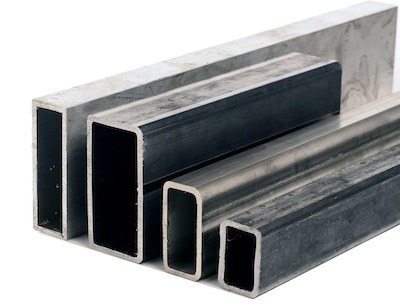

Structural Hollow Sections (HSS) are steel products used for construction and mechanical applications. HSSs are available in three basic shapes, circular/round (CHS), square (SHS), and rectangular (RHS). The article reviews each type, the ASTM/ISO specifications, and provide dimensions & weights for the most common sizes. To calculate the weight of steel plates easily, use our online calculator.

STRUCTURAL HOLLOW SECTIONS (HSS)

WHAT ARE HOLLOW SECTIONS?

HSS Definition

Hollow Structural Sections (HSS) are steel sections that come in a variety of shapes, including round (CHS), square (SHS), and rectangular (RHS).

These structural elements are made from steel and are used in a wide range of construction and mechanical applications due to their high strength-to-weight ratio, uniformity of shape, size, strength, and aesthetic appeal. Round and square HSS are the most commonly used types of structural hollow sections.

HSS Key Features and Benefits

- Versatility: HSS can be used in a broad range of structural and mechanical applications. They are favored in modern architecture and construction for both their practical and aesthetic qualities.

- Efficiency: The hollow nature of HSS makes them lighter than solid steel sections of equivalent strength, leading to savings in material and transportation costs, as well as ease of installation.

- Durability: With the proper coating or galvanization, HSSs are highly resistant to corrosion and can maintain their structural integrity over long periods, even in harsh environments.

- Aesthetic Appeal: HSSs have a clean, streamlined appearance that is often sought after in contemporary architectural design. They can be left exposed in the design of buildings for a modern look.

Applications

- Construction: Used as load-bearing columns, beams, and in the framing of buildings, stadiums, and bridges.

- Mechanical Applications: Employed in manufacturing heavy machinery, automotive frames, and conduits for electrical wiring and fluid transport pipelines.

- Architectural: Integral to the design of modern buildings, providing both structural support and aesthetic appeal in facades, canopies, and other architectural elements.

HSS are manufactured through a process that involves forming and welding steel into the desired shape. Advanced manufacturing techniques ensure tight tolerances and uniform mechanical properties across the section. The versatility and efficiency of HSS make them a preferred choice for a wide array of structural and mechanical applications.

HSS TYPES (SHAPES)

HSSs come in three primary shapes: Circular Hollow Sections (CHS), Rectangular Hollow Sections (RHS), and Square Hollow Sections (SHS).

Each has unique properties and applications, making them suitable for a wide range of uses.

Circular Hollow Sections (CHS)

- Shape: CHSs have a circular or round cross-sectional shape.

- Properties: The symmetrical geometry of CHS provides uniform strength and stiffness in all directions, making them highly resistant to multi-directional loading and torsion. The absence of corners reduces the likelihood of stress concentrations, enhancing their structural integrity.

- Applications: CHS are commonly used in construction as columns, braces, and trusses. They are also favored in applications requiring fluid conveyance, such as water and gas pipelines, due to the smooth and uniform internal surface that minimizes resistance and turbulence.

Rectangular Hollow Sections (RHS)

- Shape: RHS have a rectangular cross-section with flat faces and sharp corners.

- Properties: RHSs provide excellent resistance to bending in two principal directions, which makes them suitable for applications where strength and rigidity are required along specific axes. The sharp corners can be more prone to stress concentrations but also allow for easier connection and joining.

- Applications: RHS are often used in construction for frameworks, structural supports, and architectural elements where the rectangular shape can be an aesthetic or functional requirement. They are also used in machinery and for structural components in vehicles.

Square Hollow Sections (SHS)

- Shape: SHSs have a square cross-section that combines the benefits of CHS and RHS, offering uniformity but with a more defined aesthetic appeal.

- Properties: Like RHS, SHSs offer high resistance to bending in two principal directions. The square shape provides symmetry, making them somewhat more resistant to torsion than RHS. The corners are subject to stress concentrations but facilitate easy connections.

- Applications: SHSs are versatile and used in a variety of structural applications, including construction, framework, and supports where the square geometry can be a design feature. They are also used in industrial and residential furnishings.

SPECIFICATIONS FOR HSS

Both American and European standards exist to govern the production and use of these materials, ensuring they meet the required safety, quality, and performance criteria. Here’s a closer look at the key specifications for round, rectangular, and square HSS in both American and European contexts:

American Specifications for HSS

ASTM A500

Title: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

Scope: Covers cold-formed welded and seamless carbon steel round, square, rectangular, or specially shaped structural tubing for construction of bridges, buildings, and for structural purposes. It specifies mechanical properties and chemical compositions.

ASTM A1085

Title: Standard Specification for Cold-Formed Welded Carbon Steel Hollow Structural Sections (HSS)

Scope: A more recent specification provides for tighter tolerances and higher strength-to-weight ratios than A500. It applies to circular, square, and rectangular HSS and is intended to improve efficiency in design and reduce the cost of construction.

European Specifications for HSS

EN 10210

Title: Hot Finished Structural Hollow Sections of Non-Alloy and Fine Grain Steels

Scope: Specifies the technical delivery conditions for hot-finished hollow sections of circular, square, rectangular, or other shapes. The standard covers non-alloy and fine-grain steels, detailing dimensions and tolerances, mechanical properties, and chemical composition.

EN 10219

Title: Cold-Formed Welded Structural Hollow Sections of Non-Alloy and Fine Grain Steels

Scope: Similar to EN 10210 but for cold-formed welded HSS. This standard specifies technical delivery conditions for cold-formed welded circular, square, and rectangular hollow sections. It includes details on dimensions and tolerances, mechanical properties, and chemical composition.

Key Differences and Similarities

- Manufacturing Process: ASTM standards distinguish between seamless and welded constructions, while EN standards cover hot-finished (EN 10210) and cold-formed (EN 10219) products, focusing on the final mechanical properties and dimensions.

- Material Grades: Both standards specify different material grades based on the chemical composition and mechanical properties. European standards use part of the EN 10025 specifications for determining steel grades, while ASTM standards have their own grading system.

- Scope of Application: ASTM A1085 was developed to address some of the design limitations of ASTM A500, offering higher strength and better performance for certain applications. Similarly, EN 10210 and EN 10219 provide options for hot-finished or cold-formed sections, respectively, allowing engineers to select materials based on specific structural or aesthetic requirements.

- Geographic and Regulatory Context: The choice between American (ASTM) and European (EN) specifications often depends on the project’s location and the local regulatory environment. Engineers must comply with the standards and codes that are legally mandated or widely accepted in the region where the construction takes place.

HSS DIMENSIONS AND WEIGHTS

ROUND/CIRCULAR HOLLOW SECTIONS (CHS)

