A check valve prevents potentially damaging backflows to protect equipment like pumps and compressors. Non-return valves allow the flow of the fluid in one direction only and block reverse flows. This type of valves is available with cast and forged bodies (BS 1868, API 6D, API 602) and in several designs as swing, ball, lift, stop and piston designs.

CHECK VALVE

WHAT IS A CHECK VALVE?

Briefly, a check valve is a protection device that prevents the fluid from flowing in an unwanted direction within the piping system or the pipeline (as backflows may damage upstream equipment).

A check valve, also known as a non-return valve or one-way valve, is a type of valve that allows fluid (liquid or gas) to flow through it in only one direction. Check valves are used to prevent the backflow of fluid, automatically preventing reversed flow when the fluid in the line reverses direction. They are crucial components in various piping systems to ensure the safety and efficiency of operations.

Design and Operation

Check valves operate automatically and most do not have any valve handle or stem. The design of a check valve incorporates a mechanism that opens with forward flow and closes against reverse flow. This mechanism can vary depending on the type of check valve, but common types include ball check valves, swing check valves, and lift check valves:

- Ball Check Valve: Utilizes a ball that rests on a seat within the valve body. Forward flow lifts the ball off the seat, allowing flow, while reverse flow presses the ball back onto the seat, blocking the flow.

- Swing Check Valve: Features a disc or a door that swings on a hinge or a shaft. The disc swings off the seat to permit forward flow and swings back to the seat to block reverse flow.

- Lift Check Valve: Contains a disc or cone that lifts vertically off the seat by the pressure of the forward flow. When the flow stops or reverses, gravity or reverse flow pushes the disc back onto the seat to stop backflow.

Applications

Check valves are used in a wide range of applications to protect equipment, maintain process conditions, and ensure directional flow, including:

- Pump Protection: To prevent backflow that could damage pumps and drive systems.

- Preventing Contamination: To stop backflow in systems where contamination could be a significant issue, such as in potable water supply.

- Pressure Maintenance: In systems where pressure needs to be maintained in one part of the system, preventing fluid from flowing back and reducing pressure.

- Safety Applications: In systems where reverse flow could lead to hazardous conditions or equipment failure, such as in gas supply systems.

Advantages and Limitations

Advantages:

- Automatic operation, requiring no external controls or power.

- Simple design, leading to reliability and ease of maintenance.

- Available in a wide range of sizes and materials, suitable for various applications and fluids.

Limitations:

- Potential for water hammer or surge pressures due to the rapid closing of the valve, especially in fast-flowing systems.

- Limited flow control capabilities since they are designed primarily for preventing backflow rather than regulating flow.

- Possibility of leakage if debris prevents the valve from fully closing.

In summary, check valves play a vital role in ensuring the unidirectional flow of fluids in piping systems, offering protection against reverse flow and its associated problems. Selecting the appropriate type of check valve depends on specific system requirements, including flow rate, pressure, and the nature of the fluid.

Cast steel valves are available with flanged and butt weld ends.

Forged, small-size, valves are available with threaded and socket weld connections.

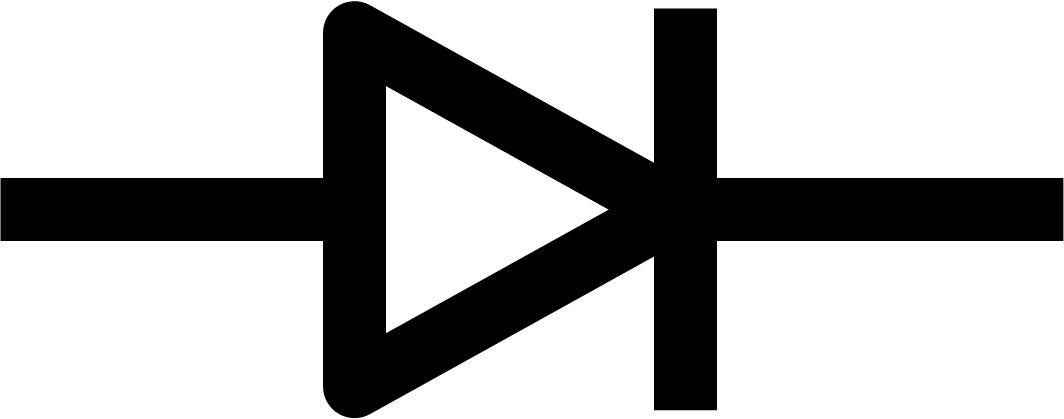

These valves are represented by the following symbol in piping P&ID diagrams:

HOW TO SELECT A CHECK VALVE?

