What is a globe valve? When shall it be used instead of gate and ball valves? In this article, we illustrate the scope of this type of valve (which is, in a word, to regulate the flow), the differences with other types of valve, the alternative designs, and specifications (BS 1873 for the cast steel and API 602/BS 5352 for the forged steel type).

GLOBE VALVE

WHAT IS A GLOBE VALVE?

Definition of Globe Valve

A globe valve is a type of valve used for regulating flow in a pipeline, or to shut off the flow, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body (even if for shut-off operations ball valves and gate valves shall always be preferred).

The term “globe” comes from the valve’s spherical body shape, though the actual shape can vary, especially in modern designs. The key function of a globe valve is to start, stop, or throttle the flow of fluid through a pipeline; it achieves this through the precise positioning of the disk against the valve seat, which forms a gap allowing the fluid to pass through in a controlled manner.

Globe valves are bi-directional valves, different from check valves, meaning that the fluid can flow either way within the valve.

Globe valves offer a reliable solution for flow control applications, combining good sealing capabilities with the ability to precisely regulate flow. Their versatility and efficiency make them a valuable component in various piping systems.

Design and Operation

The basic components of a globe valve include the body, seat, stem, disc, and handwheel or actuator. The valve’s operation is straightforward:

- Turning the handwheel or activating the actuator moves the stem and the attached disc toward or away from the seat.

- When the disc moves towards the seat, it restricts the flow path, reducing flow or stopping it completely when fully closed.

- Moving the disc away from the seat opens the flow path, allowing fluid to pass through.

Key Features

- Flow Regulation: Globe valves excel at regulating flow rates due to their design, which allows for fine adjustments of the disc position.

- Sealing Capability: The close contact between the disc and seat provides good sealing capabilities, minimizing leaks when the valve is closed.

- Directional: Typically, globe valves are used in applications where the flow direction is important, as they are designed to handle flow in one direction, which helps in reducing pressure drop and preventing backflow.

Applications

Globe valves are used across various industries where flow needs to be precisely controlled, including:

- Water and Wastewater Management: For regulating flow and pressure within distribution networks.

- HVAC Systems: In heating and cooling systems for controlling the flow of hot or cold water.

- Chemical and Petrochemical Industries: For managing the flow of various chemicals in processing plants.

- Steam Services: Such as in power plants, where steam flow must be carefully controlled.

Globe Valves Selection Considerations

Selecting the right globe valve for your application involves careful consideration of various factors to ensure optimal performance, reliability, and safety. Globe valves are used for regulating flow in a piping system, and the correct selection is crucial for effective system operation. Here’s a detailed guide on how to select a globe valve:

1. Understand the Application

- Fluid Characteristics: Identify the type of fluid (liquid, gas, corrosive, toxic, etc.) the valve will handle. This determines the material selection for the valve body, trim, and sealing components.

- Pressure and Temperature: Determine the operating pressure and temperature range. This information is crucial for selecting a valve that can withstand the system’s conditions without failure.

- Flow Requirements: Consider the flow rate and the necessity for flow regulation or throttling. Globe valves offer excellent throttling capabilities, but the degree of control required will influence the valve design.

2. Select the Proper Valve Size

- Pipe Size: The valve size should correspond to the pipe size in the system to ensure proper fit and avoid unnecessary pressure drops.

- Cv Value: Calculate the valve’s flow coefficient (Cv) required based on the flow rate, fluid density, and the pressure drop across the valve. The Cv value helps in selecting a valve size that meets the flow requirements without excessive pressure loss.

3. Choose the Valve Body Material

- Compatibility: The valve material must be compatible with the fluid to prevent corrosion. Common materials include carbon steel, stainless steel, bronze, and special alloys for corrosive applications.

- Temperature and Pressure: The material must also be suitable for the operating temperature and pressure. Refer to ASTM, ASME, and other relevant standards for guidance on material properties under specific conditions.

4. Determine the Valve End Connections

- Connection Type: Globe valves are available with flanged, threaded, butt-weld, and socket-weld end connections. The choice depends on the piping system design, pressure rating, and ease of installation or maintenance.

- Standards Compliance: Ensure the selected end connections comply with industry standards, such as ASME B16.5 for flanged connections, to ensure compatibility and integrity in the piping system.

5. Select the Appropriate Trim Material

- Service Conditions: The trim (disc, seat, and stem) material should be selected based on the fluid type, pressure, temperature, and potential for wear or corrosion. The trim material may differ from the body material to optimize performance and lifespan.

- Leakage Class: Consider the required leakage class based on system requirements. Different trim designs offer varying levels of sealing efficiency, affecting the valve’s ability to completely shut off or precisely regulate flow.

6. Actuation Method

- Manual vs. Automated: Decide between manual operation (handwheel or gear operator) and automated actuation (pneumatic, hydraulic, or electric). Automated actuators are preferred for remote control, frequent operation, or where precise control is needed.

- Actuator Sizing: Ensure the actuator is properly sized to operate the valve under all expected conditions, including the maximum differential pressure.

7. Consider Special Features

- Bellows Seal: For toxic or hazardous fluids, consider a globe valve with a bellows seal to prevent stem leakage.

