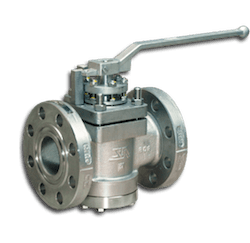

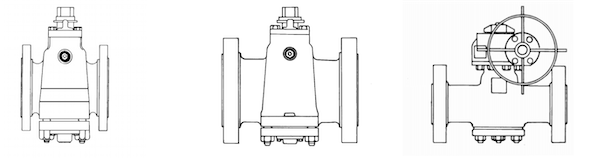

API 6D plug valves features a cylindrical or conic disc, with one or multiple horizontal hollow passageways, that can be rotated to open, close or control the flow of the fluid through the valve. The most used type is the two-port lubricated type with an open and closed position.

PLUG VALVE

WHAT IS A PLUG VALVE?

A plug valve is a type of valve used to control the flow of fluid through a pipeline. It consists of a cylindrical or tapered plug with one or more hollow passageways going sideways through the plug, allowing fluid to flow through the valve when the plug is in the open position. Turning the plug 90 degrees from the open position blocks the flow path, shutting off the flow. The simplicity of this design makes plug valves robust and reliable for on/off and moderate throttling services.

Key Features

- Simple Operation: Plug valves operate with a simple quarter-turn motion, similar to ball valves, making them easy to open and close quickly.

- Versatility: They can handle a wide variety of fluids, including those with solids in suspension, due to the straight-through flow path and the absence of pockets.

- Durability: The design of plug valves, with few moving parts and a straightforward flow path, contributes to their durability and long service life.

- Sealing: Plug valves can offer tight sealing with the use of an elastomeric sleeve or sealant injected into the seating area, depending on the design.

Plug valves can be ordered with flanged, hub, or butt weld ends and in cast (bore size >2 inches) or a forged body material (for bore sizes < 2 inches).

The two key reference specifications covering plug valves, for petrochemical applications, are the API 6D (downstream) and API 6A (upstream).

Plug valves may be manually operated, with a wrench or a gear, or actuated with Electric, Electro-Hydraulic, Pneumatic-Hydraulic, and Gas Over Oil Actuators.

Types of Plug Valves

Lubricated Plug Valve: Has a cavity in the body for a lubricant that reduces friction and wear on the plug mechanism and enhances the seal. Lubricant can be replenished through fittings on the valve body.

Non-Lubricated Plug Valve: Uses a non-metallic sleeve or a specially coated plug to reduce friction and provide a tight seal without the need for lubrication.

Eccentric Plug Valve: Features an off-center plug design that reduces wear on the plug and sleeve during operation, making it suitable for higher velocity services and slurry applications.

Expanding Plug Valve: Utilizes a mechanism that expands the plug to seal against the body, providing double isolation and bleed capabilities, ideal for critical applications where positive shutoff is required.

Multi-Port Plug Valves: Designed with three or more ports for multi-directional flow and diverting applications, simplifying piping systems by reducing the need for additional valves and tees.

Applications

Plug valves are used in various industries for a wide range of applications, including:

- Oil and Gas: For on/off control in pipelines, including crude oil, natural gas, and downstream processes.

- Chemical Processing: Handling corrosive and viscous fluids, as well as slurry services.

- Water and Wastewater Treatment: For flow control in treatment facilities and distribution systems.

- Food and Beverage: In applications requiring sanitary conditions and easy cleaning.

Plug valves can be used for liquids or gases such as:

- Neutral liquids, like oil and water

- Acidic and Alkaline (corrosive) liquids

- Slurry

- Neutral gases, such as steam and air

- Corrosive gases, including chlorine and acid vapors

Choosing a Plug Valve

When selecting a plug valve, consider the fluid characteristics, pressure and temperature ratings, and the specific requirements of the application, such as the need for tight shutoff, resistance to abrasion, or suitability for sanitary conditions. The choice of material for the body, plug, and seals (such as stainless steel, ductile iron, or PTFE) will also impact the valve’s performance and longevity in the service environment.

Well-established plug valve manufacturers are Galli & Cassina, Flowserve (Nordstrom and Durco), and Crane/Xomox.

(Source: CTE Skills Youtube Channel)

TYPES OF PLUG VALVES

There are several types of plug valves, each with specific features and benefits. Let’s delve into the details of each type:

Lubricated Plug Valve

A lubricated plug valve is a type of plug valve designed with a cavity within the valve body that holds a lubricating fluid, typically grease or oil. This lubricant is injected into the cavity to reduce friction between the plug and the valve body, facilitating smooth operation and providing a reliable seal.

Key Features

Lubrication Cavity: The lubricated plug valve features a cavity within the valve body where lubricating fluid is stored. This cavity is accessible through fittings on the valve body for injecting or replenishing lubricant as needed.

Reduced Friction: The lubricant forms a thin film between the plug and the valve body, reducing friction and wear during valve operation. This ensures smooth opening and closing of the valve, even after prolonged use.

Enhanced Seal: The lubricant also helps to improve the seal between the plug and the valve body, minimizing leakage and providing tighter shut-off capabilities.

Maintenance: Lubricated plug valves require periodic maintenance to replenish the lubricant and ensure optimal performance. Maintenance intervals may vary depending on the operating conditions and the type of lubricant used.

Applications

Lubricated plug valves are commonly used in various industries and applications, including:

- Oil and Gas: For on/off control in pipelines transporting crude oil, natural gas, and petroleum products.

- Chemical Processing: Handling corrosive fluids and chemicals where tight shut-off and reliable sealing are essential.

- Water and Wastewater Treatment: In treatment facilities and distribution systems for controlling flow and isolating sections of the pipeline.

- Petrochemical and Refining: For flow control in refining processes and petrochemical plants.

Considerations

When selecting a lubricated plug valve, several factors should be considered to ensure proper operation and longevity:

- Operating Conditions: Consider the temperature, pressure, and type of fluid being handled to select a valve with suitable materials and lubricants that can withstand the conditions.

- Maintenance Requirements: Plan for regular maintenance to replenish the lubricant and inspect the valve for wear or damage.

- Sealing Performance: Lubricated plug valves provide a reliable seal, but the effectiveness may vary depending on the design and quality of the valve and lubricant used.

- Compatibility: Ensure compatibility between the lubricant and the fluid being handled to prevent contamination or degradation of the process.

Overall, lubricated plug valves offer reliable performance, smooth operation, and enhanced sealing capabilities, making them suitable for a wide range of industrial applications where tight shut-off and minimal leakage are critical. Proper maintenance and lubrication are essential to ensure the continued performance and longevity of these valves in service.

Non-Lubricated Plug Valve

A non-lubricated plug valve is a type of plug valve designed to operate without the need for external lubrication. Unlike lubricated plug valves, which rely on a lubricating fluid to reduce friction between the plug and the valve body, non-lubricated plug valves use innovative materials and designs to achieve low-friction operation and reliable sealing without the need for additional lubrication.

Key Features

Self-Lubricating Materials: Non-lubricated plug valves utilize self-lubricating materials for the plug and valve body, such as polymers or composite materials with inherent low-friction properties. These materials reduce the coefficient of friction between the plug and the valve body, enabling smooth operation without external lubrication.

Sleeved Design: Some non-lubricated plug valves feature a sleeved design, where the plug is coated or encapsulated with a low-friction material, such as PTFE (polytetrafluoroethylene) or other polymers. This sleeve reduces wear and friction during operation, enhancing the valve’s performance and longevity.

Spring-Assisted Sealing: Non-lubricated plug valves may incorporate spring-loaded mechanisms to assist in sealing the plug against the valve body. These springs exert pressure on the plug, ensuring tight shut-off and preventing leakage even in challenging operating conditions.

Maintenance-Free Operation: Due to their self-lubricating properties and innovative design features, non-lubricated plug valves require minimal maintenance compared to lubricated plug valves. They eliminate the need for periodic lubrication, reducing downtime and maintenance costs.

Applications

Non-lubricated plug valves are commonly used in various industries and applications where reliable shut-off, minimal maintenance, and long-term performance are required. Some typical applications include:

- Water and Wastewater Treatment: In treatment plants and distribution systems for controlling flow, isolating pipelines, and regulating process fluids.

- Chemical Processing: Handling corrosive chemicals, acids, and aggressive fluids where tight shut-off and resistance to chemical attack are essential.

- Oil and Gas: For on/off control and isolation in pipelines transporting crude oil, natural gas, and petroleum products.

- Power Generation: In power plants for controlling steam, water, and other fluids in boiler feedwater systems, cooling circuits, and auxiliary processes.

Considerations

When selecting a non-lubricated plug valve, consider the following factors to ensure optimal performance and suitability for the application:

- Material Compatibility: Ensure that the materials used in the valve construction are compatible with the fluid being handled, especially in corrosive or abrasive applications.

- Operating Conditions: Consider the temperature, pressure, and flow conditions to select a valve with the appropriate design features and materials to withstand the application’s demands.

- Sealing Performance: Evaluate the valve’s sealing performance under various operating conditions, including pressure differentials, temperature variations, and flow rates, to ensure reliable shut-off and minimal leakage.

- Maintenance Requirements: While non-lubricated plug valves generally require less maintenance than lubricated ones, periodic inspection and testing may still be necessary to ensure continued performance and integrity.

Non-lubricated valves are preferred to the lubricated type when low maintenance is required, like in services for sulfur, hydrogen fluoride, or in cases where the fluids could solidify and block the valve.

The downside of non-lubricated valves is that they suit only specific applications in terms of temperature, pressure and type fo conveyed fluids (chemical resistance) due to the non-metallic seat they use.

Types of non-lubricated plug valves

The three main types of non-lubricated valves are: fully lined, elastomer sleeve and, lift-type plug valve.

A fully lined, elastomer sleeve, lift-type non-lubricated plug valve combines several design features to offer reliable performance and efficient flow control in various industrial applications. Let’s break down each aspect of this valve:

Fully Lined

The term “fully lined” refers to the construction of the valve, where both the body and the internal components are lined with a corrosion-resistant material. Typically, fluoropolymer materials such as PTFE (polytetrafluoroethylene) or PFA (perfluoroalkoxy) are used for lining. This lining provides excellent chemical resistance and prevents the process fluid from coming into contact with the metal components of the valve, protecting them from corrosion and extending the valve’s service life.

Elastomer Sleeve

The valve features an elastomer sleeve that surrounds the plug, providing a flexible and resilient seal against the valve body. Elastomeric materials such as EPDM (ethylene propylene diene monomer) or NBR (nitrile butadiene rubber) are commonly used for the sleeve. The elastomer sleeve offers excellent sealing properties, even in low-pressure or vacuum applications, and helps to reduce friction between the plug and the valve body, facilitating smooth operation without the need for external lubrication.

Lift-Type Design

The lift-type design of the plug valve refers to the mechanism used to lift the plug off the valve seat to allow fluid flow. In lift-type plug valves, the plug is raised vertically away from the seat when the valve is opened, creating an unobstructed flow path through the valve. This design minimizes the risk of fluid entrapment and reduces the potential for solids or debris to accumulate around the seating area, ensuring reliable sealing and preventing valve sticking or jamming.

Non-lubricated plug valves offer a cost-effective and reliable solution for a wide range of industrial applications, providing efficient flow control, tight shut-off, and long-term durability without the need for external lubrication.

