Pipe schedule charts, extracted from the ASME B36.10 and ASME B36.19 specifications, are useful in the engineering and design of piping systems across various industries. These charts provide standardized wall thickness dimensions for carbon, alloy, stainless steel pipes, facilitating the selection and specification process for engineers, designers, and industry professionals. Understanding these charts and their applications is crucial for ensuring that piping systems are designed and constructed to meet the required standards for safety, efficiency, and reliability.

PIPE SCHEDULE CHARTS

PIPES WALL THICKNESS IN INCHES (BY NPS/SCHEDULE)

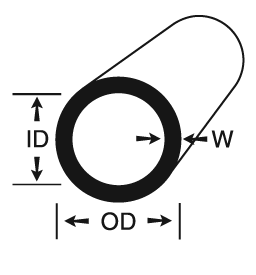

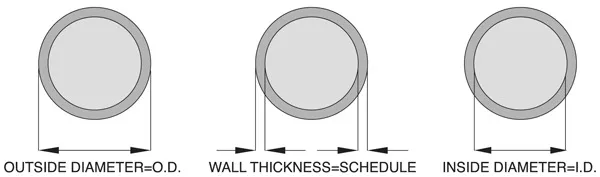

This article focuses on the standard wall thickness sizes (in inches and in millimeters) of carbon, alloy, stainless/duplex, and nickel alloy pipes. The wall thickness is expressed according to a special designation, called “Schedule”.

Learn more about the concept of Pipe Schedule.

To view the dimensions and weights (in Lbs/ft and Kg/m) of steel pipes, consult the broader ASME B36.10M and ASME B36.19M pipe sizes charts.

CARBON AND ALLOY STEEL PIPES (ASME B36.10M)

The table shows the wall thickness in inches for combinations of pipe NPS (nominal pipe size) and SCH (pipe schedule) – for carbon/alloy steel ASTM grades (according to the ASME B36.10M Specification):

| NPS | OD (inches) | Sch 5 | Sch 10 | Sch 20 | Sch 30 | Sch 40 | Sch Std | Sch 60 | Sch 80 | Sch XS | Sch 100 | Sch 120 | Sch 140 | Sch 160 | Sch XXS | NPS |

| 1/8 | 0.405 | 0.049 | 0.068 | 0.068 | 0.095 | 0.095 | 1/8 | |||||||||

| 1/4 | 0.54 | 0.065 | 0.088 | 0.088 | 0.119 | 0.119 | 1/4 | |||||||||

| 3/8 | 0.675 | 0.065 | 0.073 | 0.091 | 0.091 | 0.126 | 0.126 | 3/8 | ||||||||

| 1/2 | 0.84 | 0.065 | 0.083 | 0.095 | 0.109 | 0.109 | 0.147 | 0.147 | 0.188 | 0.294 | 1/2 | |||||

| 3/4 | 1.05 | 0.065 | 0.083 | 0.095 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | 3/4 | |||||

| 1 | 1.315 | 0.065 | 0.109 | 0.114 | 0.133 | 0.133 | 0.179 | 0.179 | 0.25 | 0.358 | 1 | |||||

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.117 | 0.14 | 0.14 | 0.191 | 0.191 | 0.25 | 0.382 | 1 1/4 | |||||

| 1 1/2 | 1.9 | 0.065 | 0.109 | 0.125 | 0.145 | 0.145 | 0.2 | 0.2 | 0.281 | 0.4 | 1 1/2 | |||||

| 2 | 2.375 | 0.065 | 0.109 | 0.125 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | 2 | |||||

| 2 1/2 | 2.875 | 0.083 | 0.12 | 0.188 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | 2 1/2 | |||||

| 3 | 3.5 | 0.083 | 0.12 | 0.188 | 0.216 | 0.216 | 0.3 | 0.3 | 0.438 | 0.6 | 3 | |||||

| 3 1/2 | 4 | 0.083 | 0.12 | 0.188 | 0.226 | 0.226 | 0.318 | 0.318 | 0.636 | 3 1/2 | ||||||

| 4 | 4.5 | 0.083 | 0.12 | 0.188 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | 4 | ||||

