Learn about API 5L pipes for pipelines. The API 5L specification covers seamless and welded pipes to convey oil, gas, and water in the natural oil & gas and petrochemical industries. API 5L line pipes are available in multiple carbon steel grades, designated as Grade B, X42, X46, X52, X56, X60, X70, X80 and in PSL1 or PSL2 specification levels.

API 5L SPECIFICATION

GENERAL INFO PIPES API 5L

API 5L is a specification published by the American Petroleum Institute (API) that defines requirements for the manufacture of two product specification levels (PSL 1 and PSL 2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.

Here are some key features of API 5L pipes:

Types

- API 5L specification covers both seamless and welded steel pipes.

- Seamless pipes are produced by piercing a solid billet to form a hollow shell, while welded pipes are manufactured by welding together flat steel plates or coils.

Grades

API 5L pipes are available in different grades designated by the letter “X” followed by a two- or three-digit number. Common grades include:

- API 5L Grade B: This is the most commonly used grade for general-purpose applications in the oil and gas industry.

- API 5L X52, X60, X65, X70, X80 (high-yield API 5L): These grades have higher yield and tensile strength and are used for pipelines operating at higher pressures and temperatures.

- Other grades such as X42, X46, X56, X60, X65, X70, X80, and so on, are also available depending on specific requirements.

Chemical Composition

- The chemical composition of API 5L pipes varies depending on the grade and product specification level (PSL 1 or PSL 2).

- Typical elements include carbon, manganese, phosphorus, sulfur, silicon, and traces of other alloying elements.

Mechanical Properties

- API 5L pipes undergo various tests to ensure compliance with mechanical property requirements, including tensile, yield, and elongation testing.

- Mechanical properties vary depending on the grade, wall thickness, and product specification level.

Dimensions and Sizes

- API 5L pipes are available in a wide range of sizes and dimensions, ranging from 2 inches to 48 inches in diameter.

- Wall thickness can vary depending on the grade and product specification level.

Applications

- API 5L pipes are primarily used for transporting oil, gas, and water in pipeline transportation systems.

- They are also used in various applications such as offshore platforms, refineries, petrochemical plants, and construction projects.

Testing and Inspection

API 5L pipes undergo stringent testing and inspection procedures to ensure quality and performance, including hydrostatic testing, non-destructive testing (NDT), dimensional inspection, and chemical analysis.

Overall, API 5L pipes are widely used in the oil and gas industry for their strength, durability, and reliability in transporting fluids over long distances. When selecting API 5L pipes for a specific application, it is essential to consider factors such as grade, size, wall thickness, and product specification level to ensure they meet the specific requirements and performance criteria.

CLASSIFICATION OF API 5L PIPES

API 5L pipes may be classified according to the following criteria:

- Execution: seamless or welded (seamless pipes may be used up to 24 inches, LSAW above 24 inches, ERW up to 20 inches)

- Specification level (API PSL1, PSL2): PSL1 is a standard quality used for pipelines, whereas PSL2 sets more stringent chemical, mechanical properties, and testing requirements

- Surface finish: black, varnish painted, anti-rust oil, galvanized, coated externally (3PL) and/or lined internally

- Pipe ends types: plain, beveled, threaded ends

KEY ADVANTAGES PIPES API 5L

The main advantages of API 5L pipe are:

- Resistance to cracking forces that may propagate in long pipelines

- Sour service suitability

- Rather inexpensive and long service life (at least grades B, X42)

SIZE RANGE API 5L PIPES

API 5L pipes are available in dimensions between 2 to 28″ (seamless execution) and up to 80″ in welded execution (generally, LSAW i.e. longitudinal submerged arc welding).

The API 5L and ASME B36.10 pipe dimensions and weights are, in fact, identical.

API 5L PIPE CHEMICAL AND MECHANICAL PROPERTIES

The yield strength of an API 5L pipe is specified with the number that follows the X in the material grade designation (in kilopounds per square inch – i.e. KSI). So, for instance, an API 5L X52 pipe has a minimum yield strength of 52 KSI.

The table shows the chemical composition of API 5L steel pipes PSL1 and PSL2 from Grade A to Grade X70, as well as their mechanical properties.

Source: API 5L specification

|

API 5L PIPE PSL1 Chemical and Mechanical Properties

|

|||||||||

|

API 5L PIPE PSL1 |

Chemical Composition |

Mechanical Property |

|||||||

|

C (Max) |

Mn (Max) |

P (Max) |

S (Max) |

TENSILE ( Min ) |

YIELD ( Min ) |

||||

|

Psi X 1000 |

Mpa |

Psi X 1000 |

Mpa |

||||||

|

Grade A25 |

CL I |

0.21 |

0.60 |

0.030 |

0.030 |

45 |

310 |

25 |

172 |

|

CL II |

0.21 |

0.60 |

0.030 |

0.030 |

|||||

|

Grade A |

0.22 |

0.90 |

0.030 |

0.030 |

48 |

331 |

30 |

207 |

|

|

Grade B |

0.26 |

1.20 |

0.030 |

0.030 |

60 |

414 |

35 |

241 |

|

|

Grade X42 |

0.26 |

1.30 |

0.030 |

0.030 |

60 |

414 |

42 |

290 |

|

|

Grade X46 |

0.26 |

1.40 |

0.030 |

0.030 |

63 |

434 |

46 |

317 |

|

|

Grade X52 |

0.26 |

1.40 |

0.030 |

0.030 |

66 |

455 |

52 |

359 |

|

|

Grade X56 |

0.26 |

1.40 |

0.030 |

0.030 |

71 |

490 |

56 |

386 |

|

|

Grade X60 |

0.26 |

1.40 |

0.030 |

0.030 |

75 |

517 |

60 |

414 |

|

|

Grade X65 |

0.26 |

1.45 |

0.030 |

0.030 |

77 |

531 |

65 |

448 |

|

|

Grade X70 |

0.26 |

1.65 |

0.030 |

0.030 |

82 |

565 |

70 |

483 |

|

| API 5L PIPE PSL2 Chemical and Mechanical Properties | ||||||||||||

|

API 5L PIPE |

Chemical Composition |

Mechanical Property |

||||||||||

|

C |

Mn |

P |

S |

Tensile |

Yield |

C. E. IMPACT ENERGY |

||||||

|

Psi x 1000 |

Mpa |

Psi x 1000 |

Mpa |

PCM |

IIW |

J |

FT/LB |

|||||

|

Grade B |

0.22 |

1.20 |

0.025 |

0.015 |

60 – 110 |

414 – 758 |

35 – 65 |

241 – 448 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X42 |

0.22 |

1.30 |

0.025 |

0.015 |

60 – 110 |

414 – 758 |

42 – 72 |

290 – 496 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X46 |

0.22 |

1.40 |

0.025 |

0.015 |

63 – 110 |

434 – 758 |

46 – 76 |

317 – 524 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X52 |

0.22 |

1.40 |

0.025 |

0.015 |

66 – 110 |

455 – 758 |

52 – 77 |

359 – 531 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X56 |

0.22 |

1.40 |

0.025 |

0.015 |

71 – 110 |

490 – 758 |

56 – 79 |

386 – 544 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X60 |

0.22 |

1.40 |

0.025 |

0.015 |

75 – 110 |

517 – 758 |

60 – 82 |

414 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X65 |

0.22 |

1.45 |

0.025 |

0.015 |

77 – 110 |

531 – 758 |

65 – 82 |

448 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X70 |

0.22 |

1.65 |

0.025 |

0.015 |

82 – 110 |

565 – 758 |

70 – 82 |

483 – 565 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

|

Grade X80 |

0.22 |

1.90 |

0.025 |

0.015 |

90 – 120 |

621 – 827 |

80 – 102 |

552 – 705 |

0.25 |

0.43 |

T/L 27/41 |

T/L 20/30 |

API 5L Equivalent Grades (ASTM, EN, DIN)

Material grades A53 Gr. B and A106 Gr. B, and also API 5L Gr. X42, are API 5L Gr. B equivalent. It is actually quite common to find on the market pipes that comply, at the same time, with all these specifications (“quadri-norm” marked pipes). While this is true in terms of chemical and mechanical properties, note that the API 5L specification sets more severe requirements and tests than those set for the two equivalent ASTM specifications.

In terms of comparison with EN pipe standards, API 5L Gr. B equivalents are EN 10216-1 P265GH (seamless) and EN 10217-1 P265 (welded) – whereas EN 10216-2 P265 GH is the EN equivalent grade for ASTM A106 Gr. B pipes.

| Line Pipe Materials: Werkstoff vs EN vs API | ||

|---|---|---|

| Werkstoff/DIN | EN | API |

| 1.0486 StE 285 | – | API 5L Grade X42 |

| 1.0562 StE 355 | P355N | API 5L Grade X52 |

| 1.8902 StE 420 | P420N | API 5L Grade X60 |

| 1.8905 StE 460 | P460N | API 5L Grade X70 |

| High Yield Steel Pipes | ||

| 1.0457 StE 240.7 | L245NB | API 5L Grade B |

| 1.0484 StE 290.7 | L290NB | API 5L Grade X42 |

| 1.0582 StE 360.7 | L360NB | API 5L Grade X52 |

| 1.8972 StE 415.7 | L415NB | API 5L Grade X60 |

| – – | – | – |

API 5L PSL1 VS. API 5L PSL2

API 5L PSL1 and PSL2 are two specification levels that differ in terms of chemical composition and test requirements. The differences between PSL1 and PSL2 are outlined in the two tables below:

|

PSL GRADE |

C, a |

Mn a |

P |

S |

Si |

V |

Nb |

Ti |

Other |

CEIIW |

CEpcm |

|

1 |

0.24 |

1.40 |

0.025 |

0.015 |

0.45 |

0.10 |

0.05 |

0.04 |

b,c |

.043 |

0.025 |

|

2 |

0.28 |

1.40 |

0.03 |

0.03 |

– |

b |

b |

b |

– |

– |

– |

| Test Requirement | API 5L PSL1 | API 5L PSL2 |

| Charpy test | None required | Required for all grades |

| Seamless NDT test | Only if the purchaser specifies SR4 | SR4 mandatory |

| Certification | Certificates when specified per SR15 | Certificates (SR 15.1) mandatory |

| Traceability | Traceable only until all tests are passed unless SR15 is specified | Traceable after completion of tests (SR 15.2) mandatory |

| Hydrostatic Test | Required | Required |

API 5L PIPE SCHEDULE CHART

DIMENSIONAL RANGE

| NPS (in) |

Outside Diameter (in) |

API 5l Pipe Schedule | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

| Wall Thickness (in) | ||||||||||||||

| 1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 1/4 | 0.540 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 1/2 | 0.840 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

| 3/4 | 1.050 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

| 1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.250 | 0.358 | |||||||

| 1 1/4 | 1.660 | 0.140 | 0.140 | 0.191 | 0.191 | 0.250 | 0.382 | |||||||

| 1 1/2 | 1.900 | 0.145 | 0.145 | 0.200 | 0.200 | 0.281 | 0.400 | |||||||

| 2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

| 2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

| 3 | 3.500 | 0.216 | 0.216 | 0.300 | 0.300 | 0.438 | 0.600 | |||||||

| 3 1/2 | 4.000 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

| 4 | 4.500 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

| 5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | ||||||

| 6 | 6.625 | 0.280 | 0.280 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

| 8 | 8.625 | 0.250 | 0.277 | 0.322 | 0.322 | 0.406 | 0.500 | 0.500 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

| 10 | 10.750 | 0.250 | 0.307 | 0.365 | 0.365 | 0.500 | 0.500 | 0.594 | 0.719 | 0.844 | 1.000 | 1.125 | 1.000 | |

| 12 | 12.750 | 0.250 | 0.330 | 0.375 | 0.406 | 0.562 | 0.500 | 0.688 | 0.844 | 1.000 | 1.125 | 1.312 | 1.000 | |

| 14 | 14.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.500 | 0.750 | 0.938 | 1.094 | 1.250 | 1.406 | |

| 16 | 16.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.500 | 0.656 | 0.500 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18.000 | 0.250 | 0.312 | 0.438 | 0.375 | 0.562 | 0.750 | 0.500 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.594 | 0.812 | 0.500 | 1.031 | 1.281 | 1.500 | 1.750 | 1.969 | |

