In constructing a piping system, engineers must ensure that the material specifications for various piping components (including pipes, fittings, flanges, stud bolts, and valves) are consistent in terms of material grades. The article provides ASTM piping material compatibility tables to guarantee uniformity in material grades throughout the system design.

PIPING MATERIALS COMPATIBILITY

WHY MATERIALS FOR PIPING PRODUCTS SHOULD MATCH?

Ensuring that the ASTM material grades of different piping products—such as pipes, valves, fittings, flanges, and stud bolts—match is crucial for several reasons, all of which contribute to the overall integrity, safety, and performance of the piping system:

- Chemical Compatibility: Matching material grades ensure that all components have similar chemical compositions, which is essential for preventing galvanic corrosion. Galvanic corrosion can occur when two dissimilar metals are in electrical contact in the presence of an electrolyte, causing the more anodic material to corrode faster than it would alone.

- Mechanical Integrity: Components with matching material grades have similar mechanical properties, such as tensile strength, yield strength, and elongation. This uniformity is vital for the system’s mechanical integrity under various operational conditions, including high pressure, temperature fluctuations, and dynamic loads.

- Thermal Compatibility: Materials with similar grades exhibit comparable thermal expansion coefficients. When exposed to temperature changes, components expand and contract at similar rates, reducing the risk of thermal stress, leaks, or material failures at the joints.

- Corrosion Resistance: Uniform material grades ensure consistent corrosion resistance throughout the piping system. This uniformity is critical in environments exposed to corrosive substances or extreme conditions, helping to prevent localized corrosion and ensuring the longevity of the system.

- Weldability: Matching material grades across components improves the weldability of the connections, ensuring strong, leak-proof welds. Disparities in material composition can lead to weld defects such as porosity, cracking, or incomplete fusion, compromising the joint’s integrity.

- Regulatory and Standards Compliance: Adhering to specific material grades across piping components ensures compliance with industry standards and regulatory requirements, which are designed to safeguard the system’s safety and reliability.

- Operational Efficiency and Safety: A piping system with uniformly matched material grades is easier to maintain and less likely to suffer premature failures, ensuring operational efficiency and safety. This uniformity facilitates easier inspection, maintenance, and replacement processes, contributing to the overall sustainability of the system.

ELECTIVE PIPING MATERIALS BY FLUID TYPE

Water (Potable and Wastewater)

- Carbon Steel ASTM A53: For transmission and distribution; requires corrosion protection if used for potable water.

- Ductile Iron ASTM A536: Common in water mains and sewage pipelines due to its high tensile strength and corrosion resistance.

- PVC (Polyvinyl Chloride) ASTM D1785: For potable water and sewage, especially in non-pressurized systems.

- HDPE (High-Density Polyethylene) ASTM D3035: For potable water distribution and wastewater due to its leak-free joints and corrosion resistance.

Oil and Petroleum Products

- API 5L Grade B-X80: For transporting oil, natural gas, and water in the oil and gas industry.

- ASTM A106 Grade B: For conveying oil and gas in refineries.

Ideal materials for specific oil types:

- Thermal Oil: Alloy Steel P22, Stainless Steel 321

- Molten Sulfur: Nickel Alloy 625, Alloy 20

Natural Gas

- API 5L Grade B-X80: Suitable for the transmission of natural gas.

- ASTM A333 Grade 6: For low-temperature services, including natural gas liquefaction and transmission.

Ideal materials for other gas types:

- Oxygen: Deoxidized Copper, Cleaned Stainless Steel 304/316

- Chlorine: Hastelloy C276, Titanium

- Ammonia: Carbon Steel, Stainless Steel 316

- Superheated Steam: Alloy Steel T91, Stainless Steel 347H

- Exhaust Gases: Incoloy 800H, due to its high-temperature strength

Acids and Alkalis

- CPVC (Chlorinated Polyvinyl Chloride) ASTM F441: Resistant to most acids and bases, used in chemical processing.

- PTFE (Polytetrafluoroethylene): Inert to most chemicals, suitable for highly corrosive acid and base applications.

- Hastelloy C276 (Nickel Alloy): For severely corrosive environments with acids.

