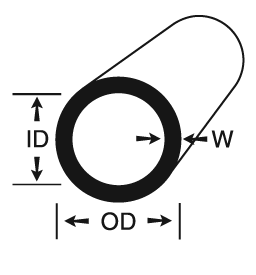

Copper Tubes for Plumbing and Oil & Gas Applications (ASTM B88, EN1057)

Discover the versatility and reliability of copper tubes for plumbing and oil & gas applications. Learn about their properties, advantages, and installation considerations in this comprehensive guide…