RSA (Rolled Steel Angle) steel angles are a versatile and widely used form of structural steel, characterized by their L-shaped cross-section. These angles are rolled from a single piece of steel, ensuring uniformity and structural integrity. RSA angles are utilized in a wide array of construction and engineering applications, including framing, bracing, supports, and detailing in both residential and commercial projects. They are available in a range of sizes and thicknesses, catering to various load-bearing and structural requirements.

RSA STEEL ANGLES

WHAT ARE STEEL ANGLES?

RSA (the acronym for “Rolled Steel Angle”) Steel angles are L-shaped cross-sections made by bending a single piece of steel (or, less often, by welding two steel plates) at a 90-degree angle.

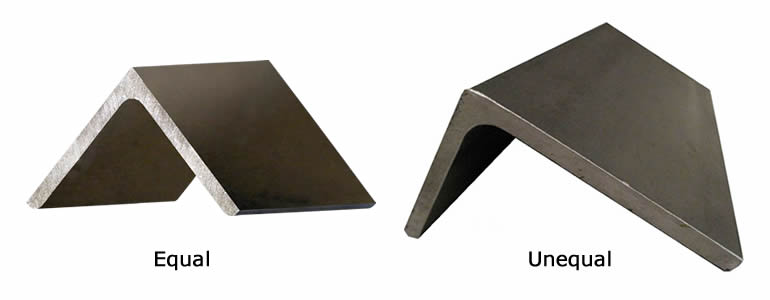

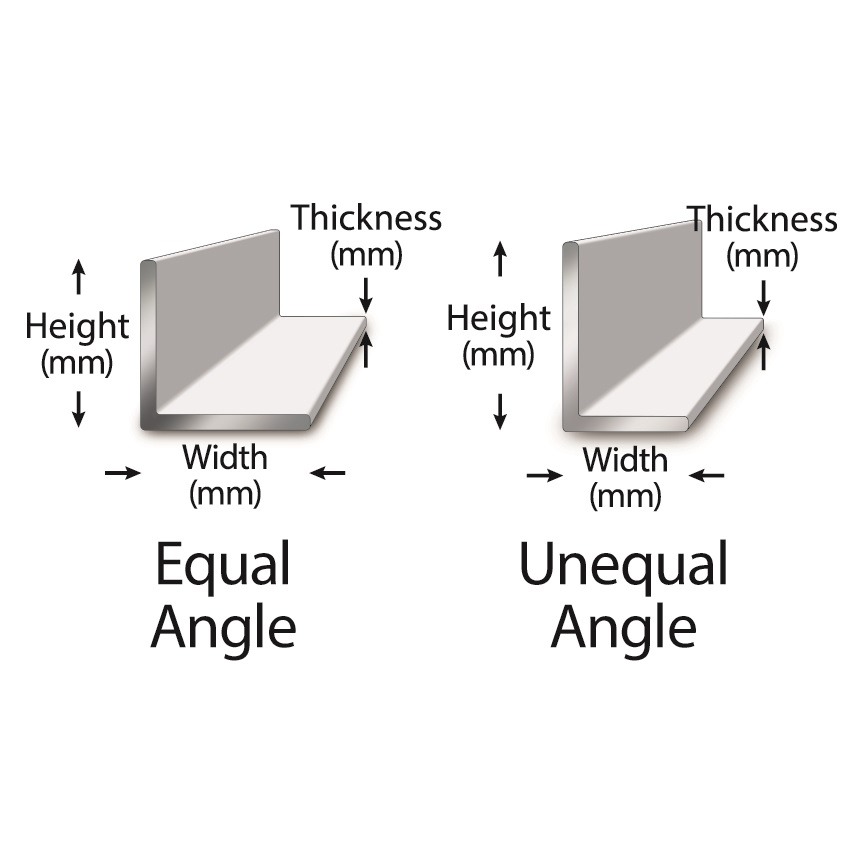

They are fundamental structural elements used in construction and engineering for framing, bracing, and supporting structures due to their strength and versatility. Steel angles come in various sizes and thicknesses, and they can be equal or unequal in leg length, catering to diverse application needs ranging from architectural design to heavy industrial construction.

To order RSA steel angles, the following parameters shall be considered:

- Dimensions: The length, width, and thickness of the angle legs are crucial in determining their strength and suitability for a particular application (a key choice is between the equal or the unequal shape).

- Material Grade: The grade of steel used impacts the angle’s mechanical properties, such as yield strength, tensile strength, and ductility. Common grades include S275 and S355 (these are materials of the EN 10025 Specification).

- Surface Finish: RSAs can be hot-rolled or cold-rolled, with hot-rolled being the most common for structural applications. The surface finish can also include galvanization or painting for additional corrosion resistance.

RSA STEEL ANGLES CHARACTERISTICS

RSA steel angles feature the following characteristics:

- L-Shaped Cross-Section: The most distinctive feature of RSA steel angles is their L-shaped cross-section, providing two planes of support for added structural strength and stability.

- Equal and Unequal Angles: RSAs can be equal or unequal in terms of leg length. Equal angles have legs of the same length, typically used in structural applications where uniform strength along both axes is required. Unequal angles have legs of different lengths and are useful in situations where a component needs to withstand unequal loads.