| 22 | 22.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.875 | 0.500 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

| 24 | 24.000 | 0.250 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.500 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 30 | 30.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.500 | ||||||||

| 32 | 32.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 34 | 34.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 36 | 36.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.750 | ||||||||

| 42 | 42.000 | 0.500 | 0.625 | 0.375 | 0.750 | |||||||||

API 5L PIPE OUTSIDE DIAMETER TOLERANCE

|

Specified outside |

API 5L Diameter tolerances mm (in) |

API 5L Out-of-roundness tolerances mm (in) |

||||

|

Pipe except at end a |

Pipe end a,b,c |

Pipe except at end a |

Pipe end a,b,c |

|||

|

SMLS pipe |

Welded pipe |

SMLS pipe |

Welded pipe |

|||

|

< 60.3 (2.375) |

– 0.8 (0.031 ) to + 0.4 (0.016) |

– 0.4 (0.016) to + 1.6 (0.063) |

d |

|||

|

≥ 60.3 (2.375) |

± 0.007 5 D |

0.020 D |

0.015 D |

|||

|

≥ 168.3 (6.625) |

± 0.007 5 D |

± 0.007 5 D but maximum of + 3.2 (0.125) |

± 0.005 D, but a maximum of ± 1.6 (0.063) |

|||

|

> 610 (24.000) |

± 0.01 D |

± 0.005 D, but maximum of + 4.0 (0.160) |

± 2.0 (0.079) |

± 1.6 (0.063) |

0.015 D |

0.01 D, |

|

but maximum of |

but maximum of 13 (0.5), |

|||||

|

for d / ts ≤ 75 |

for d / ts ≤ 75 |

|||||

|

by agreement |

by agreement |

|||||

|

for d / ts > 75 |

for d / ts > 75 |

|||||

|

> 1 422 (56 000) |

as agreed |

|||||

a — Pipe end includes a length of 100 mm (4.0 in) for each side

b — For SMLS pipe, the tolerances apply for 25.0 mm (0.984 in); tolerances for thicker pipes have to be as agreed.

c — For pipe with D219,1 mm (8.625 in) the diameter tolerance and the out-of-roundness tolerance may be determined by using the calculated inside diameter (the specified outside diameter minus two times the specified wall thickness) or measured inside diameter rather than the specified outside diameter

d — Included in the tolerance of the diameter

API 5L PIPE WALL THICKNESS TOLERANCE (WT)

|

API 5L wall thickness t |

API 5L Pipes Tolerances a |

| API 5L SMLS pipe b | |

|

≤ 4,0 ( 0.157) |

+ 0,6 (0.024) |

|

> 4,0 ( 0.157) to < 25,0 (0.984) |

+ 0,150 |

|

≥ 25,0 (0.984) |

+3,7 (0.146) or + 0,1 t whichever is the greater |

| API 5L Welded pipe c, d | |

|

≤ 5,0 (0.197) |

± 0,5 (0.020) |

|

> 5,0 (0.197) to <15,0 (0.591 ) |

± 0, 1 t |

|

≥ 15,0 (0.591) |

±1,5 (0.060) |

|

a — if the purchase order specifies a minus tolerance for wall thickness smaller than the applicable value given in this table, the plus tolerance for wall thickness shall be increased by an amount sufficient to maintain the applicable tolerance range. |

|

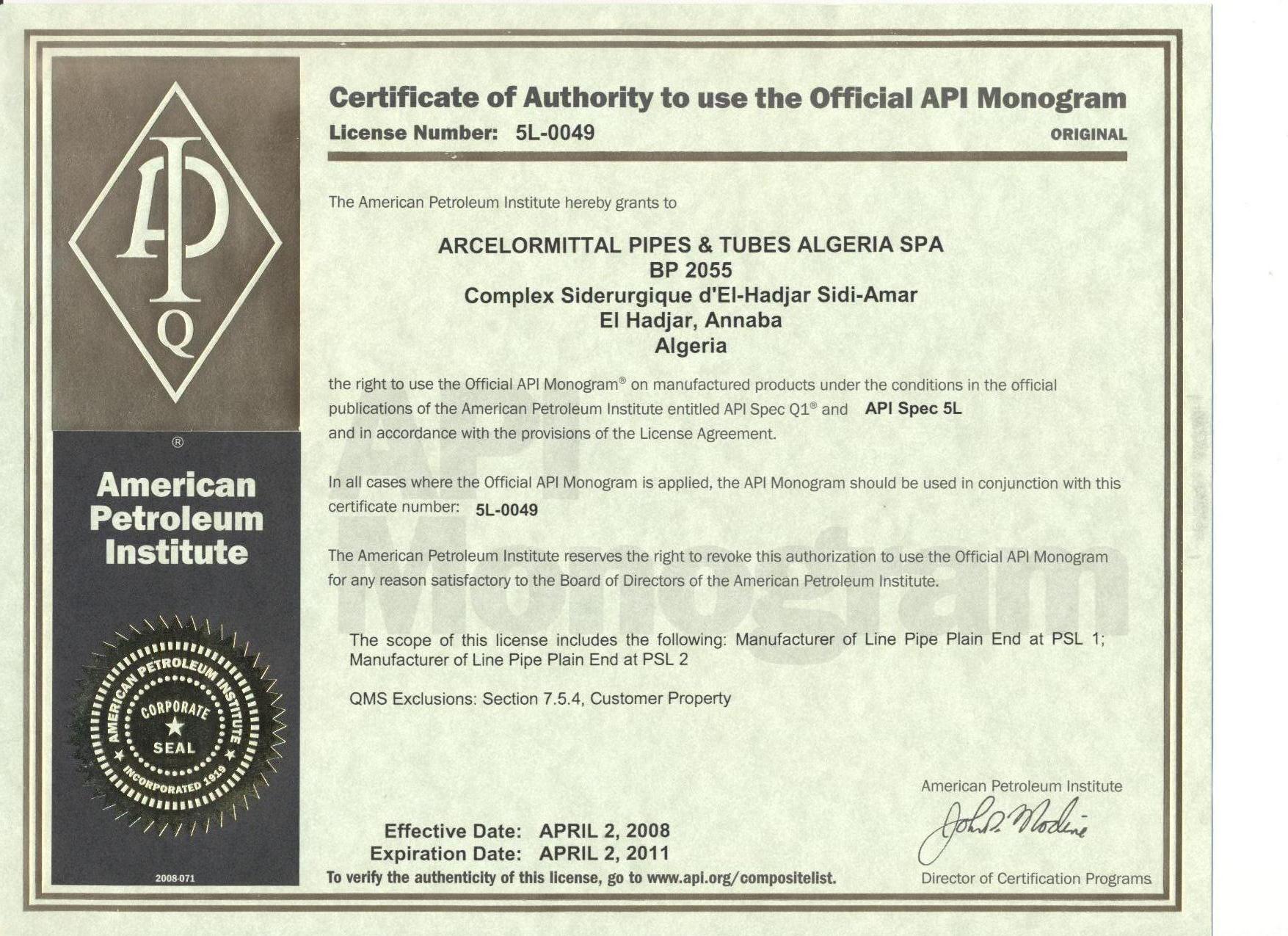

API 5L MONOGRAM

Manufacturers of steel pipes may request API an audit to assess their capabilities to comply with the API 5L standard.

Pipe mills that pass the API audit successfully are awarded an API monogram.

API lists in a composite index the names of the factories that have passed the audit successfully. The monogram has an expiration date.

The API monogram is therefore similar to the franchising scheme, however, API does not have any financial benefit from the certification of pipe mills, nor does it take any liability and the performance of the certified mills and products.

HOW TO ORDER API 5L PIPES

| Parameter | API 5L Pipe Ordering Details |

| Qty | Feet or lengths |

| Size | NPS (Outside Diameter) and Schedule Number (Average Wall Thickness) |

| PSL | PSL 1 or PSL 2 |

| Material Grade | Grade A, Grade B, X42, X46, X52, X60, X70, X80, etc |

| Execution | Seamless or Welded execution |

| Surface finish | Bare, Black, FBE, etc |

| Marking requirements | If different from the API 5L Specification |

| Pipe coating or lining requirements | To protect the pipe from erosion and corrosion, depending on the fluid to be conveyed |

| Manufacturer | Approved Manufacturer List (AML), or Country of Origin restrictions |

| Sour service | Yes / No |

We recommend purchasing the API5L specification from the API store to get a complete understanding of this topic.

