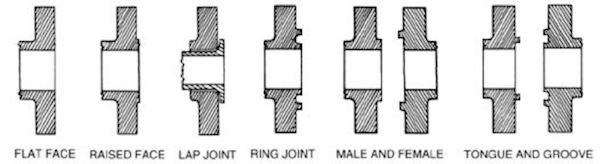

The flange face is the surface area that hosts the gasket. The 6 available types of flange faces are flat (FF), raised (RF), ring joint (RTJ), lap joint, male and female (M&F), tongue and groove (T&G). Flanges with different faces (that require different gaskets) shall never be mated to prevent leakage of the joint. RF and FF flanges may have different types of “finish” (i.e. roughness on top of the surface): smooth, stock, and serrated.

FLANGE FACE

WHAT MEANS FLANGE FACE?

The flange face refers to the surface area of a flange that comes into direct contact with the mating flange or sealing element (such as a gasket) when two pipe sections or components are joined together. This surface is crucial for creating a tight and leak-proof seal within the piping system. The design and finish of the flange face play a significant role in the effectiveness and integrity of the flange connection, affecting the distribution of pressure across the sealing surface and the overall reliability of the joint.

The ASME B16.5 and ASME B16.47 norms mention a few different types of flange faces:

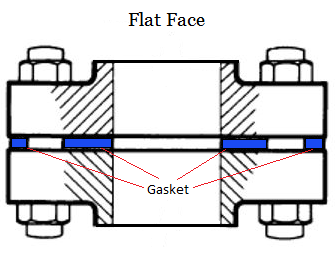

- Flat Face (FF): A flat surface that comes into direct contact with a similar flat surface on the mating flange. Flat face flanges are typically used with cast iron or other brittle materials where high tightening forces can cause damage. They are commonly used in low-pressure applications.

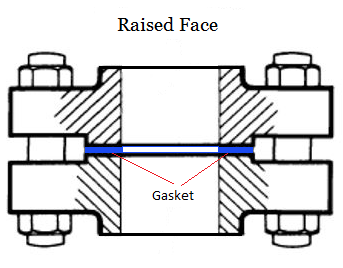

- Raised Face (RF): The most common type, featuring a raised surface area around the bore that contacts the gasket. This design concentrates the bolt load over a smaller area, enhancing the seal’s effectiveness. Raised face flanges are used in a wide range of applications, from low to high pressure.

- Ring Type Joint (RTJ): Characterized by a grooved surface on the flange face, into which a metal ring gasket is seated. The RTJ design is suitable for high-pressure and high-temperature applications, providing a highly reliable seal.

- Tongue and Groove (T&G): Large and small tongue-and-groove flange consists of a tongue (a raised surface) on one flange that fits into a corresponding groove on the mating flange. This design helps align the flanges and provides a tight seal without excessive bolt tightening, suitable for both high and low-pressure applications.

- Male and Female (M&F): Features a male face with a protrusion that fits into a female face with a matching depression on the mating flange. This configuration provides good alignment and sealing for moderate pressure levels.

- Lap Joint (LJ): A lap joint flange face is part of a two-piece assembly used in piping systems, comprising a lap joint flange and a stub end. This design allows for easy disassembly and assembly, making it particularly useful in applications where regular maintenance or frequent inspection is required. Unlike traditional flanges that are welded directly to the pipe, the lap joint flange itself does not come in direct contact with the fluid being transported; instead, it mates with the stub end, which is directly connected to the pipe.

The choice of flange face type depends on several factors, including the operating pressure and temperature of the system, the type of fluid being transported, and the materials of the flanges and gaskets. Additionally, compatibility between mating flanges and the type of gasket used is critical for ensuring a proper seal and preventing leaks.

TYPES OF FLANGE FACE

RAISED FACE FLANGE (RF)

A raised face flange (RF) is easy to recognize as the gasket surface area is positioned above the bolting line of the flange.

A raised face flange is compatible with a wide range of flange gaskets, ranging from flat to semi-metallic and metallic types (as, for example, jacketed gaskets and spiral wound gaskets), either ring or full face.

The main scope of a raised face flange design is to concentrate the pressure of the two mating flanges on a small surface and increase the strength of the seal.