By Acid type:

- Hydrochloric Acid: PTFE-lined pipes, Hastelloy C276

- Sulfuric Acid: Alloy 20, Duplex 2205

- Nitric Acid: Stainless Steel 316L, Hastelloy B3

By Alcalis type:

- Sodium Hydroxide (Caustic Soda): Nickel 200, Hastelloy C2000

- Potassium Hydroxide: CPVC, Alloy 20

Chlorinated Water

- PVC (Polyvinyl Chloride) ASTM D1785: Resistant to chlorine degradation.

- CPVC (Chlorinated Polyvinyl Chloride) ASTM F441: For higher temperature chlorinated water.

Steam (High Temperature and Pressure)

- ASTM A106 Grade B/C: For high-temperature steam lines.

- ASTM A335 P11, P22, P91: Alloy steel pipes for high-pressure steam services.

Seawater and Marine Environments

- Copper-Nickel Alloys 90/10 and 70/30: Resistant to seawater corrosion, used in shipbuilding and offshore platforms.

- Titanium Grades 2 and 5: For high corrosion resistance in seawater applications.

Cryogenic Liquids (LNG, Liquid Nitrogen)

- Stainless Steel 304/316 ASTM A312: For low-temperature applications down to -425°F (-254°C).

- ASTM A333 Grade 6: Low-temperature carbon steel for cryogenic services.

More in detail, for two specific cryogenic fluids:

- Liquid Helium: Stainless Steel 316L, due to its low-temperature toughness

- Liquid Argon: Aluminum 6061, for its low thermal conductivity

Hydrocarbons (Crude Oil, Gasoline, Diesel)

- API 5L Grade B-X80: For pipelines transporting crude oil and refined products.

- ASTM A106 Grade B: For refining processes and fuel transport.

By specific fuel types:

- Aviation Fuel: Carbon Steel API 5L, Stainless Steel 304

- Biodiesel: Stainless Steel 316L, due to its resistance to methanol and glycerin

- Ethanol: Stainless Steel 316, due to its resistance to corrosion

Corrosive Chemicals (Sulfuric Acid, Hydrochloric Acid)

- PTFE-Lined Pipes: For extreme chemical resistance to acids.

- Hastelloy C276, C22: Nickel alloys for strong acids and corrosive environments.

By Solvent type:

- Benzene: Stainless Steel 316, PTFE-lined pipes

- Toluene: HDPE, Stainless Steel 304

- Xylene: Alloy 20, PTFE-lined pipes

Slurries and Abrasive Liquids

- Rubber-Lined Carbon Steel: Provides abrasion resistance for slurry transport.

- HDPE ASTM D3035: For abrasive slurry applications due to its wear resistance.

Cooling Systems

- Brine Solutions: Super Duplex, Titanium

- Glycol Mixtures: Copper-Nickel Alloys, Stainless Steel 316L

Water treatment plants

- Chlorine Dioxide: Titanium, PVDF

- Ozone: Stainless Steel 316L, due to its resistance to oxidation

PIPING MATERIALS MATCH TABLE (ASTM GRADES)

