Branch fittings, also known as “O’lets,” comprise a group of forged items designed to create 45 or 90-degree reinforced branch connections from a main pipe (header pipe) to a secondary pipe (outlet pipe). The typical varieties of branch fittings include Weldolets, Thredolets, Sockolets, Latrolets, Elbolets, Nipolets, and Sweepolets. The principal standard governing reinforced branch connections is MSS-SP 97, which was introduced by Bonney Forge over 70 years ago and has since become a cornerstone in the piping industry.

BRANCH FITTINGS (O’LETS)

DEFINITION

Branch fittings, commonly referred to as O’lets (or “branch connections”, “pipe branch outlet fittings”, and “outlet fittings”), are a category of forged fittings designed to create 45 or 90-degree reinforced branch connections from a main pipeline (also known as the header pipe) to a secondary pipe (outlet pipe). These fittings provide an integral reinforcement for the branch connection, ensuring structural integrity and fluid flow efficiency. O’lets are utilized in a variety of piping systems to facilitate directional changes or to integrate additional lines.

Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques. They can be used as an alternative to buttweld tees, reinforcing pads, and saddles.

Reinforced branch connections/fittings come in a wide range of sizes (to accommodate most size-on-size or reducing connections), types/designs, connection types (buttweld, socket weld, threaded), and in a wide range of forged steel materials:

- Carbon steel (ASTM A105 for high-temperature, A350 LF2/LF3 for low-temperature)

- Alloy steel (ASTM A182 Grades F5, F9, F11, F22)

- Stainless steel (ASTM A182 F304, F316, other SS grades, duplex, and super duplex)

- Nickel alloys (Inconel, Hastelloy, Nickel 200, Monel, Incoloy, etc)

- Titanium, Cupronickel, and other exotic materials

INSTALLATION

The installation of branch fittings, or O’lets, is a critical process in piping systems, ensuring secure and efficient connections between the main pipe (header) and branch pipes. The installation method can vary slightly depending on the type of branch fitting used (e.g., Weldolets, Sockolets, Thredolets) and the specific application requirements. Here’s a general overview of the installation process:

1. Preparation

Selection of Fitting: Choose the appropriate type of O’let based on the connection requirements, such as the angle of the branch, the method of connection (welded, threaded, socket-weld), and the pressure rating.

Pipe Preparation: Measure and mark the location on the header pipe where the branch connection will be made. The surface of the header pipe should be cleaned around this area to ensure a good weld or connection.

2. Cutting and Drilling

Hole Creation: For Weldolets and some other O’lets, a hole is drilled or cut into the header pipe at the marked location. The diameter of the hole should match the outer diameter of the branch pipe.

3. Fitting Alignment

Alignment: Position the O’let over the hole so that its outlet aligns with the direction of the branch pipe. The O’let must fit snugly against the header pipe to ensure a secure connection.

4. Welding or Connecting

Welding: For Weldolets, Sockolets, and other weldable fittings, the next step is to weld the fitting to the header pipe. This involves carefully welding around the base of the O’let where it meets the header pipe, ensuring full penetration and a leak-proof seal.

Threading or Socket Welding: For Thredolets or Sockolets, the branch pipe may be connected via threads or a socket weld, respectively. Ensure the threads are clean and apply thread sealant if required before screwing the branch pipe into the O’let. For socket welds, insert the branch pipe into the fitting and then make the weld.

5. Inspection and Testing

Visual Inspection: After installation, visually inspect the fitting and the welds (if applicable) for any signs of defects or improper alignment.

Pressure Testing: It’s also recommended to perform pressure testing on the system to ensure that the newly installed branch connection is secure and leak-free.

6. Finishing

If the system passes inspection and testing, apply any required finishing touches, such as painting or coating the exposed metal to prevent corrosion.

