Strainers are mechanical devices to retain (and remove) foreign particles from flowing liquids and protect equipment such as pumps and compressors. There are several types of strainers, including the Y, basket, and duplex types. A critical element is the strainer’s screen, specifically its mesh size (perforation density).

STRAINERS

WHAT IS A PIPE STRAINER?

A pipe strainer is a crucial component used in piping systems to protect equipment by filtering out solids and debris from fluids that flow through pipelines.

A pipe strainer is an integral component used in piping systems to protect downstream equipment (like industrial pumps, and compressors) by capturing and removing unwanted debris and particulate matter from flowing fluids. These strainers play a critical role in ensuring the efficient operation and longevity of industrial and commercial processes by preventing clogging and damage to valves, pumps, meters, and other sensitive components. By filtering out solid particles from liquids, gases, or steam, pipe strainers help maintain system purity and operational reliability, which is particularly important in industries such as oil & gas, power generation, chemical manufacturing, and water treatment.

This safeguarding is vital in various industries, including oil and gas, power generation, and construction, where the presence of particulate matter can lead to damage, reduced efficiency, or even failure of equipment such as pumps, meters, valves, and other mechanical devices. Understanding the function, types, and importance of pipe strainers can help ensure the longevity and reliability of industrial systems.

Function of a Pipe Strainer

The primary function of a pipe strainer is to remove unwanted solids from liquid, gas, or steam lines using a perforated or wire mesh filtering element. This filtration process is essential for:

- Protecting sensitive equipment from potential damage caused by debris.

- Maintaining the efficiency and reliability of the piping system.

- Reducing downtime and maintenance costs associated with cleaning or repairing equipment damaged by particulate matter.

Types of Pipe Strainers

Pipe strainers come in various designs, each tailored to specific application requirements and flow characteristics. The most common types include:

Y-strainers: Named for their shape that resembles the letter “Y,” these strainers are typically used in liquid and gas applications where small amounts of solid particulate are expected. They are easy to install and clean, making them suitable for applications where maintenance access is limited.

Basket Strainers: Designed with a larger straining element that can hold more debris than Y-strainers, basket strainers are ideal for systems where large amounts of solids may be present. They are often used in liquid applications and feature a top removal design for easy cleaning.

Duplex Strainers: Consists of two basket strainers with a valve system that allows for one strainer to be in use while the other is being cleaned. This design ensures continuous flow in the system, making duplex strainers suitable for applications where shutdown for cleaning is not practical.

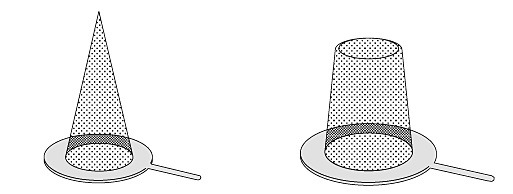

Temporary Strainers: These are simple, cost-effective strainers used in the startup phase of a system to catch debris that may have been introduced during construction. They are typically cone-shaped and installed between flanges, then removed once the system is clean.

These different types of pipe/pipeline strainers are described in greater detail below in this article.

Parts of Pipe Strainers

Strainers are assembled products, manufactured by joining the following key parts. Understanding the parts of a strainer and their functions can help in selecting the right strainer for a specific application, as well as in maintenance and troubleshooting. While the design and complexity of strainers can vary depending on their type (e.g., Y-strainers, basket strainers, duplex strainers), they share common parts with similar functions.

Body

The main structure contains the internal components of the strainer. It is designed to withstand the pressure and temperature of the process fluid and is made from materials compatible with the fluid to prevent corrosion.

Cover or Lid

A removable part that allows access to the strainer element for cleaning or replacement. The cover must seal effectively to prevent leaks and is often bolted or clamped to the body.

The cover is the part of the device that should be opened to clean the basket. The most common type is bolted, the bolts must be loosened and removed to bring access to the basket. This type of cover is the strongest and should be used for high-pressure applications.

Another type of cover is the clamping yoke, in which threaded, tee-shaped handles are used to connect the cover to the body. Often, the cover is attached to the body with a hinge mechanism, making it easy to remove. This type of cover is more expensive than the standard one.

