Double ferrule compression fittings are specialized connectors used for tubing systems to join two sections of tubes securely (leak-free & gas-tight connections) and without welding. These fittings are designed for easy assembly and disassembly, making them ideal for applications where regular maintenance or adjustments are required (they are reusable). Compression fittings can withstand vibrations, high temperatures, and pressure. The “double ferrule” component refers to the two annular rings (the front and back ferrules) that play a critical role in the sealing and holding mechanism of the fitting. Swagelok and Parker Hannifin are the two main players in the compression fittings market.

DOUBLE FERRULE COMPRESSION FITTINGS

DEFINITION

Double ferrule compression fittings are a type of mechanical joint used to connect sections of tubing in a secure and leak-proof manner, without the need for welding or threading. These fittings are comprised of four main components: the fitting body, the front ferrule, the back ferrule, and the nut. The double ferrule design is crucial for creating a strong, reliable seal and connection.

Double ferrule compression fittings facilitate the joining of two tubes, which can be either imperial (also known as “fractional tubes,” with outside diameters measured in inches) or metric (with outside diameters measured in millimeters), and even allow for connecting a fractional tube to a metric tube at opposite ends.

The typical size range for these compression fittings spans from 1/16″ to 2″ for fractional tube sizes and from 2 mm to 50 mm for metric tube sizes.

These fittings are designed to accommodate the maximum working pressure of the tubing they are used with, ensuring a secure and reliable connection.

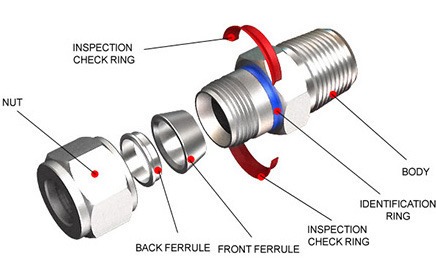

COMPRESSION FITTINGS COMPONENTS

A ferrule fitting comprises the following key components:

- Nut: A threaded component that applies compressive force when tightened.

- Back Ferrule: The rear ferrule provides the primary sealing and grips the tube to prevent it from being dislodged under pressure.

- Front Ferrule: The front ferrule that deforms under the compressive force applied by the nut, creating a tight seal between the fitting body and the tube.

- Body: The main part of the fitting that holds the tube and contains the threaded section to engage with the nut.

KEY ADVANTAGES

Compression fittings are widely used for tubing systems due to their extraordinary capacity to implement safe, reliable, reusable, and easy connections. The key advantages for installers are:

- Leak-Proof: Provides a strong, leak-proof connection suitable for high-pressure applications.

- Versatility: Compatible with a wide range of tubing materials and diameters.

- Reliability: The double ferrule design ensures a reliable seal and mechanical hold, reducing the risk of leaks or disconnection.

- Ease of Installation: Can be easily assembled and disassembled without the need for special tools or welding, facilitating quick repairs and maintenance.

- Durability: Made from materials like stainless steel, brass, and other alloys that offer corrosion resistance and durability in various environments.

SECTORS OF APPLICATION

Widely adopted across various sectors, double ferrule compression tube fittings are integral in industries including downstream petrochemicals, pulp and paper, laboratory settings, aerospace and shipbuilding, defense, power generation, semiconductor production, and other heavy industries, thanks to their versatility and reliability in creating leak-proof tube connections.

The most common fields of application are:

- Hydraulic and Pneumatic Systems: For fluid and air lines that require precise control over flow and pressure.

- Oil and Gas: In applications subject to harsh conditions and materials.

- Chemical Processing: Where chemical resistance and the ability to withstand high pressures are necessary.

- Laboratories and Analytical Instrumentation: Where leak-tight and reliable connections are critical for accurate measurements.

ARE THEY USED FOR TUBING OR PIPING?