- Variety of Sizes and Thicknesses: RSA steel angles come in a broad range of sizes and thicknesses, accommodating the specific demands of different projects. This versatility ensures that engineers and builders can select the most appropriate size for their particular structural needs.

- Durability: Steel angles are known for their durability and resistance to environmental impacts, including corrosion, when treated or coated appropriately. This makes them suitable for both indoor and outdoor applications.

- Ease of Fabrication: The simple shape of RSAs allows for easy cutting, welding, and drilling, making them highly adaptable for custom fabrication tasks.

RSA APPLICATIONS

RSA steel angles are used in a multitude of applications across various industries, including:

- Construction: As framing elements for buildings, bridges, towers, and other structures where strength and rigidity are critical.

- Infrastructure: In the construction of airports, stadiums, and railway tracks, providing support and reinforcement.

- Manufacturing: For shelving, racks, benches, and frames in the manufacturing sector, due to their strength and ease of assembly.

- Architectural: In architectural design, both as a structural component and as an aesthetic element.

- Industrial: For brackets, frames, and supports in industrial machinery and equipment.

EU & US SPECIFICATIONS FOR RSA ANGLES

When it comes to steel angles, both the European Union (EU) and the United States (US) have established detailed specifications to ensure the quality, performance, and safety of these structural components. The EU specifications are typically outlined in EN (European Norms) standards, while in the US, the American Institute of Steel Construction (AISC) provides specifications under the ANSI/AISC standards. Here’s a comparison of the EU specifications for Rolled Steel Angles (RSA) and the AISC specifications for steel angles:

EU Specifications

EN 10056-1: This standard specifies the requirements for RSA with equal and unequal legs for general purposes. It includes definitions, dimensions, tolerances, and the designation of dimensions for steel angles.

EN 10025: A series of standards that outline the technical delivery conditions for hot rolled products of structural steels. EN 10025 covers various steel grades used in manufacturing RSA, specifying their mechanical properties, chemical composition, and general technical delivery conditions.

AISC Specifications

ANSI/AISC 360: Known as the Specification for Structural Steel Buildings, this standard provides the requirements for the design, fabrication, and erection of structural steel buildings in the US. It includes criteria for materials, design, and workmanship for steel angles used in construction.

ASTM Standards: Various ASTM standards are referenced by AISC for material specifications, including ASTM A36 for carbon structural steel and ASTM A572 for high-strength low-alloy structural steel, among others. These standards define the chemical and mechanical properties of steel grades used to manufacture angles.

Key Differences and Considerations

Designation and Nomenclature: The EU and US use different nomenclatures and systems for designating steel grades and dimensions. For example, steel grades in the EU are designated by specific numbers and letters (e.g., S235, S275) under EN 10025, whereas the US uses ASTM standards with different grade names (e.g., ASTM A36, ASTM A572).

Dimensional Tolerances: EN 10056-1 outlines specific dimensional tolerances for RSA in the EU, while AISC references ASTM standards for dimensional tolerances in the US. There might be differences in the tolerances allowed for steel angles between the two systems.

Material Properties: The mechanical and chemical requirements for steel can vary between EU standards and US standards. Designers and engineers need to ensure that the material properties align with the specific requirements of their project, depending on the jurisdiction and applicable codes.

Adoption and Usage: While EU specifications are primarily adopted in European countries and other regions recognizing EN standards, AISC specifications are widely used in the United States and in countries that follow American standards for structural design.

KEY MATERIAL GRADES FOR RSA ANGLES

European Grades (EN 10025)

EN 10025 S235

- Designation: S235JR, S235J0, S235J2

- Characteristics: This grade offers good weldability, toughness, and strength. It is commonly used in general engineering and construction applications. The “JR”, “J0”, and “J2” sub-grades indicate the steel’s toughness and resistance to impact at different temperatures.

EN 10025 S275

- Designation: S275JR, S275J0, S275J2

- Characteristics: Slightly higher strength and hardness than S235, with similar weldability and toughness. Suitable for a wide range of construction applications, offering a good balance between strength and ductility.

EN 10025 S355

- Designation: S355JR, S355J0, S355J2, S355K2

- Characteristics: Higher strength and better mechanical properties compared to S235 and S275 grades. S355 is used in environments requiring high strength and toughness. The additional sub-grades (JR, J0, J2, and K2) provide options for varying impact strength and notch toughness.

EN 10025 S420 and S460

- Designation: S420N, S420NL, S460N, S460NL

- Characteristics: These are high-strength steel grades with higher yield strength than S355. They are used in heavily loaded parts of welded structures, such as bridges, storage tanks, and lifting equipment. “N” and “NL” indicate normalized or normalized rolled conditions, suitable for various temperature environments.

American Grades (AISC/ASTM)

In the United States, steel angles, including Rolled Steel Angles (RSA), are commonly specified according to ASTM International standards. The American Institute of Steel Construction (AISC) references these ASTM standards in its guidelines for the design, fabrication, and construction of structural steel. Here are some of the ASTM material grades commonly used for RSA steel angles under the AISC specifications:

ASTM A36

- Title: Standard Specification for Carbon Structural Steel

- Characteristics: ASTM A36 is the most widely used material grade for steel angles in structural applications. It provides good weldability, and strength, and can be heat treated to harden its surface. A36 steel angles are suitable for a broad range of construction and architectural applications due to their versatility.

