Choosing the appropriate flange gasket involves careful consideration of several critical factors by piping engineers, including the fluid being transported, the system’s maximum operating temperature and pressure, the design of the piping system (including flanges and stud bolts), regulatory requirements (such as fugitive emissions and safety regulations), and economic aspects (like installation and maintenance expenses, as well as the potential for operational downtime). While gaskets may constitute a small part of the overall cost of a piping system, their significance in maintaining the system’s reliability and integrity is paramount. Skimping on gasket quality to save costs upfront can result in far greater, more expensive problems down the line. It’s therefore crucial to exercise careful judgment when selecting gaskets.

HOW TO SELECT THE RIGHT GASKET

Piping engineers shall consider multiple factors when selecting the proper types of gaskets for a piping system, namely:

- the fluid to be conveyed in the system, or by the pipeline

- the operational parameters of the process (such as the temperature and the pressure)

- the flanges used in the design (type, sizes, ratings, material grades, and specifications)

- the Regulatory framework applicable in the country of installation (such as fugitive emissions and safety directives)

- other general aspects

Let’s now delve into each of these factors that have to be considered when selecting the gaskets for a specific installation.

THE FLUID TO BE CONVEYED

The first criteria to select the right type of gasket is, of course, the type of fluid conveyed by the pipeline, and, in particular:

- The Chemical Compatibility: Identify the chemical properties of the fluid being transported, including its corrosiveness, toxicity, and purity requirements. The gasket material must be compatible with the fluid to prevent degradation, which could lead to leaks or contamination.

- The max. Fluid Temperature: Consider the temperature range of the fluid. The gasket material must withstand the maximum and minimum temperatures without losing its sealing properties or degrading.

- The max. Pressure: Determine the system’s operating pressure. The gasket must maintain its integrity under the expected pressure conditions.

- Fluid contamination risks: For some applications, it is important to use gaskets that do not contaminate the fluid conveyed by the pipeline (for example; pharmaceutical and food applications, or gas pipelines)

- Toxic/Explosive Fluids: Toxic fluids require totally leakproof flanged joints to prevent soil contamination or threats to human life. As a consequence, tighter and stronger gaskets may be the natural choice for these types of applications (for example spiral wound gasket with outer ring instead of cheaper non-asbestos gasket)

Different fluids, and/or different piping applications, require different gasket materials to ensure long-lasting flanged joints. Understanding the properties of the fluid to be conveyed is therefore the first key element to consider when selecting gaskets for piping.

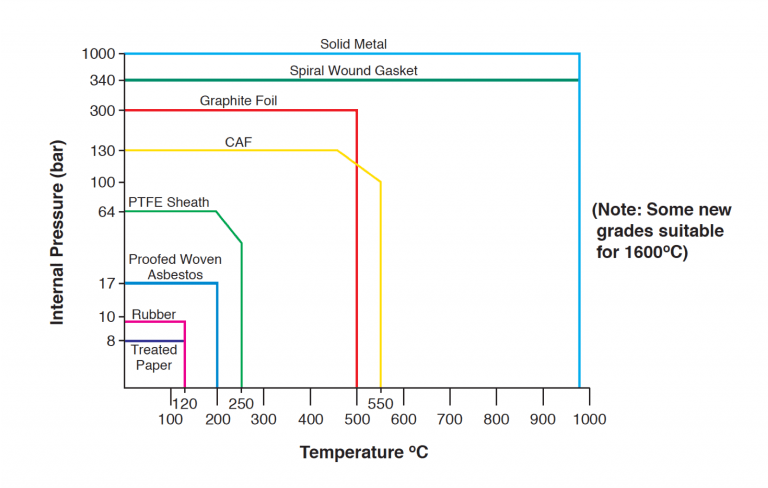

The chart reported below shows the max temperature, pressure, and creep resistance that can be withstood by different soft and metallic gasket materials:

Compressed Gaskets Chemical Resistance Chart

| Gasket Material | Max temperature (F) | Max Pressure (psi) | Gasket Thickness | Gasket Service Recommended |

| Butyl | -40 to 225 | 150 | 1/16 to 1/4 | Gases, inorganic acids & alkalis. Excellent weather/abrasion resistance. |

| EPDM | -40 to 212 | 150 | 1/16 to 1/4 | Water, steam, animal/vegetable oils, oxygenated solvents. Excellent weather resistance. |

| Natural (Pure Gum) | -20 to 140 | 100 | 1/32 to 1 | Acids, organic salts & alkalis. Non-toxic. Abrasion-resistant. Soft. |

| Neoprene | -20 to 170 | 150 | 1/32 to 2 | Oil/gasoline. Excellent weather resistance. |

| Neoprene – Cloth Inserted | -20 to 170 | 150 | 1/32 to 1/4 | Oil/gasoline. Excellent weather resistance. Handles movement. High tensile strength. |

| Nitrile (NBR, Buna-N) | -25 to 170 | 150 | 1/32 to 2 | Oil/Aromatic fuels, mineral, animal and vegetable oils, solvents, and hydraulic fluid. Available in commercial, premium, and FDA grades. |

| SBR (Red Rubber) | -20 to 170 | 150 | 1/32 to 1/4 | Air, hot/cold water. |

| SBR – Cloth Inserted | -20 to 170 | 150 | 1/16 to 1/4 | Air, hot/cold water, saturated/ low-pressure steam. Excellent for high compression loads. Handles movement. |

| Silicone | to 400 | 150 | 1/32 to 1/4 | High-temperature air or water (not oil or steam). Soft. Available in FDA grade. |

| Vinyl | 20 to 160 | 150 | 1/16 to 1/4 | Water, oxidizing agents. Excellent weather/abrasion resistance |

| Viton | to 400 | 150 | 1/32 to 1/4 | Oil/Aromatic fuels, mineral, animal and vegetable oils, solvents, and hydraulic fluid. |

Recommended Gasket Service Materials

| Gasket Material | Max temperature (F) | Max Pressure (psi) | Creep Relaxation (%) | Recommended Gasket Service |

| NON-ASBESTOS GASKETS | ||||

| Non-Asbestos/EPDM | 800 | 1200 | 15 | Steam/oxygenated solvents/mild organic acids/alkalis. Excellent aging properties. |

| Non-Asbestos/Hypalon | 400 | 900 | 40 | Strong organic & inorganic acids/oils/aromatic hydrocarbons, powerful oxidizing agents. |

| Non-Asbestos/Neoprene | 800 | 1200 | 15 | Fuel/oils. Good general-purpose material. |

| Non-Asbestos/Nitrile | 800 | 1500 | 15 | Steam/oil/fuel/solvent. Excellent general-purpose material with wide chemical resistance. |

| Non-asbestos/Nitrile (with metal insertion) | 850 | 2500 | 15 | Hot gases. High load/stress environments. Available with galvanized low-carbon steel foil or mesh insert. |

| Non-Asbestos/SBR | 800 | 1500 | 15 | Steam/industrial gases, Low pressure/temperature. |

| Pure PTFE | 500 | 800 | 35 – 55 | Excellent chemical resistance. |

| Filled PTFE | 500 | 1200 | 11-40 | Excellent chemical resistance. |

| Filled PTFE – Metal Inserted | 500 | 2500 | 20 | Excellent chemical resistance. 316 SS perforated core. |

| Expanded PTFE | 600 | 3000 | 30 | Excellent chemical resistance. Highly compressible. |

| Carbon or Graphite/Nitrile | 840 | 1900 | 20 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. |

| Carbon or Graphite/SBR | 900 | 2000 | 14 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. |

| Pure Flexible Graphite | 950 | 2100 | 5 | Excellent chemical resistance except for powerful oxidizing agents. Available laminated or homogeneous. |

| Pure Flexible Graphite – Metal Inserted | 950 | 2800 | 7 | Excellent chemical resistance except for powerful oxidizing agents. Available with 316 SS Foil, Mesh, or Tang Core. Available laminated or homogeneous. |

| METALLIC GASKETS | ||||

| Copper | 600 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. | ||

| Brass | 500 | Excellent for steam. Excellent chemical resistance except for powerful oxidizing agents. | ||

| GHL | 212 | Excellent chemical resistance except for powerful oxidizing agents. Available laminated or homogeneous. | ||

| Grafoil ® | 800 | Excellent chemical resistance except for powerful oxidizing agents. Available with 316 SS Foil, Mesh, or Tang Core. Available laminated or homogeneous. | ||

| Titanium | 1000 | Similar in strength to 300 series stainless, but tougher and much less dense. Excellent resistance to chloride solutions (sea water) and bleaching solutions. | ||

| Soft Iron, Low Carbon Steel | 1000 | Soft. Will corrode in water. Mostly used where immersed in liquid hydrocarbons. | ||

| Stainless Steel 304 | 1000 | A general-purpose, soft, corrosion-resistant, non-magnetic stainless that will not harden under heat. | ||

| Stainless Steel 316 | 1000 | Not as strong as 304, but more corrosion-resistant in chemical solutions (except for a limited range of oxidizing acids) | ||

| Stainless Steel 321 | 1600 | Stronger than 304. Used when similar performance to 304 is needed at higher temperatures. | ||

| Stainless Steel 347 | 1600 | More corrosion-resistant and harder than 321. | ||

| Stainless Steel 410 | 1200 | Commonly referred to as “Chrome”. This stainless will harden when heat-treated. It is highly magnetic, hard, and strong, but not very corrosion-resistant. | ||

| Stainless Steel 430 | 1400 | More corrosion-resistant than 410, but will not harden when heat-treated. This stainless is soft and no stronger than 300 series stainless. | ||

| Nickel | 1400 | Exhibits good corrosion and erosion resistance at moderate temperatures. | ||

| Monel | 1500 | A family of nickel/copper alloys that offer greater corrosion and erosion resistance than nickel alone. Particularly useful in seawater applications. | ||

| Inconel | 2000 | A family of nickel/chromium alloys that are non-magnetic and have corrosion resistance to elevated temperatures. | ||

| Hastelloy | 2000 | A family of Nickel/chromium/molybdenum alloys for use in highly aggressive chemical environments at elevated temperatures |

THE PROCESS TEMPERATURE AND PRESSURE

A second factor to consider to selecting the right gasket material is the working temperature and pressure of the piping system.

In particular, the gasket material shall be able to withstand the highest temperature and pressures expected for the process (highest expected temperature pressure for high-temperature applications, and lowest temperatures for low-temperature applications).

The temperature-pressure ratings of the common gasket materials are shown in the image below as a general reference.

Gaskets and temperature

Gaskets and temperature

The gasket should not creep at the highest temperature and pressure expected for the process, otherwise, the flanged joint would become ineffective generating leaks.

The flange gasket should be able to withstand the maximum pressure expected in the pipeline; this is often the test pressure, which can be at least 2 times the flange rating at ambient temperature.

THE PIPING SYSTEM DESIGN (FLANGES & BOLTS)

The piping engineer shall consider also the overall setup of the piping system when selecting the proper types of gaskets for an application, namely:

- Flange Types: The type of flanges used (e.g., raised face, flat face, ring-type joint) influences gasket selection. Each flange type has specific gasket requirements to ensure proper sealing and load distribution.

- Bolt Loading: Evaluate the flange bolting arrangement. The gasket must be able to compress and seal effectively under the available bolt load without being crushed or extruded out of the joint.

- Surface Finish: The condition and finish of the flange surfaces can affect gasket performance. Rougher surfaces may require softer gaskets that can conform to irregularities, while smoother surfaces can accommodate a wider range of gasket materials.

- Flange corrosion: Some flange materials, such as austenitic stainless steel, are subject to stress corrosion cracking, a factor to be considered in the gasket selection process

- Expected Pipeline vibration and oscillation: the gasket shall withstand the oscillations and the vibrations that may affect the pipeline

In addition to this, engineers shall also consider the financial implications of specific choices, such as:

- Life Cycle Costs: Consider not only the initial cost of the gasket but also the potential costs associated with maintenance, downtime, and replacement. A more expensive gasket that offers a longer service life or reduced maintenance requirements may be more cost-effective in the long run.

- Ease of Installation: Choose gaskets that can be easily installed and replaced with the available tools and workforce. Complicated gasket installations increase the risk of improper sealing and subsequent leaks (adding also workmanship and costs)

- Availability: Consider the availability of the gasket materials. Standard materials and sizes are typically readily available, but custom or specialized gaskets may require longer lead times.

- Financial costs of system downtime: Despite gaskets representing a minor portion of the overall cost of piping materials, choosing inappropriate gaskets can lead to significant financial consequences. Attempting to cut costs in this area can be risky for both the contractor, who might face penalties and the end-user

- Past experience within the installation plant: If possible, review the performance of gaskets previously used in similar applications within the facility. Historical data on gasket performance can provide valuable insights into which materials and designs have been most effective.

REGULATORY CONSIDERATIONS

Another important element to consider is the regulatory framework in the country of installation, in particular:

- Fugitive Emissions Laws: If the system is subject to regulations regarding fugitive emissions, select gaskets that meet the required standards for minimizing leaks of volatile organic compounds (VOCs) or hazardous air pollutants (HAPs).

- Safety Standards: Ensure the gasket selection complies with industry safety standards and guidelines, which may dictate specific materials or designs for certain applications.