Another type of strainer cover is the automatic type (which does not require manual cleaning). A rotating, circular screen is used as the basket. The water inlet goes into the basket. A rotating backwash inlet inside the basket uses the differential pressure between the atmosphere and line pressure to produce a localized reverse flow across only a portion of the basket, thereby allowing continuous cleaning.

This type of strainer is appropriate for large consumers of water such as raw water inlets from rivers and lakes used for cooling and process. Automatic pipe strainers are available in 60-in (150-mm) sizes.

Strainer Element (Screen or Basket)

The screen is the core component responsible for trapping and removing debris from the process flow. It is usually made of perforated metal, wire mesh, or a combination thereof. The size of the openings (mesh size) determines the fineness of filtration.

Gasket or Sealing Ring

Ensures a tight seal between the body and the cover to prevent leaks. Gaskets are made from materials resistant to the process fluid and operational temperatures.

Drain Plug

Allows for the removal of collected debris and fluid from within the strainer. Located at the lowest point of the strainer body, the drain plug facilitates maintenance and cleaning.

Vent Plug

Used to release trapped air from the strainer to ensure efficient operation. The vent plug is typically located at the highest point of the strainer body.

Support Legs or Mounting Brackets (optional)

Some strainers come with support legs or mounting brackets to facilitate installation and provide stability in the piping system.

Differential Pressure Tap Points (optional)

Locations on the strainer body where pressure gauges or differential pressure indicators can be installed to monitor the pressure drop across the strainer. A significant pressure drop can indicate that the strainer element is clogged and needs cleaning.

HOW TO SELECT A PIPE STRAINER?

When selecting a pipe strainer, several factors must be considered to ensure proper functionality and efficiency, including:

- Size and Location: The strainer must be appropriately sized for the pipeline and placed in a location where it can be easily accessed for cleaning and maintenance.

- Pressure Drop: The introduction of a strainer into a piping system creates a pressure drop; thus, the strainer’s design should minimize this effect to maintain system efficiency.

- Material: The construction material of the strainer should be compatible with the process fluid and the operating environment to prevent corrosion and ensure durability.

- Filtration Level: The size of the openings in the strainer element (mesh size) should be chosen based on the size of the particles that need to be removed.

HOW TO MAINTAIN A STRAINER?

Regular maintenance of pipe strainers is essential for optimal performance. This includes periodic cleaning of the strainer element to prevent clogging and ensure that the system operates efficiently. Neglecting maintenance can lead to increased pressure drop, reduced flow rate, and potential damage to downstream equipment.

In conclusion, pipe strainers play a pivotal role in maintaining the integrity and efficiency of piping systems across various industries. By selecting the appropriate type and size of strainer and adhering to a regular maintenance schedule, operators can significantly reduce the risk of equipment failure and extend the lifespan of their systems.

HOW A PIPE STRAINER WORKS

The primary function of a pipe strainer is to physically intercept and trap solid particles within a straining element, which is a screen or filter while allowing the process fluid to flow through the system. This filtration process is essential for:

- Protecting equipment from potential damage caused by debris.

- Ensuring the quality and purity of the fluid.

- Reducing downtime and maintenance costs by preventing clogs and operational disruptions.

In summary, pipe strainers are vital for the protection and efficient operation of piping systems, preventing damage and maintaining fluid quality by removing unwanted particles. The selection of the appropriate type and specifications of a pipe strainer is key to achieving optimal performance and reliability in any industrial or commercial fluid handling system.

TYPES OF STRAINERS FOR PIPELINES

There are two basic designs for pipe strainers, i.e. “y-strainers” and “basket strainers”.

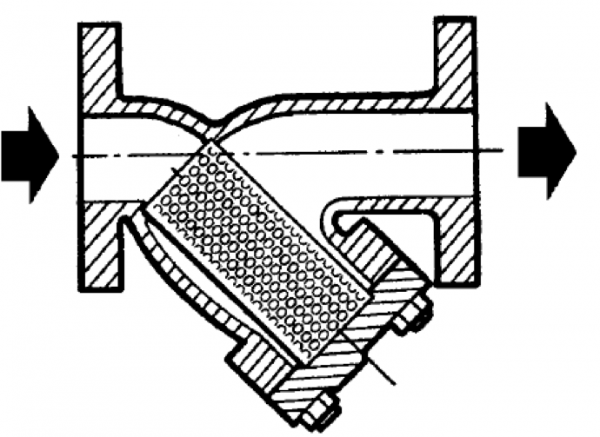

Y STRAINER

A Y-strainer is a compact device used to capture foreign particles, debris, and impurities flowing through the pipes of a pipeline together with the conveyed fluid.