| CHS Size | Weight (kg./m) | Diameter (mm) | Wall Thickness (mm) |

| 21.3 x 3.2 | 1.4 | 21.3 | 3.2 |

| 26.9 x 3.2 | 1.9 | 26.9 | 3.2 |

| 33.7 x 2.6 | 2 | 33.7 | 2.6 |

| 33.7 x 3.2 | 2.4 | 33.7 | 3.2 |

| 33.7 x 4 | 2.9 | 33.7 | 4 |

| 42.4 x 2.6 | 2.6 | 42.4 | 2.6 |

| 42.4 x 3.2 | 3.1 | 42.4 | 3.2 |

| 42.4 x 4 | 3.8 | 42.4 | 4 |

| 48.3 x 3.2 | 3.6 | 48.3 | 3.2 |

| 48.3 x 4 | 4.4 | 48.3 | 4 |

| 48.3 x 5 | 5.3 | 48.3 | 5 |

| 60.3 x 3.2 | 4.5 | 60.3 | 3.2 |

| 60.3 x 4 | 5.6 | 60.3 | 4 |

| 60.3 x 5 | 6.8 | 60.3 | 5 |

| 76.1 x 3.2 | 5.8 | 76.1 | 3.2 |

| 76.1 x 4 | 7.1 | 76.1 | 4 |

| 76.1 x 5 | 8.8 | 76.1 | 5 |

| 88.9 x 3.2 | 6.8 | 88.9 | 3.2 |

| 88.9 x 4 | 8.4 | 88.9 | 4 |

| 88.9 x 5 | 10.3 | 88.9 | 5 |

| 114.3 x 3.6 | 9.8 | 114.3 | 3.6 |

| 114.3 x 5 | 13.5 | 114.3 | 5 |

| 114.3 x 6.3 | 16.8 | 114.3 | 6.3 |

| 139.7 x 5 | 16.6 | 139.7 | 5 |

| 139.7 x 6.3 | 20.7 | 139.7 | 6.3 |

| 139.7 x 8 | 26 | 139.7 | 8 |

| 139.7 x 10 | 32 | 139.7 | 10 |

| 168.3 x 5 | 20.1 | 168.3 | 5 |

| 168.3 x 6.3 | 25.2 | 168.3 | 6.3 |

| 168.3 x 8 | 31.6 | 168.3 | 8 |

| 168.3 x 10 | 39 | 168.3 | 10 |

| 193.7 x 5 | 23.3 | 193.7 | 5 |

| 193.7 x 5.4 | 25.1 | 193.7 | 5.4 |

| 193.7 x 6.3 | 29.1 | 193.7 | 6.3 |

| 193.7 x 8 | 36.6 | 193.7 | 8 |

| 193.7 x 10 | 45.3 | 193.7 | 10 |

| 193.7 x 12.5 | 55.9 | 193.7 | 12.5 |

| 193.7 x 16 | 70.1 | 193.7 | 16 |

| 219.1 x 5 | 26.4 | 219.1 | 5 |

| 219.1 x 6.3 | 33.1 | 219.1 | 6.3 |

| 219.1 x 8 | 41.6 | 219.1 | 8 |

| 219.1 x 10 | 51.6 | 219.1 | 10 |

| 219.1 x 12.5 | 63.7 | 219.1 | 12.5 |

| 219.1 x 16 | 80.1 | 219.1 | 16 |

| 219.1 x 20 | 98.2 | 219.1 | 20 |

| 244.5 x 6.3 | 37 | 244.5 | 6.3 |

| 244.5 x 8 | 46.7 | 244.5 | 8 |

| 244.5 x 10 | 57.8 | 244.5 | 10 |

| 244.5 x 12.5 | 71.5 | 244.5 | 12.5 |

| 244.5 x 16 | 90.2 | 244.5 | 16 |

| 244.5 x 20 | 111 | 244.5 | 20 |

| 273 x 6.3 | 41.4 | 273 | 6.3 |

| 273 x 8 | 52.3 | 273 | 8 |

| 273 x 10 | 64.9 | 273 | 10 |

| 273 x 12.5 | 80.3 | 273 | 12.5 |

| 273 x 16 | 101 | 273 | 16 |

| 273 x 20 | 125 | 273 | 20 |

| 273 x 25 | 153 | 273 | 25 |

| 323.9 x 6.3 | 49.3 | 323.9 | 6.3 |

| 323.9 x 8 | 62.3 | 323.9 | 8 |

| 323.9 x 10 | 77.4 | 323.9 | 10 |

| 323.9 x 12.5 | 96 | 323.9 | 12.5 |

| 323.9 x 16 | 121 | 323.9 | 16 |

| 323.9 x 20 | 150 | 323.9 | 20 |

| 323..9 x 25 | 184 | 323.9 | 25 |

| 355.6 x 8 | 68.6 | 355.6 | 8 |

| 355.6 x 10 | 85.2 | 355.6 | 10 |

| 355.6 x 12.5 | 106 | 355.6 | 12.5 |

| 355.6 x 16 | 134 | 355.6 | 16 |

| 355.6 x 20 | 166 | 355.6 | 20 |

| 355.6 x 25 | 204 | 355.6 | 25 |

| 406.4 x 10 | 97.8 | 406.4 | 10 |

| 406.4 x 12.5 | 121 | 406.4 | 12.5 |

| 406.4 x 16 | 154 | 406.4 | 16 |

| 406 x 20 | 191 | 406.4 | 20 |

| 406.4 x 25 | 235 | 406.4 | 25 |

| 406.4 x 32 | 295 | 406.4 | 32 |

| 457 x 10 | 110 | 457 | 10 |

| 457 x 12.5 | 137 | 457 | 12.5 |

| 457 x 16 | 174 | 457 | 16 |

| 457 x 20 | 216 | 457 | 20 |

| 457 x 25 | 266 | 457 | 25 |

| 457 x 32 | 335 | 457 | 32 |

| 457 x 40 | 411 | 457 | 40 |

SQUARE HOLLOW SECTIONS (SHS)