- Cage Guided: Cage-guided trims provide stability to the plugin in high-flow conditions, reducing vibration and wear.

8. Compliance and Certifications

Ensure the globe valve meets relevant industry standards and certifications for safety, performance, and quality. Common standards include ASME, API, and ANSI specifications relevant to globe valves.

9. Consult with Manufacturers or Experts

When in doubt, consult with valve manufacturers or industry experts. They can provide valuable insights and recommendations based on experience with similar applications.

Selecting the right globe valve is a process that requires an understanding of the application requirements, knowledge of valve design principles, and consideration of the operating environment. By systematically addressing these factors, you can ensure the selected globe valve will perform efficiently and reliably in your system.

GLOBE VALVE ADVANTAGES AND DISADVANTAGES

Globe valves, recognized for their ability to regulate flow in piping systems, come with a set of advantages and disadvantages that make them suitable for specific applications while less ideal for others. Understanding these pros and cons is essential for selecting the right valve type for a particular system requirement.

Advantages of Globe Valves

Precise Flow Control: One of the primary advantages of globe valves is their exceptional capability to regulate flow. The design allows for fine adjustments of the disc position, providing superior control over the flow rate.

Good Sealing Capability: Globe valves offer a tight seal when closed, thanks to the close contact between the disc and the seat. This minimizes leaks and ensures effective isolation.

Bi-Directional: While typically used in one direction, globe valves can be designed for bi-directional flow, adding to their versatility in system design.

Availability in Various Designs: Globe valves come in several body designs (Z-body, Y-body, and angle body), each offering specific advantages for different applications, such as minimized pressure drop or enhanced flow control.

Ease of Maintenance: Many globe valve designs allow for easy access to internal components, facilitating maintenance, repairs, and part replacements without removing the valve from the pipeline.

Disadvantages of Globe Valves

Pressure Drop: The biggest drawback of globe valves is the inherent pressure drop across the valve, even when fully open. The flow path through the valve body is not straight, causing changes in flow direction and resistance that result in pressure loss.

Size and Weight: Globe valves tend to be larger and heavier than other valve types (like ball valves) of the same nominal size and pressure class, potentially requiring more space and support in a piping system.

Higher Operating Torque: Due to the design and the need for a tight seal, globe valves may require a higher torque to operate, especially in higher-pressure applications. This can necessitate larger or more powerful actuators.

Cost Considerations: Globe valves can be more expensive than other valve types, particularly in larger sizes, due to their complex design and the materials required for manufacturing.

Not Ideal for Slurry Applications: The tortuous flow path in a globe valve can lead to the accumulation of solids or slurries, which can affect the valve’s operation and lead to wear or damage.

In conclusion, globe valves are highly effective for applications requiring precise flow control and where the benefits of their design outweigh the potential drawbacks, such as in throttling applications and systems where a high degree of flow regulation is needed. However, for applications where pressure drop is a concern or where a straight-through flow path is required, alternative valve types may be more suitable.

