Metal density is a measure of how much mass a specific volume of a metal contains. It’s usually expressed in units like kilograms per cubic meter (kg/m³), grams per cubic centimeter (g/cm³), or pounds per cubic foot (lb/ft³). The density of a metal is determined by its atomic mass and how closely packed its atoms are within its structure. Densities vary widely across different metals and alloys. For instance, metals like lithium are very light with a low density, making them ideal for applications requiring lightweight materials, such as batteries for electric vehicles. On the other hand, metals like tungsten have a high density, which is useful in applications requiring heavy or high-mass materials, such as weights or radiation shielding. In this article, we explore the concept of metal density and provide the values for the most common metals used in the plant project business.

DENSITY OF METALS

WHAT IS THE DENSITY OF METALS?

The concept of density plays a pivotal role in the fields of materials science, physics, and engineering, serving as a fundamental property that characterizes the compactness of a material’s mass within a given volume.

Density, defined as mass per unit volume, is commonly expressed in units such as kilograms per cubic meter (kg/m³) or grams per cubic centimeter (g/cm³).

For metals and alloys, density is not just a mere numerical value but a key attribute that influences their selection, application, and performance across a wide range of industries.

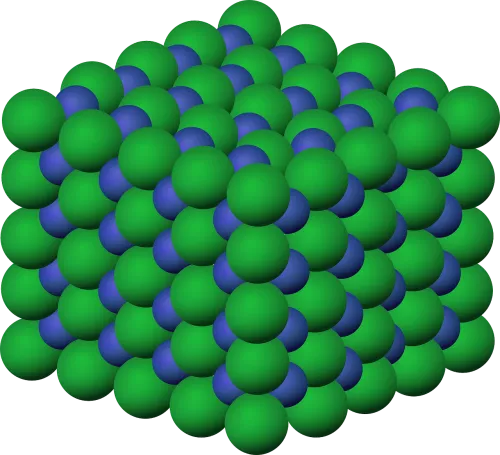

The density of metals and alloys is a direct reflection of their atomic structure and bonding. Metals consist of closely packed atoms with a sea of delocalized electrons facilitating their notable conductivity. The nature of metallic bonding, combined with the size and mass of the constituent atoms and the efficiency of their packing, dictates the metal’s density. Alloys, through the introduction of additional elements into the base metal, can exhibit densities that deviate from those of their pure metal counterparts, influenced by the type and proportion of alloying elements.

Metals, characterized by their shiny appearance, malleability, ductility, and excellent conductivity of heat and electricity, exhibit a wide range of densities. At one end of the spectrum, we have metals like lithium, with a density so low (approximately 0.534 g/cm³) that it floats on water. On the opposite end, osmium stands as the densest naturally occurring element, boasting a density of about 22.59 g/cm³. This diversity is mirrored in alloys, which are mixtures of metals and other elements designed to enhance certain properties such as strength, corrosion resistance, or ease of fabrication.

METALS DENSITY CALCULATION FORMULA

The formula for calculating density (ρ) is straightforward:

ρ = m / V

where “m” represents mass, and V denotes volume.

This simple equation, however, encapsulates a wealth of information about the material’s structure, composition, and potential applications.

The density of metals and alloys is a fundamental property that influences a wide array of material characteristics and applications. From the designer’s drafting table to the engineer’s workshop, density considerations shape decisions that affect the performance, durability, and environmental impact of metal and alloy-based products. As our understanding of material science deepens and our ability to engineer materials at the atomic level improves, the strategic manipulation of density will continue to open new horizons in material innovation and application.

RELEVANCE OF METAL DENSITY

Knowing the density of a metal provides valuable insights into its properties and potential applications. Understanding a metal’s density aids in making informed decisions regarding material selection, design considerations, and application feasibility, ensuring that the chosen metal aligns with the performance requirements of the end product.

Here are several aspects you can deduce from the density of a metal:

Material Selection

Density is a critical factor in material selection, especially for applications where weight is a crucial consideration, such as in the aerospace, automotive, and consumer electronics industries. The choice between using aluminum or titanium for aircraft components, for example, hinges on balancing the materials’ densities with their strength, cost, and performance characteristics (this is called “Strength-to-Ratio”, a concept widely used also in the automotive industry).

Design Considerations

Engineers must account for the density of materials when designing products and structures to ensure they can withstand operational stresses while maintaining efficiency and effectiveness. High-density materials may be preferred for their inherent weight and stability, while low-density materials are favored for lightweight construction.

Thermal and Electrical Performance

Although not directly related, density can influence a material’s thermal and electrical conductivities. Metals with high electron mobility, a characteristic partly dependent on their atomic arrangement and hence their density, typically exhibit excellent conductivity.

Corrosion Resistance

Though not directly related, density can be a starting point to consider corrosion resistance. Metals with higher densities often have compact atomic structures that may be less susceptible to corrosion in certain environments.

Wear and Durability

In certain applications, the density of a metal can hint at its wear resistance and durability under specific operating conditions, which is essential for parts subjected to friction and abrasion.

Material Identification

Density can help identify a metal or distinguish between two similar-looking materials, as each metal has a unique density.

Fabrication and Machinability

The density of a metal can influence its fabrication and machining processes. Heavier metals may require more energy to machine, weld, or form compared to lighter ones.

Cost and Availability

Denser metals, especially those that are rare or difficult to extract, may be more expensive. Knowing the density can help in preliminary cost estimation for material selection in projects.

Environmental and Economic Impact

The density of metals and alloys affects their sustainability and recyclability. High-density materials may require more energy to extract, refine, and process, but they might offer longer lifespans and better recyclability, impacting their overall environmental footprint.

Innovative Applications

Understanding and manipulating the density of alloys allows scientists and engineers to create materials with bespoke properties for cutting-edge applications, from superalloys capable of withstanding extreme temperatures in jet engines to lightweight alloys for electric vehicle batteries

METALS DENSITY CHART

KEY METALS

The table of densities for widely used metals in the array of products featured on Projectmaterials.com, including piping and structural steel, can be useful. To estimate the weight of an item made from a specific material, based on its weight in carbon steel, simply multiply the nominal carbon steel weight by the density ratio relative to steel (for example if you know that a 4″ Class 150 Threaded Flange in Carbon Steel weights 3 kilograms, the corresponding flange in Copper will weight 3 * 1.14 Kgs):

| Metal | Density (g/cm³) | Density vs. Steel |

| Steel | 7.85 | 1 |

| Iron | 7.85 | 1.00 |

| Aluminum | 2.73 | 0.35 |

| Brass | 8.5 | 1.08 |

| Chromium | 7.19 | 0.92 |

| Copper | 8.94 | 1.14 |

| Gold | 19.3 | 2.46 |

| Lead | 11.3 | 1.44 |

| Magnesium | 1.74 | 0.22 |

| Mercury | 13.6 | 1.73 |

| Nickel | 8.9 | 1.13 |

| Platinum | 21.4 | 2.73 |

| Silver | 10.5 | 1.34 |

| Sodium | 0.97 | 0.12 |

| Tin | 7.28 | 0.93 |

| Zinc | 7.14 | 0.91 |

ALL KEY METALS, ALLOYS, AND ELEMENTS

The table shows the density of the most common metals, alloys, and elements in kgs/m3 and in Lbs/ft3: