Steel Channel definitions, applications, types according to the European (UPN/UPE) and American specifications (AISC – C & MC), selection considerations, and dimensional range (sizes and weights).

STEEL CHANNELS

WHAT ARE STEEL CHANNELS?

Steel channels are essential structural components used in a wide range of construction and engineering applications. They provide support and stability for buildings, bridges, and other structures. The design and shape of steel channels can significantly impact their strength and utility.

Among the various types of steel channels, European standard channels such as UPN (European Standard U Channels with Tapered Flanges) and UPE (European Standard U Channels with Parallel Flanges) are widely recognized.

According to American standards (AISC), channels are instead classified into C-Channels (similar to UPN channels, C channels have tapered flanges and are popular in various construction and engineering applications), and MC-Channels (these channels have a wider flange than standard C channels and can have varying flange thicknesses. They are used in specialized applications requiring specific structural properties).

Each type is designed for specific structural requirements and applications.

EUROPEAN CHANNEL TYPES (UPN/UPE)

UPN (U Channels with Tapered Flanges)

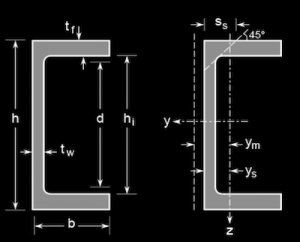

- Shape and Characteristics: UPN channels have a U-shaped cross-section with tapered inner flanges and slightly outward flange tips, which makes them look somewhat similar to the letter “U”. The tapering of the flanges provides a beneficial distribution of material, offering a good balance between the weight and structural efficiency.

- Applications: UPN channels are commonly used for building structures, frames, and supports. Their shape is optimized for strength, making them suitable for load-bearing applications in construction. They are also used in the manufacturing of vehicle frames and other heavy machinery.

- Standard Reference: The specifications for UPN channels are primarily outlined in the EN 10279 standard, which defines the dimensions, tolerances, and sectional properties of hot-rolled steel channels with tapered flanges.

- Dimensions and Properties:

- UPN channels range in size from UPN 50 to UPN 400. The number following “UPN” indicates the depth of the channel in millimeters.

- The dimensions include the depth of the channel, flange width, web thickness, and flange thickness.

- UPN channels are characterized by their tapered flanges, which provide a certain degree of structural efficiency and aesthetic appeal for architectural applications.

- The standard specifies the mass per meter, moment of inertia, and other sectional properties critical for structural design and analysis.

UPE (U Channels with Parallel Flanges)

- Shape and Characteristics: UPE channels also have a U-shaped cross-section but with parallel flanges, unlike the tapered flanges of UPN channels. This design provides a uniform surface, which can be beneficial for connecting and fitting other structural elements.

- Applications: Due to their parallel flanges, UPE channels are easier to connect and assemble, making them ideal for architectural and engineering projects where precision and ease of assembly are critical. They are used in construction, machinery frameworks, and in the industrial sector for supports and frames.

- Standard Reference: UPE channels are specified under various European standards, including EN 10279. The standard EN 10365 is also relevant, as it outlines the dimensions and sectional properties for a broader range of structural steel shapes, including UPE channels.

- Dimensions and Properties:

- UPE channels are available in sizes ranging from UPE 80 to UPE 400, with the depth of the channel in millimeters following “UPE.”

- These channels feature parallel flanges, which make them easier to connect and fabricate, providing advantages in construction and mechanical applications.

- Like UPN channels, the standard for UPE channels specifies dimensions such as depth, flange width, web, and flange thicknesses, as well as mass per meter and sectional properties like the moment of inertia.

UAP/UPA Channel (Specialty Types)

The term “UAP” is less commonly referenced in the broad spectrum of structural steel sections, especially when compared to well-known profiles like UPN or UPE channels. However, in some contexts, especially within specific markets or regions, like Switzerland for instance, “UAP” might be used to describe a particular type of steel channel. Without widespread standardization under this designation in major international standards (like those from the European Union or the American Institute of Steel Construction), the specifics of “UAP” channels, including their dimensions, material properties, and applications, could vary.