A Y-strainer, named for its physical shape that resembles the letter “Y,” is a type of pipe strainer used extensively across various industries, including oil and gas, power generation, chemical processing, and water treatment.

This device plays a critical role in protecting downstream equipment by filtering out solid debris from flowing liquids, gases, or steam. Its design allows for efficient sediment collection and ease of maintenance, making it a preferred choice for many applications where particulate matter needs to be removed to ensure the proper functioning and longevity of piping systems.

Design and Construction

The Y-strainer consists of a housing with an inlet and an outlet forming a branch, creating a shape similar to the letter “Y”. Inside the housing, there is a strainer element, typically a screen made of perforated metal or wire mesh, which traps and collects the solid particles. The degree of filtration is determined by the size of the openings in the mesh, with smaller openings providing finer filtration.

The construction materials of Y-strainers vary depending on the application and can include cast iron, stainless steel, bronze, and plastic, among others. Material selection is crucial and is based on factors such as temperature, pressure, and the corrosive nature of the fluid being filtered.

Key Features

- Efficient Filtration: The Y-strainer efficiently removes debris from the flow, protecting equipment like pumps, meters, and valves from potential damage and wear.

- Low Maintenance: The design allows for easy access to the strainer element for cleaning or replacement. In most models, this is achieved by removing a cap or plug at the end of the branch that doesn’t disrupt the main flow path.

- Versatility: Y-strainers can be used in a wide range of applications, handling various fluids, including water, oil, gas, and steam. They are suitable for both high and low pressure and temperature conditions.

- Compact Size: The Y-strainer’s design is compact and can be installed in tight spaces, making it ideal for systems where space is a premium.

Installation and Maintenance

Y-strainers can be installed in both horizontal and vertical orientations, with the strainer leg (the branch of the “Y”) typically pointing downward. This orientation facilitates the collection of particulate matter and simplifies the cleaning process.

Regular maintenance of the Y-strainer is essential for optimal performance. Over time, the collected debris can cause a pressure drop across the strainer, reducing the efficiency of the system. Maintenance involves removing the strainer element and cleaning it of trapped particles. The frequency of maintenance depends on the amount of debris present in the fluid and the capacity of the strainer element. The pipeline can be kept in service, generally, when y-strainers need a cleanup.

Y-strainers are ideal for high-pressure gas pipelines with a low concentration of foreign particles, impurities, and debris. Y-strainers have indeed a lower capacity to store dirt than basket strainers of similar sizes.

Applications

Y-strainers are used in a wide range of industrial applications where there is a need to protect equipment by removing solids from the fluid flow. Common applications include:

- Water treatment facilities, for protecting valves and pumps from sediment and debris.

- Steam and gas systems, where they remove particulate matter that could damage control valves and steam traps.

- Cooling systems, to ensure that cooling media is free of debris that could clog or damage the cooling equipment.

- Chemical processing, where they protect processing equipment from particulate contamination.

In summary, the Y-strainer is a versatile and essential component of many piping systems, offering effective protection against particulate damage with minimal maintenance requirements. Its simple yet efficient design ensures that it can be adapted to a wide range of industrial applications, safeguarding critical equipment and ensuring uninterrupted system operation.

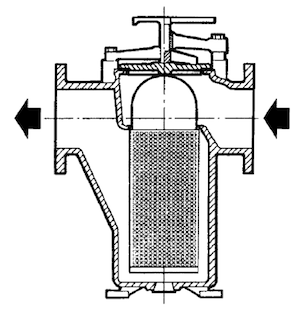

BASKET STRAINER (T-STRAINER)

A basket strainer is an industrial device used to filter out debris and particulate matter from flowing fluids in piping systems. It is designed to protect critical components such as pumps, meters, valves, and other equipment by trapping solids in a removable basket, hence its name.

