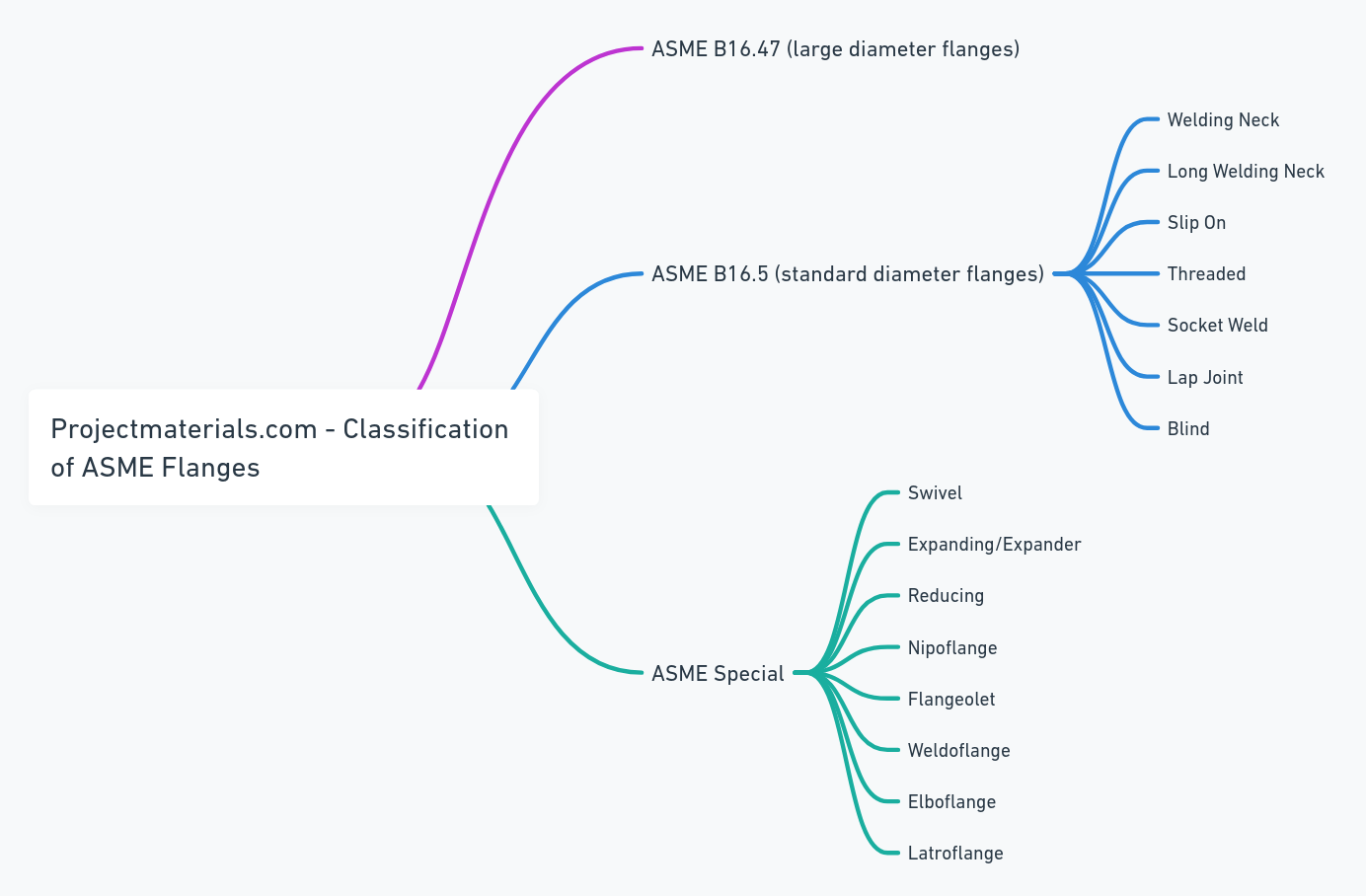

A detailed review of the standard types of flanges used in piping (Welding Neck, Long Welding Neck, Slip-on, Socket weld, Lap Joint, Threaded, and Blind) as well as of some special types (Weldoflange/Nipoflange and Elboflange, Swivel, Expander/Reducer Flange, and Orifice type).

TYPES OF FLANGES

In this article, we review the 13 types of flanges for pipelines and piping systems (ASME B16.5), divided into “standard” and “non-standard” (or less common) types.

Large flange sizes, not examined here, are ruled by the ASME B16.47 Series A-B Specification.

Let’s now delve into the features of the ASME B16.5 standard types of flanges.

STANDARD TYPES (ASME)

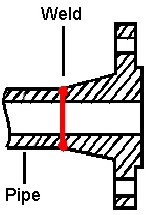

WELDING NECK FLANGE (“WNF”)

An ASME Welding Neck Flange, often referred to as a weld neck flange (WNF), is a type of pipe flange that provides a strong, durable connection for piping systems.