Double ferrule compression fittings are primarily designed for use with tubing rather than traditional piping. The distinction between tubes and pipes lies in how their dimensions are specified and their intended use. Tubing is typically defined by its outside diameter (OD) and is used in applications requiring precise diameters and wall thicknesses for pressure calculations, flow rates, and structural integrity. Pipes, on the other hand, are specified by their nominal pipe size (NPS) and schedule number, denoting wall thickness, and are used for transferring fluids and gases at varying pressures and volumes over longer distances.

Learn more about the key differences between pipes and tubes.

The precise engineering and the sealing mechanism of double ferrule compression fittings make them well-suited for applications involving tubing where leak-tight seals are crucial, especially in high-pressure, high-vibration, and critical applications like hydraulic systems, pneumatic lines, and laboratory equipment. The design of these fittings ensures a robust and secure connection by compressing the ferrules against the tube, creating a seal and grip that prevent leaks and dislodgement.

While it’s technically possible to find compression fittings that can be used on pipe, they are relatively rare and generally not referred to as “double ferrule” fittings. The majority of applications involving pipes, particularly in larger diameters and for conveying fluids over long distances, utilize other types of connections like threaded, welded, flanged, or grooved fittings, which are better suited to accommodate the size and pressure requirements of piping systems.

SINGLE VS. DOUBLE FERRULE COMPRESSION FITTINGS

Single and double ferrule compression fittings are both used to connect tubing in various applications, providing a leak-tight seal without the need for welding. Despite their shared purpose, there are distinct differences between the two, making each suitable for specific applications based on factors like pressure requirements, vibration, and ease of assembly. Here’s a comparison of the two:

Single Ferrule Compression Fittings

- Design: Consists of a body, a single ferrule, and a nut. The single ferrule serves both as the sealing element and the gripping component.

- Assembly: Typically easier and quicker to assemble because they have fewer parts. This simplicity can be advantageous in less critical applications or in confined spaces.

- Applications: Often used in low to medium-pressure systems. They are suitable for applications where ease of assembly and disassembly is prioritized over the ability to withstand high pressure or vibration.

- Industries: Commonly found in residential water systems, pneumatic systems, and light industrial applications.

Double Ferrule Compression Fittings

- Design: Feature a body, a front ferrule, a back ferrule, and a nut. The dual ferrules—one to seal and one to grip—provide enhanced security and leak protection.

- Assembly: Requires more careful assembly than single ferrule fittings. The correct sequence and degree of tightening are crucial to ensure a leak-proof seal and prevent tubing damage.

- Applications: Ideal for high-pressure, high-vibration, and critical applications where a reliable seal and mechanical strength are paramount.

- Industries: Widely used across various sectors including petrochemicals, power generation, aerospace, defense, and semiconductor manufacturing, where the integrity of the connection is critical.

Key Considerations

- Pressure and Vibration: Double ferrule fittings offer superior performance in high-pressure environments and where the system experiences significant vibration, reducing the risk of leaks or disconnection.

- Leak Integrity: The two-ferrule design provides better leak integrity and reliability, making it suitable for critical and hazardous fluid applications.

- Ease of Use: Single ferrule fittings might be preferred for their simplicity and ease of use, especially in applications where the operating conditions are less demanding.

In summary, the choice between single and double ferrule compression fittings depends on the specific requirements of the application, including the necessary pressure rating, the criticality of leak prevention, and the environmental conditions. Double ferrule fittings are generally chosen for more demanding conditions where reliability and performance are critical, while single ferrule fittings might be selected for simpler, lower-pressure applications.

HOW TO INSTALL FERRULE COMPRESSION FITTINGS

Ferrule fittings are easy to assemble and disassembly, as shown in this online tutorial from Swagelok tube fittings:

Installing compression fittings is a straightforward process that requires no special tools or welding, making them a popular choice for connecting tubing in plumbing, instrumentation, and various industrial applications.

Here’s a step-by-step guide on how to install double ferrule compression fittings:

1. Prepare the Tubing:

- Cut the Tubing: Use a tube cutter to make a clean, square cut on the tubing end. Ensure the cut is straight to avoid leaks.

- Deburr the Tubing: Remove any burrs or sharp edges from the cut end of the tubing with a deburring tool or file. This prevents damage to the sealing components.