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.258 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | 5 | |||||

| 6 | 6.625 | 0.109 | 0.134 | 0.28 | 0.28 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | 6 | |||||

| 8 | 8.625 | 0.109 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | 8 |

| 10 | 10.75 | 0.134 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.594 | 0.5 | 0.719 | 0.844 | 1 | 1.125 | 1 | 10 |

| 12 | 12.75 | 0.156 | 0.18 | 0.25 | 0.33 | 0.406 | 0.375 | 0.562 | 0.688 | 0.5 | 0.844 | 1 | 1.125 | 1.312 | 1 | 12 |

| 14 | 14 | 0.156 | 0.25 | 0.312 | 0.375 | 0.438 | 0.375 | 0.594 | 0.75 | 0.5 | 0.938 | 1.094 | 1.25 | 1.406 | 14 | |

| 16 | 16 | 0.165 | 0.25 | 0.312 | 0.375 | 0.5 | 0.375 | 0.656 | 0.844 | 0.5 | 1.031 | 1.219 | 1.438 | 1.594 | 16 | |

| 18 | 18 | 0.165 | 0.25 | 0.312 | 0.438 | 0.562 | 0.375 | 0.75 | 0.938 | 0.5 | 1.156 | 1.375 | 1.562 | 1.781 | 18 | |

| 20 | 20 | 0.188 | 0.25 | 0.375 | 0.5 | 0.594 | 0.375 | 0.812 | 1.031 | 0.5 | 1.281 | 1.5 | 1.75 | 1.969 | 20 | |

| 22 | 22 | 0.188 | 0.25 | 0.375 | 0.5 | 0.375 | 0.875 | 1.125 | 0.5 | 1.375 | 1.625 | 1.875 | 2.125 | 22 | ||

| 24 | 24 | 0.218 | 0.25 | 0.375 | 0.562 | 0.688 | 0.375 | 0.969 | 1.219 | 0.5 | 1.531 | 1.812 | 2.062 | 2.344 | 24 | |

| 26 | 26 | 0.312 | 0.5 | 0.375 | 0.5 | 26 | ||||||||||

| 28 | 28 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | 28 | |||||||||

| 30 | 30 | 0.25 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | 30 | ||||||||

| 32 | 32 | 0.312 | 0.5 | 0.625 | 0.688 | 0.375 | 0.5 | 32 | ||||||||

| 34 | 34 | 0.312 | 0.5 | 0.625 | 0.688 | 0.375 | 0.5 | 34 | ||||||||

| 36 | 36 | 0.312 | 0.5 | 0.625 | 0.75 | 0.375 | 0.5 | 36 | ||||||||

| NPS | OD (inches) | Sch 5 | Sch 10 | Sch 20 | Sch 30 | Sch 40 | Sch Std | Sch 60 | Sch 80 | Sch XS | Sch 100 | Sch 120 | Sch 140 | Sch 160 | Sch XXS | NPS |

⬇️ Download Pipe Schedule Chart ASME B36.10

STAINLESS/DUPLEX STEEL & NICKEL ALLOY PIPES (ASME B36.19M)

The table shows the wall thickness in inches for combinations of pipe NPS (nominal pipe size) and SCH (pipe schedule) – for stainless steel, duplex/super duplex steel, and nickel alloy ASTM grades (according to the ASME B36.19M Specification):