A WNF is characterized by its long tapered hub, which provides important reinforcement for use in various applications, particularly those involving high pressure and temperature. This design not only facilitates stress distribution but also reduces the concentration of stress at the base of the flange, making the weld neck flange an ideal choice for critical and demanding services.

This flange type is used, normally, in high-pressure and high/low-temperature applications that require an unrestricted flow of the fluid conveyed by the piping system (the bore of the flange matches with the bore of the pipe).

Design and Features:

- Tapered Hub: The distinguishing feature of a weld neck flange is its gradually tapered hub, which transitions smoothly from the flange diameter to the pipe diameter. This design enhances strength and supports stress distribution.

- Butt-Welded Connection: Weld neck flanges are designed to be butt-welded to the pipe. The welding process creates a continuous metal structure between the pipe and flange, offering superior strength and leak integrity.

- Bore Matching: The bore of the weld neck flange is machined to match the inside diameter of the adjoining pipe, ensuring smooth flow and reducing turbulence and erosion at the joint.

- Pressure Ratings: ASME specifies various pressure classes for weld neck flanges, including but not limited to Class 150, 300, 600, 900, 1500, and 2500. The choice of class depends on the system’s maximum operating pressure and temperature.

Standards:

Governed by the American Society of Mechanical Engineers (ASME) under standards such as ASME B16.5 (for sizes up to 24 inches) and ASME B16.47 (for larger sizes), welding neck flanges are manufactured to these specifications to ensure compatibility and safety across a wide range of applications.

Applications:

- High-Pressure Systems: Due to their robust design, weld neck flanges are widely used in high-pressure applications, such as steam lines, high-pressure gas pipelines, and power generation plants.

- High-Temperature Services: The integral connection between the flange and pipe makes weld neck flanges suitable for high-temperature applications, including refineries and chemical processing plants.

- Fluctuating Conditions: The strength and durability of weld neck flanges make them ideal for systems experiencing fluctuating pressures and temperatures, providing a stable, leak-proof connection.

Advantages:

- Strong and Durable: The welded joint provides a strong, high-integrity connection that is less likely to leak compared to other flange types.

- Reduced Stress Concentration: The tapered hub promotes better stress distribution, reducing the likelihood of fatigue and failure.

- High Compatibility: Suitable for a wide range of applications due to the availability of various materials and pressure ratings.

- Low-Pressure Drops: Limited to non-existing pressure drops prevent negative effects such as turbulence and erosion/corrosion of the metals in the proximity of the flanged joints.

- RX Inspections: The tapered hub allows a smooth distribution of the mechanical stress between the pipe and the weld neck flange and facilitates the execution of radiographic inspections to detect possible leakages and welding defects.

The dimension of the flange (NPS and the pipe schedule) shall match the dimension of the connecting pipe.

A welding neck flange is connected to a pipe by a single full penetration V-shaped butt weld. The dimensions and weights of ASME weld neck flanges are shown in this article.

LONG WELDING NECK (“LWNF”)

This flange features a longer neck compared to the standard welding neck flange, providing extra reinforcement and stability. It’s especially useful in applications that involve thermal expansion and mechanical stress, making it a preferred choice for critical service conditions.

Key Features:

- Extended Neck: The most distinguishing characteristic of a long welding neck flange is its extended neck, which provides better stress distribution and reduces the chances of bending at the joint.

- Butt-Weld Connection: Similar to standard welding neck flanges, long welding neck flanges are designed to be butt-welded to the piping. This ensures a strong, seamless connection between the pipe and the flange.

- Reinforced Structure: The extended neck acts as a reinforcement, making the flange ideal for handling loads and stresses associated with pipeline movements, vibrations, and thermal expansion.

Applications:

- Process Equipment: Frequently used in connecting piping to pressure vessels, boilers, and heat exchangers where the connection requires distance from the vessel to allow for insulation or equipment clearance.

- High-Temperature and High-Pressure Systems: Suitable for petrochemical plants, power generation facilities, and other industrial processes that operate under high temperatures and pressures.

- Complex Piping Systems: Utilized in systems where stress from piping misalignment, expansion, or contraction could otherwise compromise flange integrity.

Advantages:

- Enhanced Durability: The long neck provides superior strength and resistance to stress, minimizing the risk of flange deformation and failure.

- Improved Stress Distribution: The extended neck promotes even stress distribution along the length of the flange, reducing the concentration of stress at the critical junction between the flange and the pipe.

- Versatility: Can be used in a variety of settings that require a durable and reliable flange connection, including in challenging environmental conditions and in systems with significant thermal variations.

Standards and Specifications:

Long-welding neck flanges are manufactured according to industry standards, including those set by the American Society of Mechanical Engineers (ASME). Specifications cover dimensions, materials, and pressure ratings to ensure compatibility and safety across applications. The choice of material (carbon steel, stainless steel, alloy, etc.) and the specific pressure class (e.g., Class 150, 300, 600, 900, 1500, 2500) depend on the application’s requirements regarding temperature, pressure, and the nature of the fluid being transported.