The height of the raised face depends on the flange pressure rating as defined by the ASME B16.5 specification (for pressure classes 150 and 300, the height is 1.6 mm or 1/16 inch, for classes from 400 to 2500, the raised face height is approximately 6.4 mm, or 1/4 inch).

The most common flange finish for ASME B16.5 RF flanges is 125 to 250 micron Ra (3 to 6 micron Ra). The raised face is, according to ASME B16.5, the default flange face finish for manufacturers (this means that the buyer shall specify in the order if another flange face is required, such as the flat face or ring joint).

Raised face flanges are the most sold type of flange, at least for petrochemical applications.

FLAT FACE FLANGE (FF)

A flat face (FF) flange is a type of flange where the gasket surface is flat and covers the entire flange face. This design contrasts with raised face (RF) flanges, where the gasket surface is elevated above the bolting circle face.

Flat face flanges are typically used when connecting to cast iron equipment or flanges, other non-metallic materials, or when a softer gasket material is required for the sealing process. The flat surface ensures a full contact seal, which is necessary when the flange or mating component is made from a material that cannot withstand the high compressive forces of a raised face flange.

Key Characteristics:

- Gasket Surface: The entire flange face serves as the gasket surface, which means the gasket sits across the full diameter of the flange, providing a broad sealing area.

- Material Compatibility: Often chosen for use with brittle materials that might crack under the high stress concentrated around the raised face of other flange types. Suitable materials include cast iron, certain plastics, and fiberglass systems.

- Bolting Pattern: Similar to other flange types, flat-face flanges have a bolt circle around which bolts are evenly distributed to secure the flange. The distribution and number of bolts depend on the flange size and pressure class.

Design Considerations:

- Sealing Efficiency: While flat-face flanges provide a wide sealing surface, they may be more susceptible to leaks under high-pressure conditions compared to raised-face or ring-type joint flanges. The choice of gasket material and proper bolt tightening are crucial to ensure a leak-proof seal.

- Pressure Ratings: Flat-face flanges are generally preferred for lower-pressure applications. The broad sealing surface is less effective at containing high pressures, especially in larger sizes or at elevated temperatures.

- Application Specifics: The use of flat-face flanges is particularly common in water and wastewater treatment, HVAC systems, and applications involving non-metallic pipes or equipment where preventing damage from high compressive forces is critical.

Installation and Use:

- Alignment and Surface Condition: Care must be taken to ensure that the mating flange surfaces are perfectly aligned and free from imperfections. Any debris, scratches, or unevenness can compromise the seal.

- Gasket Selection: The gasket material should be compatible with the fluid medium, operating temperature, and pressure. Soft gasket materials are often used with flat face flanges to ensure a good seal across the wide contact area.

- Torque Requirements: Even and appropriate torque application to the bolting is necessary to compress the gasket evenly and avoid over-stressing the flange, particularly when dealing with brittle flange materials.

In summary, flat face flanges are an essential component in piping systems requiring a broad sealing surface for effective low-pressure sealing. Their design accommodates the limitations of brittle materials and facilitates the use of softer gasket materials, making them a versatile choice in specific industrial and commercial applications.

Warning: According to ASME B31.3, a flat face flange should never be mated with a raised face flange as the resulting flanged joint would definitely leak.

RING JOINT FLANGE FACE (RTJ)

A Ring Joint Flange Face (RTJ) is a type of flange face design utilized in high-pressure and high-temperature piping systems. It is characterized by a grooved face that accommodates a metal ring gasket, ensuring a tight and leak-proof seal. The RTJ flange is designed for critical service conditions where the reliability of the seal is paramount, making it an ideal choice for the oil and gas industry, petrochemical plants, power generation facilities, and other applications dealing with high pressure and temperatures.

A ring joint flange (RTJ) is used when a metal-to-metal seal between the mating flanges is required (which is a condition for high-pressure and high-temperature applications, i.e. above 700/800 C°).

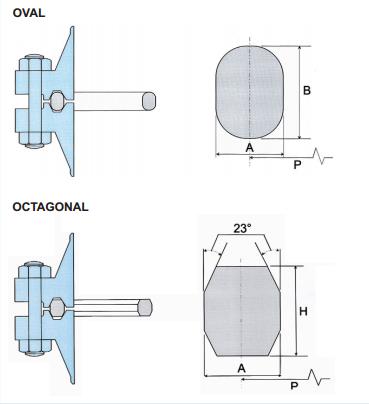

A ring joint flange features a circular groove to accommodate a ring joint gasket (oval, or rectangular).

As the two ring joint flanges are bolted together and then tightened, the applied bolting force deforms the gaskets inside the flange groove creating a very tight metal-to-metal seal. To make this happen, the material of the ring joint gasket has to be softer (more ductile) than the material of the flange.

RTJ flanges can be sealed with RTJ gaskets of different styles (R, RX, BX) and profiles (for example: octagonal/oval for the R style).

The most common RTJ gasket is the R style with an octagonal section, as it ensures a very strong seal (the oval section is an older type). A “flat groove” design, however, accepts both RTJ gaskets having an octagonal or oval section.

Key Features of RTJ Flange Face:

- Grooved Face: The distinguishing feature of an RTJ flange is the machined groove on its face, into which a metal ring gasket fits. The geometry of the groove and the gasket can vary, typically being either oval or octagonal in shape. This design allows for metal-to-metal sealing, which significantly enhances the seal’s integrity under extreme conditions.

- Metal Ring Gasket: The gasket used with RTJ flanges is made of a softer metal than the flanges themselves. Under compression, the gasket deforms and flows into the groove, creating a very tight and efficient seal that can withstand high pressures and temperatures as well as variations in pressure and temperature.

- High Integrity Seal: The metal-to-metal contact between the gasket and the flange groove provides excellent sealability, which is critical in high-pressure applications and in environments where leakage can lead to significant safety hazards or environmental concerns.

LAP JOINT FLANGE FACE

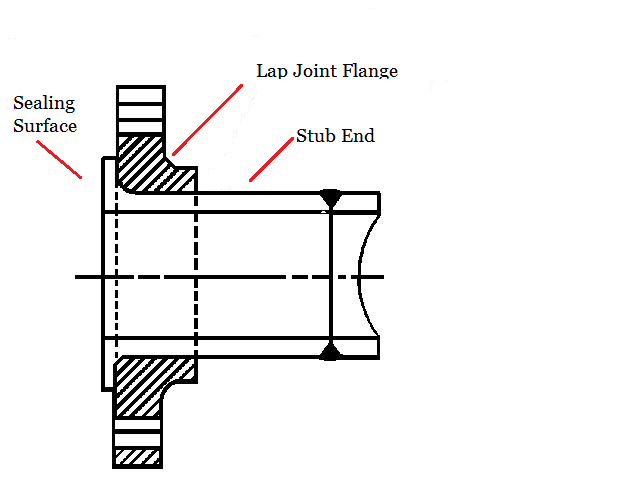

A lap joint flange has a flat face, which is not used to seal the flanged joint but simply hosts the backside of a stub end. The sealing surface is actually on the stub end itself and may be either a flat face or a raised face.

A lap joint flange face is part of a two-piece assembly used in piping systems, comprising a lap joint flange and a stub end. This design allows for easy disassembly and assembly, making it particularly useful in applications where regular maintenance or frequent inspection is required. Unlike traditional flanges that are welded directly to the pipe, the lap joint flange itself does not come in direct contact with the fluid being transported; instead, it mates with the stub end, which is directly connected to the pipe.

Design and Functionality:

- Stub End: The stub end is a short length of pipe with one flared end and a plain other end that gets butt-welded to the pipe. The flared end creates a surface for the lap joint flange to rest against.

- Lap Joint Flange: This flange has a flat face and a curved lip (“lap”) that fits over the flared end of the stub end, allowing the flange to rotate freely around the pipe. The face of the lap joint flange is the area that mates with the backside of the stub end’s flared end to form the seal.

Key Features:

- Rotatable Flange: The lap joint flange can rotate around the stub end, facilitating the alignment of bolt holes when connecting to another flange, which is particularly advantageous in complex piping systems or when aligning with equipment flanges.

- Ease of Maintenance: Since the flange is not welded to the pipe and can be detached without affecting the stub end, it simplifies the disassembly process for inspection, cleaning, or replacement of the flange.

- Cost-Effectiveness: The use of lap joint flanges can be more economical, especially when using expensive materials. The flange itself can be made of a lower-grade material than the stub end, which is the part exposed to the process fluid.

Applications:

Lap joint flanges are ideal for:

- Systems requiring frequent dismantling for access and cleaning.

- Piping systems that use lined or non-metallic pipes where direct welding of a flange to the pipe is not possible or practical.

- Applications where the benefits of flange rotation for bolt alignment are significant.

Considerations:

- The sealing capability of a lap joint flange assembly depends on the type of gasket used and the condition of the mating surfaces.

- While the lap joint flange provides flexibility and ease of maintenance, it is typically used in applications where the pressure and temperature requirements are moderate.

In essence, the lap joint flange face offers a unique solution in piping systems, combining ease of assembly and maintenance with cost savings, particularly in scenarios requiring regular access or when using costly pipe materials.

TONGUE AND GROOVE FLANGE (T&G)

A tongue and groove flange face is a type of flange connection that provides a mechanical seal within flanged joints, offering an alternative to the more common raised face or flat face designs.

This design involves two matching flanges: one with a protruding rim (tongue) and the other with a corresponding indent (groove). When the two flanges are bolted together, the tongue of one flange fits snugly into the groove of the mating flange, creating a tight and effective seal.

Key Characteristics:

- Seal Mechanism: The interlocking tongue and groove provide a strong mechanical seal that is enhanced by the compression of a gasket placed within the groove. This design minimizes the risk of leakage by containing the gasket within the groove and preventing it from being crushed or extruded under pressure.

- Alignment: The tongue and groove configuration also aids in the alignment of the flanges, ensuring a precise fit and further enhancing the seal’s integrity.

- Pressure Ratings: Suitable for a broad range of pressure applications, tongue and groove flanges are commonly used in both low and medium-pressure environments. Their design allows for effective sealing without the need for high bolt loads.

Applications:

Tongue and groove flange faces are utilized in various industries and applications where a reliable seal is crucial, but the operating conditions may not necessitate the robustness of a ring-type joint (RTJ) flange. These include:

- Chemical Processing: Where preventing leaks is critical to safety and environmental compliance.

- Water and Wastewater: In systems where the prevention of fluid leakage is essential for maintaining system integrity and protecting the environment.

- Oil and Gas: For certain non-critical applications where a reliable seal is required but without the extreme conditions that demand an RTJ flange.

Advantages:

- Effective Sealing: Provides an excellent seal that is reliable under a variety of conditions, reducing the risk of leaks.

- Gasket Protection: The groove protects the gasket from being crushed or extruded, extending the gasket’s life and maintaining the integrity of the seal.

- Ease of Alignment: Facilitates the alignment of flanges during installation, saving time and reducing the risk of the improper fitting.

Installation Considerations:

- Gasket Selection: It’s important to choose a gasket material that is compatible with the fluid being sealed and the operating conditions of the system.

- Bolting Technique: Even though high bolt loads are not required for sealing, proper bolting technique is still essential to ensure an even distribution of pressure and maintain the integrity of the seal.

Tongue and groove flanges are standardized in both large and small types.

MALE AND FEMALE FLANGE (M&F)

Similarly to tongue and groove flanges, male and female flanges (M&F face type) match one to the other as well.

One flange has an area extended beyond its face area, the male flange, and the other flange has a matching depression machined on the facing surface, the female flange.

The female face is 3/16” deep, while the male face is 1/4″ high, and both of them are smooth finished.

The outer diameter of the female face retains the gasket.

FLANGE FACE FINISH

WHAT MEANS FACE FINISH?

The term “face finish” refers to the surface texture or roughness of a flange face, which is the area where the gasket makes contact with the flange to create a seal. The finish on a flange face is crucial because it directly impacts the effectiveness of the seal between the flanges, influencing the integrity and safety of the piping system. A proper face finish ensures that the gasket can adequately conform to the flange, preventing leaks.

The concept of “face finish” applies to FF and RF flange faces, i.e. those types of flanges that are mated by using gaskets.