ADVANTAGES (OVER CONVENTIONAL FITTINGS)

The use of branch fittings instead of conventional fittings (buttweld tee, reinforcing pads, and saddles) has the following advantages (for example Weldolet):

- Just 2 welds are needed, instead of 3 (less work and weld inspections)

- Accelerated installation time

- Less space is required, making the piping system design more flexible

- The flow is fully unrestricted, due to the funnel design

More in general, branch fittings offer the following key advantages over conventional fittings:

1. Flexibility in Design and Application

Branch fittings allow for more flexibility in the design of piping systems. They can be used to create integrally reinforced connections without the need for reinforcing pads or special machining, which are often required in buttweld connections.

2. Ease of Installation

The installation of branch fittings is generally quicker and less labor-intensive. Unlike buttweld fittings, which require precise alignment and welding of both the run pipe and the branch pipe, branch fittings can be directly welded onto the existing pipeline with a single weld, simplifying the process.

3. Reduced Space Requirements

Branch fittings require less space around the pipe for installation, making them ideal for tight or congested areas where working with buttweld fittings would be challenging.

4. Versatility

They offer a wide range of sizes, types, and pressure ratings, making them suitable for various applications, from low-pressure residential and commercial systems to high-pressure industrial processes.

5. Material and Cost Efficiency

O’lets can be more material-efficient, especially for creating connections to larger main pipes. They typically use less material than buttweld fittings, leading to cost savings, particularly in high-grade materials.

6. Strength and Durability

Branch fittings are designed to provide a reinforced connection that maintains the integrity of the piping system. The design ensures that the stress distribution around the branch connection is managed effectively, reducing the risk of failure compared to some buttweld configurations.

7. Simplify Modifications and Repairs

For modifications or repairs in an existing system, branch fittings can be added without the need to cut out a section of the pipe for a tee, as would be required with buttweld fittings. This can significantly reduce downtime and labor costs.

8. Compatibility with Different Piping Materials

Branch fittings are available in a variety of materials, making them compatible with a wide range of piping systems, including those where matching the material grade and specifications is critical.

KEY SPECIFICATIONS FOR BRANCH FITTINGS

Here are some of the primary specifications and standards that apply to branch fittings:

MSS SP-97

- Title: Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends

- Description: This is the leading standard for branch fittings, covering types, dimensions, tolerances, material grades, and marking requirements. It includes specifications for Weldolets, Thredolets, Sockolets, Elbolets, Nipolets, and other specialized O’let fittings.

ASME B31.3

- Title: Process Piping

- Description: Although not exclusively focused on branch fittings, ASME B31.3 provides guidelines for process piping systems, including the use of branch connections. It covers design considerations, materials, fabrication, examination, and testing aspects.

ASME B16.25

This specification covers buttweld ends.

ASME B16.11

- Title: Forged Fittings, Socket-Welding and Threaded

- Description: This standard specifies the dimensions, material grades, and pressure/temperature ratings for forged fittings, including branch fittings with socket-welding or threaded ends.

ASTM Standards

Description: Various ASTM standards specify the material properties and grades of the steel used in manufacturing branch fittings. For example, ASTM A105 covers carbon steel forgings for piping applications, while ASTM A182 covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service.

The material of the branch fitting must be compatible with the piping system’s material and the operational conditions (temperature, corrosion potential, etc.). Common materials include carbon steel, stainless steel, alloy steel, and special alloys for high corrosion resistance.

Pressure Ratings

Branch fittings are rated for specific pressure-temperature ranges, typically following the ratings of the piping systems in which they are used. The pressure rating (Class 150, Class 300, Class 600, etc.) dictates the maximum allowable operating pressure and temperature.

Design Features

The specifications also detail design features such as the type of branch connection (45-degree, 90-degree), the method of attachment (welded, threaded, socket-weld), and the integration of reinforcement to ensure the structural integrity of the branch connection.