Basket strainers are widely used across various industries, including oil and gas, chemical processing, water treatment, and power generation, due to their efficiency, reliability, and ease of maintenance. They are particularly well-suited for systems where large particles are present and need to be removed to prevent equipment damage and ensure process efficiency.

Design and Construction

The primary components of a basket strainer include:

- Housing: The body of the strainer, typically made of metal, such as cast iron, stainless steel, or carbon steel, is designed to withstand the pressure and temperature of the system it serves.

- Basket: A removable filter element situated inside the housing. The basket is made of perforated metal or wire mesh and captures and holds debris as the fluid passes through.

- Cover: A top lid that allows access to the basket for cleaning or replacement. It can be bolted, clamped, or otherwise secured to the housing.

- Gaskets or Seals: These ensure a tight seal between the housing and cover to prevent leaks.

Key Features

- High Flow Capacity: Basket strainers are capable of handling high flow rates with minimal pressure drop, making them suitable for a wide range of industrial applications.

- Easy Maintenance: The design of the basket strainer allows for quick and easy removal of the basket for cleaning or replacement, minimizing downtime.

- Versatile Filtration: The size of the openings in the basket can be customized to meet specific filtration requirements, from coarse to fine filtration.

- Durability: Constructed from robust materials, basket strainers can withstand harsh operating conditions, including high pressures and temperatures.

Operation

In operation, the fluid enters the strainer housing and flows through the basket. The basket traps the solid particles, allowing only the cleaned fluid to exit the strainer. Over time, as debris accumulates in the basket, it may need to be cleaned or replaced to maintain efficiency and prevent a significant pressure drop across the strainer.

A basket strainer can store bigger quantities of dirt and debris than y-strainers of the same size, due to the larger size of the filtering element, and is the preferred choice when pressure drops in the pipeline are not acceptable.

T strainers shall be installed upright, and the top of the strainer can be removed for frequent cleaning (self-cleaning t-strainers are also available on the market).

Maintenance

Regular inspection and cleaning of the basket are crucial to ensure the strainer operates efficiently. The frequency of maintenance depends on the amount of debris present in the fluid and the capacity of the strainer. For systems with a high level of particulate matter, duplex basket strainers with two parallel strainer baskets and a diverter valve can be used, allowing one basket to be cleaned while the other continues to filter the flow, ensuring uninterrupted operation.

Applications

Basket strainers are used in various applications where fluid cleanliness is critical to the process and equipment’s operation. Some common applications include:

- Cooling water systems: To remove debris that could clog or damage cooling equipment.

- Process industries: To protect pumps, valves, and other process equipment from damage caused by particulate matter.

- Water treatment: To pre-filter water before it enters treatment processes, protecting equipment from sediment and debris.

- Oil and gas production: To remove solids from crude oil and other fluids, ensuring the protection of downstream equipment.

In summary, basket strainers are essential components in many industrial piping systems, offering effective protection against particulate damage with their robust design, high capacity for debris, and ease of maintenance. Their versatility and reliability make them invaluable in ensuring the smooth operation and longevity of critical process equipment.

DUPLEX STRAINER (TWIN-BASKET STRAINER)

A duplex strainer, also known as a twin basket strainer, is an advanced type of filtration device designed for use in piping systems where continuous flow must be maintained without interruption for cleaning the strainer element.

It consists of two separate strainer baskets housed within a single body, with a diverter valve that allows the flow to be switched from one basket to the other. This design enables one basket to be in operation filtering the process medium—such as liquids, gases, or steam—while the other basket is being cleaned or serviced, ensuring that the system remains operational at all times.

Duplex basket strainer

(Source: Piping Design Channel)

Design and Operation

The main components of a duplex strainer include:

- Two Strainer Baskets: These are the filtering elements where debris and particulate matter are collected. The baskets are usually made of stainless steel wire mesh or perforated metal, and they can be easily removed for cleaning.

- Body: The body houses the two baskets and the flow diverter mechanism. It is typically made from cast iron, carbon steel, stainless steel, or other materials suitable for the specific application requirements.