TOP MANUFACTURERS OF API 5L PIPES

There are numerous manufacturers worldwide that produce API 5L pipes to meet the demands of various industries, especially the oil and gas sector. Some of the prominent manufacturers of API 5L pipes include:

Tenaris

Tenaris is a global manufacturer and supplier of steel pipes and related services for the energy industry. They produce a wide range of API 5L pipes, including seamless and welded varieties, to meet the requirements of different applications.

TMK (Pipe Metallurgical Company)

TMK is one of the world’s leading producers of tubular products for the oil and gas industry. They manufacture API 5L pipes in various grades and specifications, including seamless and welded options.

Nippon Steel Corporation

Nippon Steel Corporation is a Japanese steelmaker that produces high-quality steel pipes for various industries, including oil and gas. They manufacture API 5L pipes with a focus on quality, reliability, and performance.

ArcelorMittal

ArcelorMittal is a multinational steel manufacturing corporation with operations in more than 60 countries. They produce a wide range of steel products, including API 5L pipes, to meet the needs of the energy industry.

JFE Steel Corporation

JFE Steel Corporation is a Japanese steelmaker known for its high-quality steel products. They manufacture API 5L pipes with advanced technologies and stringent quality control measures to ensure superior performance.

Vallourec

Vallourec is a leading producer of seamless steel pipes and tubes for various industrial applications, including oil and gas exploration and production. They offer a comprehensive range of API 5L pipes to meet the specific requirements of customers.

Severstal

Severstal is a Russian steel and mining company that produces a wide range of steel products, including API 5L pipes. They are known for their focus on innovation, quality, and customer satisfaction.

United States Steel Corporation (U.S. Steel):

U.S. Steel is one of the largest steel producers in the United States and manufactures API 5L pipes for the energy sector. They offer a range of seamless and welded pipes to meet the diverse needs of customers.

These are just a few examples of manufacturers of API 5L pipes. Many other companies around the world produce high-quality API 5L pipes to serve the needs of the oil and gas industry and other sectors requiring reliable pipe solutions. When selecting a manufacturer, it’s essential to consider factors such as product quality, reliability, lead times, and customer service.

Top Chinese Manufacturers

Several Chinese manufacturers produce API 5L pipes to meet the global demand for steel pipes in various industries, including the oil and gas sector. Some prominent Chinese manufacturers of API 5L pipes include:

Baosteel Group Corporation

Baosteel is one of China’s largest steel producers and manufactures a wide range of steel products, including API 5L pipes. They are known for their advanced manufacturing facilities and high-quality products.

Hunan Standard Steel Co., Ltd.

Hunan Standard Steel is a leading manufacturer and exporter of steel pipes in China. They produce API 5L pipes in various grades and specifications, including seamless and welded options.

Tianjin Pipe (Group) Corporation (TPCO)

TPCO is one of the largest seamless steel pipe manufacturers in China and produces API 5L pipes for domestic and international markets. They have advanced production facilities and adhere to strict quality control measures.

Shaanxi Huitong Special Steel Co., Ltd.

Shaanxi Huitong Special Steel is a specialized manufacturer of steel pipes and tubes, including API 5L pipes. They offer a comprehensive range of products to meet the needs of customers in different industries.

Shandong Huitong Steel Pipe Manufacturing Co., Ltd.

Shandong Huitong Steel Pipe Manufacturing is a leading manufacturer of seamless steel pipes, including API 5L pipes, in China. They focus on product quality, innovation, and customer satisfaction.

Wuxi Huayou Special Steel Co., Ltd.

Wuxi Huayou Special Steel specializes in the production of high-quality steel pipes and tubes for various applications, including API 5L pipes. They have modern production facilities and a strong commitment to quality.

Jiangsu Yulong Steel Pipe Co., Ltd.