BRANCH FITTINGS TYPES

WELDOLET

A Weldolet is a type of branch fitting used to make a 90-degree connection between a larger (main) pipeline and a smaller (branch) line. It is one of the most common types of branch connections and falls under the category of O’lets or branch fittings. Designed to provide a reinforced connection that minimizes stress concentration, a Weldolet ensures that the smaller branch has a stronger, leak-proof connection to the main pipe.

A Weldolet features beveled ends at both ends and is, therefore, welded onto the run pipe on one side and onto the branch pipe on the other side. The design of the Weldolet ensures little stress concentration on the branched pipe, providing an integral reinforcement. On the branch pipe side, Weldolets may have the same schedule of the run pipe or a higher schedule.

Weldolets are the most popular type of branch fittings, and they belong to the buttweld fittings family. Weldolets are available in a wide range of dimensions

Key advantages of Weldolets:

- Butt-Weld Connection: The Weldolet is welded to the main pipe and the branch pipe, creating a durable and permanent joint. The connection to the main pipe is made via a butt weld, ensuring the integrity and strength of the pipeline.

- Contoured Integrally Reinforced Design: It has a contoured, integrally reinforced design that aligns with the contours of the main pipe, effectively reducing stress concentrations at the base of the branch.

- Versatility: Weldolets can accommodate a wide range of pipe diameters and schedules, making them suitable for various applications and industries, including oil and gas, petrochemical, and water treatment plants.

- Material Compatibility: Available in various materials to match the pipe system, including carbon steel, stainless steel, alloy steel, and more, ensuring compatibility with the fluid being transported and the operating conditions.

- Pressure Ratings: Weldolets are designed to match the pressure ratings of standard pipes, providing a safe connection capable of withstanding the system’s operational pressures.

How to install a Weldolet: Bonney Forge

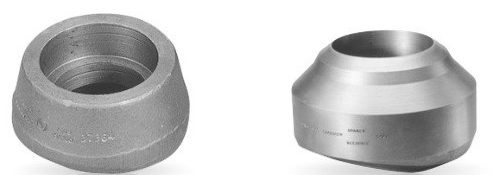

SOCKOLET

A Sockolet fitting is a type of branch connection used in piping systems to provide an outlet from a larger (main) pipe to a smaller (branch) pipe. Likewise Weldolets, Sockolets are used to make a 90-degree pipe branch. Sockolets may be “size on size” or “reducing”. Sockolet is a member of the O’let family, which includes various fittings designed for different connection needs. The Sockolet is specifically designed for socket weld connections, which distinguishes it from other types of branch fittings, such as Weldolets (designed for butt-weld connections) or Threadolets (designed for threaded connections).

A Sockolet is essentially similar to a Weldolet, with the difference that the branch pipe is connected to the run pipe, via the Olet, with a socket weld connection that shall conform to ASME B16.11.

Fillet welds are used to connect the branch pipe to the branch side of the Sockolet. On the pipe run side, a Sockolet requires a welded connection.

Key advantages of Sockolets:

- Socket Weld Connection: Sockolets are used to create a 90-degree branch connection and are welded into place via a socket weld. The branch pipe is inserted into the Sockolet’s socket and then welded around the top to secure it. This method provides a strong, leak-proof connection.

- High-Pressure Applications: Sockolets are well-suited for high-pressure applications where the fluid dynamics require a smooth transition and minimal turbulence at the connection points.

- Size and Pressure Ratings: They are available in a range of sizes and pressure ratings to match the requirements of various piping systems, ensuring compatibility with the main pipe’s diameter and wall thickness.

- Material Variability: Like other O’lets, Sockolets are manufactured in various materials, including carbon steel, stainless steel, and alloy steel, to cater to different environmental conditions and fluid types in the piping system.

- Reduced Stress Concentration: The design of a Sockolet aims to minimize stress concentration at the branch connection, enhancing the overall integrity and longevity of the piping system.

SOCKOLET VS. WELDOLET

Sockolets belong to the “socket fittings” family (forged fittings) and are available in classes 3000#, 6000#, and 9000#, whereas Weldolets are classified as buttweld fittings. Sockolets are used for lower pressure applications, and smaller pipe diameters, than Weldolets.