- Flow Diverter Valve: This is a crucial component that allows the flow to be directed through either of the strainer baskets while isolating the other. The valve can be operated manually, or it can be automated with actuators for remote operation.

- Drain and Vent Ports: These allow for the draining and venting of the isolated basket chamber during cleaning or maintenance, ensuring safety and ease of operation.

Advantages of Duplex Strainers

- Continuous Operation (uninterrupted pipeline/piping system service): The primary advantage of a duplex strainer is its ability to maintain continuous flow in the system, crucial for processes that cannot be shut down for maintenance.

- Versatility: Duplex strainers can handle a wide range of process fluids and are suitable for various industrial applications, including oil and gas, chemical processing, water treatment, and manufacturing.

- High Capacity: With two baskets, duplex strainers can accommodate larger amounts of debris than single-basket strainers, extending the intervals between cleanings.

- Ease of Maintenance: The design allows for easy access to the baskets for cleaning without having to shut down the process flow.

Applications

Duplex strainers are used in applications where process continuity is critical and where the fluid being processed contains particles that need to be removed to protect downstream equipment. Common applications include:

- Cooling Water Systems: Protecting heat exchangers and cooling towers from debris that could cause blockages or reduce efficiency.

- Fuel Oil Systems: In power generation and marine applications, where clean fuel is essential for engine performance and reliability.

- Process Industries: Such as chemicals, pharmaceuticals, and food and beverage, where product purity is critical, and production cannot be interrupted.

- Water Treatment: For protecting pumps, valves, and other sensitive equipment from sediment and debris.

Maintenance and Selection Considerations

While duplex strainers offer the advantage of continuous operation, they also require regular maintenance to ensure optimal performance. This includes routine cleaning of the baskets, inspection of the diverter valve for proper operation, and checking the seals and gaskets to prevent leaks. The selection of a duplex strainer for a particular application should consider factors such as the size and nature of the particulate to be removed, the flow rate, the process fluid’s characteristics, and the operating conditions (pressure and temperature).

In summary, a duplex strainer is a highly efficient and versatile filtration solution for industrial applications where uninterrupted flow is necessary. Its dual-basket design ensures system protection against particulate damage while allowing for easy maintenance and ensuring continuous operation.

MATERIALS FOR PIPE STRAINERS

STRAINER BODY MATERIALS (+COVER/LID)

The most common materials used to manufacture the body of pipe/pipeline strainers are cast iron, ductile iron, bronze, carbon steel, stainless steel, and plastic. In practice, Y-strainers feature bodies made of the same cast and forged materials as the other commercial valves widely discussed in other articles of our knowledge base.

Also, forged steel grades are used for strainers <2 inches in diameter, whereas cast grades are used for larger bore sizes (>2 inches).

To select the appropriate type of body material for a strainer, the piping engineer shall consider the following factors:

- Compatibility with Process Media: The material must be resistant to the chemical composition, temperature, and pressure of the process media to prevent corrosion, degradation, and mechanical failure.

- Operating Conditions: The material must withstand the maximum expected operating temperatures and pressures.

- Cost: While more advanced alloys offer better performance in harsh conditions, they also come with higher costs. The selection often involves balancing cost against required performance, lifespan, and safety requirements.

- Regulatory and Safety Requirements: Certain applications may have specific material requirements due to safety, health, or environmental regulations.

Let’s now delve into some common body materials for Y and Basket strainers:

CAST IRON

Because of its low cost, cast iron is the most popular strainer body. It is used in systems where the pressure and temperature of the water are not high and the system is not subject to high thermal or mechanical shock. Cast iron is mostly used for larger-size potable water lines and many non-potable water systems in addition to a variety of other product and process uses.

- Characteristics: Good tensile strength and resistance to wear.

- Applications: Suitable for water, steam, and other non-corrosive applications. Commonly used in lower temperature and pressure applications.

CARBON STEEL (ASTM A216WBC, ASTM A351)

Carbon steel bodies are used with high temperature and pressure applications and when a good resistance to thermal and mechanical stress is required. Carbon steel is used also in the case of applications involving the risk of fire.