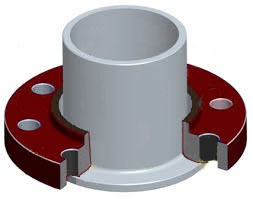

SLIP-ON FLANGE

A slip-on flange is a type of pipe flange that slides over the end of a pipe and is then welded on both the inside and outside to provide sufficient strength and prevent leakage.

This design allows for an easier and less precise alignment compared to some other flange types, such as weld neck flanges, making the slip-on flange a popular choice for lower-pressure and temperature applications.

Key Features:

- Ease of Installation: Slip-on flanges are easier to align than weld neck flanges, making them suitable for applications where the precise alignment is challenging.

- Welding Requirements: Requires less welding compared to weld neck flanges. The welding process involves welding around the outer diameter of the flange to secure it to the pipe and may include welding the inside diameter for additional strength and leak prevention.

- Cost-Effectiveness: Generally, slip-on flanges are more cost-effective than weld neck flanges due to their simpler design and reduced material usage.

- Versatility: They can be used with both seamless and welded pipes and are available in a variety of materials, including carbon steel, stainless steel, alloy steel, and more, to suit different applications.

Applications:

Slip-on flanges are commonly used in lower-pressure and non-critical applications, such as water distribution, heating and cooling systems, and various piping systems within commercial and light industrial settings. They are not recommended for high-pressure or high-temperature applications or for systems with a high risk of fatigue due to bending forces.

Advantages:

- Cost Efficiency: Less material is required for manufacturing, and the simpler design translates to lower costs.

- Simplified Installation: The ability to easily slide the flange onto the pipe before welding simplifies the installation process, especially in tight spaces.

- Flexibility: Suitable for various piping materials and applications where the conditions do not demand the high integrity of a weld neck flange.

Limitations:

- Lower Strength: Slip-on flanges have a lower pressure and temperature rating compared to weld neck flanges, limiting their use in high-pressure applications.

- Risk of Leakage: While less common, the potential for leakage exists if not properly welded on both sides.

Installation Considerations:

When installing slip-on flanges, it’s important to ensure proper alignment before welding and to follow appropriate welding procedures to secure the flange to the pipe. Both the inside and outside welds are crucial for the structural integrity of the connection and to prevent leaks.

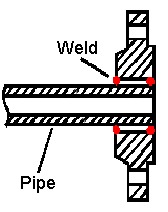

A slip-on flange is connected to the pipe or the fittings by two fillet welds, one executed inside and one outside the cavity of the flange.

The bore size of a slip-on flange is larger than the outside diameter of the connecting pipe, as the pipe has to slide inside the flange to be connected by the execution of a fillet weld.

Slip-on flanges are also defined as “Hubbed Flanges” and they are easy to recognize due to their slim and compact shape.

The dimensions and weights of slip-on flanges ANSI/ASME are available on this page.

WELD NECK VS SLIP-ON FLANGE

Flanged joints made with slip-on flanges are, in the long run, a bit more fragile than connections made with welding neck flanges (in similar service conditions). This fact, observed several times on oil & gas fields, seems due to the following facts:

- a welding neck flange features a tapered hub, absent in a socket weld flange, which distributes the mechanical stress between the pipe and the flange more evenly

- a welding neck joint as only one welding area instead of two (socket weld flange).

Another advantage of the welding neck flange is that it can be connected either to pipes and fittings, whereas socket weld flanges suit pipes only.

To summarize the differences between slip-on and welding-neck flanges:

- Strength and Integrity: Weld neck flanges offer higher strength and integrity, making them suitable for severe service conditions, whereas slip-on flanges are better suited for lower-pressure and temperature applications.

- Cost and Installation: Slip-on flanges are generally more cost-effective and easier to install but may require more care to ensure a leak-proof seal.

- Application Suitability: The choice between weld neck and slip-on flanges depends on the application’s pressure, temperature, and criticality. Weld neck flanges are preferred for high-pressure and temperature applications, while slip-on flanges are adequate for less demanding conditions.

THREADED FLANGE

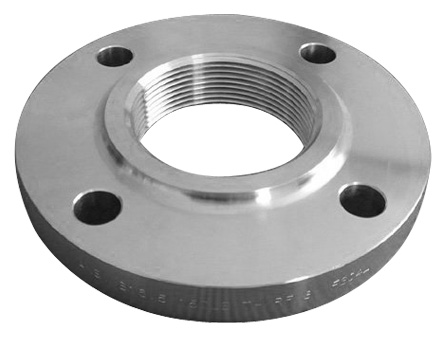

Threaded flanges are joined to pipes by screwing the pipe (which has a male thread, generally NPT per ASME B1.20.1) into the flange, without the need to execute seam welds (in certain cases, though, small welds are applied to increase the strength of the connection).