The key differences between Weldolets and Sockolets are:

Connections Methods

- Sockolet: Designed for socket weld connections. The branch pipe is inserted into the Sockolet’s socket and then welded around the top. This method is typically used for smaller pipe diameters and provides a smooth and compact connection.

- Weldolet: Made for butt-weld connections. It is welded onto the side of the main pipe and the end of the branch pipe, allowing for a direct and structurally sound connection. Weldolets are used for a wider range of pipe sizes and can handle significant changes in pipe diameter.

Applications

- Sockolet: Suited for high-pressure and high-temperature applications where space is limited and a leak-proof connection is essential. The socket weld connection offers excellent strength and is commonly used in smaller bore piping on projects that require a reliable seal.

- Weldolet: More versatile in application, Weldolets can be used in both high-pressure and low-pressure systems. They are preferred for creating branch connections where the branch size is significant compared to the main pipe. Due to their design, they are better suited for withstanding stress and are often used in industries such as oil and gas, petrochemical, and water treatment.

Sizes

- Sockolet: Generally used for smaller branch connections, typically up to 2 inches in diameter. They are rated for high-pressure applications, often in alignment with the pressure ratings of the socket weld fittings.

- Weldolet: Can accommodate a broader range of sizes, from very small to very large diameters, making them suitable for a wider variety of applications. Weldolets can also match the pressure ratings of the main pipe, allowing for their use in both high and low-pressure systems.

Stress Distribution

- Sockolet: The socket weld connection of a Sockolet minimizes stress concentration, making it suitable for applications where the integrity of the piping system is critical under high pressure.

- Weldolet: Designed to minimize stress concentrations at the branch connection through its contoured, integrally reinforced design. This makes Weldolets particularly effective in situations where the branch connection might be subjected to thermal or mechanical stress.

Installation Complexity

- Sockolet: Requires precise fitting and welding inside the socket, which can be more challenging in tight or confined spaces.

- Weldolet: Installation involves preparing the main pipe surface and executing a butt-weld, which can be more labor-intensive but allows for a more versatile application across different pipe sizes and conditions.

THREDOLET

A Threadolet is a type of branch fitting that is used to provide an outlet from a larger pipe to a smaller one. Unlike Weldolets and Sockolets, which are designed for welding, Threadolets facilitate connections via threaded fittings. This characteristic makes Threadolets particularly useful in applications where welding is not feasible or where a detachable connection is preferred for maintenance or operational flexibility.

Thredolets are used for low-pressure 90-degree pipe branches. The branch pipe is screwed on the Thredolet, which is welded on the run pipe. The threading is generally of the NPT type and conforms to the ASME B1.20.1 specification.

Thredolets belong to the “threaded fittings” family (forged fittings) and are available in classes 3000# and 6000#.

Threadolets are commonly used in low-pressure piping systems where a removable connection might be necessary, such as for instrumentation ports, pressure gauge connections, and smaller branches from main pipes. They are particularly valued in oil and gas, chemical processing, and petrochemical industries, where their ease of installation and maintenance, as well as their adaptability to various environments, make them an ideal choice.

Key Thredolets features:

- Threaded Connection: Threadolets are equipped with female threads to accommodate the male threads of the branch pipe. This enables a secure and leak-proof connection without the need for welding.

- Versatile Applications: Suitable for a wide range of applications, especially in systems where flammable or hazardous materials are present, and hot work (like welding) poses a safety risk.

- Material Compatibility: Available in various materials to match the piping system, including carbon steel, stainless steel, alloy steel, and more, ensuring compatibility with different fluid types and operational conditions.

- Pressure Ratings: Threadolets are designed to withstand the pressure demands of the system they are integrated into, with ratings often matching those of standard pipe fittings for consistency and safety.

- Size Range: They can be used to create branch connections in a broad range of sizes, providing flexibility in designing and retrofitting piping systems.