- Characteristics: High strength and toughness, good weldability, and relatively low cost.

- Applications: Widely used in oil and gas, petrochemical, and power generation for systems carrying water, oil, gas, or steam. Suitable for higher pressure and temperature conditions compared to cast iron.

STAINLESS STEEL (SS304/316)

Stainless steel is the preferred body, basket, and screen material for the pharmaceutical, food processing, and chemical industries because of its resistance to corrosion and contamination and ease of cleaning. The downside is that stainless steel may cost 4 to 5 times more than cast iron/ductile iron.

- Characteristics: Excellent corrosion resistance, good strength, and high-temperature capabilities.

- Applications: Ideal for corrosive environments, such as chemical processing, food and beverage, and pharmaceutical industries. SS 316 offers higher corrosion resistance compared to SS 304, making it suitable for more aggressive media.

Duplex and super duplex strainers are also available on the market:

- Characteristics: Higher strength and superior corrosion resistance compared to standard stainless steel.

- Applications: Used in aggressive environments, such as offshore and marine applications, chemical processing, and desalination plants, where corrosion resistance and durability are critical.

CHROME-MOLY ALLOY

For high pressures and temperatures over 1000 °F, chrome-moly steel is usually specified for pipes (A335 grade) and strainers.

BRONZE

A bronze body is preferred for brackish, saline, and seawater service. It is often used for potable water services. Bronze strainers are of course way more expensive than those fabricated out of iron and/or carbon steel.

- Characteristics: Good resistance to corrosion and fatigue, lower strength than steel.

- Applications: Suitable for water, seawater, and certain chemicals. Common in marine applications and potable water systems.

NICKEL ALLOYS

Strainers are also available in Nickel-Alloys such as Inconel, Hastelloy (which has exceptional corrosion resistance in severe environments, including resistance to pitting and stress-corrosion cracking), Alloy20 (Carpenter 20 – which has excellent resistance to sulfuric acid and other aggressive chemicals), and Monel (that shows resistance to seawater and various forms of corrosive and caustic media).

PLASTIC

Plastic strainers (PVC, PE; PP) are used for less severe applications, like irrigation plants, and residential or office buildings.

The screen of a strainer is a crucial component designed to filter out and trap debris, particles, and other unwanted materials from a fluid flowing through a piping system. It serves as the primary filtration element within the strainer, ensuring that only the fluid passes through while solid contaminants are collected and retained. The effectiveness of a strainer in protecting downstream equipment—such as valves, pumps, meters, and other process equipment—largely depends on the design, material, and mesh size of the screen.

Design and Construction

- Material: Strainer screens are typically made from durable materials such as stainless steel, brass, or monel to resist corrosion, wear, and tear from the process fluid. The choice of material depends on the fluid’s characteristics, including its temperature, pressure, chemical composition, and the level of corrosion resistance required.

- Mesh Size: The screen’s mesh size is a critical factor in its filtration capability, defined by the number of openings per inch (OPI) or the size of the openings in microns. A higher number of openings per inch (a finer mesh) means smaller particles are filtered out, while a lower number (a coarser mesh) allows larger particles to pass through. The selection of mesh size is based on the requirements of the process and the size of the particles that need to be removed.

- Construction: Screens can be either a single layer of mesh or multiple layers laminated together for added strength and finer filtration. The construction must ensure that the screen maintains its integrity under the flow conditions and does not become clogged or damaged easily.

Function

The screen’s primary function is to protect downstream equipment by:

- Removing Solids: Preventing solids and debris from passing through, thereby protecting sensitive components downstream from damage or clogging.

- Maintaining Flow Efficiency: Ensuring that the flow of the process medium remains efficient and uninterrupted by particulate blockages.

- Facilitating Maintenance: Collecting debris in a way that facilitates easy cleaning and maintenance of the strainer, thereby reducing downtime and operational disruptions.

Types and Shapes

- Perforated Screens: Made from sheets of metal with holes punched out, suitable for larger particles.

- Wire Mesh Screens: Woven from metal wires to create a fine mesh for filtering out smaller particles.

- Shapes: The shape of the screen corresponds to the type of strainer—Y-strainers have cylindrical or conical screens, basket strainers have larger, basket-shaped screens and duplex strainers feature screens designed to fit within each chamber of the strainer housing.