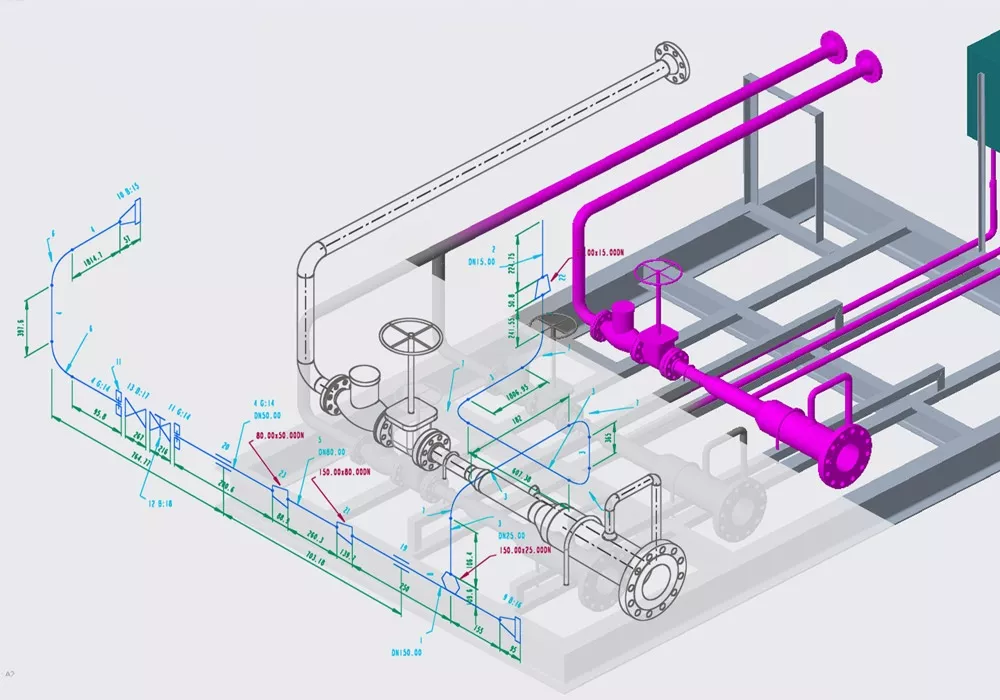

A piping materials compatibility or match table, specifically concerning ASTM (American Society for Testing and Materials) grades, is a comprehensive reference tool used in the design and construction of piping systems.

This table outlines which materials are compatible based on their ASTM grades, ensuring that all components of the piping system—such as pipes, valves, fittings, flanges, and stud bolts—can work together effectively without risk of failure due to material incompatibility.

A piping materials compatibility table is an essential resource during the design phase of a piping system, assisting engineers and designers in selecting materials that match in terms of ASTM grades. It helps in creating a harmonized system where all components possess compatible properties, thereby enhancing the system’s overall reliability, safety, and performance.

The piping materials match table reported below shows, for example, that an A106 Gr. A pipe matches with ASTM A234 buttweld fitting, with ASTM A105 forged fittings, flanges, and valves, with A216 WCB cast valves, and with ASTM A193 B7 stud bolts. The same logic applies to any other ASTM material grade listed in the table.

The table starts with the ASTM material grades for pipes and continues by listing the compatible material grades for any additional piping component (buttweld fittings, forged products such as flanges, socket-weld/threaded fittings, cast valves, and stud bolts):

| PIPING MATERIALS | PIPES | BW FITTINGS | FORGINGS* | CAST VALVES | STUD BOLTS |

|---|---|---|---|---|---|

| High-Temperature Carbon Steel | A106 Gr A | A234 Gr WPA | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A106 Gr B/A53 Gr B/API 5L Gr. B | A234 Gr WPB | A105 | A216 Gr WCB | ||

| A106 Gr C | A234 Gr WPC | A105 | A216 Gr WCB | ||

| Carbon Steel Alloy High-Temp | A335 Gr P1 | A234 Gr WP1 | A182 Gr F1 | A217 Gr WC1 | A193 Gr B7 A194 Gr 2H |

| A335 Gr P11 | A234 Gr WP11 | A182 Gr F11 | A217 Gr WC6 | ||

| A335 Gr P12 | A234 Gr WP12 | A182 Gr F12 | A217 Gr WC6 | ||

| A335 Gr P22 | A234 Gr WP22 | A182 Gr F22 | A217 Gr WC9 | ||

| A335 Gr P5 | A234 Gr WP5 | A182 Gr F5 | A217 Gr C5 | ||

| A335 Gr P9 | A234 Gr WP9 | A182 Gr F9 | A217 Gr C12 | ||

| A 335 Gr P91 | A234 Gr WP91 | A182 Fr F91 | |||

| Carbon Steel Alloy Low-Temp | A333 Gr 6 | A420 Gr WPL6 | A350 Gr LF2 | A352 Gr LCB | A320 Gr L7 A194 Gr 7 |

| A333 Gr 3 | A420 Gr WPL3 | A350 Gr LF3 | A352 Gr LC3 | ||

| Austenitic Stainless Steel | A312 Gr TP304 | A403 Gr WP304 | A182 Gr F304 | A182 Gr F304 | A193 Gr B8 A194 Gr 8 |

| A312 Gr TP316 | A403 Gr WP316 | A182 Gr F316 | A182 Gr F316 | ||

| A312 Gr TP321 | A403 Gr WP321 | A182 Gr F321 | A182 Gr F321 | ||

| A312 Gr TP347 | A403 Gr WP347 | A182 Gr F347 | A182 Gr F347 |

KEY ASTM MATERIALS FOR PIPING

STEEL PIPES

ASTM material grades for pipes specify the composition, mechanical properties, and manufacturing methods for different types of pipes used in various applications, including construction, oil and gas, chemical processing, and water transport. These grades are established by the American Society for Testing and Materials (ASTM) to ensure that materials meet specific minimum standards for performance and safety.