LATROLET

A Latrolet fitting is a type of branch connection used within piping systems to create a 45-degree lateral connection from a main pipe to a smaller branch pipe. It is part of the family of O’let fittings, which includes various specialized fittings designed for making branch connections in different configurations. Latrolets are specifically engineered for situations where a 45-degree branch is needed, either for a change in the direction of the flow or to connect auxiliary equipment.

Latrolets are commonly utilized in both new construction and retrofitting projects within the oil and gas, petrochemical, power generation, and water treatment industries. Their design makes them particularly useful for adding instrumentation, vents, drains, or other auxiliary connections at a 45-degree angle, facilitating optimal flow dynamics and accessibility.

Latrolets are available with butt weld connections to meet demanding reinforcement requirements or with socket weld/threaded connections in classes 3000# or 6000#.

Key Features:

- Angled Branch Connection: The defining feature of a Latrolet is its ability to create a 45-degree branch, which can be crucial for directional changes in piping systems or for integrating lateral connections efficiently.

- Versatile Connection Types: Latrolets can be manufactured for butt weld, socket weld, or threaded connections, providing flexibility to match the requirements of the piping system and the installation preferences.

- Range of Sizes and Pressure Ratings: They are available in various sizes and pressure ratings, allowing them to be used in a wide range of applications, from low-pressure residential systems to high-pressure industrial settings.

- Material Compatibility: Similar to other O’let fittings, Latrolets are made from a variety of materials, including carbon steel, stainless steel, and alloy steel, to ensure compatibility with the main pipe’s material and the operational environment.

ELBOLET

An Elbolet is a specialized type of branch fitting designed to provide an outlet connection on the curvature of an elbow. It is part of the broader family of O’let fittings, which are used to create integrally reinforced branch connections from a larger (main) pipe to a smaller (branch) pipe. The unique feature of an Elbolet is its ability to be installed on the 90-degree or other curved surfaces of elbows, making it an ideal solution for adding branch connections at these points in a piping system.

Elbolets are commonly used in piping systems that require branch connections directly on elbows, such as in oil and gas, chemical processing, power generation, and water treatment facilities. They are particularly valuable in situations where space constraints or specific flow directions necessitate the use of elbows for branch connections, including instrumentation take-offs, vent lines, or sampling ports.

Elbolets are available with butt weld connections or with socket weld/threaded connections in classes 3000# or 6000#.

- Specific Design for Elbows: Elbolets are specifically engineered to fit the contour of pipe elbows, allowing for the creation of branch connections on the elbow’s surface where standard Weldolets or Threadolets might not be suitable.

- Versatile Applications: They are used in both long and short-radius elbows, adaptable to various piping configurations and applications, ensuring a secure and leak-proof connection.

- Connection Types: Elbolets can accommodate different types of connections, including butt weld, socket weld, and threaded connections, offering flexibility in how the branch pipe is connected to the main system.

- Material and Pressure Compatibility: Available in a wide range of materials such as carbon steel, stainless steel, and alloy steel, Elbolets can be selected to match the material specifications of the main piping system. They are also rated for different pressure classes to suit the operational requirements of the system.

- Size Range: Elbolets are manufactured in various sizes to connect a broad range of branch pipe diameters to the main elbow, facilitating precise control over flow and pressure in the system.

NIPOLET

A Nipolet is a specialized type of branch fitting designed for extended applications, serving as a combination of a nipple and an O’let. This fitting is used to create a branch outlet from a main pipe to a smaller outlet pipe, typically for instrumentation connections, drains, and vents. Nipolets are particularly useful in applications where space is limited or where a conventional O’let fitting might not be the most practical solution.

Nipolets are widely used for creating branch connections in piping systems where direct instrumentation connections, vents, or drains are required. Their compact design makes them particularly advantageous in tight spaces or in applications where a minimal protrusion from the pipe surface is desired. Nipolets offer a reliable and efficient method for integrating auxiliary lines or equipment into existing piping systems without the need for extensive modifications.