- Clean the Tubing: Wipe the tubing end to remove any debris or contaminants.

2. Assemble the Fitting:

- Slide on the Nut: First, slide the compression nut onto the tubing, with the threads facing the end of the tube where the fitting will be attached.

- Place the Ferrule(s): Next, place the Ferrule (s) onto the tubing. For double ferrule fittings, the front (conical) ferrule goes on first, followed by the back (ring-shaped) ferrule. Ensure they’re oriented correctly.

3. Insert the Tubing:

Insert into the Fitting Body: Carefully insert the tubing with the nut and ferrule(s) into the fitting body. Push the tubing in until it bottoms out or as specified by the manufacturer.

4. Tighten the Nut:

- Hand Tighten: Initially, tighten the nut by hand to ensure it’s not cross-threaded.

- Wrench Tighten: Using a wrench, tighten the nut to the manufacturer’s recommended torque. For most applications, this involves turning the nut 1-1/4 turns to 1-1/2 turns past finger tight. However, it’s essential to refer to the specific instructions provided by the fitting manufacturer, as over-tightening can damage the ferrule and under-tightening can result in leaks.

5. Inspect and Test:

- Inspect the Connection: After tightening, visually inspect the connection to ensure it’s secure and there are no gaps between the nut and the fitting body.

- Test for Leaks: It’s crucial to test the system under pressure before it’s fully put into service. Use a leak detection fluid or method appropriate for the system to check for any leaks around the fitting.

Tips for Successful Installation:

- Proper Sizing: Ensure the tubing and fitting sizes match. Using incompatible sizes can lead to leaks or fitting failure.

- No Reuse of Ferrules: Ferrules are designed for a single use as they deform to create a seal. If you disassemble a connection, replace the ferrule with a new one of the same material (if available) before reassembling.

- Avoid Over-Tightening: Follow the manufacturer’s torque specifications to avoid damaging the tubing or fittings.

Compression fittings offer a reliable and easy method for connecting tubing without the need for specialized tools. Proper preparation of the tubing, correct assembly of the fitting components, and adherence to the manufacturer’s instructions for tightening are key to ensuring a leak-tight and secure connection. Regular inspection and maintenance will also help prolong the life of the connection.

COMPRESSION FITTINGS TYPES

CLASSIFICATION BY FITTING SHAPE

Double ferrule compression fittings are classified by their shape to suit various routing and connection needs in piping and tubing systems. The shape of the fitting determines its function, whether to connect straight sections, change the direction of the tubing, branch out, or adapt to different sizes or threads.

Here’s a classification of double ferrule compression fittings by shape:

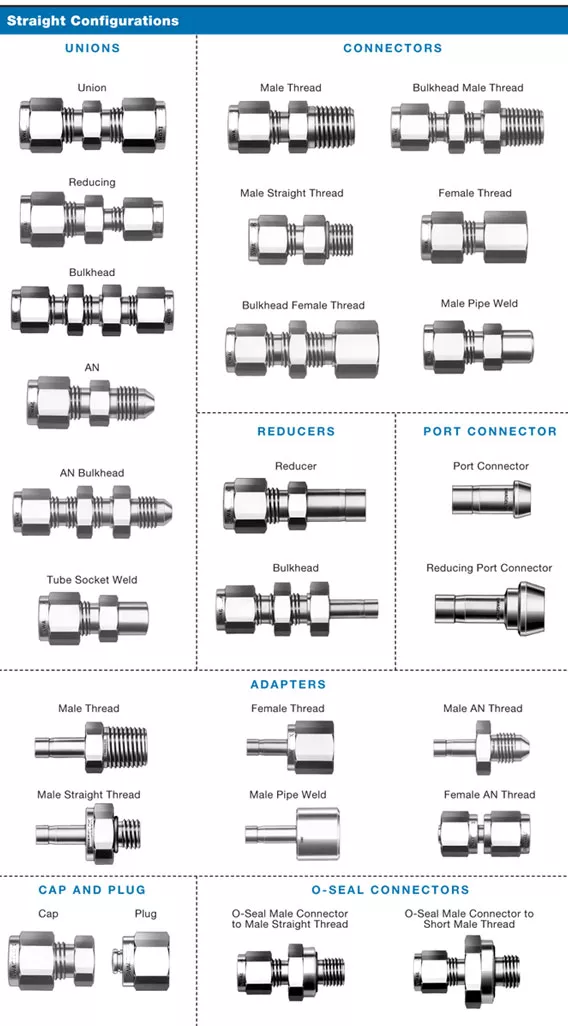

Straight Fittings

These are the simplest type of fittings, used to connect two pieces of tubing in a straight line. They come in various types, including tube-to-tube unions, tube-to-male or female threads, and tube-to-weld fittings.

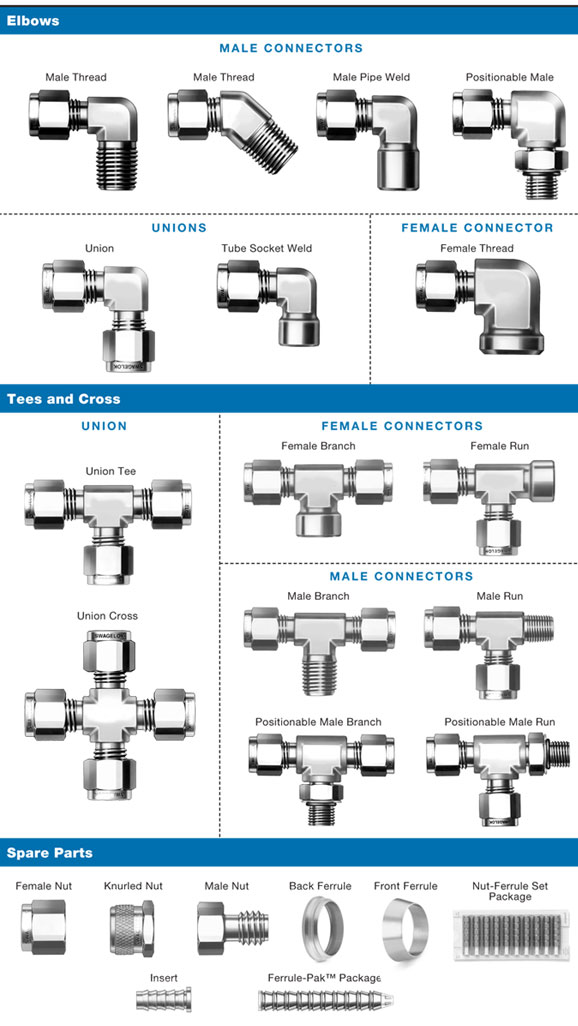

Elbows

Elbow fittings are designed to change the direction of the tubing. They are typically available in 45-degree and 90-degree angles. Elbows can connect tubing to tubing, tubing to male or female threads, or be used in combination with other fittings for more complex routing.

Tees

Tee fittings are used to branch tubing into two directions, creating a T-shape. This allows for the distribution of fluid or gas from a single source to two outlets, or for combining flow from two sources into one outlet.

Crosses

Cross fittings are similar to tees but have four openings, creating a cross shape. They are used to branch or combine flow in four different directions. Cross fittings can be particularly useful in systems requiring multiple inputs or outputs from a central point.

Reducers

Reducer fittings are used to connect sections of tubing with different diameters, allowing for a smooth transition between sizes. They help in adapting the system to varying flow rates or fitting the tubing to components with different connection sizes.

Caps and Plugs

Caps are used to seal the end of a tube, preventing flow. Plugs serve a similar purpose but are inserted into the end of a fitting rather than over the tubing. Both are used for sealing systems, whether for maintenance, pressure testing, or terminating unused ports.

Bulkhead Fittings

Bulkhead fittings are designed to pass through a panel or wall, securing the tubing while maintaining the integrity of the barrier. They ensure that the system can traverse different compartments or enclosures securely.