Here are some common ASTM material grades for pipes:

Carbon Steel Pipes

- ASTM A53: Used for welded and seamless steel pipes in both black and galvanized finishes, applicable for mechanical and pressure applications.

- ASTM A106: Covers seamless carbon steel pipes for high-temperature service, suitable for bending, flanging, and similar forming operations.

- ASTM A333: Specifies seamless and welded steel pipe for low-temperature service.

For more details about ASTM carbon steel grades for pipes, consult this article.

Alloy Steel Pipes

- ASTM A335: For seamless ferritic alloy-steel pipe designed for high-temperature service, including P1, P2, P5, P9, P11, P22, and P91.

- ASTM A691: Covers carbon and alloy steel pipe, electric-fusion-welded for high-pressure service at high temperatures.

For more details about ASTM low-alloy steel grades for pipes (chrome-moly), consult this article.

Stainless Steel Pipes

- ASTM A312: Covers seamless and welded austenitic stainless steel pipes used for high-temperature and general corrosive service.

- ASTM A358: Pertains to electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for high-temperature and general corrosive service.

For more details about ASTM stainless steel grades for pipes, consult this article.

Other Material Grades

- ASTM A790: Specifies seamless and welded ferritic/austenitic stainless steel pipe (duplex stainless steel).

- ASTM A928: superduplex pipes

- ASTM A252: For welded and seamless steel pipe piles used in the construction of marine and foundation structures.

- ASTM A519: Covers several grades of carbon and alloy steel seamless mechanical tubing.

CAST VALVES

ASTM material grades for cast valves specify the composition, mechanical properties, and applicable testing requirements for various types of valve materials. These grades ensure that the materials used in valve manufacturing meet specific standards for performance, durability, and safety across a wide range of applications, including industrial, chemical, water treatment, and oil and gas sectors.

Below are some common ASTM material grades used for cast valves:

Carbon Steel Cast Valves

- ASTM A216 (WCA, WBC, WCC): Standard specification for carbon steel castings suitable for fusion welding for high-temperature service. This grade is widely used for general industrial applications.

- ASTM A352 LCB/LCC: Covers low-temperature carbon steel valve castings. LCB and LCC variants offer excellent toughness at low temperatures.

Stainless Steel Cast Valves

- ASTM A351 (CF8, CF8M): Specification for cast austenitic stainless steel valve castings, equivalent to Type 316 stainless steel. CF8M is used for its resistance to corrosive media and high temperatures.

- ASTM A351 CF3M: Similar to CF8M but with lower carbon content, making it more suitable for welding and applications where corrosion resistance, especially to sulphuric acids, is critical.

Alloy Steel Cast Valves

- ASTM A217 WC6: Specification for alloy steel castings for high-temperature service, typically used for pressure-containing parts suitable for high-temperature service.

- ASTM A217 C5: Another alloy steel casting grade used for high-temperature service, offering good strength and resistance to thermal fatigue and corrosion.

Special Alloys Cast Valves

- ASTM A494 CW6M: Specification for nickel-copper alloy castings, offering excellent resistance to seawater and acidic environments.

- ASTM A995 4A (CD3MN): Duplex stainless steel castings provide high strength and resistance to chlorides and stress corrosion cracking.

For more details about the ASTM material grades for cast (and forged valves), refer to this article.

FORGED PIPING PRODUCTS

ASTM standards specify the materials used for various components in piping systems, including forged valves, flanges, and fittings. These materials are chosen based on their mechanical properties, corrosion resistance, and suitability for the intended service environment. Below are some commonly specified ASTM material grades for forged valves, flanges, and fittings:

Forged Valves

- ASTM A105: This specification covers carbon steel forgings for piping applications, including valves. It is widely used for its good mechanical properties and cost-effectiveness in moderate to high-temperature service.