TYPES OF FLANGE FACE FINISH

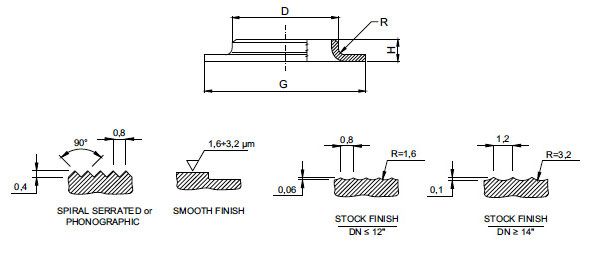

Face finishes are categorized by their method of creation and the resulting surface roughness, measured in microinches (µin) or micrometers (µm).

Source: Officine Orsi, Italy

Source: Officine Orsi, Italy

The five common types of flange’s face finishes include:

- Stock Finish: A standard finish for many flanges, suitable for a wide range of gasket types. It’s typically produced by machining with a cutting tool and has a relatively rough surface.

- Spiral Serrated Finish: Characterized by concentric grooves that are cut into the flange face at a defined angle and pitch. This finish is often used with spiral-wound gaskets to enhance sealing by trapping the gasket between the grooves.

- Concentric Serrated Finish: Similar to the spiral serrated finish but with concentric grooves. This finish provides multiple sealing points and is compatible with a variety of gasket materials.

- Smooth Finish: A finer finish with low surface roughness, intended for use with soft gasket materials, such as PTFE, that can conform to even minor surface imperfections. It’s achieved through machining or grinding to a high degree of smoothness.

- Ring Joint (RTJ) Finish: Specific to ring-type joint flanges, this finish is exceptionally smooth because it must mate perfectly with a metal ring gasket to form a metal-to-metal seal.

Importance of Face Finish

- Sealing Efficiency: The right face finish enhances the gasket’s ability to seal, preventing fluid leakage and ensuring the safety and efficiency of the piping system.

- Gasket Compatibility: Different gasket materials require different face finishes to achieve an optimal seal. For example, soft gaskets require a smoother finish, whereas metal gaskets may require a serrated finish to ensure proper sealing.

- Longevity and Reliability: A suitable face finish minimizes the risk of gasket failure and prolongs the service life of both the gasket and the flange by ensuring a consistent and reliable seal.

Selection Considerations

Selecting the appropriate face finish involves considering factors such as the type of fluid being sealed, the flange material, operating pressure and temperature, and the chosen gasket material. The objective is to match the face finish with the gasket requirements to achieve the best possible seal under the specific operating conditions of the piping system.

Let’s now delve into the features of these types of flange face finish, which are also shown in the image below:

STOCK FINISH

A stock finish for a flange face refers to the standard, default surface texture or roughness produced by the machining process used in manufacturing the flange. This type of finish is characterized by a relatively rough surface that is suitable for a wide range of sealing applications, particularly when using flat or spiral-wound gaskets. The stock finish is typically achieved through traditional machining operations, such as turning or milling, without any additional processes to reduce surface roughness.

Characteristics:

- Roughness Measurement: The surface roughness of a stock finish is usually measured in microinches (µin) or micrometers (µm), with common values ranging from 125 to 250 µin RA (Roughness Average). This range provides a general guideline, although specific values can vary based on manufacturer standards and industry practices.

- Application Compatibility: Stock finishes are versatile and can accommodate a variety of gasket materials and types. They are especially effective with non-metallic or semi-metallic gaskets that can conform to the surface irregularities to create a tight seal.

- Cost-Effectiveness: Since it does not require additional finishing processes, a stock finish is generally more cost-effective than smoother or more specialized finishes.

Importance:

The choice of a stock finish balances the need for a reliable seal with economic considerations. It is designed to provide adequate surface texture for the gasket to seal against, making it a practical choice for many standard flanging applications. The slight roughness of the finish helps to trap the gasket material and prevent lateral movement, enhancing the sealing performance.

Considerations:

- Gasket Selection: The type of gasket used must be compatible with the surface roughness of the stock finish. Softer gasket materials, which can compress and conform to the surface irregularities, are typically preferred.