Union Fittings

Unions are designed for quick disassembly and reassembly, allowing for easy maintenance or modification of the system. They securely connect two pieces of tubing and can be easily removed without disturbing the entire system.

These common types of tube fittings are shown in the images below. Note that for each type, the key sub-categorization is: male, female, and union type.

CLASSIFICATION BY END-TYPE

Double ferrule compression fittings offer versatility in making connections within a variety of systems, accommodating different types of tubing and requirements. Here are the main types of connections for which double ferrule compression fittings are commonly used:

Tube-to-Tube Connections

These are straightforward connections between two pieces of tubing. They are the most common application of double ferrule compression fittings, providing a secure and leak-tight seal between sections of the same or different diameters.

Tube-to-Male Threads

This connection involves attaching tubing to a component or system with male threaded ends. The double ferrule compression fitting on one end of the tube connects to the male threads, typically found on valves, instruments, or equipment, facilitating an interface between the tubing and threaded systems.

Tube-to-Female Threads

Similar to the tube-to-male thread connection, but in this case, the tubing is connected to a component or system with female threaded ends. The compression fitting allows for a secure connection to the internal threads of a receiving port, offering versatility in system design.

Tube-to-Welded Systems

Double ferrule compression fittings can be used to connect tubing to a system or component that has welded connections. This is particularly useful for systems where welding is preferred for certain sections, but the flexibility of a compression fitting is needed for service or maintenance.

Tube-to-Flange Connections

In applications requiring frequent disassembly or where flanged connections are standard, double ferrule compression fittings can be used to adapt tubing to flanged components. This is achieved through the use of a compatible flange adapter that interfaces with the compression fitting.

Bulkhead Connections

Bulkhead fittings are used to pass tubing through a panel or enclosure, securing the connection while maintaining the integrity of the barrier. Double ferrule compression fittings provide a reliable method for creating these pass-through connections, ensuring both the seal’s strength and the system’s overall integrity.

Angle and Tee Connections

For branching or changing the direction of tubing, double ferrule compression fittings are available in configurations such as elbows (90-degree fittings) and tees. These fittings maintain the leak-tight integrity of the system while allowing for the necessary routing and distribution of fluids or gases.

Double ferrule compression fittings provide a highly adaptable solution for creating various types of connections in tubing systems. Their design ensures a reliable, secure, and leak-tight seal, making them suitable for a wide range of applications across different industries. The selection of the appropriate type of connection depends on the specific requirements of the system, including flow direction, system pressure, and compatibility with existing components.

COMPRESSION FITTINGS SIZES & RATING

DIMENSIONS

Ferrule compression fittings are available in a wide range of sizes to accommodate various tubing outside diameters, with sizes expressed in either imperial (inches) or metric (millimeters) measurements. The choice between imperial and metric sizes typically depends on the regional standards, the specific industry, and the equipment being used. Here are the typical sizes for both imperial and metric ferrule compression fittings:

Imperial or Fractional Sizes (USA)

Imperial sizes are commonly referred to as fractional sizes and are measured in inches. They are widely used in the United States and in certain industries that adhere to traditional U.S. standards. Common imperial sizes for ferrule compression fittings include:

- 1/16”

- 1/8”

- 3/16”

- 1/4″

- 3/8”

- 1/2″

- 5/8”

- 3/4″

- 1”

- 1 1/4″

- 1 1/2″

- 2”

These sizes refer to the outside diameter (OD) of the tubing that the fitting is designed to accommodate.

Metric Sizes (EU)

Metric sizes are measured in millimeters and are more commonly used internationally, outside of the United States. Metric ferrule compression fittings are available in a range of sizes to fit different tubing diameters, including:

- 2 mm

- 3 mm

- 4 mm

- 6 mm

- 8 mm

- 10 mm

- 12 mm

- 16 mm

- 18 mm

- 20 mm

- 25 mm

- 32 mm

- 38 mm

- 50 mm

As with imperial sizes, these metric sizes refer to the tubing’s outside diameter that the fitting will connect.

Selection Considerations

- Tubing Material: The choice of fitting size also depends on the material of the tubing (e.g., stainless steel, copper, nylon) and its wall thickness.