Eccentric Plug Valve

An eccentric plug valve is a type of plug valve designed with an off-center or eccentric plug. Unlike traditional plug valves where the plug is centered within the valve body, the eccentric plug in this design is positioned off-center, typically at an angle of 30 degrees or more from the valve’s centerline. This unique design offers several advantages in terms of flow control, sealing performance, and resistance to wear and abrasion.

The design of an eccentric valve features a half plug that is a key benefit for applications that require a stronger seating force and minimal friction from the open to the closed position.

Eccentric valves show also improved shut off capabilities compared to the concentric design.

The typical applications of this type of plug valve are dirty waters, sewage, sludge and slurries, air, and other similar services requiring tight shut off.

Here’s a closer look at the key features and benefits of eccentric plug valves:

Key Features

Off-Center Plug: The plug in an eccentric plug valve is positioned off-center, which allows for a non-slam, quick-closing action. This design minimizes wear and abrasion on the plug and valve seat, extending the valve’s service life.

Asymmetric Flow Path: The eccentric plug creates an asymmetric flow path through the valve, which helps to reduce turbulence and pressure drop during operation. This ensures smoother flow control and improved efficiency compared to traditional plug valves.

Self-Cleaning Action: The off-center plug design promotes a self-cleaning action as the plug rotates during operation. This helps to prevent buildup of solids or debris on the seating surface, reducing the risk of valve sticking or jamming.

Bidirectional Sealing: Eccentric plug valves are capable of bidirectional sealing, meaning they provide tight shut-off in both flow directions. This makes them suitable for applications where flow reversal occurs, such as in pipeline systems.

Flexible Seating: The eccentric plug valve can utilize various seating materials, including elastomers, metal-to-metal, or ceramic, depending on the application requirements. This flexibility allows for compatibility with a wide range of process fluids and operating conditions.

Applications

Eccentric plug valves are commonly used in industries such as:

- Oil and Gas: for flow control and isolation in pipelines transporting crude oil, natural gas, and petroleum products.

- Chemical Processing: for handling corrosive chemicals, acids, and abrasive slurries.

- Water and Wastewater Treatment: for regulating flow and isolating sections of the pipeline in treatment plants and distribution systems.

- Power Generation: in power plants for controlling steam, water, and other fluids in boiler feedwater systems, cooling circuits, and auxiliary processes.

Considerations

When selecting an eccentric plug valve, consider factors such as the type of process fluid, temperature, pressure, and flow characteristics. Ensure that the valve materials and design are suitable for the application requirements to achieve optimal performance and reliability.

In summary, eccentric plug valves offer enhanced flow control, bidirectional sealing, and resistance to wear and abrasion, making them well-suited for a wide range of industrial applications where reliable performance and long service life are essential.

Expanding Plug Valve (Double Block and Bleed – DBB)

n expanding plug valve is a type of plug valve characterized by its unique design, which allows the plug to expand radially to form a tight seal against the valve body. This expansion mechanism ensures reliable shut-off and excellent sealing performance, making expanding plug valves suitable for various industrial applications. Here’s a closer look at the key features and functionality of expanding plug valves:

Key Features

Expanding Plug: The defining feature of an expanding plug valve is its plug, which can expand radially when activated. The plug typically consists of multiple segments or sleeves that can be expanded outward to contact the inner surface of the valve body. This expansion creates a tight seal, effectively blocking flow through the valve.

Segmented Design: Expanding plug valves often feature a segmented plug design, where the plug is divided into multiple sections or sleeves. Each segment can move independently to accommodate variations in the valve body’s internal diameter and ensure uniform sealing around the circumference of the plug.

Actuation Mechanism: Expanding plug valves are typically actuated using external mechanisms such as handwheels, gears, pneumatic actuators, or electric actuators. The actuation mechanism controls the expansion and contraction of the plug segments, allowing for precise flow control and shut-off.

Bidirectional Sealing: Expanding plug valves are capable of bidirectional sealing, meaning they can effectively seal flow in both directions. This bidirectional sealing capability makes expanding plug valves versatile and suitable for applications where flow reversal may occur.

Robust Construction: Expanding plug valves are constructed from durable materials such as carbon steel, stainless steel, or alloys, depending on the application requirements. This robust construction ensures longevity and reliability in demanding industrial environments.

Applications

Expanding plug valves are commonly used in industries such as:

- Oil and Gas: for flow control and isolation in pipelines, refineries, and petrochemical plants.

- Chemical Processing: for handling corrosive fluids, acids, and chemicals in chemical processing facilities.

- Water and Wastewater Treatment: for regulating flow and isolating sections of the pipeline in water treatment plants and distribution systems.

- Power Generation: in power plants for controlling steam, water, and other fluids in boiler feedwater systems, cooling circuits, and auxiliary processes.

Considerations

When selecting an expanding plug valve, consider factors such as the type of process fluid, temperature, pressure, flow characteristics, and operating conditions. Ensure that the valve’s materials, design, and actuation mechanism are suitable for the specific application requirements to achieve optimal performance and reliability.

Expanding type are the most complex plug valve design, as it features multiple components that allow a mechanical expansion of the valve to give it a true double block and bleed function (DBB).

They are often used to prevent product contamination in applications that do not require double isolation.

The expanding valve uses a mechanism that rotates between the open and closed position and protects both seals from the flow path. During the rotation, the body and seals do not get in contact, and slips expand onto the body seat when the valve is closed to prevent wear or abrasion to the seals.

In summary, expanding plug valves offer efficient flow control, bidirectional sealing, and reliable shut-off capabilities, making them well-suited for a wide range of industrial applications where tight sealing and precise flow regulation are essential.

Multiport Plug Valve

Multi-port plug valves, also known as multi-way plug valves or multi-port valves, are specialized valves designed to control the flow of fluids through multiple inlet and outlet ports. These valves feature a plug mechanism that can be rotated to divert or combine flow between different ports, offering versatility in fluid handling and distribution.

Here’s a detailed explanation of multi-port plug valves:

Key Features

Multiple Ports: Multi-port plug valves have more than two ports, typically three or more, arranged around the valve body. These ports allow for various flow configurations, including straight-through flow, cross-flow, or combinations thereof.

Rotating Plug Mechanism: The plug inside the valve body can be rotated to direct flow between different ports. By adjusting the position of the plug, operators can control the flow pattern, diverting fluid from one port to another or combining flows from multiple ports.

Durable Construction: Multi-port plug valves are constructed from robust materials such as stainless steel, carbon steel, or alloys, ensuring durability and resistance to corrosion and wear. This construction allows them to withstand high-pressure and high-temperature applications.

Sealing Mechanism: Similar to standard plug valves, multi-port plug valves utilize a sealing mechanism to prevent leakage between the plug and the valve body. Depending on the application, the sealing mechanism may consist of elastomeric seals, metal-to-metal seals, or a combination of both.

Actuation Options: Multi-port plug valves can be manually operated or actuated using pneumatic, electric, or hydraulic actuators for remote control. Actuation allows for precise positioning of the plug and automation of flow control processes.

Applications

Multi-port plug valves find application in various industries and processes where versatile fluid handling is required, including:

- Chemical Processing: for blending, mixing, or distributing different chemicals or additives in manufacturing processes.

- Oil and Gas: for manifold systems, distribution networks, and metering stations in upstream, midstream, and downstream operations.

- Water Treatment: for controlling flow between different treatment stages, such as filtration, disinfection, and chemical dosing.

- Food and Beverage: for processing and distributing different ingredients or products in food processing and beverage production facilities.

Considerations

When selecting a multi-port plug valve, consider factors such as the number and configuration of ports, the size and material of construction, pressure and temperature ratings, and compatibility with the process fluid. Proper valve sizing and selection are essential to ensure optimal performance and reliability in the intended application.