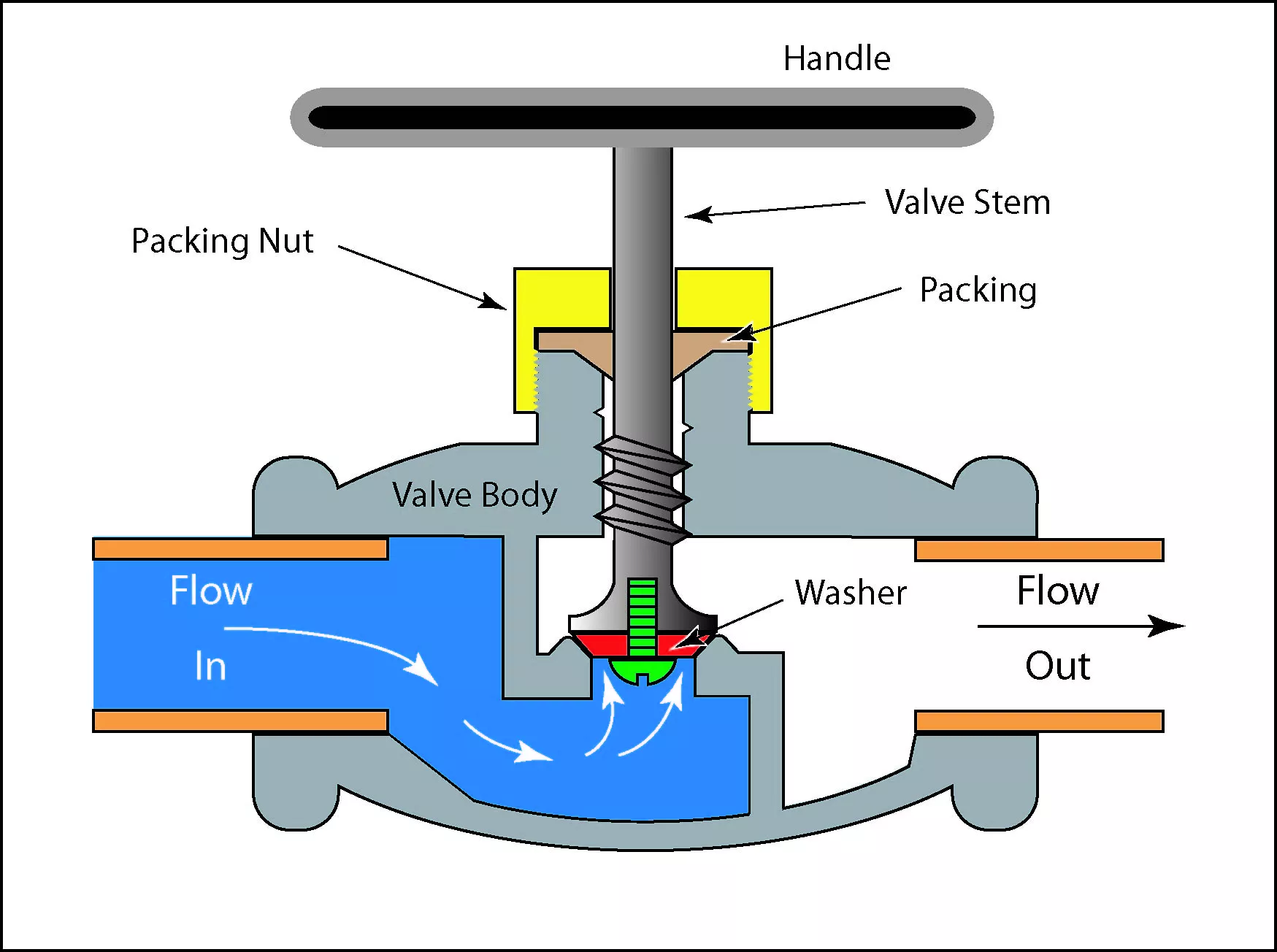

MAIN PARTS OF GLOBE VALVES

A globe valve, widely used for regulating fluid flow in piping systems, consists of several key components that enable its operation and functionality. These main parts include:

1. Body

The body of the globe valve serves as the main structure that houses the internal components. It’s typically spherical or globular in shape, which is where the valve gets its name. The body material varies depending on the application and can include cast iron, stainless steel, brass, and other alloys suitable for specific fluid services.

2. Bonnet

The bonnet is attached to the valve body and provides a leak-proof closure at the top. It encases the stem and other internal parts, protecting them from external elements and containing the fluid pressure. The bonnet can be bolted, screwed, or welded to the valve body.

3. Seat

The seat is a critical component that provides a sealing surface for the disc to rest against when the valve is closed. It’s either integrated into the valve body or designed as a replaceable component. The seat material is selected based on the fluid type, temperature, and pressure, aiming for durability and a tight seal.

4. Disc

The disc, or plug, is the component that moves perpendicular to the flow path to regulate or block fluid flow. In globe valves, the disc can be a solid plug, a ring, or other shapes designed for specific flow characteristics. The disc’s precise positioning against the seat allows for effective flow control.

5. Stem

The stem connects the actuator (such as a handwheel or an electric actuator) to the disc. As the actuator is operated, the stem transmits the motion to the disc, moving it towards or away from the seat to open or close the valve. Stems can be rising (moving up and down with the disc) or non-rising, depending on the valve design.

6. Actuator

The actuator operates the valve, typically through a handwheel, lever, gear mechanism, or an automated actuator (electric, pneumatic, or hydraulic). Manual actuators like handwheels or levers are common for smaller valves or in applications where automatic control is not required.

7. Packing

Packing material is used to create a tight seal around the stem, preventing fluid leakage out of the valve body. It’s usually made from flexible materials like PTFE (Teflon), graphite, or other composites that can withstand the fluid’s temperature and chemical properties.

8. Gland and Gland Flange

The gland and gland flange assembly compresses the packing around the stem to ensure a tight seal. The gland flange allows for adjustments to the packing tightness, ensuring the seal’s effectiveness over time.

Each of these components plays a vital role in the globe valve’s operation, contributing to its ability to precisely control fluid flow, withstand varying pressure and temperature conditions, and maintain a reliable seal in diverse applications.

The image depicts the operation of a globe valve and its primary components: essentially, the flow is controlled by a disc that can be raised (either manually or with actuators) away from the seat, thereby adjusting the amount of flow permitted.

KEY APPLICABLE SPECIFICATIONS (BS, API, ASME)

Globe valves, widely used for flow regulation in piping systems, are subject to various standards and specifications to ensure their reliability, safety, and compatibility across different applications. These standards are set by prominent organizations such as the British Standards Institution (BS), the American Society of Mechanical Engineers (ASME), and the American Petroleum Institute (API). Below is an overview of key BS, ASME, and API specifications applicable to globe valves:

BS (British Standards)

BS 1873: Specifies requirements for steel globe and globe stop and check valves for the petroleum, petrochemical, and allied industries. It covers valve design, materials, pressure-temperature ratings, and testing.

BS 5160: This standard is focused on steel globe valves, globe stop and check valves, check valves, and gate valves for general-purpose applications. It includes details on design, dimensions, testing, and marking.