Threaded flanges are available in sizes up to 4 inches and multiple pressure ratings, however, they are used, mostly, small size piping in low-pressure and low-temperature applications, like water and air utility services.

Threaded flanges are also a mandatory requirement in explosive areas, such as gas stations and plants, as the execution of welded connections in such environments could be dangerous.

Consult this article, to find out about the dimensions of ANSI/ASME threaded flanges.

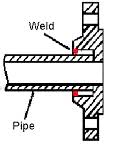

SOCKET WELD FLANGE

.

.

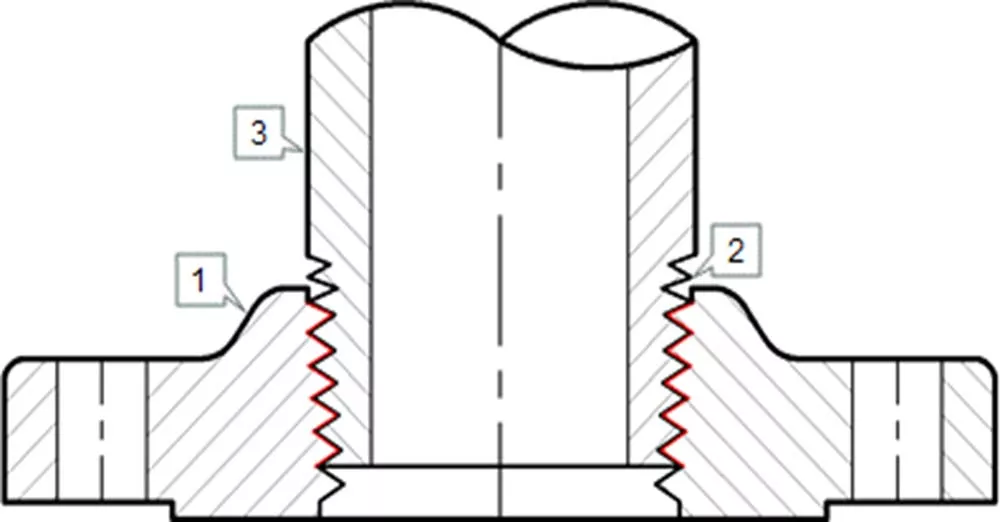

According to ASME B31.1, to execute a flanged connection using a socket weld flange, the pipe shall be at first inserted in the socket of the flange until it reaches the bottom of the flange, then it should be lifted by 1.6 mm and finally welded.

This gap shall be left to allow proper positioning of the pipe inside the flange socket after the solidification of the weld.

Socket Weld Flanges are used for small-size and high-pressure piping that do not transfer highly corrosive fluids.

This is because these flange types are subject to corrosion in the gap area between the end of the pipe and the shoulder of the socket.

The static strength of socket weld flanges is similar to slip-on flanges, but their fatigue strength is higher due to the presence of a single, instead of double, fillet weld.

LAP JOINT FLANGE

Lap joint flanges feature a flat face and are always used in conjunction with a stub end.

Lap joint flanges resemble, in shape, slip-on flanges except for the radius at the crossing of the flange face and the bore to accommodate the flanged portion of the stub end.

A lap joint flange slips over the pipe and seats on the back of the stub end and the two are kept together by the pressure of the bolts.

The use of lap joint flanges in combination with stub ends is a cost-effective solution for stainless steel or nickel alloy pipelines, as the material of the lap joint flange can be of a lower grade (generally carbon steel) than the material of the stub end (which has to match the pipe grade, as in contact with the conveyed fluid).

This arrangement, therefore, has these two advantages:

- reduces the overall cost of the pipeline’s flanged joints, as the use of higher-grade materials is minimized;

- bolting operations are simplified, as the lap joint flange can be rotated around the pipe to help with bolt alignment.

BLIND FLANGE

Differently from all the flange types seen above, blind flanges do not have a center hole and are used to blind or seal a pipeline, or a valve/pressure vessel and block the flow of the fluid.

Blind flanges have to withstand remarkable mechanical stress due to the system pressure and the required bolting forces.

Blind flanges allow easy access to the pipeline, as they can be easily unbolted to let the operator execute activities inside the terminal end of the pipe (this is also the reason why the blind flange type is used as a manhole for pressure vessels, at times).

It is maybe interesting to observe that, while this flange type is easier to manufacture, they are sold at a premium average cost per kilogram compared to the other flange types.

Refer to this article to learn about the dimensions of blind flanges per ANSI/ASME B16.5.

SPECIAL TYPES (ASME)

NIPOFLANGE

A Nipoflange is used for branch pipelines at 90 degrees and is a product manufactured by combining a welding neck flange with a forged Nipolet.

However, a Nipoflange is a solid single piece of forged steel and not two different products welded together.

To install a Nipoflange, the piping staff has to weld the Nipolet part of the device on the run pipe and bolt the flanged part on the flange of the branched pipe.