| SHS Size | Weight (kg./m) | Height (mm) | Width (mm) | Wall Thickness (mm) |

| 20 x 20 x 2 | 1.1 | 20 | 20 | 2 |

| 20 x 20 x 2.5 | 1.3 | 20 | 20 | 2.5 |

| 25 x 25 x 2 | 14 | 25 | 25 | 2 |

| 25 x 25 x 2.5 | 1.7 | 25 | 25 | 2.5 |

| 25 x 25 x 3 | 2 | 25 | 25 | 3 |

| 30 x 30 x 2 | 1.7 | 30 | 30 | 2 |

| 30 x 30 x 2.5 | 2.1 | 30 | 30 | 2.5 |

| 30 x 30 x 3 | 2.5 | 30 | 30 | 3 |

| 40 x 40 x 2.5 | 2.9 | 40 | 40 | 2.5 |

| 40 x 40 x 3 | 3.4 | 40 | 40 | 3 |

| 40 x 40 x 3.2 | 3.6 | 40 | 40 | 3.2 |

| 40 x 40 x 3.6 | 4 | 40 | 40 | 3.6 |

| 40 x 40 x 4 | 4.4 | 40 | 40 | 4 |

| 40 x 40 x 5 | 5.3 | 40 | 40 | 5 |

| 50 x 50 x 2.5 | 3.7 | 50 | 50 | 2.5 |

| 50 x 50 x 3 | 4.4 | 50 | 50 | 3 |

| 50 x 50 x 3.2 | 4.6 | 50 | 50 | 3.2 |

| 50 x 50 x 3.6 | 5.1 | 50 | 50 | 3.6 |

| 50 x 50 x 4 | 5.6 | 50 | 50 | 4 |

| 50 x 50 x 5 | 6.9 | 50 | 50 | 5 |

| 50 x 50 x 6 | 8 | 50 | 50 | 6 |

| 50 x 50 x 6.3 | 8.3 | 50 | 50 | 6.3 |

| 60 x 60 x 2.5 | 4.5 | 60 | 60 | 2.5 |

| 60 x 60 x 3 | 5.3 | 60 | 60 | 3 |

| 60 x 60 x 3.2 | 5.6 | 60 | 60 | 3.2 |

| 60 x 60 x 3.6 | 6.3 | 60 | 60 | 3.6 |

| 60 x 60 x 4 | 6.9 | 60 | 60 | 4 |

| 60 x 60 x 5 | 8.4 | 60 | 60 | 5 |

| 60 x 60 x 6 | 9.9 | 60 | 60 | 6 |

| 60 x 60 x 6.3 | 10.3 | 60 | 60 | 6.3 |

| 60 x 60 x 8 | 12.5 | 60 | 60 | 8 |

| 70 x 70 x 3 | 6.2 | 70 | 70 | 3 |

| 70 x 70 x 3.2 | 6.6 | 70 | 70 | 3.2 |

| 70 x 70 x 3.6 | 7.4 | 70 | 70 | 3.6 |

| 70 x 70 x 4 | 8.2 | 70 | 70 | 4 |

| 70 x 70 x 5 | 10 | 70 | 70 | 5 |

| 70 x 70 x 6 | 11.8 | 70 | 70 | 6 |

| 70 x 70 x 6.3 | 12.3 | 70 | 70 | 6.3 |

| 70 x 70 x 8 | 15 | 70 | 70 | 8 |

| 80 x 80 x 3 | 7.2 | 80 | 80 | 3 |

| 80 x 80 x 3.2 | 7.6 | 80 | 80 | 3.2 |

| 80 x 80 x 3.6 | 8.5 | 80 | 80 | 3.6 |

| 80 x 80 x 4 | 9.4 | 80 | 80 | 4 |

| 80 x 80 x 5 | 11.6 | 80 | 80 | 5 |

| 80 x 80 x 6 | 13.6 | 80 | 80 | 6 |

| 80 x 80 x 6.3 | 14.2 | 80 | 80 | 6.3 |

| 80 x 80 x 8 | 17.8 | 80 | 80 | 8 |

| 90 x 90 x 5 | 13.1 | 90 | 90 | 5 |

| 90 x 90 x 6 | 15.5 | 90 | 90 | 6 |

| 90 x 90 x 6.3 | 16.2 | 90 | 90 | 6.3 |

| 90 x 90 x 8 | 20.1 | 90 | 90 | 8 |

| 100 x 100 x 3.6 | 10.8 | 100 | 100 | 3.6 |

| 100 x 100 x 4 | 11.9 | 100 | 100 | 4 |

| 100 x 100 x 5 | 14.7 | 100 | 100 | 5 |

| 100 x 100 x 6 | 17.4 | 100 | 100 | 6 |

| 100 x 100 x 6.3 | 18.2 | 100 | 100 | 6.3 |

| 100 x 100 x 8 | 22.6 | 100 | 100 | 8 |

| 100 x 100 x 10 | 27.4 | 100 | 100 | 10 |

| 120 x 120 x 4 | 14.4 | 120 | 120 | 4 |

| 120 x 120 x 5 | 18 | 120 | 120 | 5 |

| 120 x 120 x 6 | 21.2 | 120 | 120 | 6 |

| 120 x 120 x 6.3 | 22.2 | 120 | 120 | 6.3 |

| 120 x 120 x 8 | 27.6 | 120 | 120 | 8 |

| 120 x 120 x 10 | 33.7 | 120 | 120 | 10 |

| 120 x 120 x 12 | 39.5 | 120 | 120 | 12 |

| 120 x 120 x 12.5 | 40.9 | 120 | 120 | 12.5 |

| 140 x 140 x 5 | 21 | 140 | 140 | 5 |

| 140 x 140 x 6 | 24.9 | 140 | 140 | 6 |

| 140 x 140 x 6.3 | 26.1 | 140 | 140 | 6.3 |

| 140 x 140 x 8 | 32.6 | 140 | 140 | 8 |

| 140 x 140 x 10 | 40 | 140 | 140 | 10 |

| 140 x 140 x 12 | 47 | 140 | 140 | 12 |

| 140 x 140 x 12.5 | 48.7 | 140 | 140 | 12.5 |

| 150 x 150 x 5 | 22.6 | 150 | 150 | 5 |

| 150 x 150 x 6 | 26.8 | 150 | 150 | 6 |