ASME (American Society of Mechanical Engineers)

ASME B16.34 – Valves – Flanged, Threaded, and Welding End: This standard provides requirements for materials, design, pressure-temperature ratings, and testing for gate, globe, check, ball, and butterfly valves. It is widely referenced for valve specifications in various industries.

ASME B16.10 – Face-to-Face and End-to-End Dimensions of Valves: While not specific to globe valves alone, this standard is crucial for determining the proper installation dimensions for globe valves, ensuring they fit correctly within piping systems.

ASME B16.5 – Pipe Flanges and Flanged Fittings: Relevant for globe valves with flanged connections, this standard specifies dimensions, tolerances, and materials for flanges and flanged fittings, ensuring compatibility with flanged piping systems.

API (American Petroleum Institute)

API 602 – Compact Steel Gate Valves – Flanged, Threaded, Welding, and Extended-Body Ends: Although primarily focused on gate valves, API 602 also covers small-sized, forged carbon steel globe valves used in the petroleum and natural gas industries.

API 598 – Valve Inspection and Testing: This standard outlines the testing and inspection requirements for gate, globe, and check valves, ensuring they meet the required leakage rates and performance criteria.

API 600 – Steel Gate Valves – Flanged and Butt-Welding Ends, Bolted Bonnets: Similar to API 602, API 600, while focused on gate valves, sets the benchmark for quality and performance applicable to globe valves, particularly in terms of design and material specifications for use in the petroleum and natural gas industry.

These BS, ASME, and API specifications cover a wide range of aspects related to globe valves, from design and manufacturing to testing and inspection. Compliance with these standards ensures that globe valves are suitable for their intended applications, offering reliable performance and safety in various industrial environments.

GLOBE VALVE TYPES

Globe valves, recognized for their ability to regulate flow in piping systems, come in various designs tailored to specific applications and flow characteristics. The primary differentiation among globe valve types lies in their internal body design, which impacts flow direction, pressure drop, and application suitability. Here’s a detailed look at the different types of globe valves:

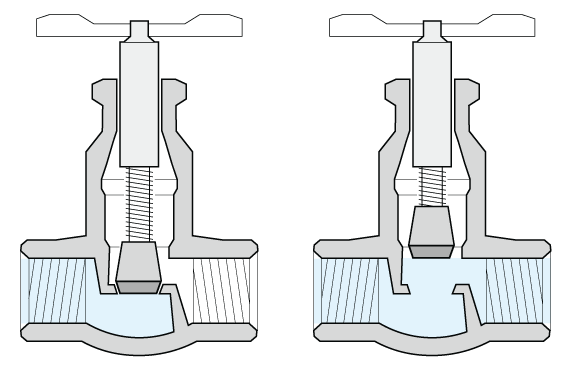

1. Z-Body Globe Valve

The Z-body is the most common and traditional type of globe valve. It features a Z-shaped partition inside the valve body that directs the flow in a Z pattern. The seat and stem are positioned at an angle, typically at 90 degrees to the valve’s pipeline, which allows for a straightforward and effective method to start, stop, and regulate the flow.

- Advantages: Simple design, easy to maintain.

- Disadvantages: Higher pressure drop due to the flow path; not ideal for applications requiring minimal flow resistance.

2. Y-Body Globe Valve (“Wye” Type)

Y-body globe valves are designed to reduce the pressure drop across the valve. The stem and seat are angled at approximately 45 degrees to the pipe axis, which offers a smoother flow path for the fluid. This design is particularly beneficial for high-pressure and high-temperature applications, such as steam services.

- Advantages: Lower pressure drop compared to Z-body valves, suitable for high-pressure conditions.

- Disadvantages: The angled design may complicate installation in some piping configurations.

3. Angle Globe Valve

Angle globe valves have a 90-degree body design that changes the flow direction only once, which helps in reducing the pressure drop. These valves combine the functions of a globe valve and an elbow, making them suitable for applications where space constraints exist or where the piping system requires a directional change.

- Advantages: Efficient flow with reduced pressure drop; can replace both a valve and an elbow in a system.

- Disadvantages: Limited to applications where the change in flow direction is beneficial or required.

4. T-Pattern or Through-Way Globe Valve

The T-pattern globe valve, also known as a through-way globe valve, offers a straighter flow path compared to the Z-body design, resulting in a somewhat lower pressure drop. It’s a variation more akin to traditional globe valves but optimized for better flow dynamics.

- Advantages: Improved flow performance over Z-body designs; good for throttling and regulating.

- Disadvantages: Still presents a higher pressure drop than ball or gate valves.

5. Oblique Pattern Globe Valve

Oblique pattern globe valves feature a body design where the inlet and outlet ports are oriented diagonally to each other, providing a more direct flow path than traditional Z-body designs. This type is less common but can be used in specific applications requiring efficient flow regulation with a moderate pressure drop.

- Advantages: Moderately lower pressure drop compared to Z-body valves; effective for flow regulation.

- Disadvantages: Not as widely available or standardized as other globe valve designs.

Each globe valve type offers distinct advantages for flow control and regulation, with the choice depending on specific application needs, performance requirements, and system design considerations.

The globe valve symbol in P&ID diagrams is the following:

GLOBE VALVE MATERIALS (CAST/FORGED)

Globe valves, utilized extensively for flow regulation in piping systems, can be constructed with either cast or forged body materials. The choice between cast and forged bodies depends on the application’s specific requirements, including pressure, temperature, and the fluid’s nature. Understanding the distinctions between cast and forged materials is crucial for selecting the appropriate globe valve for a particular service environment.

Cast Body Materials

Manufacturing Process: Casting involves pouring molten metal into a mold of the desired shape and allowing it to solidify. This process enables the production of complex shapes and sizes, making it suitable for manufacturing globe valve bodies with intricate internal geometries.

Materials: Common cast materials for globe valves include:

- Cast Carbon Steel (e.g., ASTM A216 WCB): Widely used for moderate temperatures and pressures.

- Cast Stainless Steel (e.g., ASTM A351 CF8M): Offers excellent corrosion resistance, suitable for aggressive media.

- Cast Alloy Steel (e.g., ASTM A217 WC6): Used for high-temperature and high-pressure applications, resistant to thermal fatigue.

Advantages:

- Versatility in design and size.

- Generally more cost-effective for large sizes due to simpler manufacturing for complex shapes.

- Suitable for lower pressure-temperature applications.

Disadvantages:

- Potential for casting defects (e.g., porosity, inclusions), which could affect the valve’s integrity and performance.

- Material properties may be less uniform compared to forged valves.

Forged Body Materials

Manufacturing Process: Forging involves shaping metal under high pressure, typically by hammering or pressing. This process aligns the metal’s grain structure, enhancing its strength and durability.

Materials: Common forged materials for globe valves include:

- Forged Carbon Steel (e.g., ASTM A105): Offers good strength and impact resistance, suitable for general service applications.

- Forged Stainless Steel (e.g., ASTM A182 F316): Provides superior corrosion resistance, ideal for corrosive environments.

- Forged Alloy Steel (e.g., ASTM A182 F11): Used in high-temperature services, offering excellent mechanical properties.

Advantages:

- Higher strength and toughness due to the forging process, make them suitable for high-pressure and high-temperature applications.

- Reduces the likelihood of material defects, ensuring greater reliability and performance.

- More uniform material properties, providing consistent performance.

Disadvantages:

- The range of shapes and sizes is more limited compared to casting, potentially increasing the cost of complex designs.

- Generally more expensive than cast valves, especially for larger sizes, due to the intensive labor and material requirements of the forging process.

Choosing between Cast and Forged Globe Valves

When selecting between cast and forged globe valves, consider the following factors:

- Service Conditions: Forged valves are preferred for severe service conditions involving high pressure and temperature, where material strength and integrity are critical.

- Fluid Properties: Cast valves may be more suitable for applications involving corrosive media, given the availability of various corrosion-resistant alloys.

- Cost Considerations: For large valves or when cost is a significant factor, cast valves might offer a more economical solution.

- Design Complexity: Complex valve designs with intricate internal features are more easily achieved with casting.

Ultimately, the choice between cast and forged globe valves depends on balancing the application’s specific demands with considerations of performance, reliability, and cost.

GLOBE VALVE VS. OTHER TYPES OF VALVE

GLOBE VALVE VS GATE VALVE

Globe valves and gate valves are two widely used valve types in piping systems, each serving distinct functions with specific advantages and applications. Understanding the differences between these two valve types is crucial for selecting the right valve for a particular system requirement.

Design and Operation

Globe Valves: Designed for regulating flow, globe valves feature a movable disk or plug that comes into contact with a stationary ring seat to control flow. The flow path through a globe valve typically changes direction, which provides the valve with good throttling capabilities and the ability to precisely control the flow rate. The movement of the disk is perpendicular to the seat, allowing for fine adjustments of flow.

Gate Valves: Primarily used for on/off control, gate valves have a gate or wedge that moves up and down in the flow path. When the gate valve is fully open, it provides a straight-through passage with minimal obstruction to flow, resulting in a very low-pressure drop. Gate valves are not suitable for throttling purposes because partial opening can cause vibration and rapid wear of the gate and seats.

Applications

Globe Valves: Because of their excellent ability to regulate flow, globe valves are often used in applications where flow needs to be adjusted regularly or where flow rate must be precisely controlled, such as in cooling systems, fuel oil systems, and process control in chemical plants.

Gate Valves: Gate valves are best suited for applications where a valve primarily needs to be either fully open or fully closed and where minimal pressure drop is desired. They are commonly used in water and wastewater treatment, oil and gas pipelines, and other applications where fluid needs to flow freely without obstructions.

Advantages and Disadvantages

Globe Valves:

- Advantages: Excellent for throttling and regulating flow; provide a good seal when closed.

- Disadvantages: The flow path through the valve causes a higher pressure drop compared to gate valves; generally, more expensive due to their complex design.

Gate Valves:

- Advantages: Low-pressure drop when fully open; simpler design usually results in lower costs; suitable for both cryogenic and high-temperature applications.

- Disadvantages: Not suitable for throttling; prone to seat and gate damage if operated partially open; slower to open and close due to the need to move the gate out of the flow path.