Jiangsu Yulong Steel Pipe is a well-known manufacturer of steel pipes and tubes in China. They produce API 5L pipes with advanced technologies and stringent quality control measures to ensure superior performance.

Zhejiang Huatian Stainless Steel Manufacturing Co., Ltd.

Zhejiang Huatian Stainless Steel is a leading manufacturer of stainless steel pipes and tubes, including API 5L pipes, in China. They have a strong focus on research and development to produce high-quality products.

These are just a few examples of Chinese manufacturers of API 5L pipes. China has a large number of steel companies that produce a wide range of steel pipes to meet the needs of domestic and international markets. When selecting a Chinese manufacturer, it’s essential to consider factors such as product quality, certifications, production capacity, and customer service.

8 Responses

What was the first edition of API5L in which PSL2 grade was present?

Dear Sir,

We are extending this request to you.

Kindly tender your best offer as soon as possible

REQUEST FOR QUOTATION:- 5LPP INSULATION COATING PIPES AND BENDS

S/N DESCRIPTION UOM QTY

1 254mm ID x 24.7WT 90 degree bend, radius 1270mm c/w with 6000mm+4000mm mm tangents API5L X65 or API5L X52 or API5L X42, with 104mm 5LPP insulation coating EA 1

2 End caps and Test port for above pipes and bends to withstand a test pressure of 330bar EA 3

Test Bend:

• Since this bend is a test bend which will be discarded after the FAT of the clamps, The idea is not to fabricate a new pipe using CPY specification which are very stringent. However what bidders needs to look for an existing mother pipe which will be bend to 90 degree to provide the above required bend. (There could also be welding required for adding the tangents).

• The MTC of this pipe is to be submitted to the CPY prior to the order so that CPY can have a look and approve the same. That’s why CPY specifications are not important.

• The MTC should be 3.1 or 3.2 certified by a recognized 3rd party.

• The OD of bend is most important for us and The tolerance range for OD would be 301.1 – 305.7mm range. Outside this range the bend will be rejected. Weld seams, if any, to be machined or grinded.

• The surface roughness of the end product need to be Sa 2.5 or finer.

• Tensile strength and hardness also need to be maintained. A standard API 5L X52 or higher grade pipe can be provided.

End caps with test port:

• The cap can be of welded type which need to be welded to the ends of the bend or screw on type which can be screwed to the outside or inside of the bend ends (Bidder to make arrangement for the threads on the test bend to suit) or any other hydraulic or mechanical lock.

• The end caps should have test port for pressurization and de-pressurization.

• The end caps should be suitable for a 330 bar pressure.

Instruction for Tender

Your quote should contain the following below;

1. Datasheet or Drawing

2. Shipping cost

3. Total shipping weight

4. Delivery time

5. Confirm you quoted without no deviation (If any, please indicate)

6. Indicate our line/item number on your quote

You are kindly requested to submit your complete technical offer and your rock bottom prices on CIF Alexandria Seaport Basis for supplying the attached items according to technical specifications including the best delivery schedule.

on or before 6 January 2021

4”PlPE API 5L GR.B SCH.40 BARE 50

3”PlPE API 5L GR.B SCH.40 BARE 650

I”PIPE API 5L GR.B SCH.40 BARE 70

4”PlPE API 5L GR.B SCH.40 COATED 200

3”PlPE API 5L GR.B SCH.40 COATED 2600

I”PIPE API 5L GR.B SCH.40 COATED 70

We have these pipes. Please email us on mktg.aristo@gmail.com

API 5L PSL1 VS. API 5L PSL2 : it seems the chemical grades are inverted i.e. against PSL1 the chemistry given pertains to PSL2 and vise versa, also footnotes marked a,b,c is not given.

Can pipes with OD >84″ be API monogrammed? As Table 9 limits OD to 84″ and Table 21 provides details for pipes with OD >84″. Please help me to understand.

Below could cover if pipe (SA-333 Gr.6) is UT tested in accordance with API 5L, N5, E/I and ISO10893-8

“Seamless pipe shall be examined on their full length by ultrasonic testing, in accordance with ASTM E213, by pulse angle beam method.”

Very good information for Oil and Gas industry operator.