| NPS | OD (in Inch.) | 5S | 10S | 40S | 80S | NPS |

| 1/8 | 0.405 | 0.049 | 0.068 | 0.095 | 1/8 | |

| 1/4 | 0.54 | 0.065 | 0.088 | 0.119 | 1/4 | |

| 3/8 | 0.675 | 0.065 | 0.091 | 0.126 | 3/8 | |

| 1/2 | 0.84 | 0.065 | 0.083 | 0.109 | 0.147 | 1/2 |

| 3/4 | 1.05 | 0.065 | 0.083 | 0.113 | 0.154 | 3/4 |

| 1 | 1.315 | 0.065 | 0.109 | 0.133 | 0.179 | 1 |

| 1 1/4 | 1.66 | 0.065 | 0.109 | 0.14 | 0.191 | 1 1/4 |

| 1 1/2 | 1.9 | 0.065 | 0.109 | 0.145 | 0.2 | 1 1/2 |

| 2 | 2.375 | 0.065 | 0.109 | 0.154 | 0.218 | 2 |

| 2 1/2 | 2.875 | 0.083 | 0.12 | 0.203 | 0.276 | 2 1/2 |

| 3 | 3.5 | 0.083 | 0.12 | 0.216 | 0.3 | 3 |

| 3 1/2 | 4 | 0.083 | 0.12 | 0.226 | 0.318 | 3 1/2 |

| 4 | 4.5 | 0.083 | 0.12 | 0.237 | 0.337 | 4 |

| 5 | 5.563 | 0.109 | 0.134 | 0.258 | 0.375 | 5 |

| 6 | 6.625 | 0.109 | 0.134 | 0.28 | 0.432 | 6 |

| 8 | 8.625 | 0.109 | 0.148 | 0.322 | 0.5 | 8 |

| 10 | 10.75 | 0.134 | 0.165 | 0.365 | 0.5 | 10 |

| 12 | 12.75 | 0.156 | 0.18 | 0.375 | 0.5 | 12 |

| 14 | 14 | 0.156 | 0.188 | 0.375 | 0.5 | 14 |

| 16 | 16 | 0.165 | 0.188 | 0.375 | 0.5 | 16 |

| 18 | 18 | 0.165 | 0.188 | 0.375 | 0.5 | 18 |

| 20 | 20 | 0.188 | 0.218 | 0.375 | 0.5 | 20 |

| 22 | 22 | 0.188 | 0.218 | 22 | ||

| 24 | 24 | 0.218 | 0.25 | 0.375 | 0.5 | 24 |

| 30 | 30 | 0.25 | 0.312 | 30 | ||

| NPS | OD (in Inch.) | 5S | 10S | 40S | 80S | NPS |

⬇️ Download Pipe Schedule Chart ASME B36.19

PIPES WALL THICKNESS IN MILLIMETERS (BY DN/SCHEDULE)

CARBON AND ALLOY STEEL PIPES (ASME B36.10M)

The table shows the wall thickness in millimeters for combinations of pipe DN (nominal diameter) and SCH (pipe schedule) – for carbon/alloy steel ASTM grades (according to the ASME B36.10M Specification):

| DN (mm) | OD (mm) | Sch 5 | Sch 10 | Sch 20 | Sch 30 | Sch 40 | Sch Std | Sch 60 | Sch 80 | Sch XS | Sch 100 | Sch 120 | Sch 140 | Sch 160 | Sch XXS |

| 6 | 10.3 | 1.24 | 1.73 | 1.73 | 2.41 | 2.41 | |||||||||

| 8 | 13.7 | 1.65 | 2.24 | 2.24 | 3.02 | 3.02 | |||||||||

| 10 | 17.1 | 1.65 | 1.85 | 2.31 | 2.31 | 3.2 | 3.2 | ||||||||

| 15 | 21.3 | 1.65 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 26.7 | 1.65 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 33.4 | 1.65 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 42.2 | 1.65 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||||

| 40 | 48.3 | 1.65 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.16 | |||||

| 50 | 60.3 | 1.65 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 73 | 2.11 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 88.9 | 2.11 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | |||||

| 90 | 101.6 | 2.11 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | 16.15 | ||||||