- ASTM A182: This standard specifies forged or rolled alloy and stainless steel pipe flanges, forged fittings, valves, and parts, particularly suitable for high-temperature service. Grades under A182 include F304, F316, F321, F347 (austenitic stainless steels), F5, F9, F11, F22 (alloy steels), and others.

Check this article for more information about the ASTM materials for forged valves.

Flanges (ASME B16.5)

- ASTM A105: As mentioned, A105 is also the standard specification for carbon steel flanges for ambient and higher-temperature service in pressure systems.

- ASTM A350: This specification covers several grades of carbon and low-alloy steel forged or ring-rolled flanges, forged fittings, and valves intended primarily for low-temperature service and requiring notch toughness testing. Grades include LF2 and LF3.

Check this article for more information about the ASTM materials for forged flanges.

Forged Fittings (ASME B16.11)

- ASTM A105: Again, A105 is applicable here for carbon steel forged fittings.

- ASTM A182: Similar to its use for valves, A182 covers a wide range of alloy and stainless steel grades for forged fittings suitable for high-temperature and general corrosive service.

- ASTM A234: This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction. These fittings are used in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. Grades include WPB for carbon steel and WP5, WP9, WP11, and WP22 for alloy steels.

Check this article for more information about the ASTM materials for forged fittings ASME B16.11.

BUTTWELD FITTINGS

ASTM materials for buttweld fittings specify the composition, mechanical properties, and other important criteria necessary for ensuring that these components are suitable for their intended use, especially in piping systems that require seamless flow and strong, leak-proof connections.

Here are some commonly used ASTM material grades for buttweld fittings:

Carbon Steel Buttweld Fittings

ASTM A234: This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction. These fittings are used for moderate and high-temperature service. Grades include WPB (wrought grade of carbon steel) and WPC, along with alloy grades like WP1, WP5, WP9, WP11, WP22, and WP91 for different alloy compositions and intended service conditions.

Stainless Steel Buttweld Fittings

ASTM A403: This standard specifies wrought austenitic stainless steel piping fittings for corrosive and high-temperature service. Grades include WP304, WP304L, WP316, WP316L, WP321, and WP347, among others, which correspond to different types of stainless steel alloys with varying carbon contents and additional alloying elements for specific properties like corrosion resistance and temperature endurance.

Alloy Steel Buttweld Fittings

ASTM A234: As mentioned, this specification also includes various alloy steel grades suitable for buttweld fittings, designed for high-temperature service. The alloy grades such as WP5, WP9, WP11, WP22, and WP91 offer enhanced strength, durability, and resistance to high temperatures and pressures.

High Yield Carbon Steel Buttweld Fittings

ASTM A860: This specification covers wrought high-strength ferritic steel butt-welding fittings of seamless and electric fusion-welded construction for applications in high-pressure gas and oil transmission and distribution systems. Grades include WPHY 42, WPHY 52, WPHY 60, WPHY 65, and WPHY 70, which indicate the yield strength of the material in ksi.

Special Fittings

ASTM A815: Specifies wrought ferritic, ferritic/austenitic, and martensitic stainless steel piping fittings for general corrosive service, with grades including UNS S31803, S32205 (duplex), and UNS S32750 (super duplex), offering higher strength and corrosion resistance compared to standard austenitic stainless steel grades.

Check this article for more information about the ASTM materials for butt-weld fittings ASME B16.9.

STUD BOLTS

ASTM materials for stud bolts are specified to ensure that these fasteners meet the necessary standards for strength, corrosion resistance, and durability required in various applications, including piping systems, flanges, and pressure vessels. Stud bolts are critical components in ensuring tight and secure connections in industrial environments.

Here’s a look at commonly used ASTM material grades for stud bolts:

Carbon and Alloy Steel Stud Bolts

ASTM A193: This specification covers alloy and stainless steel bolting materials for high-temperature or high-pressure service. Grades within A193 suitable for stud bolts include B7 (chromium-molybdenum steel) for high-temperature services, B7M (similar to B7 but with restricted hardness requirements), and B16 (a higher-temperature variant of B7). For corrosion-resistant applications, grades like B8 (304 stainless steel) and B8M (316 stainless steel) are used.