UPA stands for a distinct category of channel sections characterized by their parallel flanges, manufactured in compliance with EN 10365 and adhering to the tolerances outlined in EN 10279: 2000. Unlike the UPE series, UPA channels feature flanges and webs of identical material thickness, falling under the Upe-Upn-Pfc classification. While UPA channels may exhibit lower static values compared to UPE channels of the same profile height, they are regarded as a cost-effective solution for various applications due to their advantageous weight-to-meter ratio.

General Considerations for Specialty Channels

When dealing with specialty channels like a “UAP” profile, here are some considerations:

- Specifications and Dimensions: It’s important to refer directly to the manufacturer’s data sheets or the engineering specifications provided in project documents. These will detail the profile’s dimensions, material grade, and mechanical properties.

- Applications: Specialized profiles are often designed for specific applications that benefit from their unique shape. Understanding the intended use can provide insights into why a particular profile was chosen over more standard options.

- Availability and Fabrication: Specialty profiles might have limited availability compared to standard sections and could require custom fabrication. This can affect lead times and costs for a project.

Differences Between UPN and UPE EU Channels

UPN (European Standard Channels with Tapered Flanges) and UPE (European Standard Channels with Parallel Flanges) are two prominent types of structural steel channels used across construction and engineering projects. Despite their similarities in serving as structural elements, they have distinct characteristics that make them suitable for different applications. Understanding the differences between UPN and UPE channels can help in selecting the appropriate type for specific structural needs.

Flange Shape

UPN Channels: The flanges of UPN channels are tapered, meaning they narrow towards the end of the flange. This tapering results in a profile that is more efficient in resisting bending and torsional loads for certain applications.

UPE Channels: UPE channels have parallel flanges, which means the width of the flange is consistent along its length. This feature makes them easier to connect with other structural elements and more suitable for applications requiring flat surfaces for bolting or welding.

Structural Efficiency

UPN Channels: The tapered flanges may offer a slightly higher structural efficiency in bending compared to UPE channels with the same depth, due to the distribution of material. However, this advantage can vary based on specific structural configurations and load conditions.

UPE Channels: The parallel flanges provide a uniform surface that can be advantageous for connections and fabrications, potentially leading to a reduction in construction time and costs.

Aesthetic Considerations

UPN Channels: The unique tapered flange design of UPN channels can be a desirable aesthetic feature in certain architectural applications, providing a slender appearance.

UPE Channels: The straight and uniform shape of UPE channels offers a modern and clean look, which can be preferred in visible structural applications for architectural projects.

Availability and Market Preference

UPN Channels: Widely available in European and international markets, UPN channels have been a long-standing choice for various structural applications, particularly where the tapered profile is beneficial.

UPE Channels: Introduced more recently than UPN channels, UPE profiles have been gaining popularity due to their manufacturing efficiency and the ease of making connections, especially in projects emphasizing fast and economical construction.

Applications

UPN Channels: Often used in industrial and civil engineering projects, such as supports, frames, and bases, where the specific properties of tapered flanges offer advantages.

UPE Channels: Commonly chosen for projects requiring extensive welding or bolting at the flanges, including frames for buildings, equipment supports, and other structures where parallel flanges facilitate easier assembly and attachment.

AMERICAN CHANNEL TYPES (C/MC)

The American Institute of Steel Construction (AISC) sets guidelines and dimensions for structural steel shapes used in the United States, including C-shaped channels and MC (Miscellaneous Channels). These profiles are essential components in construction and engineering, offering versatility and efficiency for a wide range of applications. Here’s an overview of the characteristics and differences between C channels and MC channels under AISC standards.

C Channels

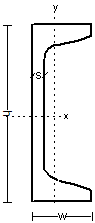

- Shape and Characteristics: C channels, or “American Standard Channels,” have a C-shaped cross-section with tapered inner flanges. This profile is efficient for applications requiring strength for loads applied perpendicular to the axis of the channel. The shape provides a good strength-to-weight ratio and is easy to bolt or weld to other structures.

- Applications: C channels are commonly used in building construction, including frames for floors and walls, supports for roofs, and various other structural applications. Their design allows for efficient use in light to medium structural applications.