- Sealing Pressure: While suitable for a range of applications, extremely high-pressure systems may require a smoother finish or different flange face design to ensure the integrity of the seal.

- Maintenance and Inspection: Regular inspection of flanged connections with stock finishes is essential to detect any wear or damage that could compromise the seal.

The stock finish is the most widespread type of finish as it suits the large majority of applications. The pressure embeds the soft face of the gasket into the flange finish and results in the formation of a good seal due to the friction existing between the contacting parts.

As the mating flanges are bolted together, gaskets get “squeezed” into the flange face surface and create a very tight seal.

A stock finish face is manufactured using a phonographic spiral groove featuring a 1.6mm radius round-nose tool with a depth of 0.15mm and a feed rate of 0.8mm per revolution. The resulting “Ra” value (AARH) for the surface ranges from 125µinch to 500 µinch (125 µm to 12.5 µm).

SPIRAL SERRATED

A spiral serrated flange finish is a specific type of surface texture applied to the face of a flange, designed to enhance the sealing capabilities of gasket connections in piping systems. This finish is characterized by concentric grooves that are machined into the flange face in a spiral pattern.

The serrations or grooves are intended to provide multiple sealing points and trap the gasket material within them, thereby improving the seal’s effectiveness and reliability.

Characteristics:

- Groove Pattern: The grooves are typically cut in a V-shape profile, with a standard depth and pitch. The spiral pattern starts from the center of the flange face and extends outward to the periphery.

- Surface Roughness: Between the serrations, the surface is relatively rough, with the roughness value typically specified by the manufacturer or relevant industry standards. This roughness aids in the mechanical interlocking of the gasket material.

- Gasket Compatibility: Spiral serrated finishes are particularly effective with softer gasket materials, such as compressed non-asbestos, elastomers, and PTFE. The grooves help to contain the gasket material, preventing flow or extrusion under pressure.

Advantages:

- Enhanced Sealing: The spiral serrations increase the mechanical engagement between the flange and the gasket, improving the integrity of the seal under varying pressures and temperatures.

- Reduced Leakage Risk: By trapping the gasket material within the grooves, the spiral serrated finish minimizes the risk of gasket displacement and leakage.

- Versatility: This finish is suitable for a wide range of applications, including those involving fluctuating pressures and temperatures, where maintaining a reliable seal is critical.

Applications:

Spiral serrated flange finishes are used in various industrial settings where fluid containment and pressure integrity are paramount. These include oil and gas production, chemical processing, power generation, and water treatment facilities. The finish is particularly valued in applications where the sealing surfaces are subject to thermal cycling, which can cause expansion and contraction of the flange and gasket materials.

Installation Considerations:

- Proper Gasket Selection: The effectiveness of a spiral serrated finish depends on the selection of an appropriate gasket material that can conform to the serrations without being damaged or excessively compressed.

- Bolt Tightening: Uniform bolt tightening is essential to ensure that the gasket is evenly compressed into the serrations, creating a tight seal across the entire flange face.

- Inspection and Maintenance: Regular inspection of flanged connections with spiral serrated finishes is crucial to detect wear or damage that could affect sealing performance.

The spiral serrated finish is a phonographic spiral groove type that differs from the stock finish as the groove is crafted by a 90-degree tool (instead of a round-nosed one) that creates a “V” geometry with a 45-degree serration angle.

A serrated finish, concentric or spiral, has from 30 to 55 grooves per inch and roughness between 125 to 250 µinch.

CONCENTRIC SERRATED

A concentric serrated flange face finish features a series of concentric grooves cut into the face of a flange. These grooves are machined in a pattern that radiates outward from the center of the flange face to its perimeter, similar to the rings seen on a target. The serrations are designed to enhance the sealing capability of gasket materials by providing multiple, small sealing points across the face of the flange.

The grooves are crafted with the same 90-degree tool used for the spiral serrated finish, but the serrations have an even design on the face of the flange. To have concentric grooves, the tool has a feed rate of 0.039mm per revolution and a depth of 0.079mm.

Key Characteristics:

- Groove Profile: The grooves in a concentric serrated finish are typically machined with a V-shape or a similar profile. The exact dimensions and pattern of the serrations, including their depth and pitch, can vary based on manufacturer specifications and industry standards.