Stainless Steel Stud Bolts

ASTM A320: This specification is intended for alloy steel and stainless steel bolting for low-temperature service. Grades L7, L43, and L7M are common for alloy steel, similar to A193 but suited for lower temperatures. For stainless steel in low-temperature applications, grades like B8 (304 stainless steel) and B8M (316 stainless steel) under A320 are appropriate, mirroring A193 but with an emphasis on impact properties at lower temperatures.

Carbon Steel Stud Bolts

ASTM A307: This specification covers carbon steel bolts, studs, and threaded rods of 60,000 PSI tensile strength. Grade B within A307 is often used for stud bolts in general applications where high strength is not required. It is commonly used in flanged connections in piping systems that do not involve high temperatures or pressures.

Special Applications

ASTM F1554: This specification covers anchor bolts designed to anchor structural supports to concrete foundations. While not typically used for high-temperature or pressure applications, grades like 55 and 105 might find use in specialized settings where anchoring strength is critical.

Check this article for more information about the ASTM materials for stud bolts for flanges.

“CARBON CONTENT” & WELDABILITY

WHAT IS CARBON CONTENT?

The term “pipe carbon content” refers to the percentage of carbon present in the steel used to manufacture the pipe. Carbon is a fundamental alloying element in steel, significantly influencing its mechanical properties and behavior. The carbon content in steel pipes can vary widely, affecting their strength, ductility, weldability, and overall performance in different applications.

The carbon content in steel pipes significantly influences their weldability, which is a crucial factor in the manufacturing and application of piping systems. Weldability refers to the ability of a material to be joined securely and effectively through welding, without leading to undesirable outcomes such as cracking, porosity, or weak joints.

Understanding the relationship between carbon content and weldability helps in selecting the appropriate material for welded constructions, especially in critical applications where safety and durability are paramount.

IMPACT OF CARBON CONTENT ON PIPING WELDABILITY

- Low Carbon Content (Low-Carbon Steel): Steel pipes with a low carbon content, typically less than 0.3%, are known for their excellent weldability. Low carbon content reduces the risk of forming brittle microstructures in the weld area, such as martensite, and decreases the potential for weld cracking. This makes low-carbon steels (often referred to as mild steels) ideal for a wide range of welding methods, including MIG, TIG, and arc welding.

- Medium Carbon Content (Medium-Carbon Steel): Steels with medium carbon content, ranging from 0.3% to 0.6%, present more challenges in welding due to the increased possibility of forming harder and more brittle microstructures in the heat-affected zone (HAZ). Preheating and post-weld heat treatments are often necessary to avoid weld cracking and to achieve satisfactory weld properties.

- High Carbon Content (High-Carbon Steel): With a carbon content greater than 0.6%, high-carbon steels are generally considered difficult to weld. The high carbon level increases the risk of creating very hard and brittle structures in the welded joint, significantly raising the likelihood of cracking. Special welding techniques, careful control of the welding parameters, preheating, and post-weld heat treatment are essential to successfully weld high-carbon steels.

CARBON EQUIVALENT

To better predict the weldability of steel, the concept of Carbon Equivalent (CE) is used. CE takes into account not only the carbon content but also the presence of other alloying elements such as manganese, chromium, molybdenum, and vanadium, which can also affect the steel’s hardenability and, consequently, its weldability. A lower CE value indicates better weldability.

HOW TO IMPROVE WELDABILITY

- Preheating: Applying heat to the steel before welding can help to reduce the cooling rate after welding, minimizing the risk of forming brittle phases in the HAZ.

- Post-Weld Heat Treatment (PWHT): Heating the weldment after welding can help to relieve stresses and temper hard microstructures, improving the toughness and ductility of the weld zone.

- Using Low-Hydrogen Welding Processes: These processes minimize the introduction of hydrogen into the weld, reducing the risk of hydrogen-induced cracking.

The carbon content of steel pipes is a critical determinant of their weldability, influencing the selection of welding processes, parameters, and additional treatments required to ensure strong, ductile, and crack-free welds. Understanding and managing the effects of carbon content—and by extension, the carbon equivalent—is essential for the successful application of welded steel pipes across various industries.