Key features:

- Integrated Nipple Design: The Nipolet incorporates a nipple, or a short piece of pipe with external threading, directly into the O’let fitting. This design simplifies the connection process by eliminating the need for a separate nipple piece, facilitating a direct, threaded connection to the branch pipe or equipment.

- Versatile Connection Options: Nipolets can be used for both butt weld connections to the main pipe and threaded connections to the branch line, offering flexibility in installation and application.

- Material and Size Range: Available in a variety of materials, including carbon steel, stainless steel, and alloy steel, Nipolets can be selected to match the piping system’s specifications. They come in a range of sizes to accommodate different pipe diameters and system requirements.

- High Pressure and Temperature Ratings: Designed to withstand high-pressure and high-temperature environments, Nipolets are suitable for use in demanding industrial applications, including oil and gas, chemical processing, and power generation.

SWEEPOLET

A Sweepolet is a specialized type of branch fitting designed for creating integrally reinforced branch connections on piping systems, particularly where there is a need for a smooth flow transition. It belongs to the O’let family, which includes various fittings used to connect smaller-diameter branch pipes to larger-diameter main pipes. The distinctive feature of a Sweepolet is its contoured, gradually curved shape that allows for a more gradual flow change from the main pipe into the branch pipe, minimizing turbulence and stress concentration.

Sweepolets are used in piping systems that require a minimized pressure drop and reduced turbulence at branch connections. Their design is particularly advantageous in high-velocity systems or where the fluid has erosive characteristics, as the gradual transition helps to protect the piping material and maintain system integrity. Applications include critical process lines, high-temperature steam services, and other systems where fluid dynamics are a concern.

Key features:

- Smooth Flow Transition: The curved design of the Sweepolet facilitates a smoother flow of fluid from the main pipe into the branch pipe. This is particularly beneficial in systems where maintaining a laminar flow or reducing flow-induced vibration is critical.

- Reinforced Branch Connection: Like other O’lets, Sweepolets provide an integrally reinforced connection, ensuring the structural integrity of the branch connection without the need for additional reinforcement pads.

- Butt-Weld Connection: Sweepolets are typically installed using a butt-weld connection to both the main pipe and the branch pipe, providing a strong and leak-proof joint.

- Material and Size Range: Available in various materials such as carbon steel, stainless steel, and alloy steel, Sweepolets can be selected to match the piping system’s material specifications. They are manufactured in a range of sizes to accommodate different pipe diameters and system requirements.

- High Pressure and Temperature Ratings: Designed to withstand the operational demands of high-pressure and high-temperature environments, making them suitable for use in industries such as oil and gas, power generation, and chemical processing.

The welded connection on the run pipe side can be easily inspected with radiographic examination (RX or RT), ultrasounds (UT), and other non-destructive tests.

COUPOLET

A Coupolet fitting is a type of branch connection or branch outlet fitting that is designed to provide an outlet from a larger diameter pipe to a smaller one. It is one of the many types of fittings used in piping and plumbing systems to facilitate changes in direction or pipe diameter or to add auxiliary equipment. Specifically, a coupolet is used to create a 90-degree branch connection on pipelines, making it an integral component in various industrial applications, including the oil and gas, petrochemical, and power generation sectors.

Key Characteristics of Coupolet Fittings:

Design and Function: Coupolets are designed with a contoured, integrally reinforced, weldable insert that allows for a full penetration weld to the run pipe while providing a branch outlet. This design ensures structural integrity and minimizes stress concentrations at the base of the branch.

Size and Ratings: These fittings are generally used for branch connections where the branch size is less than half the run pipe size, and they are available in a wide range of sizes and material grades to accommodate different pressures and temperatures.

Installation: The installation of a coupolet involves welding the fitting onto the run pipe and then welding the branch pipe to the coupolet. This method ensures a strong and leak-proof connection, crucial for maintaining the safety and efficiency of the piping system.