ASTM A572

- Title: Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

- Characteristics: Offers higher strength than A36, with improved corrosion resistance. ASTM A572 steel angles are available in several grades, with Grade 50 being the most common for structural applications. This grade provides enhanced strength and is suitable for applications requiring a higher strength-to-weight ratio.

ASTM A588

- Title: Standard Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi [345 MPa] Minimum Yield Point, with Atmospheric Corrosion Resistance

- Characteristics: Known for its superior atmospheric corrosion resistance, making it ideal for structures exposed to the elements. ASTM A588 steel angles are often used in bridge construction, building facades, and other applications where durability in harsh environmental conditions is critical.

ASTM A709

- Title: Standard Specification for Structural Steel for Bridges

- Characteristics: This specification covers carbon and high-strength low-alloy steel structural shapes and plates used in the construction of bridges. Several grades are included, offering varying levels of strength, weldability, and toughness to meet the specific requirements of bridge construction projects.

DIMENSIONS AND WEIGHTS OF RSA ANGLES

EUROPEAN RSA STEEL ANGLES (EN 10056)

Equal RSA Steel Angles

The table below shows the dimensions of unequal steel angles according to the EN 10056 European Specification (steel angle weight in kilograms per meter and surface area in square meters by meter length). Note that, as the name suggests, equal steel angles have legs of the same size.

Equal Steel Angle h x b X t (in mm) | surface area in m2 per meter | weight in kg/meter |