Nipoflanges are available in different materials, such as carbon steel ASTM A105 (high-temperature service), ASTM A350 (low-temperature carbon steel), ASTM A182 (stainless steel grades, including duplex and super duplex), and nickel alloys (Inconel, Incoloy, Hastelloy, etc).

Nipoflanges are also manufactured in the reinforced variant, which has additional mechanical strength compared to a standard Nipoflange.

WELDOFLANGE

Weldoflange

A Weldoflange, often referred to as a welding neck flange outlet, is a specialized flange used in the piping industry to create a branch connection from a main pipe. It combines the design features of a welding neck flange with the functionality of a branch connection, allowing for the direct welding of the flange onto the run pipe while providing an outlet for branch connections. This design simplifies the process of creating branch connections, especially in high-pressure and high-temperature applications where reliability and integrity are crucial.

Key Features:

- Integrated Design: A Weldoflange consists of a flange with a neck (similar to a weld neck flange) that is directly welded to the side of a pipe. A branch pipe is then connected to the flange, creating a reinforced, leak-proof branch connection.

- High Integrity Connection: The weld between the Weldoflange and the run pipe provides a strong, permanent connection that can handle high pressures and temperatures, making it suitable for critical applications.

- Space-Saving: By integrating the flange and branch connection, Weldoflanges save space compared to traditional tee and flange combinations, making them ideal for tight or congested areas.

Applications:

Weldoflanges are widely used in various industrial sectors, such as oil and gas, petrochemical, power generation, and other process industries, where they facilitate the branching off of auxiliary lines from main pipes. Their robust design makes them suitable for:

- Process piping systems that require reliable branch connections.

- High-pressure and high-temperature environments where the integrity of branch connections is critical.

- Situations where space limitations or system layout constraints necessitate a compact branching solution.

Advantages:

- Reliability: Offers a high-integrity, leak-proof connection suitable for severe service conditions.

- Efficiency: Simplifies the piping design by eliminating the need for separate fittings and flanges for branch connections.

- Versatility: Available in various sizes and materials to match the piping system requirements and fluid characteristics.

Installation Considerations:

- Proper welding techniques are crucial to ensure the integrity of the connection between the Weldoflange and the main pipe.

- The selection of Weldoflanges must consider the pressure, temperature, and chemical compatibility of the system to ensure performance and safety.

- Inspection and testing of the welded joints are essential to verify the quality and reliability of the connection.

ELBOFLANGE

An Elboflange is a specialized piping component that combines the functionality of an elbow with that of a flange. Essentially, it is an elbow (a pipe fitting that allows for a change in the direction of the flow) that has an integral flange at one or both ends. This integrated design streamlines the connection of pipes at an angle to equipment, other pipes, or fittings that require a flanged connection, making it a practical solution for various piping system configurations.

Key Features:

- Integrated Design: The Elboflange merges two critical piping components into a single unit, reducing the number of required fittings and simplifying the piping layout.

- Directional Change with Flanged Connection: It facilitates directional change in the piping system while providing a ready-made flanged end for bolting to other flanged components, such as valves, pumps, or other pipes.

- High Integrity Connection: Like standalone flanges, the flanged end of an Elboflange is designed to ensure a secure, leak-proof connection when mated with a corresponding flange and sealed with a gasket.

Applications:

Elboflanges are used in various industrial settings where piping systems require directional changes and secure, flanged connections, including:

- Oil and Gas: For connecting piping to equipment like compressors, reactors, or tanks where the pipeline needs to turn.

- Chemical Processing: In systems requiring precise control of flow direction and secure connections to process equipment.

- Power Generation: For steam and water lines that need to navigate around obstacles or connect to boilers and turbines.

Advantages:

- Simplified Installation: By combining an elbow and a flange, the Elboflange reduces the number of fittings and welds required, simplifying installation and maintenance.

- Space Saving: Ideal for use in tight spaces where combining separate elbows and flanges would be impractical or would create unnecessary complexity.

- Versatility: Available in various sizes, materials, and pressure ratings to suit a wide range of applications and media.

Installation Considerations:

- Compatibility: Ensure that the Elboflange material is compatible with the media being transported and the operating conditions (pressure, temperature) of the system.

- Alignment: Proper alignment with the connecting flange is crucial to avoid leaks. The use of appropriate gaskets and bolts according to the flange specifications is essential.

- Inspection and Maintenance: Regular inspection of the bolted connections and gasket integrity is necessary to maintain the system’s safety and reliability.

LATROFLANGE

A Latroflange is a specialized piping component that combines the features of a lateral tee and a flange. It’s designed to create a branch connection from a main pipe at an angle other than 90 degrees, typically 45 degrees, with a flanged end on the branch. This allows for the direct attachment of equipment, instruments, or additional piping via a flanged connection. The main body of a Latroflange is similar to a lateral tee, facilitating a diagonal flow path, while one end of the branch is equipped with a flange.