- Dimensions: The AISC provides dimensions for C channels in its manual, including depth, flange width, web thickness, and weight per unit length. The size range typically covers from smaller sections around 3 inches deep to larger sections up to approximately 15 inches deep.

MC Channels (Miscellaneous Channels)

- Shape and Characteristics: MC channels are similar to C channels but feature wider flanges and are not classified under a standard channel category due to their variable flange width and other dimensions that do not conform to the C channel classification. MC channels can have parallel or tapered flanges.

- Applications: MC channels are used in a broader range of structural applications compared to C channels due to their increased flange width and flexibility in design. They are suitable for heavy-duty structural applications, including industrial and commercial construction, equipment manufacturing, and large infrastructure projects.

- Dimensions: AISC’s manual specifies dimensions for MC channels, which include a more extensive range of depths, flange widths, web thicknesses, and weights. MC channels can vary significantly in size, accommodating more specialized structural needs.

Key Differences Between C and MC Channels

- Flange Width: The most noticeable difference is the flange width, with MC channels generally having wider flanges than C channels. This difference affects the channels’ load-bearing capabilities and structural applications.

- Design Flexibility: MC channels offer greater flexibility in design and are used in more diverse applications due to their varied sizes and properties.

- Applications: While both C and MC channels are used in construction and engineering, MC channels are often preferred for applications requiring higher strength and greater support due to their larger and more varied dimensions.

SELECTION CONSIDERATIONS

When selecting a steel channel for a project, engineers and architects consider several factors, including:

- Structural Requirements: The load the channel needs to support and the type of stresses it will face.

- Compatibility with Other Components: How the channel will fit and connect with other structural elements.

- Material Efficiency: The balance between the strength provided by the channel and its weight or material use.

- Cost and Availability: The cost of different types of channels and their availability in the desired specifications.

CHANNELS DIMENSIONS AND WEIGHTS

UPN Channels

Dimensions are per Standard UNI 5680-73

| UPN Channels | Weight (kg/m) | Sectional Area (cm2) | Inertial Moment | Resistance Modules | Inertial Radius | |||||||

| h | b | a | e | r | Jx (cm4) | Jy (cm4) | Wx (cm3) | Wy (cm3) | ix (cm) | iy (cm) | ||