- Pressure Ratings: Both the fitting and the tubing should have compatible pressure ratings to ensure the safety and integrity of the connection.

- Application Requirements: Consider the specific requirements of the application, including temperature, fluid type, and environmental conditions, when selecting the size and material of ferrule compression fittings.

Choosing the correct size for ferrule compression fittings is crucial for ensuring a secure, leak-tight connection. It’s important to refer to the manufacturer’s specifications and recommendations to select the appropriate fitting size based on the outside diameter and material of the tubing being used.

More detailed dimensional details for compression fitting, by shape, can be found on the catalogs of key manufacturers:

PRESSURE RATING

The pressure ratings of double ferrule compression fittings can vary widely depending on the material of the fitting, the design, the size, and the type of tubing used.

Exceeding the pressure rating of double ferrule compression fittings can lead to failure of the fitting, which might result in leaks, blowouts, or other hazardous conditions. It’s critical to select fittings with appropriate pressure ratings for your specific application and to consider factors like temperature fluctuations and the potential for pressure spikes in the system.

As a general categorization of pressure ratings, compression fittings may be divided into “standard” (rating up to 11 kPSiG), “medium” (11 to 20kpsig), and “high-pressure” (up to 60kpsig). See the tables below for more details about each class.

STANDARD TUBE FITTINGS (< 11 Kpsig)

| Pressure Ratings | Up to 11.000 PSIG (760 bar) |

| Materials | Stainless steel |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts, and ferrules Chromatograph and Column End |

MEDIUM PRESSURE TUBE FITTINGS (11 to 20kpsig)

| Pressure Ratings | Up to 20.000 PSIG (1378 bar) |

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless Steel or Alloy 625 |

| End Connections | Unions, NPT, medium-pressure cone, and thread adapters, male SAE/MS, reducers, port connectors, tube adapters, caps, plugs |

| Dimensional Range | 1/4, 3/8, 1/2, 9/16, 3/4 in.; 6, 10, 12 mm |

| Configurations | Straights, elbow, tees, cross |

| Other medium-pressure products available | Medium-pressure ball valves, medium-pressure tubing |

CONE AND THREAD TUBE FITTINGS (MEDIUM PRESSURE)

Cone and thread connection types are suited for medium and high-pressure performance and can be equipped with antivibration components. They can meet NACE MR0175/ISO 15156.

| Pressure Ratings | Up to 20.000 PSIG (1378 bar) |

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless Steel Alloy 2507 Alloy 625 |

| End Connections | 1/4 to 1-1/2 in. |

| Configurations | Straights, elbow, tees |

CONE AND THREAD TUBE FITTINGS (HIGH PRESSURE)

| Pressure Ratings | Up to 60.000 PSIG (4134 bar) |

| Temperature Ratings | Up to 1000°F (537°C) |

| Materials | 316 Stainless Steel Alloy 2507 Alloy 625 |

| End Connections | 1/4 to 9/16 in. |

| Configurations | Straights, elbow, tees |

COMPRESSION FITTINGS MATERIALS

FITTING BODY MATERIAL

Compression fittings are manufactured from a variety of materials to suit different applications, ranging from general water supply to high-pressure, corrosive, or sanitary environments.

The choice of material affects the fitting’s durability, corrosion resistance, pressure rating, and compatibility with the tubing and the medium being transported.

Here are some typical material grades used for compression fittings:

Stainless Steel

- 304 Stainless Steel: Offers good corrosion resistance in many environments and is suitable for a wide range of applications. It’s one of the most commonly used stainless steel grades for fittings.

- 316 Stainless Steel: Contains molybdenum, which provides enhanced corrosion resistance compared to 304, especially against chlorides and marine environments. It’s preferred for more corrosive applications and is widely used in the chemical, food processing, and maritime industries.

Brass

- CW617N (Leaded Brass): Offers good machinability and is commonly used for lower-pressure applications. Suitable for water and gas fittings but not recommended for corrosive fluids.