Key Features:

- Angled Branch: The Latroflange provides an angled branch from the main pipeline, offering a more gradual directional change compared to traditional tees, which can be beneficial for flow dynamics and reducing pressure losses.

- Flanged Connection: The flanged end on the branch allows for easy attachment to other flanged components, such as valves, meters, or equipment, providing versatility in system design and maintenance.

- Integrated Design: By combining the lateral connection and flange into a single unit, the Latroflange reduces the need for multiple fittings and simplifies the piping system layout.

Applications:

Latroflanges are used in various industrial applications where a diagonal branch connection with a flange is required, including:

- Process Piping Systems: In chemical, petrochemical, and oil and gas industries for branching out to process equipment or instrumentation.

- Water Treatment: For attaching monitoring equipment or bypass lines in treatment plants.

- Power Generation: In steam and cooling water systems where controlled flow distribution to auxiliary equipment is needed.

Advantages:

- Efficient Flow Distribution: The angled branch can help reduce turbulence and minimize pressure drops in the system.

- Ease of Installation and Maintenance: The flanged branch end allows for quick attachment or detachment of components, facilitating easier system modifications, inspections, and cleaning.

- Space Saving: The integrated design saves space compared to using separate fittings and flanges to achieve the same configuration.

Installation Considerations:

- Material Compatibility: The material of the Latroflange should be compatible with the fluid being handled and the operating conditions (temperature, pressure, and corrosion potential) of the system.

- Flange Standards: The flange part of the Latroflange must conform to relevant standards (such as ASME B16.5) to ensure proper sealing and compatibility with other flanged components.

- Proper Alignment: Careful alignment with the connecting flange is essential to prevent leaks. Using the appropriate gasket and following specified bolt-tightening procedures are critical for a leak-proof connection.

SWIVEL FLANGE

Swivel ring flanges facilitate the alignment of the bolt holes between the two mating flanges, a feature that is helpful in many circumstances, such as the installation of large-diameter pipelines, subsea and offshore pipelines, pipe works in shallow waters, and similar environments. Swivel flanges suit oil, gas, hydrocarbons, water, chemical, and other demanding fluids in petrochemical and water management applications.

In the case of a large diameter pipeline, for instance, the pipe is fitted, at one end, with a standard welding neck flange, and with a swivel flange at the other end: by simply rotating the swivel flange on the pipe, the operator can achieve a perfect alignment of the bolt holes in a way easier and faster way.

The major standards for swivel ring flanges are ASME/ANSI, DIN, BS, EN, ISO, etc. The most common standard for petrochemical application is the ANSI/ASME B16.5 or ASME B16.47.

Swivel flanges are available in all the standard shapes of common flanges, i.e. weld-neck, slip-on, lap-joint, socket weld, etc, in all material grades and in a wide dimensional range (sizes can vary from 3/8” to 60” and pressure rating from 150 to 2500).

Swivel flanges can be manufactured in carbon steel (ASTM A105), alloy steel (ASTM A182 F1, A182 F5, A182 F9, A182 F91), and, stainless steel (ASTM A182 F304, A182 F304L, A182 F316, A182 F316L).

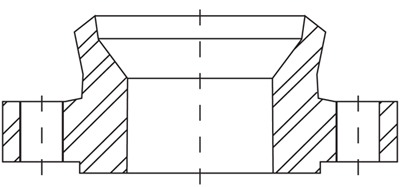

EXPANDING FLANGE (“EXPANDER”)

Expanding flanges, or “expander flanges”, are used to increase the bore of the pipeline from one specific point to another or to connect pipes to other mechanical devices such as pumps, compressors, and valves that have different inlet sizes.

The expanding flange represented in the picture is a welding neck flange with a larger bore on the non-flanged end.

Expanding flanges can be used to increase the run pipe bore only by one or a maximum of two sizes and not more (for example: from 2 to 3 or a maximum of 4 inches).

Expander flanges are a cheaper (and lighter) solution compared to the combination of a buttweld reducer and a standard flange (which is the standard solution for pipe bore increases above 2 sizes).

The most common materials for expanding flanges are A105 (high-temp. carbon steel), A350 (LTCS), and ASTM A182 (stainless steel and above).

Pressure ratings and dimensions of expanding flanges are by the ANSI/ASME B16.5 specification and are available with raised or flat faces (RF, FF).

The drawing of an ASME expanding flange.

REDUCING FLANGE (“REDUCER”)

Reducing flanges, otherwise called reducer flanges, have an opposite function than expander flanges seen above, i.e. they are used to decrease the bore of a pipeline.

The bore of the run pipe can be safely reduced by only 1 or 2 sizes (otherwise a solution based on the combination of a butt weld reducer and a standard flange has to be used).

Reducing flanges are available in most sizes and material grades, and are not generally available from stock.

Reducing flanges follows the same considerations in terms of specifications, sizes, and material grades as expander flanges.