| UPN 30 | 33 | 5,0 | 7,0 | 7,0 | 4.27 | 5,44 | 6,39 | 5,10 | 4,26 | 2,60 | 1,08 | 0,968 |

| UPN 40 | 35 | 5,0 | 7,0 | 7,0 | 4,88 | 6,21 | 14,1 | 6,68 | 7,07 | 3,08 | 1,51 | 1,04 |

| UPN 50 | 38 | 5,0 | 7,0 | 7,0 | 5,59 | 7,12 | 26,5 | 9,10 | 10,06 | 3,74 | 1,93 | 1,13 |

| UPN 65 | 42 | 5,5 | 7,5 | 7,5 | 7,09 | 9,03 | 57,5 | 14,0 | 17,7 | 5,05 | 2,52 | 1,25 |

| UPN 80 | 45 | 6,0 | 8,0 | 8,0 | 8,65 | 11,0 | 106 | 19,4 | 26,5 | 6,35 | 3,10 | 1,33 |

| UPN 100 | 50 | 6,0 | 8,5 | 8,5 | 10,6 | 13,5 | 205 | 29,1 | 41,1 | 8,45 | 3,91 | 1,47 |

| UPN 120 | 55 | 7,0 | 9,0 | 9,0 | 13,3 | 17,0 | 364 | 43,1 | 60,7 | 11,1 | 4,63 | 1,59 |

| UPN 140 | 60 | 7,0 | 10,0 | 10,0 | 16,0 | 20,4 | 605 | 62,5 | 86,4 | 14,7 | 5,45 | 1,75 |

| UPN 160 | 65 | 7,5 | 10,5 | 10,5 | 18,9 | 24,0 | 925 | 85,1 | 116 | 18,2 | 6,21 | 1,88 |

| UPN 180 | 70 | 8,0 | 11,0 | 11,0 | 22,0 | 28,0 | 1.354 | 114 | 150 | 22,4 | 6,96 | 2,01 |

| UPN 200 | 75 | 8,5 | 11,5 | 11,5 | 25,3 | 32,2 | 1.911 | 148 | 191 | 26,9 | 7,71 | 2,14 |

| UPN 220 | 80 | 9,0 | 12,5 | 12,5 | 29,4 | 37,4 | 2.691 | 196 | 245 | 33,5 | 8,48 | 2,29 |

| UPN 240 | 85 | 9,5 | 13,0 | 13,0 | 33,2 | 42,3 | 3.599 | 247 | 300 | 39,5 | 9,22 | 4,42 |

| UPN 260 | 90 | 10,0 | 14,0 | 14,0 | 37,9 | 48,3 | 4.824 | 317 | 371 | 47,8 | 10,0 | 2,56 |

| UPN 280 | 95 | 10,0 | 15,0 | 15,0 | 41,9 | 53,4 | 6.276 | 398 | 448 | 57,2 | 10,8 | 2,73 |

| UPN 300 | 100 | 10,0 | 16,0 | 16,0 | 46,1 | 58,8 | 8.028 | 493 | 535 | 67,6 | 11,7 | 2,90 |

UPE Channel Sizes

| Description | kg/m | h | b | tw | tf |

| UPE 80 | 7.7 | 80 | 50 | 4 | 7 |

| UPE 100 | 9.7 | 100 | 55 | 4.5 | 7.5 |

| UPE 120 | 11.9 | 120 | 60 | 5 | 8 |

| UPE 140 | 14.3 | 140 | 65 | 5 | 9 |

| UPE 160 | 16.9 | 160 | 70 | 5.5 | 9.5 |

| UPE 180 | 19.6 | 180 | 75 | 5.5 | 10.5 |

| UPE 200 | 22.6 | 200 | 80 | 6 | 11 |

| UPE 220 | 26.5 | 220 | 85 | 6.5 | 12 |

| UPE 240 | 30.1 | 240 | 90 | 7 | 12.5 |

| UPE 270 | 35.1 | 270 | 95 | 7.5 | 13.5 |

| UPE 300 | 44.5 | 300 | 100 | 9.5 | 15 |

| UPE 330 | 53.1 | 330 | 105 | 11 | 16 |

| UPE 360 | 61.2 | 360 | 110 | 12 | 17 |

| UPE 400 | 72.4 | 400 | 115 | 13.5 | 18 |

AISC C-Channel Sizes (inches/Lbs)

| Channel Type | Channel Dimensions | Static Parameters | |||||||

| Inertia | Elastic Section Modulus | ||||||||

| Imperial (in x lb/ft) | h: Depth (in) | w: With (in) | s: Web Thickness (in) | Sectional Area (in2) | Weight (lbf/ft) | Ix (in4) | Iy (in4) | Sx (in3) | Sy (in3) |