| 100 | 114.3 | 2.11 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||

| 125 | 141.3 | 2.77 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 168.3 | 2.77 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 273 | 3.4 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 15.09 | 12.7 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 323.8 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 9.53 | 14.27 | 17.48 | 12.7 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 355.6 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 9.53 | 15.09 | 19.05 | 12.7 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 406.4 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 9.53 | 16.66 | 21.44 | 12.7 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 457 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 9.53 | 19.05 | 23.83 | 12.7 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 508 | 4.78 | 6.35 | 9.53 | 12.7 | 15.09 | 9.53 | 20.62 | 26.19 | 12.7 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 559 | 4.78 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 28.58 | 12.7 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 610 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 9.53 | 24.61 | 30.96 | 12.7 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 660 | 7.92 | 12.7 | 9.53 | 12.7 | ||||||||||

| 700 | 711 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | |||||||||

| 750 | 762 | 6.35 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 813 | 7.92 | 12.7 | 15.88 | 17.48 | 9.53 | 12.7 | ||||||||

| 850 | 864 | 7.92 | 12.7 | 15.88 | 17.48 | 9.53 | 12.7 | ||||||||

| 900 | 914 | 7.92 | 12.7 | 15.88 | 19.05 | 9.53 | 12.7 | ||||||||

| 950 | 9.53 | 12.7 | |||||||||||||

| 1000 | 9.53 | 12.7 | |||||||||||||

| 1050 | 9.53 | 12.7 | |||||||||||||

| 1100 | 9.53 | 12.7 | |||||||||||||

| 1150 | 9.53 | 12.7 | |||||||||||||

| 1200 | 9.53 | 12.7 |

STAINLESS/DUPLEX STEEL & NICKEL ALLOY PIPES (ASME B36.19M)

The table shows the wall thickness in millimeters for combinations of pipe NPS (nominal diameter) and SCH (pipe schedule) – for stainless steel, duplex/super duplex steel, and nickel alloy ASTM grades (according to the ASME B36.19M Specification):

| DN (mm) | OD (mm) | Sch 5s | Sch 10s | Sch 40s | Sch 80s |

| 6 | 10.3 | 1.24 | 1.73 | 2.41 | |

| 8 | 13.7 | 1.65 | 2.24 | 3.02 | |

| 10 | 17.1 | 1.65 | 2.31 | 3.2 | |

| 15 | 21.3 | 1.65 | 2.11 | 2.77 | 3.73 |

| 20 | 26.7 | 1.65 | 2.11 | 2.87 | 3.91 |

| 25 | 33.4 | 1.65 | 2.77 | 3.38 | 4.55 |

| 32 | 42.2 | 1.65 | 2.77 | 3.56 | 4.85 |

| 40 | 48.3 | 1.65 | 2.77 | 3.68 | 5.08 |

| 50 | 60.3 | 1.65 | 2.77 | 3.91 | 5.54 |

| 65 | 73 | 2.11 | 3.05 | 5.16 | 7.01 |

| 80 | 88.9 | 2.11 | 3.05 | 5.49 | 7.62 |

| 90 | 101.6 | 2.11 | 3.05 | 5.74 | 8.08 |

| 100 | 114.3 | 2.11 | 3.05 | 6.02 | 8.56 |

| 125 | 141.3 | 2.77 | 3.4 | 6.55 | 9.53 |

| 150 | 168.3 | 2.77 | 3.4 | 7.11 | 10.97 |

| 200 | 219.1 | 2.77 | 3.76 | 8.18 | 12.7 |

| 250 | 273 | 3.4 | 4.19 | 9.27 | 12.7 |

| 300 | 323.8 | 3.96 | 4.57 | 9.53 | 12.7 |

| 350 | 355.6 | 3.96 | 4.78 | 9.53 | 12.7 |

| 400 | 406.4 | 4.19 | 4.78 | 9.53 | 12.7 |

| 450 | 457 | 4.19 | 4.78 | 9.53 | 12.7 |

| 500 | 508 | 4.78 | 5.54 | 9.53 | 12.7 |

| 550 | 559 | 4.78 | 5.54 | ||

| 600 | 610 | 5.54 | 6.35 | 9.53 | 12.7 |

| 750 | 762 | 6.35 | 7.92 |