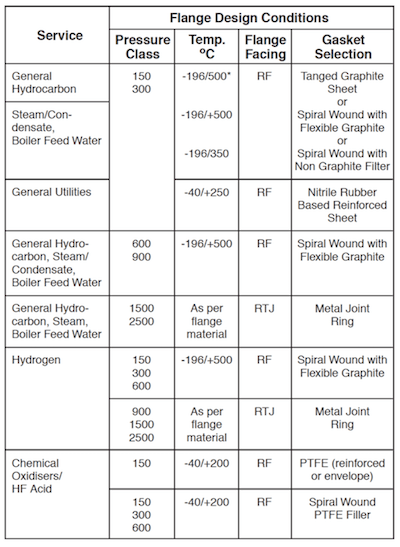

As a general reference, the following table shows the recommended types of gaskets by service, pipeline temperature, pressure rating, and flange-facing types:

FACTORS AFFECTING GASKET PERFORMANCE

The Flange Load

All gasket materials must have sufficient flange pressure to compress the gasket enough to ensure that a tight, unbroken seal occurs. The flange pressure, or minimum seating stress, necessary to accomplish this is known as the “y” factor. This flange pressure must be applied uniformly across the entire seating area to achieve perfect sealing. However, in actual service, the distribution around the gasket is not uniform. The greatest force is exerted on the area directly surrounding the bolts. The lowest force occurs mid-way between two bolts. This factor must be taken into account by the flange designer.

Pressure in the Piping System

In service, as soon as pressure is applied to the vessel, the initial gasket compression is reduced by the internal pressure acting against the gasket (blowout pressure) and the flanges (hydrostatic end force). To account for this, an additional preload must be placed on the gasket material. An “m” or maintenance factor has been established by ASME to account for this preload. The “m” factor defines how many times the residual load (original load minus the internal pressure) must exceed the internal pressure. In this calculation, the normal pressure and the test pressure should be taken into account.

Temperature in the Piping System

The effects of both ambient and process temperature on the gasket material, the flanges, and the bolts must be taken into account. These effects include bolt elongation, creep relaxation of the gasket material, or thermal degradation. This can result in a reduction of the flange load. The higher the operating temperature, the more care needs to be taken with the gasket material selection. As the system is pressurized and heated, the joint deforms. Different coefficients of expansion between the bolts, the flanges, and the pipe can result in forces that can affect the gasket. The relative stiffness of the bolted joint determines whether there is a net gain or loss in the bolt load. Generally, flexible joints lose bolt load.

Fluid Type

The media being sealed is usually a liquid or a gas with a gas being harder to seal than a liquid. The effect of temperature on many fluids causes them to become more aggressive. Therefore, a fluid that can be sealed at ambient temperature, may adversely affect the gasket at a higher temperature. The gasket material must be resistant to corrosive attack from the fluid. It should chemically resist the system fluid to prevent serious impairment of its physical properties.

Gasket Outer Diameter

For two gaskets made of the same material and having the same width, the one with a larger outer diameter will withstand a higher pressure. Therefore, it is advisable to use a gasket with an external diameter that is as large as possible.

Gasket Thickness

For a given material, it is a general rule that a thinner gasket can handle higher compressive stresses than a thicker one. However, thinner materials require a higher surface finish quality. As a rule of thumb, the gasket should be at least four times thicker than the maximum surface roughness of the flange faces. The gasket must be thick enough to occupy the shape of the flange faces and still compress under the bolt load. In situations where vibration is unavoidable, a thicker gasket than the minimum required should be employed.

Gasket Width

To reduce the bolt load required to produce a particular gasket pressure, it is advisable not to have the gasket wider than is necessary. For a given gasket stress, a raised face flange with a narrow gasket will require less pre-load and thus less flange strength than a full-face gasket. In general, high-pressure gaskets tend to be narrow.

Gasket Surface Finish

The surface finish of a gasket — which consists of grooves or channels pressed or machined onto the outer surface — governs the thickness and compressibility required by the gasket material to form a physical barrier in the clearance gap between the flanges. A finish that is too fine or shallow is undesirable, especially on hard gasket materials, because the smooth surface may lack the required grip, which will allow extrusion to occur. On the other hand, a finish that is too deep will yield a gasket that requires a higher bolt load, which may make it difficult to form a tight seal, especially when large flange surfaces are involved. Fine machining marks applied to the flange face, tangent to the direction of applied fluid pressure can also be helpful. Flange faces with non-slip grooves that are approximately 0.125 mm deep are recommended for gaskets more than 0.5 mm thick; and for thinner gaskets, grooves 0.065 mm deep are recommended. Under no circumstances should the flange-sealing surface be machined with tool marks extending radially across the gasket-sealing surface; such marks could allow leakage.

Stress Relaxation

This factor is a measure of the material’s resiliency over some time and is normally expressed as a percentage loss per unit of time. All gasket material will lose some resiliency over time, due to the flow or thinning of the material caused by the applied pressure. After some initial relaxation, the residual stress should remain constant for the gasket.

5 Responses

Good to know about this. and thanks for sharing this informative blog.

Thank you for sharing this content on selecting a gasket for the flange. I learned from Recommended Gasket Service Materials. If you need more information about Anti Ligature Gasketed Access Panels, let us know.

I’m looking for a gasket for a flange connection for natural gas up to 1,000 F

(in closed proximity to burners)

Informative…

Thanks for update…

Thanks for the great post on gasket