Maintenance

Regular maintenance of the strainer screen is essential for ensuring optimal performance of the strainer. This includes periodic inspection for damage or wear, cleaning to remove trapped debris, and replacement if the screen becomes too worn or damaged to function effectively. The ease of access to the screen for cleaning and maintenance is an important consideration in the design and selection of a strainer.

STRAINER MESH

The terminology “screen” and “mesh” often are used interchangeably in the context of strainer components, but mesh refers to the material’s structure that performs the filtration (whereas the screen is the overall filtration element).

The screen typically consists of a perforated metal plate or a woven wire mesh. Perforated plates have holes of a fixed size drilled or punched through them, while wire mesh is made by weaving metal wires to create a grid-like structure.

Screens can be made from various materials, including stainless steel, brass, or monel, depending on the specific requirements for corrosion resistance, strength, and compatibility with the process fluid.

The term “mesh” specifically refers to the number of openings per linear inch in the screen. It’s a critical parameter that determines the fineness of filtration:

- Higher Mesh Number: A higher number indicates smaller openings, resulting in finer filtration. This is suitable for applications where very small particles need to be removed from the fluid.

- Lower Mesh Number: Conversely, a lower mesh number means larger openings, allowing for coarser filtration. This is used when only larger particles need to be removed or to prevent clogging when dealing with fluids that contain a high level of debris.

The screen mesh size can be designated in mm, in inches, in microns, or by a mesh number.

When selecting a screen for a strainer, and the mesh, several factors must be considered to ensure optimal performance and protection of downstream equipment:

- Process Fluid: The compatibility of the screen material with the process fluid is crucial to prevent corrosion and ensure longevity.

- Operating Conditions: The screen must withstand the temperature and pressure conditions of the system (consideration shall be given also to the maximum acceptable pressure-drop in the system).

- Filtration Requirements: The size and nature of the particulate matter to be removed determine the appropriate mesh size. Finer meshes are used for smaller particles, but they may require more frequent cleaning due to quicker clogging.

- Maintenance and Cleaning: Screens with smaller mesh sizes or systems with high levels of debris may need more frequent maintenance. The ease of removing and cleaning or replacing the screen should be considered.

Y-STRAINER MESH SIZE CHART

A Y-strainer mesh size chart is a reference tool used to select the appropriate mesh size for a strainer based on the specific filtration requirements of a system. Mesh size is crucial because it determines the fineness of the filtration, i.e., the size of particles that the strainer can effectively remove from the fluid passing through it.

The appropriate selection of the mesh size of the screen is crucial:

- if the mesh is too big, some unwanted debris may not be filtered, passing through the screen, and affecting the downstream equipment.

- If the mesh is too small, extra loads of debris may accumulate in the strainer cage, causing pressure drops in the piping system and higher than-needed maintenance costs.

The chart typically lists mesh sizes and the corresponding particle sizes that can be filtered.

Mesh size is often expressed in terms of the number of openings per inch (e.g., 100 mesh means 100 openings per inch), or sometimes by the size of the openings in microns. The higher the mesh number, the finer the filtration, as more openings per inch mean smaller particles are captured.

Understanding Mesh Size in Y-Strainers

- Mesh Number: Indicates the number of openings per linear inch. A higher mesh number signifies a finer mesh with smaller openings.

- Micron Size: This represents the size of the smallest particle that can be effectively filtered by the mesh. One micron (μm) equals one millionth of a meter.

Example of Mesh Size Chart for Y-Strainers

| Mesh Number | Opening Size (Microns) | Typical Application |

|---|---|---|

| 20 | 841 | Coarse filtration, removing large debris |

| 40 | 400 | Medium filtration, general industrial applications |

| 60 | 250 | Fine filtration, protecting sensitive equipment |

| 80 | 177 | Very fine filtration, for high purity processes |

| 100 | 149 | Extra fine filtration, specialty applications |

Key Points When Using a Mesh Size Chart

- Application Specific: The ideal mesh size for a Y-strainer depends on the requirements of the specific application, including the type of fluid, the nature of the particulates to be removed, and the sensitivity of downstream equipment.