| 16 x 16 x3 | 0.061 | 0.704 |

| 20 x 20 x3 | 0.077 | 0.902 |

| 20 x 20 x4 | 0.077 | 1.16 |

| 25 x 25 x3 | 0.097 | 1.14 |

| 25 x 25 x4 | 0.097 | 1.49 |

| 25 x 25 x5 | 0.097 | 1.81 |

| 30 x 30 x3 | 0.116 | 1.39 |

| 30 x 30 x4 | 0.116 | 1.81 |

| 30 x 30 x5 | 0.116 | 2.22 |

| 35 x 35 x3 | 0.136 | 1.63 |

| 35 x 35 x4 | 0.136 | 2.13 |

| 35 x 35 x5 | 0.136 | 2.62 |

| 35 x 35 x6 | 0.136 | 3.09 |

| 40 x 40 x3 | 0.155 | 1.88 |

| 40 x 40 x4 | 0.155 | 2.46 |

| 40 x 40 x5 | 0.155 | 3.03 |

| 40 x 40 x6 | 0.155 | 3.58 |

| 45 x 45 x5 | 0.174 | 3.44 |

| 45 x 45 x6 | 0.174 | 4.07 |

| 50 x 50 x4 | 0.194 | 3.11 |

| 50 x 50 x5 | 0.194 | 3.84 |

| 50 x 50 x6 | 0.194 | 4.55 |

| 50 x 50 x7 | 0.194 | 5.25 |

| 50 x 50 x8 | 0.194 | 5.93 |

| 50 x 50 x9 | 0.194 | 6.6 |

| 55 x 55 x6 | 0.213 | 5.05 |

| 55 x 55 x8 | 0.213 | 6.58 |

| 60 x 60 x 6 | 0.233 | 5.53 |

| 60 x 60 x 7 | 0.233 | 6.38 |

| 60 x 60 x 8 | 0.233 | 7.22 |

| 60 x 60 x 10 | 0.233 | 8.85 |

| 65 x 65 x 6 | 0.252 | 6.02 |

| 65 x 65 x 7 | 0.252 | 6.96 |

| 65 x 65 x 8 | 0.252 | 7.88 |

| 65 x 65 x 9 | 0.252 | 8.8 |

| 70 x 70 x 7 | 0.272 | 7.52 |

| 70 x 70 x 8 | 0.272 | 8.56 |

| 70 x 70 x 9 | 0.272 | 9.5 |

| 70 x 70 x 10 | 0.272 | 10.5 |

| 75 x 75 x 6 | 0.29 | 6.98 |

| 75 x 75 x 7 | 0.291 | 8.09 |

| 75 x 75 x 8 | 0.291 | 9.17 |

| 75 x 75 x 10 | 0.291 | 11.3 |

| 75 x 75 x 12 | 0.291 | 13.3 |

| 80 x 80 x 8 | 0.311 | 9.81 |

| 80 x 80 x 10 | 0.311 | 12.1 |

| 80 x 80 x 12 | 0.311 | 14.3 |

| 90 x 90 x 8 | 0.351 | 11.1 |

| 90 x 90 x 9 | 0.351 | 12.4 |

| 90 x 90 x 10 | 0.351 | 13.7 |

| 90 x 90 x 12 | 0.351 | 16.2 |

| 100 x 100 x 8 | 0.39 | 12.4 |

| 100 x 100 x 10 | 0.39 | 15.3 |

| 100 x 100 x 12 | 0.39 | 18.2 |

| 100 x 100 x 14 | 0.39 | 21 |

| 100 x 100 x 15 | 0.39 | 22.3 |

| 110 x 110 x 10 | 0.43 | 16.9 |

| 110 x 110 x 12 | 0.43 | 20.1 |

| 110 x 110 x 14 | 0.43 | 23.2 |

| 120 x 120 x 10 | 0.469 | 18.5 |

| 120 x 120 x 11 | 0.469 | 20.3 |

| 120 x 120 x 12 | 0.469 | 22 |

| 120 x 120 x 15 | 0.469 | 27.1 |

| 130 x 130 x 12 | 0.508 | 24 |

| 130 x 130 x 14 | 0.508 | 27.8 |

| 140 x 140 x 13 | 0.547 | 28 |

| 140 x 140 x 15 | 0.547 | 32 |

| 150 x 150 x 12 | 0.586 | 27.9 |

| 150 x 150 x 14 | 0.586 | 32.2 |

| 150 x 150 x 15 | 0.586 | 34.4 |

| 150 x 150 x 18 | 0.586 | 40.8 |

| 160 x 160 x 15 | 0.625 | 36.8 |

| 180 x 180 x 16 | 0.705 | 44.3 |

| 180 x 180 x 18 | 0.705 | 49.5 |

| 200 x 200 x 16 | 0.785 | 49.4 |

| 200 x 200 x 18 | 0.785 | 55.3 |

| 200 x 200 x 20 | 0.785 | 61.1 |

| 200 x 200 x 24 | 0.785 | 72.5 |

Unequal RSA Steel Angles

The table below shows the dimensions of unequal steel angles according to the EN 10056 European Specification (steel angle weight in kilograms per meter and surface area in square meters by meter length). Note that, as the name suggests, unequal steel angles have two legs of two different sizes (one shorter, one longer).

Unequal Steel Angle Dimensions h x b x t (in mm) | surface area in m2 per meter | weight in kg/meter |