- DZR Brass (Dezincification-resistant Brass): Resists dezincification, making it suitable for use in water supply systems where corrosion might be an issue.

Carbon Steel

A105 Carbon Steel: Provides good mechanical properties and is used for fittings in high-pressure and high-temperature applications. However, it’s prone to corrosion if not properly protected or coated.

Alloy Steel

Chrome-Molybdenum Steel (e.g., F11, F22): Offers excellent strength and resistance to high temperatures and pressures, suitable for power plants and petrochemical applications.

Copper and Copper Alloys

- Copper: Known for its excellent thermal conductivity and corrosion resistance in water. Used for medical gases and water applications.

- Copper-Nickel Alloys (e.g., CuNi 70/30): Cupronickel offers superior resistance to marine biofouling and is used in seawater applications.

Nickel-Alloys

- Hastelloy: Offers exceptional resistance to strong acids and is used in highly corrosive environments.

- Inconel: Known for its strength and resistance to oxidation and corrosion at high temperatures, suitable for extreme environments.

- Monel: Resistant to sea water and steam, used in marine and chemical applications.

Plastic

- Polyvinyl Chloride (PVC) and Chlorinated PVC (CPVC): Used in low-pressure, non-corrosive applications. CPVC can handle higher temperatures than PVC.

- Polypropylene (PP) and Polyethylene (PE): Offer good chemical resistance and are used in chemical processing and water treatment.

- Polytetrafluoroethylene (PTFE): Known for its high chemical resistance and temperature tolerance, used in highly corrosive and high-purity applications.

The selection of material for compression fittings depends on the specific requirements of the application, including the medium being transported, environmental conditions, pressure and temperature ranges, and regulatory standards. Each material grade offers distinct advantages, and the choice should be made based on a thorough evaluation of the application needs.

NEED MORE INFO?

For more information about compression tube fittings, we suggest the Swagelok Essential Guide or the Parker Fittings Tubing Guide.

9 Responses

Your blog so good and also helpful for me.keep it up

Nice summary, we are in Australia and have used all 3 of the brands mentioned (Swage-lok, Parker, and DK-Lok) and never had an issue with these top 3 quality wise or even mixing on selected parts. We did find the service from Valve and Flow Control Specialists on the DK-Lok to be better although Swagelok seemed to have a better availability when it came to above 1″ (25mm). The larger sizes though are not as easy to install.

You have a picture of the make-up of a Superlok fitting with a built-in gap gauge, but no link to that particular fitting. Check out Superlok World, https://superlokworld.com/ to source the i-Fitting tube fittings from the first picture in the article and watch this Tube Fitting Basics video on How to Properly Install Tube Fittings: https://www.youtube.com/watch?v=HwmkNiTNGeU

We are in need of Union Assly of carbon steel zinc plated and chrome passivated Nut and body of straight fittings with SS 316 Quality double ferrule size.

(1) 1/4″ inches Qty 120 Nos.

(2) 3/8″ inches Qty 120 Nos.

(3) 1/2″ inches Qty 120 Nos.

Dear sir good afternoon myself from Danish Engineers . We are manufacturer of instrumentation valves and fittings upto 15,000 psi .

located in navi mumbai . please revert your requirement on sales@danishengineers.in.

DEAR SIR WE HAVE HUGE NUMBER OF SS316 GRADE PARKER AND MARIOFF HI FOG FITTINGS IN STOCK COMPLETE LOT FOR SALE. More details please send Email: ngk@qmarz.com

visit proflow.co.in

Dear R.K.Gadia:

We are a manufacturer of instrumentation tube fittings in stainless steel, brass, and carbon steel materials.

Contact me at yolanda2021@npt-lok.com

Best Regards

Yolanda

Fsinox provide stainless steel railing tube and component fitting manufacturer in Foshan, which is specializing in the delivery of base cover, bar holder, elbow, end cap, glass clamp, handrail bracket, wall bracket, 25x21mm/ 42.4mm/48.3mm slotted tube fitting and LED Handrail to Europe, South American, and Australia Market. Visit Website