| C 15 x 50 | 15 | 3.716 | 0.716 | 14.7 | 50 | 404 | 11 | 53.8 | 3.78 |

| C 15 x 40 | 15 | 3.52 | 0.52 | 11.8 | 40 | 349 | 9.23 | 46.5 | 3.37 |

| C 15 x 33.9 | 15 | 3.4 | 0.4 | 9.96 | 33.9 | 315 | 8.13 | 42 | 3.11 |

| C 12 x 30 | 12 | 3.17 | 0.51 | 8.82 | 30 | 162 | 5.14 | 27 | 2.06 |

| C 12 x 25 | 12 | 3.047 | 0.387 | 7.35 | 25 | 144 | 4.47 | 24.1 | 1.88 |

| C 12 x 20.7 | 12 | 2.942 | 0.282 | 6.09 | 20.7 | 129 | 3.88 | 21.5 | 1.73 |

| C 10 x 30 | 10 | 3.033 | 0.673 | 8.82 | 30 | 103 | 3.94 | 20.7 | 1.65 |

| C 10 x 25 | 10 | 2.886 | 0.526 | 7.35 | 25 | 91.2 | 3.36 | 18.2 | 1.48 |

| C 10 x 20 | 10 | 2.739 | 0.379 | 5.88 | 20 | 78.9 | 2.81 | 15.8 | 1.32 |

| C 10 x 15.3 | 10 | 2.6 | 0.24 | 4.49 | 15.3 | 67.4 | 2.28 | 13.5 | 1.16 |

| C 9 x 20 | 9 | 2.648 | 0.448 | 5.88 | 20 | 60.9 | 2.42 | 13.5 | 1.17 |

| C 9 x 15 | 9 | 2.485 | 0.285 | 4.41 | 15 | 51 | 1.93 | 11.3 | 1.01 |

| C 9 x 13.4 | 9 | 2.433 | 0.233 | 3.94 | 13.4 | 47.9 | 1.76 | 10.6 | 0.96 |

| C 8 x 18.75 | 8 | 2.527 | 0.487 | 5.51 | 18.75 | 44 | 1.98 | 11 | 1.01 |

| C 8 x 13.75 | 8 | 2.343 | 0.303 | 4.04 | 13.75 | 36.1 | 1.53 | 9.03 | 0.85 |

| C 8 x 11.5 | 8 | 2.26 | 0.22 | 3.38 | 11.5 | 32.6 | 1.32 | 8.14 | 0.78 |

| C 7 x 14.75 | 7 | 2.299 | 0.419 | 4.33 | 14.75 | 27.2 | 1.38 | 7.78 | 0.78 |

| C 7 x 12.25 | 7 | 2.194 | 0.314 | 3.6 | 12.25 | 24.2 | 1.17 | 6.93 | 0.7 |

| C 7 x 9.8 | 7 | 2.09 | 0.21 | 2.87 | 9.8 | 21.3 | 0.97 | 6.08 | 0.63 |

| C 6 x 13 | 6 | 2.157 | 0.437 | 3.83 | 13 | 17.4 | 1.05 | 5.8 | 0.64 |

| C 6 x 10.5 | 6 | 2.034 | 0.314 | 3.09 | 10.5 | 15.2 | 0.87 | 5.06 | 0.56 |

| C 6 x 8.2 | 6 | 1.92 | 0.2 | 2.4 | 8.2 | 13.1 | 0.69 | 4.38 | 0.49 |

| C 5 x 9 | 5 | 1.885 | 0.325 | 2.64 | 9 | 8.9 | 0.63 | 3.56 | 0.45 |

| C 5 x 6.7 | 5 | 1.75 | 0.19 | 1.97 | 6.7 | 7.49 | 0.48 | 3 | 0.38 |

| C 4 x 7.25 | 4 | 1.721 | 0.321 | 2.13 | 7.25 | 4.59 | 0.43 | 2.29 | 0.34 |

| C 4 x 5.4 | 4 | 1.584 | 0.184 | 1.59 | 5.4 | 3.85 | 0.32 | 1.93 | 0.28 |

| C 3 x 6 | 3 | 1.596 | 0.356 | 1.76 | 6 | 2.07 | 0.31 | 1.38 | 0.27 |

| C 3 x 5 | 3 | 1.498 | 0.258 | 1.47 | 5 | 1.85 | 0.25 | 1.24 | 0.23 |

| C 3 x 4.1 | 3 | 1.41 | 0.17 | 1.21 | 4.1 | 1.66 | 0.2 | 1.1 | 0.2 |

5 Responses

Hi

I have a question, is there any significant difference between UPE and UPN in application?

They are both used in light purposes, is that correct?

Urgently Required UPN MS MC 160 x 65 mm – 4.5 MT

Dear Mr. Export Manager

Hi, have a good day

A. First; we are pleased to introduce ourselves as one of the largest and leading companies in the Kingdom of Saudi Arabia with over sixty years in existing. Our vast activities cover the whole kingdom through our more than seventy-three branches dealing with all kinds of building Material, Industry and Trade.