Choosing between Globe and Gate valves

When choosing between a globe valve and a gate valve, consider:

- Purpose: If precise flow control or throttling is needed, a globe valve is preferable. For simple on/off control with minimal pressure drop, a gate valve is more suitable.

- Operating Conditions: Consider the system’s pressure, temperature, and the nature of the fluid.

- Cost and Space: Globe valves typically require more space and are more expensive than gate valves due to their design complexity.

In summary, the choice between globe and gate valves depends on the specific needs of the application, including whether flow needs to be precisely controlled or if the primary requirement is the minimal restriction of flow.

GLOBE VALVE VS BALL VALVE

Globe valves and ball valves are two distinct types of control valves used across various industries for fluid management in piping systems. Each valve type offers unique features and operational benefits, making them suitable for specific applications based on the requirements of flow control, pressure drop, and sealing efficiency. Understanding the differences between these valves is crucial for making an informed selection that aligns with system requirements.

Design and Operation

Globe Valves: Globe valves are characterized by their spherical body shape with a baffle that splits the interior space into two chambers. They regulate flow through a movable disk (or plug) and a stationary ring seat. The disk moves perpendicularly to the seat, offering precise control over the flow rate by adjusting the gap between the disk and the seat. Globe valves are primarily designed for throttling and regulating flow.

Ball Valves: Ball valves feature a spherical ball with a hole (or bore) through its center. Rotating the ball 90 degrees around its axis opens or closes the flow path. In the open position, the hole in the ball aligns with the flow path, allowing fluid to pass through with minimal resistance. Ball valves are known for their on/off control but can also provide throttling capabilities when equipped with a control mechanism.

Applications

Globe Valves: Due to their excellent capability to regulate flow, globe valves are commonly used in applications requiring precise flow control, such as in HVAC systems, chemical processing plants, and water distribution networks. They are especially useful where flow needs to be adjusted or maintained at a specific rate.

Ball Valves: Ball valves are versatile and suitable for a wide range of applications, from residential water systems to industrial processes involving gases and liquids. They are preferred for applications requiring a tight seal and quick, reliable on/off operation, such as in gas pipelines and storage tanks. Some specialized ball valves are designed for flow modulation in process control.

Advantages and Disadvantages

Globe Valves:

- Advantages: Excellent for precise flow control and regulation; capable of withstanding high pressure; good sealing capabilities.

- Disadvantages: Higher pressure drop due to the tortuous flow path; generally larger and more expensive than ball valves; slower to operate.

Ball Valves:

- Advantages: Low-pressure drop when fully open; quick and easy to operate with a quarter-turn mechanism; provides a tight seal with low torque.

- Disadvantages: Not as precise for flow control as globe valves; can be prone to cavitation and erosion in throttling applications; limited suitability for slurry applications due to potential clogging.

Choosing between Globe and Ball Valves

When choosing between a globe valve and a ball valve, consider the following:

- Flow Control Requirements: For precise flow regulation, a globe valve is preferable. For on/off control or applications requiring minimal pressure drop, a ball valve is more suitable.

- Operating Conditions: Consider the fluid properties, pressure, temperature, and whether the system requires frequent operation.

- Cost and Space Constraints: Ball valves are typically more compact and cost-effective than globe valves, making them attractive for space-constrained or budget-sensitive applications.

In summary, the choice between globe and ball valves hinges on the specific needs of the application, with globe valves being the go-to option for precise flow control and ball valves offering superior performance for on/off control and applications requiring minimal pressure drop.

GLOBE VALVE VS BUTTERFLY VALVE

Globe valves and butterfly valves serve different purposes in fluid control systems, each with distinct design features, operational advantages, and preferred applications. Understanding the differences between these two types of valves can help in selecting the most suitable valve for a specific application based on the requirements of flow control, pressure drop, sealing efficiency, and cost.

Design and Operation

Globe Valves: Globe valves are characterized by a spherical body with an internal baffle that divides the interior into two chambers. They control fluid flow using a movable disk (or plug) and a stationary ring seat. The disk moves linearly, perpendicular to the flow, allowing for precise flow regulation by adjusting the gap between the disk and the seat. Globe valves are designed primarily for throttling and fine flow control.

Butterfly Valves: Butterfly valves consist of a flat disc that rotates around a central axis within the valve body. Turning the disc 90 degrees opens or closes the valve. When the disc is parallel to the flow, the valve is fully open, and when it is perpendicular, the valve is closed. Butterfly valves are known for their compact design and are used for both on/off control and moderate flow regulation.

Applications

Globe Valves: Ideal for applications requiring precise flow control and where pressure drop is not a significant concern. They are commonly used in water treatment plants, fuel oil systems, and chemical processing industries where the accurate adjustment of flow rate is necessary.

Butterfly Valves: Suitable for a wide range of applications, butterfly valves are often used in large-diameter pipes for water distribution, HVAC systems, and in applications where space and weight are critical considerations. They provide efficient on/off and throttling control with minimal structural support.

Advantages and Disadvantages

Globe Valves:

- Advantages: Excellent for precise flow regulation; good sealing capabilities; suitable for high-pressure applications.

- Disadvantages: Higher pressure drop across the valve due to the tortuous flow path; larger and more expensive compared to butterfly valves; slower to actuate.

