS, BRANCH WEIGHT – SCHEDULE 160, MATERIAL- IN ACCORDANCE WITH NACE MR0175 FORGED CARBON STEEL FOR LOW TEMP SERVICE ASTM-A694 GRADE F60 IN ACCORDANCE WITH W-ST-2029 REV.1. MATERIAL TO;SHORT RUSSIAN TRANSLATION:БОБЫШКА ПРИВАРНАЯ; 4 Ea

3 WELDOLET:PIPE;SIZE:6INX2IN,WT 9.53 MM/SCH 160 A694 F60, WELDOLET:PIPE;SIZE:6INX2IN,WT 9.53 MM/SCH 160 A694 F60, ITEM BRANCH FITTING BUTT-WELD;RATING:;MATERIAL:;TYPE:WELDOLET HEADER WEIGHT – 9.53 MM WALL THICKNESS. BRANCH WEIGHT – SCHEDULE 160 WALL THICKNESS;SPECIFICATION:IN ACCORDANCE WITH NACE MR0175 / ISO 15156. FORGED CARBON STEEL FOR LOW TEMP SERVICE. ASTM A694 GRADE F60.STANDARDS – ASME B16.9 /ASME B31.3/MSS-SP-97 INSPECTION REQUIREMENTS SHALL INCLUDE BS EN 10204. 3.2 IN ACCORDANCE WITH TCO SPEC. L-ST-2009 LATEST REVISION;GRADE:;STANDARDS:;ADDITIONAL INFO:;SHORT RUSSIAN TRANSLATION:БОБЫШКА; 2 Ea

Thank you and looking forward to your reply!

We are manufacturer of Pipe Fittings and Flanges in Stainless Steel, Carbon Steel & Alloy Steel.

Please send us all your inquiry for Fittings and Flanges at info@astralloyindia.com

I need offer for below items:

Sl Description of Materials Specifications, if any Code/Color/ Grade Unit Required Qty Material

1 Weldolet DN25 Steel 20 TU 14-3-190-2004 Nos 6

2 Weldolet T DN20 Steel 20 TU 14-3-190-2004 Nos 8

3 Weldolet TDN15 Steel 20 TU 14-3-190-2004 Nos 6

4 Socket DR 100 GOST 5525-88 Nos 14 Cast iron

My Header/Run Pipe 52″ piggable, we would like insert 24″ weldolet, is possible to add custom bar to avoid pig stuck during pigging operation

Dear Sir,

kindly quote your best price for the following below items.

S/N

Description

Unit

Unit

Ord. QTY

1

32″ X 1″ WELDOLET REDUCING SIZE, ASME B16.25, Sch. 160, WT 6.35 mm

(Material grade :ASTM A860 WPHY 52)

Nos.

10

2

32″ X 2″ WELDOLET REDUCING SIZE, ASME B16.25, Sch. 160, WT. 8.7 mm

(Material grade :ASTM A860 WPHY 52)

Nos.

10

3

32″ X 4″ WELDOLET REDUCING SIZE, ASME B16.25, Sch. 160, WT. 13.5 mm

(Material grade :ASTM A860 WPHY 52).

Nos.

12

4

WN FLANGE 1″, RTJ, #1500 ASME B16.5, WT. 6.35 mm

(Material Grade: ISO 5590-3 450-LS)

Nos.

10

5

WN FLANGE 2″, RTJ, #1500 ASME B16.5, WT. 8.7 mm

(Material Grade: ISO 5590-3 450-LS)

Nos.

10

6

WN FLANGE 4″, RTJ, #1500 ASME B16.5, WT. 13.5 mm

(Material Grade: ISO 5590-3 450-LS)

Nos.

12

7

WN FLANGE 32″, RTJ, # 1500 ASME B16.5, WT. 26.3 mm

(Material Grade: ISO 5590-3 450-LS)

Nos.

1

8

BLIND FLANGE 1″, RTJ, #1500 ASME B16.5

(Material Grade: ISO 5590-3 450-LS)

Nos.

10

9

BLIND FLANGE 2″, RTJ, #1500 ASME B16.5

(Material Grade: ISO 5590-3 450-LS)

Nos.

10

10

BLIND FLANGE 4″, RTJ, #1500 ASME B16.5

(Material Grade: ISO 5590-3 450-LS)

Nos.

12

19

1″ FLANGE BALL VALVE, RTJ, # 1500 FULL BORE ASME B16.10

(Material Grade : ASTM A350 )

Nos.

8

20

2″ FLANGE BALL VALVE, RTJ, # 1500 FULL BORE ASME B16.10

(Material Grade : ASTM A350 )

Nos.

8

21

4″ FLANGE BALL VALVE, RTJ # 1500 FULL BORE ASME B16.10

(Material Grade : ASTM A350 )

Nos.

6

Please send your inquiries for Flanges, Fittings to us at info@astralloyindia.com

I need weldolet and sockolet for size 1650mm