| 30 x 20 x 3 | 0.097 | 1.14 |

| 30 x 20 x 4 | 0.097 | 1.49 |

| 40 x 20 x 3 | 0.117 | 1.38 |

| 40 x 20 x 4 | 0.117 | 1.8 |

| 40 x 25 x 4 | 0.127 | 1.97 |

| 45 x 30 x 4 | 0.146 | 2.3 |

| 45 x 30 x 5 | 0.146 | 2.82 |

| 50 x 30 x 5 | 0.156 | 3.02 |

| 50 x 30 x 6 | 0.156 | 3.58 |

| 50 x 40 x 4 | 0.177 | 2.77 |

| 50 x 40 x 5 | 0.177 | 3.42 |

| 50 x 40 x 6 | 0.177 | 4.03 |

| 60 x 30 x 5 | 0.175 | 3.43 |

| 60 x 30 x 6 | 0.175 | 4.06 |

| 60 x 30 x 7 | 0.175 | 4.68 |

| 60 x 40 x 5 | 0.195 | 3.83 |

| 60 x 40 x 6 | 0.195 | 4.54 |

| 60 x 40 x 7 | 0.195 | 5.24 |

| 65 x 50 x 5 | 0.224 | 4.43 |

| 65 x 50 x 6 | 0.224 | 5.26 |

| 65 x 50 x 7 | 0.224 | 6.08 |

| 65 x 50 x 8 | 0.224 | 6.88 |

| 75 x 50 x 5 | 0.244 | 4.83 |

| 75 x 50 x 6 | 0.244 | 5.75 |

| 75 x 50 x 7 | 0.244 | 6.65 |

| 75 x 50 x 8 | 0.244 | 7.53 |

| 75 x 50 x 9 | 0.244 | 8.4 |

| 75 x 55 x 5 | 0.254 | 5.04 |

| 75 x 55 x 7 | 0.254 | 6.93 |

| 75 x 65 x 6 | 0.273 | 6.49 |

| 75 x 65 x 8 | 0.273 | 8.48 |

| 75 x 65 x 10 | 0.273 | 10.5 |

| 80 x 40 x 6 | 0.234 | 5.51 |

| 80 x 40 x 8 | 0.234 | 7.21 |

| 80 x 60 x 6 | 0.273 | 6.49 |

| 80 x 60 x 7 | 0.273 | 7.5 |

| 80 x 60 x 8 | 0.273 | 8.48 |

| 80 x 65 x 6 | 0.283 | 6.73 |

| 80 x 65 x 8 | 0.283 | 8.82 |

| 80 x 65 x 10 | 0.283 | 10.9 |

| 90 x 65 x 6 | 0.303 | 7.22 |

| 90 x 65 x 7 | 0.303 | 8.32 |

| 90 x 65 x 8 | 0.303 | 9.44 |

| 90 x 65 x 10 | 0.303 | 11.7 |

| 100 x 50 x 6 | 0.292 | 6.98 |

| 100 x 50 x 8 | 0.292 | 9.16 |

| 100 x 50 x 10 | 0.292 | 11.3 |

| 100 x 65 x 7 | 0.321 | 8.96 |

| 100 x 65 x 8 | 0.321 | 10.2 |

| 100 x 65 x 9 | 0.321 | 11.3 |

| 100 x 65 x 10 | 0.321 | 12.5 |

| 100 x 75 x 7 | 0.341 | 9.52 |

| 100 x 75 x 8 | 0.341 | 10.8 |

| 100 x 75 x 9 | 0.341 | 12.1 |

| 100 x 75 x 10 | 0.341 | 13.3 |

| 100 x 75 x 11 | 0.341 | 14.6 |

| 100 x 75 x 12 | 0.341 | 15.8 |

| 120 x 80 x 8 | 0.391 | 12.4 |

| 120 x 80 x 10 | 0.391 | 15.3 |

| 120 x 80 x 12 | 0.391 | 18.2 |

| 130 x 65 x 8 | 0.381 | 12.1 |

| 130 x 65 x 10 | 0.381 | 14.9 |

| 130 x 65 x 12 | 0.381 | 17.7 |

| 130 x 75 x 8 | 0.401 | 12.7 |

| 130 x 75 x 10 | 0.401 | 15.7 |

| 130 x 75 x 12 | 0.401 | 18.6 |

| 130 x 90 x 10 | 0.43 | 17 |

| 130 x 90 x 12 | 0.43 | 20.1 |

| 150 x 75 x 9 | 0.441 | 15.7 |

| 150 x 75 x 10 | 0.441 | 17.4 |

| 150 x 75 x 11 | 0.441 | 18.9 |

| 150 x 75 x 12 | 0.441 | 20.6 |

| 150 x 90 x 10 | 0.47 | 18.6 |

| 150 x 90 x 12 | 0.47 | 22 |

| 150 x 90 x 15 | 0.47 | 27.1 |

| 150 x100 x 10 | 0.489 | 19.3 |

| 150 x100 x 12 | 0.489 | 23 |

| 150 x100 x 14 | 0.489 | 26.6 |

| 160 x 80 x 10 | 0.469 | 18.5 |

| 160 x 80 x 12 | 0.469 | 22 |

| 160 x 80 x 14 | 0.469 | 25.4 |

| 200 x100 x 10 | 0.587 | 23.4 |

| 200 x100 x 12 | 0.587 | 27.8 |

| 200 x100 x 15 | 0.587 | 34.4 |

AMERICAN RSA STEEL ANGLES (AISC)

Equal RSA Steel Angles

The table below shows the dimensions of RSA equal steel angles according to the AISC 360/A6 Specification (dimensions are in inches):

| Steel Angles Size in inches (in x in) | Steel Angle Dimensions AISC | Static Measures | |||

|---|---|---|---|---|---|

| Angle Legs length (inches) | Thickness (inches) | Sectional Area (in2) | Weight (lbf/ft) | Inertial Moment Ix | |