| 150 x 150 x 6.3 | 28.1 | 150 | 150 | 6.3 |

| 150 x 150 x 8 | 35.1 | 150 | 150 | 8 |

| 150 x 150 x 10 | 43.1 | 150 | 150 | 10 |

| 150 x 150 x 12 | 50.8 | 150 | 150 | 12 |

| 150 x 150 x 12.5 | 52.7 | 150 | 150 | 12.5 |

| 150 x 150 x 16 | 65.2 | 150 | 150 | 16 |

| 160 x 160 x 5 | 24.1 | 160 | 160 | 5 |

| 160 x 160 x 6 | 28.7 | 160 | 160 | 6 |

| 160 x 160 x 6.3 | 30.1 | 160 | 160 | 6.3 |

| 160 x 160 x 8 | 37.6 | 160 | 160 | 8 |

| 160 x 160 x 10 | 46.3 | 160 | 160 | 10 |

| 160 x 160 x 12 | 54.6 | 160 | 160 | 12 |

| 160 x 160 x 12.5 | 56.6 | 160 | 160 | 12.5 |

| 160 x 160 x 16 | 70.2 | 160 | 160 | 16 |

| 180 x 180 x 5 | 27.3 | 180 | 180 | 5 |

| 180 x 180 x 6 | 32.5 | 180 | 180 | 6 |

| 180 x 180 x 6.3 | 34 | 180 | 180 | 6.3 |

| 180 x 180 x 8 | 42.7 | 180 | 180 | 8 |

| 180 x 180 x 10 | 52.5 | 180 | 180 | 10 |

| 180 x 180 x 12 | 62.1 | 180 | 180 | 12 |

| 180 x 180 x 12.5 | 64.4 | 180 | 180 | 12.5 |

| 180 x 180 x 16 | 80.2 | 180 | 180 | 16 |

| 200 x 200 x 5 | 30.4 | 200 | 200 | 5 |

| 200 x 200 x 6 | 36.2 | 200 | 200 | 6 |

| 200 x 200 x 6.3 | 38 | 200 | 200 | 6.3 |

| 200 x 200 x 8 | 47.7 | 200 | 200 | 8 |

| 200 x 200 x 10 | 58.8 | 200 | 200 | 10 |

| 200 x 200 x 12 | 69.6 | 200 | 200 | 12 |

| 200 x 200 x 12.5 | 72.3 | 200 | 200 | 12.5 |

| 200 x 200 x 16 | 90.3 | 200 | 200 | 16 |

| 220 x 220 x 6 | 40 | 220 | 220 | 6 |

| 220 x 220 x 6.3 | 41.9 | 220 | 220 | 6.3 |

| 220 x 220 x 8 | 52.7 | 220 | 220 | 8 |

| 220 x 220 x 10 | 65.1 | 220 | 220 | 10 |

| 220 x 220 x 12 | 77.2 | 220 | 220 | 12 |

| 220 x 220 x 12.5 | 80.1 | 220 | 220 | 12.5 |

| 220 x 220 x 16 | 100 | 220 | 220 | 16 |

| 250 x 250 x 5 | 38.3 | 250 | 250 | 5 |

| 250 x 250 x 6 | 45.7 | 250 | 250 | 6 |

| 250 x 250 x 6.3 | 47.9 | 250 | 250 | 6.3 |

| 250 x 250 x 8 | 60.3 | 250 | 250 | 8 |

| 250 x 250 x 10 | 74.5 | 250 | 250 | 10 |

| 250 x 250 x 12 | 88.5 | 250 | 250 | 12 |

| 250 x 250 x 12.5 | 91.9 | 250 | 250 | 12.5 |

| 250 x 250 x 16 | 115 | 250 | 250 | 16 |

| 260 x 260 x 6 | 47.6 | 260 | 260 | 6 |

| 260 x 260 x 6.3 | 49.9 | 260 | 260 | 6.3 |

| 260 x 260 x 8 | 62.8 | 260 | 260 | 8 |

| 260 x 260 x 10 | 77.7 | 260 | 260 | 10 |

| 260 x 260 x 12 | 92.2 | 260 | 260 | 12 |

| 260 x 260 x 12.5 | 95.8 | 260 | 260 | 12.5 |

| 260 x 260 x 16 | 120 | 260 | 260 | 16 |

| 300 x 300 x 6 | 55.1 | 300 | 300 | 6 |

| 300 x 300 x 6.3 | 57.8 | 300 | 300 | 6.3 |

| 300 x 300 x 8 | 72.8 | 300 | 300 | 8 |

| 300 x 300 x 10 | 90.2 | 300 | 300 | 10 |

| 300 x 300 x 12 | 107 | 300 | 300 | 12 |

| 300 x 300 x 12.5 | 112 | 300 | 300 | 12.5 |

| 300 x 300 x 16 | 141 | 300 | 300 | 16 |

| 350 x 350 x 8 | 85.4 | 350 | 350 | 8 |

| 350 x 350 x 10 | 106 | 350 | 350 | 10 |

| 350 x 350 x 12 | 126 | 350 | 350 | 12 |

| 350 x 350 x 12.5 | 131 | 350 | 350 | 12.5 |

| 350 x 350 x 16 | 166 | 350 | 350 | 16 |

| 400 x 400 x 8 | 97.9 | 400 | 400 | 8 |

| 400 x 400 x 10 | 122 | 400 | 400 | 10 |

| 400 x 400 x 12 | 145 | 400 | 400 | 12 |

| 400 x 400 x 12.5 | 151 | 400 | 400 | 12.5 |

| 400 x 400 x 16 | 191 | 400 | 400 | 16 |

| 400 x 400 x 20 | 235 | 400 | 400 | 20 |

RECTANGULAR HOLLOW SECTIONS (RHS)