In summary, multi-port plug valves offer flexibility and versatility in fluid handling applications by allowing control over flow direction and distribution between multiple ports. These valves play a crucial role in various industries where precise flow control and distribution are essential for efficient operations.

SHORT vs. LONG PATTERN PLUG VALVE

Short and long pattern plug valves refer to variations in the overall length of the valve body.

Short, regular, and Venturi plug valve.

Here’s a breakdown of the differences between short and long pattern plug valves:

Short Pattern Plug Valve

Compact Design: Short pattern plug valves have a more compact design compared to long pattern valves. They feature a shorter overall length, making them ideal for applications where space is limited or where a shorter valve is preferred.

Reduced Weight: Due to their shorter length, short pattern plug valves typically have a lower weight compared to long pattern valves. This can make them easier to handle and install, especially in applications with weight restrictions or accessibility challenges.

Limited Flow Capacity: Short pattern plug valves may have a slightly reduced flow capacity compared to long pattern valves due to their shorter body length. However, they are still capable of handling a wide range of flow rates and pressures, making them suitable for many applications.

Long Pattern Plug Valve

Extended Length: Long pattern plug valves feature an extended body length compared to short pattern valves. This extended length provides additional space between the inlet and outlet connections, allowing for improved flow characteristics and reduced pressure drop.

Increased Flow Capacity: The longer body length of long pattern plug valves allows for larger internal passageways, resulting in higher flow capacities compared to short pattern valves. This makes them suitable for applications requiring higher flow rates or lower pressure drop.

Enhanced Sealing: Long pattern plug valves may offer enhanced sealing performance compared to short pattern valves, particularly in applications with higher pressures or temperatures. The extended length provides additional contact area for the sealing components, improving leak-tightness and reliability.

Application Considerations

Space Limitations: Short pattern plug valves are preferred in applications where space is limited or where a compact valve design is desired.

Flow Requirements: Long pattern plug valves are suitable for applications requiring higher flow capacities or lower pressure drop, thanks to their extended body length and larger internal passageways.

Pressure and Temperature: Both short and long pattern plug valves are available in various pressure and temperature ratings to suit different operating conditions and fluid handling requirements.

In summary, the main differences between short and long pattern plug valves are related to the overall length, flow capacity, and sealing performance of the valve.

The choice between the two types (short vs. long pattern plug) depends on factors such as space limitations, flow requirements, and operating conditions.

- The short pattern design type has compact face-to-face dimensions and port areas accounting for 40% to 60% of a full-bore type

- The regular pattern has longer face-to-face dimensions and a port area of 50-70% of the full-bore plug valves and is designed to provide minimal loss of flow.

- Full bore design has long face-to-face dimensions and a round port (Venturi).

This last configuration provides unrestricted flow and allows pigging operations of the pipeline. Modern plug valves are an evolution of a basic design that was developed back in the Roman Empire.

PLUG VALVE VS. OTHER TYPES OF VALVE

PLUG VALVE VS. BALL VALVE

Plug valves and ball valves are both types of quarter-turn valves commonly used in various industries for flow control applications. While they share similarities in their operation, they have distinct designs and characteristics that make them suitable for different applications. Here’s a comparison between plug valves and ball valves:

Plug Valve

Design:

- Plug valves feature a cylindrical or conical plug with a through-hole or port that can be rotated within the valve body to control flow.

- The plug typically has a tapered or cylindrical shape and seals against the valve seat to regulate fluid flow.

Operation:

- Plug valves operate by rotating the plug 90 degrees from the fully open to the fully closed position, allowing for quick and easy on/off control.

- They offer reliable sealing and tight shut-off when closed, making them suitable for applications where leak prevention is critical.

Flow Characteristics:

- Plug valves can provide linear or equal percentage flow characteristics depending on the shape of the plug and the design of the port.