| 12 x 12 | 12 | 1 3/8 | 30.9 | 105 | 410.0 |

| 12 | 1 1/4 | 28.3 | 96.4 | 377.5 | |

| 12 | 1 1/8 | 25.6 | 87.2 | 344.1 | |

| 12 | 1 | 22.9 | 77.8 | 310.4 | |

| 10 x 10 | 10 | 1 3/8 | 25.6 | 87.1 | 232.1 |

| 10 | 1 1/4 | 23.5 | 79.9 | 215.1 | |

| 10 | 1 1/8 | 21.2 | 72.3 | 196.2 | |

| 10 | 1 | 19.0 | 64.7 | 177.3 | |

| 10 | 7/8 | 16.7 | 56.9 | 157.6 | |

| 10 | 3/4 | 14.4 | 49.1 | 137.2 | |

| 8 x 8 | 8 | 1 1/8 | 16.7 | 56.9 | 98.0 |

| 8 | 1 | 15.0 | 51.0 | 89.0 | |

| 8 | 7/8 | 13.2 | 45.0 | 79.6 | |

| 8 | 3/4 | 11.4 | 38.9 | 69.7 | |

| 8 | 5/8 | 9.6 | 32.7 | 59.4 | |

| 8 | 9/16 | 8.7 | 29.6 | 54.1 | |

| 8 | 1/2 | 7.8 | 26.4 | 48.6 | |

| 6 x 6 | 6 | 1 | 11.0 | 37.4 | 35.5 |

| 6 | 7/8 | 9.7 | 33.1 | 31.9 | |

| 6 | 3/4 | 8.4 | 28.7 | 28.2 | |

| 6 | 5/8 | 7.1 | 24.2 | 24.2 | |

| 6 | 9/16 | 6.4 | 21.9 | 22.1 | |

| 6 | 1/2 | 5.8 | 19.6 | 19.9 | |

| 6 | 7/16 | 5.1 | 17.2 | 17.7 | |

| 6 | 3/8 | 4.4 | 14.9 | 15.4 | |

| 6 | 5/16 | 3.7 | 12.4 | 13.0 | |

| 5 x 5 | 5 | 7/8 | 8.0 | 27.2 | 17.8 |

| 5 | 3/4 | 6.9 | 23.6 | 15.7 | |

| 5 | 5/8 | 5.9 | 20.0 | 13.6 | |

| 5 | 1/2 | 4.8 | 16.2 | 11.3 | |

| 5 | 7/16 | 4.2 | 14.3 | 10.0 | |

| 5 | 3/8 | 3.6 | 12.3 | 8.74 | |

| 5 | 5/16 | 3.0 | 10.3 | 7.42 | |

| 4 x 4 | 4 | 3/4 | 5.4 | 18.5 | 7.67 |

| 4 | 5/8 | 4.6 | 15.7 | 6.66 | |

| 4 | 1/2 | 3.8 | 12.8 | 5.56 | |

| 4 | 7/16 | 3.3 | 11.3 | 4.97 | |

| 4 | 3/8 | 2.9 | 9.8 | 4.36 | |

| 4 | 5/16 | 2.4 | 8.2 | 3.71 | |

| 4 | 1/4 | 1.9 | 6.6 | 3.04 | |

| 3 1/2 x 3 1/2 | 3 1/2 | 1/2 | 3.3 | 11.1 | 3.64 |

| 3 1/2 | 7/16 | 2.9 | 9.8 | 3.26 | |

| 3 1/2 | 3/8 | 2.5 | 8.5 | 2.87 | |

| 3 1/2 | 5/16 | 2.1 | 7.2 | 2.45 | |

| 3 1/2 | 1/4 | 1.7 | 5.8 | 2.01 | |

| 3 x 3 | 3 | 1/2 | 2.75 | 9.4 | 2.22 |

| 3 | 7/16 | 2.43 | 8.3 | 1.99 | |

| 3 | 3/8 | 2.11 | 7.2 | 1.76 | |

| 3 | 5/16 | 1.78 | 6.1 | 1.51 | |

| 3 | 1/4 | 1.44 | 4.9 | 1.24 | |

| 3 | 3/16 | 1.09 | 3.7 | 0.96 | |

| 2 1/2 x 2 1/2 | 2 1/2 | 1/2 | 2.25 | 7.7 | 1.23 |

| 2 1/2 | 3/8 | 1.73 | 5.9 | 0.98 | |

| 2 1/2 | 5/16 | 1.46 | 5.0 | 0.85 | |

| 2 1/2 | 1/4 | 1.19 | 4.1 | 0.70 | |

| 2 1/2 | 3/16 | 0.90 | 3.1 | 0.55 | |

| 2 x 2 | 2 | 3/8 | 1.36 | 4.7 | 0.48 |

| 2 | 5/16 | 1.15 | 3.9 | 0.42 | |

| 2 | 1/4 | 0.94 | 3.2 | 0.35 | |

| 2 | 3/16 | 0.72 | 2.4 | 0.27 | |

| 2 | 1/8 | 0.48 | 1.7 | 0.19 | |

Unequal RSA Steel Angles

The table below shows the dimensions of RSA unequal steel angles according to the AISC 360/A6 Specification (dimensions are in inches):

| RSA Size | Depth (in) | Width (in) | Thickness (in) | Sectional Area (in) | Weight (lb/ft) | Moment of Inertia – I (in4) | Section of Modulus – Sx (in3) |