The last type of forged product that resembles the shape of a flange is the so-called spectacle blind: while not properly a flange, a blind (or a ring spacer or spade) is used in between pipes to isolate the pipeline mechanically and in a very easy way. More details are provided in another section of our Wiki for piping.

EUROPEAN TYPES OF FLANGES (EN ISO)

European flanges, often specified and used within projects and industries across Europe, adhere to standards developed by European organizations (CEN, EN, ISO, DIN, etc.).

These flanges are designed to ensure compatibility, safety, and reliability in various applications, including oil and gas, chemical processing, water treatment, and power generation. The most notable standards governing European types of flanges are those issued by the European Committee for Standardization (CEN) and the International Organization for Standardization (ISO). Here’s an overview of key European flange types and their standards:

1. EN 1092-1 Flanges

Standard: This standard specifies requirements for circular steel flanges ranging from DN 10 to DN 4000 and includes flanges for PN-designated pressures, and the PN (Pressure Nominale) numbers signifying nominal pressure in bars.

Types: EN 1092-1 flanges come in various types, including:

- Type 01: Plate (flat) flanges for welding.

- Type 02: Loose plate flanges with weld-on plate collar.

- Type 05: Blank (blind) flanges.

- Type 11: Weld-neck flanges.

- Type 13: Hubbed threaded flanges.

Applications: Used across a wide range of industries for piping systems that transport water, oil, gas, and chemicals.

2. DIN Flanges

Before the adoption of the EN 1092-1 standard, Germany’s DIN (Deutsches Institut für Normung) standards were widely used, not just in Germany but across Europe. Some common DIN standards for flanges include:

- DIN 2501: Standard covers bolt dimensions and flange face dimensions for PN designated flanges.

- DIN 2631 to DIN 2638: Specifications for weld neck flanges.

- DIN 2576: Slip-on flanges for welding.

Applications: Although EN standards are now more commonly specified, DIN flanges are still used and recognized, especially in older systems and in projects with specific requirements.

3. BS EN Flanges

The British Standards Institution (BSI) adopts EN standards for use in the UK, such as BS EN 1092-1, aligning with European specifications for flanges.

Applications: These flanges are used in the UK and internationally, wherever British standards are specified or required for compatibility and quality assurance.

4. ISO Flanges

ISO Standards: While not exclusively European, ISO standards for flanges, such as ISO 7005-1, mirror and complement European standards, ensuring global compatibility and interoperability.

Types and Applications: ISO standards cover a range of flange types similar to those in EN 1092-1, facilitating their use in international projects and applications.

Material and Pressure Ratings

- European flanges are available in various materials, including carbon steel, stainless steel, and alloy materials, to suit different environmental conditions and fluid properties.

- Pressure ratings follow the PN designation or are specified according to the applicable EN or ISO standards, ensuring that the flanges can withstand the operational pressures of the system.

European flanges, characterized by their diverse types and adherence to standardized specifications, play a crucial role in ensuring the safety, reliability, and efficiency of piping systems across a wide array of industrial applications within Europe and globally.

HOW TO SELECT A FLANGE

Different types of flanges in piping are available to meet diverse operational requirements, environmental conditions, and specific applications within industrial systems. The variety in flange types allows for flexibility in assembly, maintenance, and performance across a wide range of piping scenarios.

Here are the main reasons why various types of flanges are used, and the criteria to be followed to select the most suited type of flange for a piping project:

1. Pressure and Temperature Requirements

Different flanges are rated for different pressure and temperature ranges. For instance, weld neck flanges are preferred for high-pressure and high-temperature applications due to their robust structure, whereas slip-on flanges might be used in lower-pressure, moderate-temperature scenarios.

2. Fluid Properties

The nature of the fluid being transported (e.g., corrosive chemicals, hydrocarbons, steam, water) dictates the material and type of flange. Corrosive fluids may require stainless steel or alloy flanges with specific corrosion resistance.

3. Ease of Assembly and Maintenance

Certain flange types, such as lap joint flanges, offer ease of assembly and maintenance, especially in systems where regular disassembly is required for inspection and cleaning.

4. Space and Weight Considerations

In applications where space is limited or weight is a concern, compact flange designs such as threaded or socket weld flanges may be preferred for their smaller size and lower weight compared to other types.

5. Cost

The cost can vary significantly between flange types. For example, slip-on flanges are generally less expensive than weld neck flanges and might be chosen for cost savings in suitable applications. The use of stub ends, again as an example, may reduce the cost of flanged joints in high-grade piping systems.

6. System Integrity and Safety

The integrity of the piping system, especially in high-risk environments like oil and gas extraction, chemical processing, or power generation, requires flanges that can provide a reliable seal under all operating conditions. Flange types are selected based on their ability to maintain system integrity and ensure safety.

7. Installation Requirements

Some flange types are more suited to certain installation conditions than others. For example, threaded flanges are used where welding is not advisable due to the material or the environment, and blind flanges are used to terminate piping systems or isolate sections for maintenance.