- They are well-suited for throttling and moderate flow control applications, especially in high-pressure and high-temperature environments.

Applications:

- Plug valves are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation.

- They are preferred for applications requiring frequent operation, tight shut-off, and resistance to abrasive or corrosive fluids.

Ball Valve

Design:

- Ball valves feature a spherical or cylindrical closure element (the ball) with a port through the center that allows fluid to flow when aligned with the valve body.

- The ball rotates within the valve body to open or close the flow path, providing a full bore or reduced bore configuration.

Operation:

- Ball valves operate by rotating the ball 90 degrees from the fully open to the fully closed position, allowing for quick and reliable flow control.

- They offer low torque operation and are suitable for automation using electric, pneumatic, or hydraulic actuators.

Flow Characteristics:

- Ball valves typically provide quick and full-flow shut-off with minimal pressure drop across the valve.

- They are well-suited for on/off applications and are less suitable for precise throttling or flow control compared to plug valves.

Applications:

- Ball valves are widely used in various industries, including oil and gas, water distribution, HVAC systems, and general industrial applications.

- They are preferred for applications requiring bubble-tight shut-off, ease of operation, and minimal maintenance.

Conclusion

- Plug valves are preferred for applications requiring frequent operation, tight shut-off, and moderate flow control.

- Ball valves are suitable for applications requiring quick on/off operation, full-flow shut-off, and minimal pressure drop.

- The choice between plug valves and ball valves depends on factors such as flow control requirements, operating conditions, and the specific needs of the application.

- plug valves are more economical than ball valves, generally, due to their simpler design

- plug valves are less prone to contamination by debris, and accumulation of dirt in the interstitial spaces, compared to ball valves (an issue that is frequently faced by ball valves, due to the spaces existing between the sphere and the body of the valve)

- ball valves require more maintenance than plug valves, especially after planned or unplanned plant shut-downs

- plug valves have a full port design, without pressure drops, ball valves may be reduced or full port (a full port ball valve would be heavier and bulkier than a plug valve of the same size)

In general, plug valves are good alternatives to ball valves, even if ball valves are still considered the industry standard for shut-off operations at least in the oil & gas industry.

PLU VALVES SPECIFICATIONS (ASME/API)

The American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) have established specifications for plug valves to ensure their quality, performance, and compatibility with various industrial applications. Here are some of the key ASME and API specifications relevant to plug valves:

ASME Specifications

ASME B16.34 – Valves Flanged, Threaded, and Welding End: This standard covers the design, materials, dimensions, tolerances, and testing requirements for plug valves, among other types of valves. It provides guidelines for pressure-temperature ratings, end connections, and valve marking.

ASME B16.10 – Face-to-Face and End-to-End Dimensions of Valves: This standard specifies the dimensions and tolerances for the face-to-face and end-to-end dimensions of plug valves, allowing for interchangeability and compatibility with piping systems.

ASME B16.11 – Forged Fittings, Socket-Welding and Threaded: While primarily focused on forged fittings, ASME B16.11 also includes provisions for plug valves with socket-welding or threaded end connections. It covers dimensions, materials, and pressure ratings for these types of valves.

API Specifications

API 6D – Specification for Pipeline Valves: API 6D is a widely used specification for pipeline valves, including plug valves, intended for use in the petroleum and natural gas industries. It covers design, materials, manufacturing, testing, and inspection requirements for pipeline valves.

API 599 – Metal Plug Valves – Flanged and Welding Ends: API 599 specifically addresses metal plug valves, providing requirements for design, materials, dimensions, pressure ratings, testing, and marking. It applies to plug valves with flanged or welding end connections.

API 6A – Specification for Wellhead and Christmas Tree Equipment: While primarily focused on wellhead and Christmas tree equipment for the oil and gas industry, API 6A also includes provisions for plug valves used in these applications. It covers design, materials, dimensions, and testing requirements.

One Response

How can you tell the preferred pressure side on a plug valve?