| RHS Size | Weight (kg./m) | Height (mm) | Width (mm) | Wall Thickness (mm) |

| 50 x 25 x 2.5 | 2.7 | 50 | 25 | 2.5 |

| 50 x 25 x 2.5 | 2.7 | 50 | 25 | 2.5 |

| 50 x 25 x 3 | 3.2 | 50 | 25 | 3 |

| 50 x 30 x 2.5 | 2.9 | 50 | 30 | 2.5 |

| 50 x 30 x 3 | 3.4 | 50 | 30 | 3 |

| 50 x 30 x 3.2 | 3.6 | 50 | 30 | 3.2 |

| 50 x 30 x 3.6 | 4 | 50 | 30 | 3.6 |

| 50 x 30 x 4 | 4.4 | 50 | 30 | 4 |

| 50 x 30 x 5 | 5.3 | 50 | 30 | 5 |

| 60 x 40 x 2.5 | 3.7 | 60 | 40 | 2.5 |

| 60 x 40 x 3 | 4.4 | 60 | 40 | 3 |

| 60 x 40 x 3.2 | 4.6 | 60 | 40 | 3.2 |

| 60 x 40 x 3.6 | 5.1 | 60 | 40 | 3.6 |

| 60 x 40 x 4 | 5.6 | 60 | 40 | 4 |

| 60 x 40 x 5 | 6.9 | 60 | 40 | 5 |

| 60 x 40 x 6 | 8 | 60 | 40 | 6 |

| 60 x 40 x 6.3 | 8.3 | 60 | 40 | 6.3 |

| 80 x 40 x 3 | 5.3 | 80 | 40 | 3 |

| 80 x 40 x 3.2 | 5.6 | 80 | 40 | 3.2 |

| 80 x 40 x 3.6 | 6.3 | 80 | 40 | 3.6 |

| 80 x 40 x 4 | 6.9 | 80 | 40 | 4 |

| 80 x 40 x 5 | 8.4 | 80 | 40 | 5 |

| 80 x 40 x 6 | 9.9 | 80 | 40 | 6 |

| 80 x 40 x 6.3 | 10.3 | 80 | 40 | 6.3 |

| 80 x 40 x 8 | 12.5 | 80 | 40 | 8 |

| 90 x 50 x 3 | 6.2 | 90 | 50 | 3 |

| 90 x 50 x 3.2 | 6.6 | 90 | 50 | 3.2 |

| 90 x 50 x 3.6 | 7.4 | 90 | 50 | 3.6 |

| 90 x 50 x 4 | 8.2 | 90 | 50 | 4 |

| 90 x 50 x 5 | 10 | 90 | 50 | 5 |

| 90 x 50 x 6 | 11.8 | 90 | 50 | 6 |

| 90 x 50 x 6.3 | 12.3 | 90 | 50 | 6.3 |

| 90 x 50 x 8 | 15 | 90 | 50 | 8 |

| 100 x 50 x 3 | 6.7 | 100 | 50 | 3 |

| 100 x 50 x 3.2 | 7.1 | 100 | 50 | 3.2 |

| 100 x 50 x 3.6 | 8 | 100 | 50 | 3.6 |

| 100 x 50 x 4 | 8.8 | 100 | 50 | 4 |

| 100 x 50 x 5 | 10.8 | 100 | 50 | 5 |

| 100 x 50 x 6 | 12.7 | 100 | 50 | 6 |

| 100 x 50 x 6.3 | 13.3 | 100 | 50 | 6.3 |

| 100 x 50 x 8 | 16.3 | 100 | 50 | 8 |

| 100 x 60 x 3 | 7.2 | 100 | 60 | 3 |

| 100 x 60 x 3.2 | 7.6 | 100 | 60 | 3.2 |

| 100 x 60 x 3.6 | 8.5 | 100 | 60 | 3.6 |

| 100 x 60 x 4 | 9.4 | 100 | 60 | 4 |

| 100 x 60 x 5 | 11.6 | 100 | 60 | 5 |

| 100 x 60 x 6 | 13.6 | 100 | 60 | 6 |

| 100 x 60 x 6.3 | 14.2 | 100 | 60 | 6.3 |

| 100 x 60 x 8 | 17.5 | 100 | 60 | 8 |

| 120 x 60 x 3.6 | 9.7 | 120 | 60 | 3.6 |

| 120 x 60 x 4 | 10.7 | 120 | 60 | 4 |

| 120 x 60 x 5 | 13.1 | 120 | 60 | 5 |

| 120 x 60 x 6 | 15.5 | 120 | 60 | 6 |

| 120 x 60 x 6.3 | 16.2 | 120 | 60 | 6.3 |