| L9 x 4 x 5/8 | 9 | 4 | 0.625 | 7.73 | 26.3 | 64.9 | 11.5 |

| L9 x 4 x 9/16 | 9 | 4 | 0.563 | 7 | 23.8 | 59.1 | 10.4 |

| L9 x 4 x 1/2 | 9 | 4 | 0.5 | 6.25 | 21.3 | 53.2 | 9.34 |

| L8 x 6 x 1 | 8 | 6 | 1 | 13 | 44.2 | 80.8 | 15.1 |

| L8 x 6 x 7/8 | 8 | 6 | 0.875 | 11.5 | 39.1 | 72.3 | 13.4 |

| L8 x 6 x 3/4 | 8 | 6 | 0.75 | 9.94 | 33.8 | 63.4 | 11.7 |

| L8 x 6 x 5/8 | 8 | 6 | 0.625 | 8.36 | 28.5 | 54.1 | 9.87 |

| L8 x 6 x 9/16 | 8 | 6 | 0.563 | 7.56 | 25.76 | 49.3 | 8.95 |

| L8 x 6 x 1/2 | 8 | 6 | 0.5 | 6.75 | 23 | 44.3 | 8.02 |

| L8 x 6 x 7/16 | 8 | 6 | 0.438 | 5.93 | 20.2 | 39.2 | 7.1 |

| L8 x 4 x 1 | 8 | 4 | 1 | 11 | 37.4 | 69.6 | 14.1 |

| L8 x 4 x 3/4 | 8 | 4 | 0.75 | 8.44 | 28.7 | 54.9 | 10.9 |

| L8 x 4 x 9/16 | 8 | 4 | 0.563 | 6.43 | 21.9 | 42.8 | 8.35 |

| L8 x 4 x 1/2 | 8 | 4 | 0.5 | 5.75 | 19.6 | 38.5 | 7.49 |

| L7 x 4 x 3/4 | 7 | 4 | 0.75 | 7.69 | 26.2 | 37.8 | 8.42 |

| L7 x 4 x 5/8 | 7 | 4 | 0.625 | 6.48 | 22.1 | 32.4 | 7.14 |

| L7 x 4 x 1/2 | 7 | 4 | 0.5 | 5.25 | 17.9 | 26.7 | 5.81 |

| L7 x 4 x 3/8 | 7 | 4 | 0.375 | 3.98 | 13.6 | 20.6 | 4.44 |

| L6 x 4 x 7/8 | 6 | 4 | 0.875 | 7.98 | 27.2 | 27.7 | 7.15 |

| L6 x 4 x 3/4 | 6 | 4 | 0.75 | 6.94 | 23.6 | 24.5 | 6.25 |

| L6 x 4 x 5/8 | 6 | 4 | 0.625 | 5.86 | 20 | 21.1 | 5.31 |

| L6 x 4 x 9/16 | 6 | 4 | 0.563 | 5.31 | 18.1 | 19.3 | 4.83 |

| L6 x 4 x 1/2 | 6 | 4 | 0.5 | 4.75 | 16.2 | 17.4 | 4.33 |

| L6 x 4 x 7/16 | 6 | 4 | 0.368 | 4.18 | 14.3 | 15.5 | 3.83 |

| L6 x 4 x 3/8 | 6 | 4 | 0.375 | 3.61 | 12.3 | 13.5 | 3.32 |

| L6 x 4 x 5/16 | 6 | 4 | 0.313 | 3.03 | 10.3 | 11.4 | 2.79 |

| L6 x 3 1/2 x 1/2 | 6 | 3.5 | 0.5 | 4.5 | 15.3 | 16.6 | 4.24 |

| L6 x 3 1/2 x 3/8 | 6 | 3.5 | 0.375 | 3.42 | 11.7 | 12.9 | 3.24 |

| L6 x 3 1/2 x 5/16 | 6 | 3.5 | 0.313 | 2.87 | 9.8 | 10.9 | 2.73 |

| L5 x 3 1/2 x 3/4 | 5 | 3.5 | 0.75 | 5.81 | 19.8 | 13.9 | 4.28 |

| L5 x 3 1/2 x 5/8 | 5 | 3.5 | 0.625 | 4.92 | 16.8 | 12 | 3.65 |

| L5 x 3 1/2 x 1/2 | 5 | 3.5 | 0.5 | 4 | 13.6 | 10 | 2.99 |

| L5 x 3 1/2 x 7/16 | 5 | 3.5 | 0.438 | 3.53 | 12 | 8.9 | 2.64 |

| L5 x 3 1/2 x 3/8 | 5 | 3.5 | 0.375 | 3.05 | 10.4 | 7.78 | 2.29 |

| L5 x 3 1/2 x 5/16 | 5 | 3.5 | 0.313 | 2.56 | 8.7 | 6.6 | 1.94 |

| L5 x 3 1/2 x 1/4 | 5 | 3.5 | 0.25 | 2.06 | 7 | 5.39 | 1.57 |

| L5 x 3 x 5/8 | 5 | 3 | 0.625 | 4.61 | 15.7 | 11.4 | 3.55 |

| L5 x 3 x 1/2 | 5 | 3 | 0.5 | 3.75 | 12.8 | 9.45 | 2.91 |

| L5 x 3 x 7/16 | 5 | 3 | 0.438 | 3.31 | 11.3 | 8.43 | 2.58 |

| L5 x 3 x 3/8 | 5 | 3 | 0.375 | 2.86 | 9.8 | 7.37 | 2.24 |

| L5 x 3 x 5/16 | 5 | 3 | 0.313 | 2.4 | 8.2 | 6.26 | 1.89 |

| L5 x 3 x 1/4 | 5 | 3 | 0.25 | 1.94 | 6.6 | 5.11 | 1.53 |

| L4 x 3 1/2 x 5/8 | 4 | 3 | 0.625 | 4.3 | 14.7 | 6.37 | 2.35 |

| L4 x 3 1/2 x 1/2 | 4 | 3 | 0.5 | 3.5 | 11.9 | 5.32 | 1.94 |

| L4 x 3 1/2 x 7/16 | 4 | 3 | 0.438 | 3.09 | 10.6 | 4.76 | 1.72 |

| L4 x 3 1/2 x 3/8 | 4 | 3 | 0.375 | 2.67 | 9.1 | 4.18 | 1.49 |

| L4 x 3 1/2 x 5/16 | 4 | 3 | 0.313 | 2.25 | 7.7 | 3.56 | 1.26 |

| L4 x 3 1/2 x 1/4 | 4 | 3 | 0.25 | 1.81 | 6.2 | 2.91 | 1.03 |

| L4 x 3 x 5/8 | 4 | 3 | 0.625 | 3.98 | 13.6 | 6.03 | 2.3 |