Materials: Like other piping components, Coupolets are available in various materials, including carbon steel, stainless steel, alloy steel, and others, to match the pipe material and meet the specific requirements of the operating environment, such as temperature, pressure, and the nature of the fluids being transported.

Applications:

Coupolets are particularly useful in high-pressure and high-temperature applications where a reliable and robust branch connection is critical. Their applications span across various industries:

Oil and Gas: Used in both upstream and downstream operations for creating branch connections in pipelines and process piping systems.

Petrochemical: In the petrochemical industry, Coupolets are used to facilitate the addition of instrumentation, such as pressure gauges and thermowells, to process lines.

Power Generation: In power plants, Coupolets serve to connect auxiliary systems, such as lubrication or cooling systems, to main steam or water lines.

Standards and Specifications:

The design, manufacture, and testing of Coupolets are governed by industry standards to ensure quality and safety. Although there might not be a specific standard exclusively for Coupolets, they generally adhere to the standards applicable to branch connection fittings, such as the MSS SP-97 (Manufacturers Standardization Society Standard Practice 97), “Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends.” This standard specifies the dimensions, tolerances, and material grades for branch connection fittings, ensuring their compatibility and performance in piping systems.

HOW TO ORDER BRANCH FITTINGS

Suppliers of Weldolets, Thredolets, Sockolets, and other branch fittings need the following information to identify the needed product:

- Header run pipe size (which is generally expressed as a range of possible sizes, for example, 36-22)

- Branch pipe size (the NPS of the connecting pipe to the run pipe, for example, 6 inches)

- Branch pipe schedule (which can be STD, XS, 160, XXS) for buttweld types of connections (rating shall be provided for socket weld and NPT threaded Olets)

- Style of branch fitting (Weldolet, Thredolet, Nipolet, Sockolet, etc)

- Material Grade (example A105, A350 LF2, A182 F304)

EXAMPLE: 36-22 | 6 INCH Sch. STD | Weldolet | ASTM A105

19 Responses

Wonderful article. I became well-versed in it. Also visit Rajkrupa Metal Industries to know more about Round Bars Manufacturer in India.

Thank you for your kind words. We’re glad to hear that our article helped you become well-versed in weldolet, threadolet, and sockolet. We appreciate your suggestion to visit Rajkrupa Metal Industries to learn more about round bars manufacturing in India. It’s always beneficial to explore different sources for comprehensive knowledge in the field.

Bonjour,

Je recherche un latrolets ou threadolet taraudé dn 15 BSP . acier carbone proche A105N , P280GH/EN10222-2.

Le collecteur est en DN300 , la connexion en DN 15 femelle

Merci

3 weldolet branch connections on pipe at the same heigth, is it possible?

Nice information i am also from the same industry and i have more information and product as well so kindly visit us https://goyalsteeltubes.com/

Very Good information. For weldolet welding guidelines check it out: https://www.materialwelding.com/weldolet-welding-requirements-details-you-need-to-know/

Good Blog, was very helpful also if you want Round bar Kanak Metals is a good option to go with. We are Round Bar Manufacturer in India and the best Alloy Steel Round Bar Manufacturer in India.

Nice Info, also check wire mesh manufacturer in India and visit our website at Bhansali Steel.We Manufacture various types of steel products like Rectangular Wire Mesh and Hastelloy Wire Mesh.