| 120 x 60 x 8 | 20.1 | 120 | 60 | 8 |

| 120 x 60 x 10 | 24.6 | 120 | 60 | 10 |

| 120 x 80 x 3.6 | 10.8 | 120 | 80 | 3.6 |

| 120 x 80 x 4 | 11.9 | 120 | 80 | 4 |

| 120 x 80 x 5 | 14.7 | 120 | 80 | 5 |

| 120 x 80 x 6 | 17.4 | 120 | 80 | 6 |

| 120 x 80 x 6.3 | 18.2 | 120 | 80 | 6.3 |

| 120 x 80 x 8 | 22.6 | 120 | 80 | 8 |

| 120 x 80 x 10 | 27.4 | 120 | 80 | 10 |

| 140 x 80 x 4 | 13.2 | 140 | 80 | 4 |

| 140 x 80 x 5 | 16.3 | 140 | 80 | 5 |

| 140 x 80 x 6 | 19.3 | 140 | 80 | 6 |

| 140 x 80 x 6.3 | 20.2 | 140 | 80 | 6.3 |

| 140 x 80 x 8 | 25.1 | 140 | 80 | 8 |

| 140 x 80 x 10 | 30.6 | 140 | 80 | 10 |

| 150 x 100 x 4 | 15.1 | 150 | 100 | 4 |

| 150 x 100 x 5 | 18.6 | 150 | 100 | 5 |

| 150 x 100 x 6 | 22.1 | 150 | 100 | 6 |

| 150 x 100 x 6.3 | 23.1 | 150 | 100 | 6.3 |

| 150 x 100 x 8 | 28.9 | 150 | 100 | 8 |

| 150 x 100 x 10 | 35.3 | 150 | 100 | 10 |

| 150 x 100 x 12 | 41.4 | 150 | 100 | 12 |

| 150 x 100 x 12.5 | 42.8 | 150 | 100 | 12.5 |

| 160 x 80 x 4 | 14.4 | 160 | 80 | 4 |

| 160 x 80 x 5 | 17.8 | 160 | 80 | 5 |

| 160 x 80 x 6 | 21.2 | 160 | 80 | 6 |

| 160 x 80 x 6.3 | 22.2 | 160 | 80 | 6.3 |

| 160 x 80 x 8 | 27.6 | 160 | 80 | 8 |

| 160 x 80 x 10 | 33.7 | 160 | 80 | 10 |

| 160 x 80 x 12 | 39.5 | 160 | 80 | 12 |

| 160 x 80 x 12.5 | 40.9 | |160 | 80 | 12.5 |

| 180 x 100 x 4 | 16.9 | 180 | 100 | 4 |

| 180 x 100 x 5 | 21 | 180 | 100 | 5 |

| 180 x 100 x 6 | 24.9 | 180 | 100 | 6 |

| 180 x 100 x 6.3 | 26.1 | 180 | 100 | 6.3 |

| 180 x 100 x 8 | 32.6 | 180 | 100 | 8 |

| 180 x 100 x 10 | 40 | 180 | 100 | 10 |

| 180 x 100 x 12 | 47 | 180 | 100 | 12 |

| 180 x 100 x 12.5 | 48.7 | 180 | 100 | 12.5 |

| 200 x 100 x 4 | 18.1 | 200 | 100 | 4 |

| 200 x 100 x 5 | 22.6 | 200 | 100 | 5 |

| 200 x 100 x 6 | 26.8 | 200 | 100 | 6 |

| 200 x 100 x 6.3 | 28.1 | 200 | 100 | 6.3 |

| 200 x 100 x 8 | 35.1 | 200 | 100 | 8 |

| 200 x 100 x 10 | 43.1 | 200 | 100 | 10 |

| 200 x 100 x 12 | 50.8 | 200 | 100 | 12 |

| 200 x 100 x 12.5 | 52.7 | 200 | 100 | 12.5 |

| 200 x 100 x 16 | 65.2 | 200 | 100 | 16 |

| 200 x 120 x 6 | 28.7 | 200 | 120 | 6 |

| 200 x 120 x 6.3 | 29.9 | 200 | 120 | 6.3 |

| 200 x 120 x 8 | 37.3 | 200 | 120 | 8 |

| 200 x 120 x 10 | 45.9 | 200 | 120 | 10 |