B. Second; You are kindly requested to quote us your rock bottom prices and aerialist delivery time CFR Dammam of our requirements of the following products; its Assortment as follow :

a. Angel:

i. 100 Ton Size 25 x 25 x 2.5 mm x 6mtr

ii. 050 Ton Size 30 x 30 x 2.5 mm x 6mtr

iii. 100 Ton Size 30 x 30 x 3.0 mm x 6mtr

b. UPE:

i. 050 Ton Size 140 x 58 mm x 4.9 mm x 8.1 mm x 12 MTR – thersitical weight 12.3 kg/m

ii. 050 Ton Size 160 x 64 mm x 5.0 mm x 8.4 mm x 12 MTR – thersitical weight 14.2 kg/m

iii. 050 Ton Size 200 x 76 mm x 5.2 mm x 9.0 mm x 12 MTR – thersitical weight 18.4 kg/m

c. U Channel ( Japanese Standard):

i. 050 Ton Size 40 x 20 mm x 5.0 mm x 5.5 mm x 06 MTR thersitical weight 2.87 kg/m

ii. 050 Ton Size 50 x 25 mm x 5.0 mm x 6.0 mm x 06 MTR thersitical weight 3.86 kg/m

iii. 050 Ton Size 60 x 30 mm x 6.0 mm x 6.0 mm x 06 MTR thersitical weight 5.07 kg/m

iv. 050 Ton Size 125 x 65 mm x 6.0 mm x 8.0 mm x 12 MTR thersitical weight 13.4 kg/m

v. 100 Ton Size 150 x 75 mm x 5.7 mm x 10.0 mm x 06 MTR thersitical weight 16.8 kg/m

vi. 150 Ton Size 150 x 75 mm x 5.7 mm x 10.0 mm x 12 MTR thersitical weight 16.8 kg/m

C. Our payment : will be by LC 100% .

D. Absolutely. We prefer to deal with you directly, but If you have any exclusive agent here in our region, please let us have their communication details to enable us to liaise with them to buy your products

E. Quotation requirements: Please state all required terms & all conditions; specially the following:

a. Specification in details; including Standards, Grade, and consider that ; the mill test certificate should be presented to our bank at proceed of the original shipping documents

b. Your offer Validity : we need not less than 7 days from the date of your offer, to enable us to proceed with our purchasing committee & our principals

c. SABER ( Saudi Platform) handling : Consider that ; after our confirmation, we need from you to select a surveyor and inspection party ( should be listed in our Saudi SABER platform) to check the materials in your premises and UPLOAD certificate of conformity (COC) for your account and also upload the shipment certificate before 15 days from the shipment date, also for your account. Please check this SABER Saudi platform, to recognize what about the requirement of every party turn ( your company – surveyor company – Our company)

d. State eighter you have valid ISO certificate or similar, which you are kindly requested attach with your quotation.

e. Your packing mode of every bundle, and its weight and number of sheets inside.

f. Your shipping marks or logo printed on your ID card which will attach with every bundle.

g. Shipment style.

i. Maximum vessel age you intend to use; for insurance purpose

ii. Separate Prices: we need separate prices for shipments by containers and break-bulk

1. In case by break-bulk shipments, we need the following:

a. Packing mode in details of 6 sides.

b. Exact schedule delivery time.

2. In case by containers shipments, we need the following :

a. Packing mode in details of 6 sides

b. Exact schedule delivery time.

c. What about the maximum allotted time to return the containers back to the local of shipping line? We need 4 weeks free of detention

F. Waiting your elaborated offer including all above-mentioned details will enable us to maintain and confirm our order promptly if it is satisfactory.

G. Again; thanks a lot .

B. Regards

• Branch of AL Rajhi Endowment Co., for Industry & Trade

• Mustafa Mohammad, Purchasing Manager; mobile No.: +966.(0)50.808.21.24

• Our direct fax: +966 11 455 7053; +966 11 454 7201

• Our direct Tel: + 966 11 20 49 790; + 966 2049 791; 794; 795

• Our Website: http://www.rajhibuild.com

• Our e-mails:

1. purchase@rajhibuild.com

2. rajhico_mustafa@hotmail.com

Dear Sir,

Kindly Send us Quotation of following Structural Steel. Kindly Confirm the availability of material after confirmation order.

EN 10365 with tolerances according to EN 10279: 2000.

UPE Channel Size : UPE 240……400 mtr

UPE Channel Size : UPE 330…..400 Mtr

Is this requirement still alive ?