- Surface Roughness: The serrations create a rough surface between each concentric groove. This roughness helps to mechanically lock the gasket material in place, preventing it from flowing or extruding out under pressure.

- Gasket Compatibility: This type of finish is particularly suitable for soft gasket materials, such as compressed fiber, elastomers, and PTFE. The concentric grooves ensure that the gasket conforms closely to the flange face, filling in the spaces to create a tight seal.

Advantages:

- Improved Sealing Efficiency: The concentric grooves provide multiple sealing paths, which can compensate for imperfections on the mating flange surface and ensure a reliable seal.

- Versatility: Suitable for a wide range of applications and operating conditions, including varying pressures and temperatures, where maintaining a strong seal is essential.

- Gasket Retention: The serrated pattern helps to retain the gasket in place, reducing the likelihood of leaks due to gasket displacement or blowout.

Applications:

Concentric serrated flange faces are used in industries where fluid sealing integrity is critical, such as in chemical processing, oil and gas production, power generation, and water treatment facilities. They are chosen for applications that require enhanced sealing capabilities to handle fluctuating pressures, thermal cycling, and aggressive media.

Installation Considerations:

- Gasket Selection: Choosing the right gasket material that can effectively fill the grooves and withstand the system’s operating conditions is crucial for achieving an optimal seal.

- Bolt Tightening: Even and proper bolt tightening is essential to ensure uniform compression of the gasket into the serrations, achieving a consistent seal across the entire flange face.

- Maintenance: Regular inspection and maintenance are recommended to ensure the integrity of the seal over time, especially in systems experiencing significant thermal or pressure cycling.

Compared to the spiral serrated type explained above, the concentric serrated flange finish features concentric grooves instead of spirals.

In summary, a concentric serrated flange face finish offers a reliable solution for enhancing the sealing performance of flanged connections in industrial piping systems. Its design maximizes the sealing surface area and provides a mechanical lock for the gasket material, making it a preferred choice for applications demanding high sealing integrity.

SMOOTH FINISH

In the context of flange face finishes, a smooth finish refers to a flange surface with a very low roughness, characterized by minimal surface irregularities. This type of finish is achieved through fine machining or grinding processes, resulting in a highly polished surface that provides an optimal mating surface for softer gasket materials, such as rubber, PTFE (polytetrafluoroethylene), or compressed non-asbestos fiber gaskets.

Key Characteristics:

- Surface Roughness: A smooth finish on a flange face typically has a roughness average (Ra) value in the range of 125 microinches (µin) or less, although specific requirements can vary based on industry standards or the demands of a particular application.

- Sealing Efficiency: The high level of smoothness ensures a tighter seal with the gasket material, as some fewer gaps or irregularities could lead to leaks.

- Gasket Compatibility: Ideal for use with soft gasket materials that can conform closely to the flange face, enhancing the seal’s integrity without the need for the gasket to deform significantly to fill surface grooves or serrations.

Advantages:

- Enhanced Seal with Soft Gaskets: The smooth surface allows for effective sealing with less gasket material deformation, reducing the risk of leaks, especially in low-pressure applications.

- Reduced Risk of Gasket Damage: The lack of abrasive features on the flange face minimizes the potential for gasket damage during installation or operation.

- Aesthetic Appeal: Beyond functional benefits, a smooth finish can also provide a cleaner, more polished appearance for visible components.

Applications:

Smooth finish flanges are commonly used in applications where the sealing pressure is relatively low, and the risk of leakage must be minimized. They are particularly suited to:

- Water treatment and distribution systems

- Pharmaceutical and food processing pipelines, where cleanliness and non-contamination are critical

- Low-pressure air and gas lines

- Systems utilizing highly corrosive fluids that require inert gasket materials like PTFE

Installation Considerations:

- Surface Inspection: Before installation, it’s essential to inspect the flange face for any scratches, nicks, or imperfections that could compromise the seal.

- Gasket Selection: The gasket material should be selected based on its compatibility with the fluid, operating temperature, and the smooth finish of the flange face to ensure a proper seal.