| 200 x 120 x 12 | 54.5 | 200 | 120 | 12 |

| 200 x 120 x 12.5 | 55.7 | 200 | 120 | 12.5 |

| 250 x 150 x 5 | 30.4 | 250 | 150 | 5 |

| 250 x 150 x 6 | 36.2 | 250 | 150 | 6 |

| 250 x 150 x 6.3 | 38 | |250 | 150 | 6.3 |

| 250 x 150 x 8 | 47.7 | 250 | 150 | 8 |

| 250 x 150 x 10 | 58.8 | 250 | 150 | 10 |

| 250 x 150 x 12 | 69.6 | 250 | 150 | 12 |

| 250 x 150 x 12.5 | 72.3 | 250 | 150 | 12.5 |

| 250 x 150 x 16 | 90.3 | 250 | 150 | 16 |

| 260 x 180 x 6 | 40 | 260 | 180 | 6 |

| 260 x 180 x 6.3 | 41.9 | 260 | 180 | 6.3 |

| 260 x 180 x 8 | 52.7 | 260 | 180 | 8 |

| 260 x 180 x 10 | 65.1 | 260 | 180 | 10 |

| 260 x 180 x 12 | 77.2 | 260 | 180 | 12 |

| 260 x 180 x 12.5 | 80.1 | 260 | 180 | 12.5 |

| 260 x 180 x 16 | 100 | 260 | 180 | 16 |

| 300 x 200 x 5 | 38.3 | 300 | 200 | 5 |

| 300 x 200 x 6 | 45.7 | 300 | 200 | 6 |

| 300 x 200 x 6.3 | 47.9 | 300 | 200 | 6.3 |

| 300 x 200 x 8 | 60.3 | 300 | 200 | 8 |

| 300 x 200 x 10 | 74.5 | 300 | 200 | 10 |

| 300 x 200 x 12 | 88.5 | 300 | 200 | 12 |

| 300 x 200 x 12.5 | 91.9 | 300 | 200 | 12.5 |

| 300 x 200 x 16 | 115 | 300 | 200 | 16 |

| 350 x 250 x 6 | 55.1 | 350 | 250 | 6 |

| 350 x 250 x 6.3 | 57.8 | 350 | 250 | 6.3 |

| 350 x 250 x 8 | 72.8 | 350 | 250 | 8 |

| 350 x 250 x 10 | 90.2 | 350 | 250 | 10 |

| 350 x 250 x 12 | 107 | |350 | 250 | 12 |

| 350 x 250 x 12.5 | 112 | 350 | 250 | 12.5 |

| 350 x 250 x 16 | 141 | 350 | 250 | 16 |

| 400 x 200 x 6 | 55.1 | 400 | 200 | 6 |

| 400 x 200 x 6.3 | 57.8 | 400 | 200 | 6.3 |

| 400 x 200 x 8 | 72.8 | 400 | 200 | 8 |

| 400 x 200 x 10 | 90.2 | 400 | 200 | 10 |

| 400 x 200 x 12 | 107 | 400 | 200 | 12 |

| 400 x 200 x 12.5 | 112 | 400 | 200 | 12.5 |

| 400 x 200 x 16 | 141 | 400 | 200 | 16 |

| 450 x 250 x 8 | 85.4 | 450 | 250 | 8 |

| 450 x 250 x 10 | 106 | 450 | 250 | 10 |

| 450 x 250 x 12 | 126 | 450 | 250 | 12 |

| 450 x 250 x 12.5 | 131 | 450 | 250 | 12.5 |

| 450 x 250 x 16 | 166 | 450 | 250 | 16 |

| 500 x 300 x 8 | 97.9 | 500 | 300 | 8 |

| 500 x 300 x 10 | 122 | 500 | 300 | 10 |

| 500 x 300 x 12 | 145 | 500 | 300 | 12 |

| 500 x 300 x 12.5 | 151 | 500 | 300 | 12.5 |

| 500 x 300 x 16 | 191 | 500 | 300 | 16 |

| 500 x 300 x 20 | 235 | 500 | 300 | 20 |