| L4 x 3 x 1/2 | 4 | 3 | 0.5 | 3.25 | 11.1 | 5.05 | 1.89 |

| L4 x 3 x 7/16 | 4 | 3 | 0.438 | 2.87 | 9.8 | 4.52 | 1.68 |

| L4 x 3 x 3/8 | 4 | 3 | 0.375 | 2.48 | 8.5 | 3.96 | 1.46 |

| L4 x 3 x 5/16 | 4 | 3 | 0.313 | 2.09 | 7.2 | 3.38 | 1.23 |

| L4 x 3 x 1/4 | 4 | 3 | 0.25 | 1.69 | 5.8 | 2.77 | 1 |

| L3 1/2 x 3 x 1/2 | 3.5 | 3 | 0.5 | 3 | 10.2 | 3.45 | 1.45 |

| L3 1/2 x 3 x 7/16 | 3.5 | 3 | 0.438 | 2.65 | 9.1 | 3.1 | 1.29 |

| L3 1/2 x 3 x 3/8 | 3.5 | 3 | 0.375 | 2.3 | 7.9 | 2.72 | 1.13 |

| L3 1/2 x 3 x 5/16 | 3.5 | 3 | 0.313 | 1.93 | 6.6 | 2.33 | 0.95 |

| L3 1/2 x 3 x 1/4 | 3.5 | 3 | 0.25 | 1.56 | 5.4 | 1.91 | 0.78 |

| L3 1/2 x 2 1/2 x 1/2 | 3.5 | 2.5 | 0.5 | 2.75 | 9.4 | 3.24 | 1.41 |

| L3 1/2 x 2 1/2 x 7/16 | 3.5 | 2.5 | 0.438 | 2.43 | 8.3 | 2.91 | 1.26 |

| L3 1/2 x 2 1/2 x 3/8 | 3.5 | 2.5 | 0.375 | 2.11 | 7.2 | 2.56 | 1.09 |

| L3 1/2 x 2 1/2 x 5/16 | 3.5 | 2.5 | 0.313 | 1.78 | 6.1 | 2.19 | 0.93 |

| L3 1/2 x 2 1/2 x 1/4 | 3.5 | 2.5 | 0.25 | 1.44 | 4.9 | 1.8 | 0.76 |

| L3 x 2 1/2 x 1/2 | 3 | 2.5 | 0.5 | 2.5 | 8.5 | 2.08 | 1.04 |

| L3 x 2 1/2 x 7/16 | 3 | 2.5 | 0.438 | 2.21 | 7.6 | 1.88 | 0.93 |

| L3 x 2 1/2 x 3/8 | 3 | 2.5 | 0.375 | 1.92 | 6.6 | 1.66 | 0.81 |

| L3 x 2 1/2 x 5/16 | 3 | 2.5 | 0.313 | 1.62 | 5.6 | 1.42 | 0.69 |

| L3 x 2 1/2 x 1/4 | 3 | 2.5 | 0.25 | 1.31 | 4.5 | 1.17 | 0.56 |

| L3 x 2 1/2 x 3/16 | 3 | 2.5 | 0.188 | 1 | 3.39 | 0.91 | 0.43 |

| L3 x 2 x 1/2 | 3 | 2 | 0.5 | 2.25 | 7.7 | 1.92 | 1 |

| L3 x 2 x 7/16 | 3 | 2 | 0.438 | 2 | 6.8 | 1.73 | 0.89 |

| L3 x 2 x 3/8 | 3 | 2 | 0.375 | 1.73 | 5.9 | 1.53 | 0.78 |

| L3 x 2 x 5/16 | 3 | 2 | 0.313 | 1.46 | 5 | 1.32 | 0.66 |

| L3 x 2 x 1/4 | 3 | 2 | 0.25 | 1.19 | 4.1 | 1.09 | 0.54 |

| L3 x 2 x 3/16 | 3 | 2 | 0.188 | 0.9 | 3.1 | 0.84 | 0.42 |

| L2 1/2 x 2 x 3/8 | 2.5 | 2 | 0.375 | 1.55 | 5.3 | 0.91 | 0.55 |

| L2 1/2 x 2 x 5/16 | 2.5 | 2 | 0.313 | 1.31 | 4.5 | 0.79 | 0.47 |

| L2 1/2 x 2 x 1/4 | 2.5 | 2 | 0.25 | 1.06 | 3.62 | 0.65 | 0.38 |

| L2 1/2 x 2 x 3/16 | 2.5 | 2 | 0.188 | 0.81 | 2.75 | 0.51 | 0.29 |

| L2 1/2 x 1 1/2 x 5/16 | 2.5 | 1.5 | 0.313 | 3.92 | |||

| L2 1/2 x 1 1/2 x 1/4 | 2.5 | 1.5 | 0.25 | 0.938 | 3.19 | ||

| L2 1/2 x 1 1/2 x 3/16 | 2.5 | 1.5 | 0.1875 | 0.715 | 2.44 | ||

| L2 x 1 1/2 x 1/4 | 2 | 1.5 | 0.25 | 0.813 | 2.77 | ||

| L2 x 1 1/2 x 3/16 | 2 | 1.5 | 0.1875 | 0.621 | 2.12 | ||

| L2 x 1 1/2 x 1/8 | 2 | 1.5 | 0.125 | 0.422 | 1.44 | ||

| L2 x 1 1/4 x 1/4 | 2 | 1.25 | 0.25 | 2.55 | |||

| L2 x 1 1/4 x 3/16 | 2 | 1.25 | 0.1875 | 1.96 | |||

| L1 3/4 x 1 1/4 x 1/4 | 1.75 | 1.25 | 0.25 | 2.34 | |||

| L1 3/4 x 1 1/4 x 3/16 | 1.75 | 1.25 | 0.1875 | 1.8 | |||

| L1 3/4 x 1 1/4 x 1/8 | 1.75 | 1.25 | 0.125 | 1.23 | |||

| L1 1/2 x 1 1/4 x 3/16 | 1.5 | 1.25 | 0.1875 | 1.64 | |||

| L1 3/8 x 7/8 x 3/16 | 1.375 | 0.875 | 0.1875 | 1.32 | |||

| L1 3/8 x 7/8 x 1/8 | 1.375 | 0.875 | 0.125 | 0.91 | |||

| L1 x 3/4 x 1/8 | 1 | 0.75 | 0.125 | 0.7 | |||

| L1 x 5/8 x 1/8 | 1 | 0.625 | 0.125 | 0.64 |

One Response

Hi Dear Sir/Madam,

kindly quote me angle bar SUS 316L size: 160x80x10?