8. Regulatory and Standards Compliance

Industry standards and regulatory requirements may dictate the use of specific flange types. Standards such as ASME B16.5, ASME B16.47, and others provide guidelines on flange types, materials, and applications.

41 Responses

Great information. Nice Blog!!

#asia129

https://top129.shop

Tube Expander

The Best Product

More information is in the link in the website box

The details given about flanges are informative, crispy and handy. It is easy to read and understand for non technical person also. Looking forward for more read.

A disadvantage of slip-on and socket weld flanges is that it is not possible to perform radiographic inspection on the weld. You imply this in the description of the weld neck flange, where you point out that radiographic examination is possible. Radiographic examination is generally possible on all butt welds and not possible on fillet welds – also not possible on nipoflanges and weldoflanges.

Top notched information available

Great article! You have explained about the various kinds of flanges in great detail in this article. I have now understood the various kinds of flanges such as Inconel Flanges, Hastelloy Flanges, Monel Flanges and Nickel Flanges. Thank you for sharing all this information with us.

Thanks for posting this helpful blog and We are a HUSAIN S.S FABRICATION Company whose that fabrication work near me and S.S Steel Works in Gurgaon.Before More Information visit our website:- http://www.husainssfabriction.co.in

This site is excellent.it has very nice look and perefect writing style. This information is better and very important for machinery/flanging-series It is maybe interesting to observe that, while this flanges type is easier to manufacture, they are sold at a premium average cost per kilogram compared to the other flange types. This is part important for mattress flanging machines

Hi There,

Thanks for sharing the blog and this great information which is definitely going to help us. Well done.

https://dic-oiltools.com/flanges.php

Weld repairs to aircraft and component parts use such equipment as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), plasma arc welding, and oxyacetylene gas hobby tig welder welding. When repairs of hobby tig welder any of flight-critical parts are required,

Your article answered all of the important points and seemed fantastic and helpful. Keep up the wonderful work!

Thanks for the info about pipes and flanges. I need to buy pipes. I’ll consider this information as I look for steel pipes to purchase.

Very informative blog

Thank you so much for the pipe welding information. TIG welder is the best, durable, reliablle and affordable way to weld the pipes no matter what kind of including steel, copper, mild etc.

This blog post is full of great information! Thank you for sharing your knowledge.

Do you have a distributor in United Arab Emirates ? If so please let me know, Regards,

Great information shared. i want to get the customized flanges products as per my requirements so any one tell me the best place where i can buy it now.

Dear sir

Can the outer rim of the 2” #150 be snip a of a bit to avoid touching another pipe

Dear Alex, may you please explain the question a bit more?

how we decide number of holes on a flange? Do we have any calculation?

Please suggest any reference material to get to the answer of my question.

thanks

Thank you so much for writing such an informative blog.

If you are looking for ms flange manufacturer then do consider Apex ms flange.

What’s up, this weekend is good designed for me, because this point in time i am reading this impressive

informative paragraph here at my home.

Can you tell us more about this? I’d care to find out more details.

I have a flange of 24″ 600 psi to match a pipe of 24″ sch 30 (0.532 inch), but the skirt of the flange is 0.602. Can I accept this kind of flange with that difference

very nice post, I found something more interesting

Thanks, what an informative post! Everything we need to know are found in this article. We hope you keep posting quality articles.

we liked your blogs very much

thanks for such good information

for more Details On Example link

This blog is exceptionally valuable explicitly for giving the total subtleties and clarification.

This blog is very useful specifically for giving the complete details and explanation.

Thanks!;)

What are the two welded dots on a slip on flange for?

THAT IS PIPE TO FLANGE WELDING POINT

Thank you for your appreciated comment. Should you need further information on some specific topics, kindly send us an email to support@projectmaterials.com. To submit an RFQ for piping materials, please visit this page: https://projectmaterials.com/submit-rfq-mto. Best regards, Projectmaterials

Good knowledge

Thank you for your appreciated comment. Should you need further information on some specific topics, kindly send us an email to support@projectmaterials.com. To submit an RFQ for piping materials, please visit this page: https://projectmaterials.com/submit-rfq-mto. Best regards, Projectmaterials

a very good and informative blog thanks for this blog waiting for you to make a blog on different types of fittings .

Thank you for your appreciated comment. Should you need further information on some specific topics, kindly send us an email to support@projectmaterials.com. To submit an RFQ for piping materials, please visit this page: https://projectmaterials.com/submit-rfq-mto. Best regards, Projectmaterials

Thank you very much. Your blog helped me a lot during my research!

Thank you for your appreciated comment. Should you need further information on some specific topics, kindly send us an email to support@projectmaterials.com. To submit an RFQ for piping materials, please visit this page: https://projectmaterials.com/submit-rfq-mto. Best regards, Projectmaterials

informative blog, can you make a blog on its application of carbon flanges.

ms flanges

Such a great blog and I really appreciate to read this blog.