- Torque Specification: Proper bolt tightening and torque specification must be followed to ensure even pressure distribution across the gasket without over-compressing or damaging it.

Flanges with a smooth finish do not show visible tool markings to the naked eye.

This type of flange finish is used with metal-facing gaskets such as the jacketed type.

As per the stock finish, this is achieved by having the contact surface machined with a continuous spiral groove generated by a 0.8mm radius round-nosed tool at a feed rate of 0.3mm per revolution with a depth of 0.05mm (that creates a roughness between Ra 3.2 and 6.3 micrometers, i.e. 125 – 250 microinches).

COLDWATER FINISH

The cold water finishes appear shiny to the naked eye and very smooth. The AARH value for these surfaces ranges between 85 µinch to 100 µinch. They are used with metal-to-metal seals (no gasket).

WHAT MEANS “AARH”?

The term AARH (“arithmetic average roughness height”) refers to the flange face smoothness/roughness. The average arithmetic roughness height values are very important during the selection of flanges and gasket materials. Higher “Ra” values depict a more rough surface, while lower values represent a smoother surface.

Every material possesses a surface roughness and sometimes surfaces are finished deliberately to have a specific roughness (small or bigger).

The “Arithmetic Average Roughness Height” (AARH) is the common indicator to measure the roughness of a surface, and it is the average height of the irregularities on the metal surface, from the mean line as shown in the following figure.

The symbols Y1 to Y8 represent the peak heights which are measured from the mean line.

Arithmetic Average Roughness Height is usually measured in micro-inches and denoted by the symbol “Ra”.

There are various standards for the roughness of surfaces, set according to their type of application. The equipment used to measure the surface roughness is the so-called “profilometer” (which is available in the contact and non-contact types).

In contact type profilometer the roughness is measured by moving the material under the profilometer stylus. However, modern equipment features non-contact measurements, leveraging optical and ultrasonic technologies.

FLANGE AARH

ASME/ANSI defined specific roughness standards for the flanges, as the flange face finish plays a pivotal role in the gasket’s reliability and service life.

According to the ASME/ANSI specifications, the serrated, spiral serrated, and concentric flange face finish should have an average roughness of 125 µinch to 250 µinch (3.2 µm to 6.3 µm).

The tool used to imprint a rough finish on the flange should have a radius of 0.06 inch (1.5mm) or larger. The groove density on the flange face should be from 45 grooves per inch to 55 grooves per inch (1.8 grooves/ mm. to 2.2 grooves/ mm.).

These are the standards for semi-metallic and nonmetallic gaskets. If the average roughness of the flange face is not according to the described standards, the contacting surfaces will not properly seal and the flanged joint may wear after some time working under pressure (resulting in loss of bolt joint tightness and a possible leakage).

Soft nonmetallic materials such as PTFE may be used for more comfortable facing and better creep resistance.

ALLOWED AARH IMPERFECTIONS

The sealing performance of the flanges’ gaskets depends on the AARH, the flange dimensions, and the pressure of the stud bolts. According to ASME, the adjacent imperfections should be separated by a distance of at least 4 times the maximum radial projection.

The radial projection can be evaluated by subtracting the inner radius from the outer radius.

The serrations shall be at the same level, and the protrusion above them is not permitted. It can cause the adjacent serrations to lose hold of the gasket material and may result in wear and leakages.

9 Responses

Is RTJ more expensive than RF WN flange of same size?

thank’s for the information

Concentric and phonographic groove features/profiles are well defined. How much of the face of a flat flange should have the grooves? I cannot find this information in either ASTM or ASME. Thank you.

Very much informative and useful . Like this site 🙂

I am 4 years working oil and gas industry But in this website very useful for improving my

knowledge.

Simply want to say your article is as astonishing. The clarity to your submit is just great and that i can think you’re a professional in this subject. Fine together with your permission allow me to grasp your feed to stay up to date with approaching post. Thank you 1,000,000 and please carry on the rewarding work.

My brother suggested I might like this blog. He was entirely right. This post actually made my day. You can not imagine just how much time I had spent for this information! Thanks!

I’ve been absent for some time, but now I remember why I used to love this site. Thank you, I’ll try and check back more often. How frequently you update your website?

Very often! thank you for your interest!