Butterfly Valves:

- Advantages: Compact and lightweight design; quick operation with a quarter-turn mechanism; lower cost, especially for large-diameter applications; lower pressure drop when fully open.

- Disadvantages: Not as precise in flow control as globe valves; potential for reduced sealing effectiveness over time, especially in high-pressure applications; can be susceptible to cavitation and flow turbulence.

Choosing between Globe and Butterfly Valves

When choosing between a globe valve and a butterfly valve, consider the following factors:

- Flow Control Requirements: Globe valves are better for situations that require precise flow control. Butterfly valves are more suitable for general on/off and moderate flow regulation applications.

- Space and Weight: Butterfly valves are preferred when space is limited and weight is a concern.

- Pressure Drop: If minimizing pressure drop is essential, butterfly valves offer an advantage due to their straight-through flow design.

- Budget Constraints: Butterfly valves are generally more cost-effective, especially for large pipe diameters.

In summary, the choice between globe and butterfly valves depends on the specific application requirements. Globe valves are ideal for precise flow control in high-pressure systems, while butterfly valves offer a compact, economical solution for on/off and moderate flow regulation in larger pipes and where space constraints exist.

GLOBE VALVE VS PLUG VALVE

Globe valves and plug valves are both commonly used in various industries for controlling fluid flow in piping systems. Each type of valve has distinct features, operational mechanisms, and advantages that make it suitable for specific applications. Understanding these differences is crucial for selecting the right valve for your needs.

Globe Valves

Design and Operation:

- Globe valves are characterized by their spherical body shape, with an internal baffle that splits the interior into two chambers.

- They control flow using a movable disk (or plug) and a stationary ring seat. The disk moves linearly, perpendicular to the flow direction, allowing for precise flow regulation by adjusting the gap between the disk and the seat.

- Primarily designed for throttling and regulating flow, globe valves offer excellent control over flow rate.

Applications:

- Ideal for applications requiring precise flow control, such as cooling systems, fuel oil systems, and chemical processing.

- Commonly used in situations where the flow needs to be adjusted frequently or maintained at a specific rate.

Advantages:

- Excellent for precise flow regulation and control.

- Provides a good sealing capability when closed.

- Suitable for both high-pressure and high-temperature applications.

Disadvantages:

- Higher pressure drop due to the tortuous flow path.

- Larger and more expensive compared to other valve types.

- Not suitable for applications requiring minimal flow resistance or for handling slurries and viscous fluids.

Plug Valves

Design and Operation:

- Plug valves feature a cylindrical or tapered plug with a hole or passage that allows fluid to flow through when aligned with the inlet and outlet ports.

- The plug rotates within the valve body to open or close the flow path. This rotation aligns the port in the plug with the valve body ports.

- Plug valves can be used for on/off control as well as for moderate throttling applications.

Applications:

- Widely used in applications requiring quick and easy operation, such as in water and wastewater treatment, gas services, and in industries where fast isolation is needed.

- Suitable for handling fluids with suspended solids, due to the straight-through flow path.

Advantages:

- Simple and compact design, making them easy to operate and maintain.

- Quick to open and close, providing efficient flow control.

- Generally more resistant to clogging from slurries or viscous fluids compared to globe valves.

Disadvantages:

- Not as precise in flow control as globe valves.

- The sealing surfaces can wear out more quickly, potentially leading to leaks.

- Some designs may have higher torque requirements and can be more difficult to operate under high-pressure conditions.

Choosing between Globe and Plug Valves

When choosing between a globe valve and a plug valve, consider the following:

- Flow Control Needs: Globe valves are preferred for precise flow regulation, while plug valves are better for quick isolation and applications requiring frequent operation.

- Fluid Characteristics: Plug valves are more suitable for fluids with suspended solids, whereas globe valves are ideal for clean liquids or gases.

- Pressure Drop: If minimizing pressure drop is a priority, plug valves may offer an advantage due to their straight-through flow design.

- Application Requirements: Consider the specific requirements of your application, including temperature, pressure, and the need for flow adjustment or quick isolation.

In summary, the choice between globe and plug valves depends on the specific needs of the application, including the level of flow control required, the type of fluid being handled, and operational considerations.

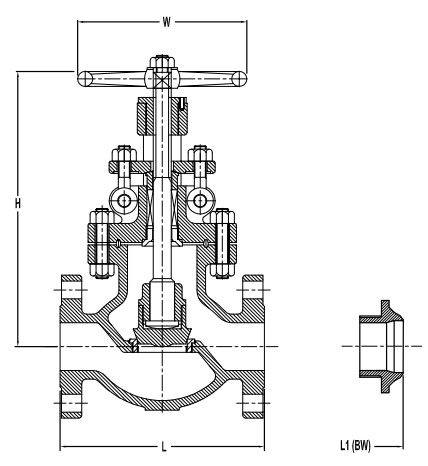

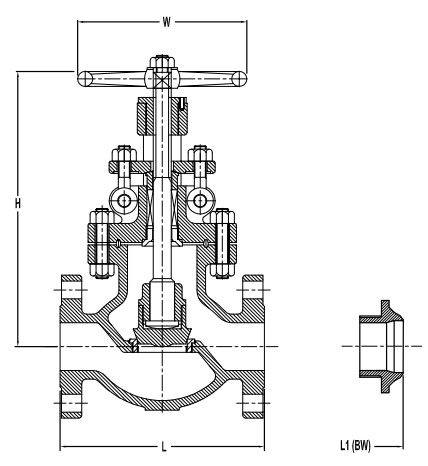

GLOBE VALVE GA DIAGRAM

Note: GA stands for “General Assembly” (drawing).