PRICE QUOTATION

Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY:2

Material PO Text: 20″ X 2″ WELDOLET, MSS-SP97, ASTM A 350 GR. LF3 CL.1 BWSCH 80 X SCH 160 QUANTITY:1

Material PO Text: 4″ X 2″ CONC REDUCER A234 WPB SCH 80 X SCH 40, BW QUANTITY:10

Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY: 10

Material PO Text: 4″ X 2″ CONC REDUCER A234 WPB SCH 80 X SCH 40, BW QUANTITY:5

Material PO Text: 2″ X 3/4″ SOCKOLET 3000LBS, SW, A105 QUANTITY:5

Material PO Text: 3/4″ PIPE SCH 80 A106 – Gr. B SMLS BE QUANTITY:5

Material PO Text: 20″ X 2″ WELDOLET, MSS-SP97, ASTM A 350 GR. LF3 CL.1 BWSCH 80 X SCH 160 QUANTITY:1

Hello, here are European Origin Prices for your items

SOCKOLET A105 2″ x 3/4″ 3000# SW 17pcs @ 7.50 EURO/ea, WEDOLET ASTM A350 LF2 20″ x 2″ S-80/160 2pcs @ 40 EURO/ea, CONCENTRIC REDUCER ASTM A234 WPB 4″ S-80 x 2″ S-40 15PCS @ 75 EURO/ea

Thank you for providing the European Origin Prices for the items mentioned in the previous conversation. It is helpful to have a clear understanding of the pricing for SOCKOLET, WELDOLET, and CONCENTRIC REDUCER.

Based on your information, the SOCKOLET A105 2″ x 3/4″ 3000# SW is priced at 7.50 EURO/ea, with a quantity of 17 pieces. The WELDOLET ASTM A350 LF2 20″ x 2″ S-80/160 is priced at 40 EURO/ea, with a quantity of 2 pieces. Lastly, the CONCENTRIC REDUCER ASTM A234 WPB 4″ S-80 x 2″ S-40 is priced at 75 EURO/ea, with a quantity of 15 pieces.

Having these specific prices allows us to make more informed decisions regarding the purchase of these items. It would be helpful to know if these prices are inclusive of any additional charges or if there are any terms and conditions associated with them.

Thank you again for providing this information.

Nice Info, also check on Titanium Vessel Manufacturer in India , Titanium Refineries Manufacturer in India and visit our website at Ladhani Metal Corporation.We also manufacture Titanium Butterfly Valve, and Titanium C Clamp.

Thank you for sharing an informative blog. Also Visit-

Trimac piping solutions

Flanges Manufacturer in India

Flanges Supplier in dubai

Thank you for sharing an informative blog. Also Visit-

Trimac piping solutions

Flanges Manufacturer in India

Carbon Steel IS 2062 flange

Hi, I have purchased 10″-18″(Run size) x 2″ SCH 160 (Branch size) weldolet as per the CL 900 piping class. My question is does the header size pipe thickness matters? Currently my header size thickness is SCH 120 for 10″ pipe and SCH 100 for 16″ to 18″.

The reason I am asking whether the header size pipe thickness matters is because, I have a requirement of wedloelt16″ (Run size) X 2″ SCH 160(Branch size) for pipe line whose thickness is 10.9 mm and 11.91 mm.

Can I use the same weldolet mentioned in the first line (surpluss available) which was procured as per piping class to install on the 16″ pipe line with wall thickness 10.9 mm and 11.91 mm but having the branch size of 2″ with SCH 160.

You have high / low pressure mixed up regarding your 3000# and 6000# fittings. Those are for high pressure applications, as is implied by them having a higher pound rating literally within their name.

Please quote your best price and delivery (AIR FREIGHT) for the item below :

1. CAP 12″ S60 A234 WP11 – 1 PC

2. FLAT WELDOLET 1.1/2” X 12”-36”, A182 F11 CL2 – 1 PC

Please below see the price

CAP 12″ S60 A234 WP11 – 1 PC

PRICE: 189.1/- $ PER EACH

FLAT WELDOLET 1.1/2” X 12”-36”, A182 F11 CL2 – 1 PC

PRICE: 59.5/- $ PER EACH

THANKS AND REGARDS

AMRUT MODI

SAKSHI METAL INDUSTRIES

EMAIL: sakshimetalindia@gmail.com

WHATSAPP: +91 9892802783

please i need proforma for sockolet 10 x3/4″