FULLY KILLED VS. SEMI-KILLED CARBON STEEL

The terms “fully killed” and “semi-killed” refer to the deoxidation practices employed during the steelmaking process, which significantly influence the characteristics and applications of the resulting carbon steel. The choice between fully killed and semi-killed steel depends on the required material properties and the specific application.

⚠️ This classification is commonly used when discussing carbon steel materials. However, it’s important to note that in the realm of piping, the distinction is not really applicable, as 90% of piping applications use fully killed carbon steel materials (in practice, semi-killed carbon steel might be found in some non-critical, general-purpose piping applications where the specific benefits of fully killed steel, such as fine grain structure and uniformity, are not strictly necessary; this might include certain low-pressure, ambient-temperature water systems or structural applications where the primary concerns are cost and availability rather than extreme mechanical properties or low-temperature performance).

FULLY KILLED CARBON STEEL

Definition: Fully killed steel is a steel in which the oxygen content has been reduced to a minimum through the addition of deoxidizing agents such as silicon or aluminum, before casting. This process eliminates virtually all gas porosity in the ingot, leading to a more uniform composition and improved quality.

Characteristics:

- Fine-grained: The addition of deoxidizing agents promotes the formation of fine grains, enhancing the toughness and ductility of the steel.

- Uniform Quality: The elimination of oxygen results in minimal segregation and a more uniform distribution of elements within the steel.

- No Gas Pockets: The fully killed process prevents the formation of gas pockets and porosity in the ingot, which can lead to weakness in the finished product.

Applications: Fully killed steel is used in demanding applications where homogeneous structure and properties are critical. It is preferred for steel forgings, pressure vessels, structural applications, and where low-temperature toughness is required.

SEMI-KILLED CARBON STEEL

Definition: Semi-killed steel is produced with a partially deoxidized process, using a lesser amount of deoxidizing agents compared to fully killed steel. This results in a partial reduction of oxygen and allows some carbon monoxide to evolve during solidification, leading to a less uniform structure than fully killed steel.

Characteristics:

- Coarse Grain Structure: The steel tends to have a coarser grain structure compared to fully killed steel, due to the presence of some remaining oxygen.

- Some Porosity: Semi-killed steel typically has some porosity, resulting from the evolution of carbon monoxide during solidification, which can lead to a slight decrease in density.

- Moderate Uniformity: While it is less uniform than fully killed steel, semi-killed steel still offers a moderate level of uniformity and quality suitable for many applications.

Applications: Semi-killed steel is often used in structural steel applications and components where extreme toughness and uniformity are not critical. It’s suitable for a wide range of general manufacturing uses.

The choice between fully killed and semi-killed carbon steel primarily depends on the specific requirements of the application:

- Fully killed carbon steel, with its finer grain structure and uniformity, is suitable for high-quality applications where strength, toughness, and low-temperature properties are essential.

- Semi-killed carbon steel, offering a balance between quality and cost, is adequate for many structural and manufacturing applications where extreme uniformity is not necessary.

Understanding the differences between these deoxidation practices helps in selecting the appropriate steel grade for specific applications, ensuring optimal performance and cost-effectiveness.

6 Responses

first of all, very appreciate for providing information.

Is it permissible to inquire why the list of cast valves for austenitic stainless steel includes specifications for forgings?

Very good experience

A good comprehensive information and Quick References, but need more info.

Thanks, Rick. Have you seen the platform projectmaterials.com? We offer several services for people engaged in project business:

– Academy (150+ not-too technical articles about piping and steel, to know the basics)

– Stockists Directory (directory of 1000+ stockists of piping products that you can search and contact)

– RFQs (if you have an RFQ/MTO and need offers, you can simply post it on the platform and let suppliers come to you)

– Surplus (if you have surplus stock, you can post it and convert it into cash)

We help buyers and sellers of materials for projects! We hope you can pass this information to your friends and colleagues, to help us grow our community!

With our best regards, Projectmaterials Lugano Switzerland

Hello.

I’ve got a question.

Where do I get that chart ?? or Which is source information??

Can you reply me ???

Thanks for your information

This is well worth a read. You presented great insight and information. Thanks.