A general assembly drawing for globe valves is shown in the image:

Nonetheless, a large number of variations exist, depending on the following factors:

- body material: cast (BS 1873) and forged (API 602/BS 5352)

- bonnet design: standard or pressure seal type (for high-pressure applications)

- bonnet to body connection: bolted or welded

- valve end connections type: flanged (as shown in the image), buttweld, socket weld/threaded (forged bodies)

- disc type

- stem type (rising/non-rising)

- seal type: conical or flat

- specification: BS, API, EN

- type of actuation: manual, with a gearbox, with an actuator

GLOBE VALVES DIMENSIONS

The tables show the dimensions and weights of BS 1873 valves, bolted bonnet type.

CLASS 150

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 8 (203) | 13-3/8 (340) | 8-7/8 (225) |

| 2-1/2″ | 8-1/2 (216) | 14-1/2 (368) | 8-7/8 (225) |

| 3″ | 9-1/2 (241) | 16-1/2 (419) | 11-7/8 (302) |

| 4″ | 11-1/2 (292) | 17-3/8 (441) | 12-3/4 (325) |

| 5″ | 14 (356) | 24 (610) | 12-3/4 (325) |

| 6″ | 16 (406) | 24 (610) | 17-3/4 (451) |

| 8″ | 19-1/2 (495) | 26-3/4 (679) | 21-5/8 (549) |

| 10″ | 24-1/2 (622) | 30 (762) | 30 (762) |

| 12″ | 27-1/2 (699) | 33-7/8 (860) | 30 (762) |

| 14″ | 31 (787) | 56 (1422) | 31-1/2 (800) |

| 16″ | 36 (914) | 64 (1626) | 35-1/2 (902) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 10″ AND ABOVE | |||

CLASS 300

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 10-1/2 (267) | 13-3/8 (340) | 9 (229) |

| 2-1/2″ | 11-1/2 (292) | 15-3/8 (390) | 9 (229) |

| 3″ | 12-1/2 (318) | 16-1/2 (419) | 13 (330) |

| 4″ | 14 (356) | 19-3/8 (492) | 14 (356) |

| 5″ | 15-3/4 (400) | 21-1/2 (546) | 15-3/4 (400) |

| 6″ | 17-1/2 (445) | 24-3/8 (619) | 17-3/4 (451) |

| 8″ | 22 (559) | 31-1/4 (794) | 22 (559) |

| 10″ | 24-1/2 (622) | 45 (1143) | 34 (864) |

| 12″ | 28 (711) | 49 (1245) | 34 (864) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | |||

CLASS 600

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 11-1/2 (292) | 15-1/2 (394) | 9-1/2 (241) |

| 2-1/2″ | 13 (330) | 17 (432) | 11 (279) |

| 3″ | 14 (356) | 19 (483) | 13 (330) |

| 4″ | 17 (432) | 21 (533) | 14 (356) |

| 5″ | 20 (508) | 25 (635) | 15-3/4 (400) |

| 6″ | 22 (559) | 26-7/8 (683) | 18 (457) |

| 8″ | 26 (660) | 35 (889) | 20 (508) |

| 10″ | 31 (787) | 49 (1245) | 24 (610) |

| 12″ | 33 (838) | 58 (1473) | 30 (762) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8″ AND ABOVE | |||

CLASS 900

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 14-1/2 (368) | 20-1/2 (521) | 12 (305) |

| 3″ | 15 (381) | 22-3/4 (578) | 14 (356) |

| 4″ | 18 (457) | 26-1/2 (673) | 21-1/2 (546) |

| 6″ | 24 (610) | 36 (914) | 20 (508) |

| 8″ | 29 (737) | 37 (940) | 24 (610) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||

CLASS 1500

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 14-1/2 (368) | 24 (610) | 14 (356) |

| 3″ | 18-1/2 (470) | 26 (660) | 16 (406) |

| 4″ | 21-1/2 (546) | 28 (711) | 18 (457) |

| 6″ | 27-3/4 (705) | 37-1/2 (952) | 24 (610) |

| 8″ | 32-3/4 (832) | 45 (1143) | 24 (610) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||

CLASS 2500

Dimensions in inches (millimeters)

| Sizes | L / L1 | H (Open) | W |

|---|---|---|---|

| 2″ | 17-3/4 (451) | 25-1/2 (648) | 16 (406) |

| 3″ | 22-3/4 (578) | 32-1/2 (825) | 20 (508) |

| 4″ | 26-1/2 (673) | 47 (1194) | 24 (610) |

| 6″ | 36 (914) | 70-1/2 (1790) | 28 (711) |

| 8″ | 40-1/4 (1022) | / | / |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6″ AND ABOVE | |||