- Balance Filtration and Flow: Finer meshes provide better filtration but can lead to increased pressure drops and require more frequent cleaning. It’s important to balance the need for filtration with the impact on system performance.

- Material Compatibility: Besides mesh size, consider the material of the mesh to ensure compatibility with the process fluid, especially in terms of corrosion resistance.

Customization and Consultation

It’s also worth noting that mesh size charts can vary between manufacturers, and some applications may require customized solutions. Consulting with strainer manufacturers or engineering experts can help determine the most suitable mesh size and material for your specific application needs.

Remember, selecting the appropriate mesh size is crucial for ensuring effective protection of downstream equipment while maintaining efficient flow and minimizing maintenance requirements in your piping system.

The table below shows the holes dimensions in inches, microns, and mm by US mesh size:

| STRAINER MESH USA | in INCHES | in MICRONS | in MM |

| 3 | 0.265 | 6730 | 6.73 |

| 4 | 0.187 | 4760 | 4.76 |

| 5 | 0.157 | 4000 | 4 |

| 6 | 0.132 | 3360 | 3.36 |

| 7 | 0.111 | 2830 | 2.83 |

| 8 | 0.0937 | 2380 | 2.38 |

| 10 | 0.0787 | 2000 | 2 |

| 12 | 0.0661 | 1680 | 1.68 |

| 14 | 0.0555 | 1410 | 1.41 |

| 16 | 0.0469 | 1190 | 1.19 |

| 18 | 0.0394 | 1000 | 1 |

| 20 | 0.0331 | 841 | 0.841 |

| 25 | 0.028 | 707 | 0.707 |

| 30 | 0.0232 | 595 | 0.595 |

| 35 | 0.0197 | 500 | 0.5 |

| 40 | 0.0165 | 400 | 0.4 |

| 45 | 0.0138 | 354 | 0.354 |

| 50 | 0.0117 | 297 | 0.297 |

| 60 | 0.0098 | 250 | 0.25 |

| 70 | 0.0083 | 210 | 0.21 |

| 80 | 0.007 | 177 | 0.177 |

| 100 | 0.0059 | 149 | 0.149 |

| 120 | 0.0049 | 125 | 0.125 |

| 140 | 0.0041 | 105 | 0.105 |

| 170 | 0.0035 | 88 | 0.088 |

| 200 | 0.0029 | 74 | 0.074 |

| 230 | 0.0024 | 63 | 0.063 |

| 270 | 0.0021 | 53 | 0.053 |

| 325 | 0.0017 | 44 | 0.044 |

| 400 | 0.0015 | 37 | 0.037 |

NEED MORE INFO?

Need to learn more? You can consult the technical information about strainers provided by Spirax Sarco – one of the most well-known manufacturers of pipeline strainers.

7 Responses

Wot an amazing blog related to the y-strainer-asme! I must say, the people you are looking for this information, for them your blog will definitely helpful for them.

Great information. Thanks for providing us such useful information on strainer. I really appreciate your hardwork and dedication. Keep up the good work and continue providing us more quality information from time to time. I am having my own company and I am very happy with GTS Filters & System services.

Regarding the screen material, wire mesh or perforated metal can be used. But for smaller micron rating such as 50 micron (270 mesh), the mesh is soft, thin and weak. A solution is welding or sintering the fine mesh with other coarse mesh or perforated metal. Welding is not expensive and workable. Sintering is not cheap but the sintered mesh is robust and can withstand high pressure without risking of fine mesh peeling from coarse mesh or other support material.

Detailed description of basket filter, how to choose in different application areas. This is a great article. I’ve also read a similar article and would like to share it with you.

Thanks for the Info, Please also inform – Is plate material (ASTM A182 Gr.F304) strainer better than Forged material (ASTM A240 304/304L Dual grade strainer?

Is there a way to check the functionality of a strainer if it’s already connected to the rig?

Thnks, Good imformative artcle. It will be better if you include information about End connections of strainers. We manufacture these Basket Strainers, Y type Strainers, T type Strainers, Duplex Strainers, Pot Strainers and Conical strainers. To visit our website click on this link