Selecting the right check valve for a particular application requires careful consideration of various factors to ensure optimal performance, reliability, and safety of the piping system. Here’s a step-by-step guide on how to select a check valve:

1. Understand the Application

- Fluid Type: Determine the type of fluid (water, oil, gas, etc.), as this will influence the material selection for the check valve to ensure compatibility and prevent corrosion.

- Flow Conditions: Consider the flow rate, pressure, and temperature of the system. The check valve must be capable of operating effectively under these conditions.

2. Determine the Correct Size

- Pipe Size: The check valve should match the size of the connecting pipe to ensure proper fit and minimize installation issues.

- Flow Requirements: Calculate the required flow rate (Cv) to ensure the valve can handle the system’s flow without causing excessive pressure drop or flow restriction.

3. Select the Valve Type

Based on the application requirements, decide on the type of check valve needed. Common types include:

- Swing Check Valves: Suitable for larger pipe diameters and low-pressure drop applications.

- Ball Check Valves: Ideal for viscous fluids or applications with varying flow rates.

- Lift Check Valves: Best for high-pressure systems where tight sealing is required.

- Wafer Check Valves: Used in space-constrained applications, offering a compact design.

- Dual Plate Check Valves: Provide quick closing to prevent fluid hammer in liquid systems.

Each type of check valve is discussed later in greater detail.

4. Choose the Material

- Body and Trim Material: Select materials that are compatible with the fluid type and the operating conditions (temperature and pressure). Common materials include stainless steel for corrosive fluids, cast iron for water applications, and PVC for chemical services.

- Sealing Material: Ensure the sealing material (e.g., NBR, EPDM, Viton) is suitable for the fluid type and temperature.

5. Consider End Connections

- Connection Type: Choose the appropriate end connection (flanged, threaded, wafer, socket weld, etc.) based on the piping system design and ease of maintenance.

6. Evaluate Special Requirements

- Leakage: Determine the acceptable level of leakage, if any. Some systems may require a zero-leakage valve.

- Orientation: Consider the installation orientation (horizontal, vertical flow up, vertical flow down) as it may affect the valve’s operation.

- Pressure Drop: Minimize pressure drop by selecting a valve with an appropriate flow design.

- Back Pressure: Ensure the system provides sufficient back pressure to close the valve properly.

7. Regulatory and Standards Compliance

- Verify that the check valve meets any applicable industry standards (e.g., API, ASME, ANSI) and regulatory requirements for safety and performance.

8. Manufacturer and Warranty

- Select a reputable manufacturer with proven experience in check valves for similar applications. Review warranty terms and post-sale support.

By systematically addressing these selection criteria, you can ensure that the chosen check valve will perform efficiently and reliably within your specific application, contributing to the overall safety and effectiveness of the piping system.

APPLICABLE SPECIFICATIONS (BS, API, ASME)

The key specifications that cover this type of valve are:

Check valves, critical components in various piping systems, are governed by numerous standards to ensure their reliability, safety, and performance. These standards, set by recognized bodies like the British Standards (BS), the American Petroleum Institute (API), and the American Society of Mechanical Engineers (ASME), specify design criteria, material specifications, testing requirements, and performance characteristics for check valves. Here’s a brief overview of some key BS, API, and ASME specifications applicable to check valves:

British Standards (BS)

BS 1868: Steel Check Valves for the Petroleum, Petrochemical, and Allied Industries

- Specifies requirements for steel check valves with flanged and butt-welding ends, designed for the petroleum, petrochemical, and allied industries. It covers valves of nominal sizes DN 50 to DN 600 and specifies body materials, pressure-temperature ratings, and testing.

BS EN 12334: Industrial Valves – Check Valves of Metallic Materials

- This European Standard specifies requirements for check valves made from metallic materials excluding steel and applies to check valves used for all industrial applications. It includes provisions for nominal sizes, pressure designations, and aspects of design, testing, and marking.

American Petroleum Institute (API)

API 6D: Specification for Pipeline and Piping Valves

- While API 6D covers a broad range of pipeline valves, it includes specific requirements for check valves used in pipeline applications. It addresses aspects like design, materials, testing, and documentation for valves intended for use in the petroleum and natural gas industries.

API 594: Check Valves: Flanged, Lug, Wafer, and Butt-Welding

- API 594 is dedicated to check valves and covers design, materials, face-to-face dimensions, pressure-temperature ratings, and testing for check valves with flanged, lug, wafer, and butt-welding ends. It applies to types A (single plate) and B (double plate).

API 598: Valve Inspection and Testing

- While not specific to check valves, API 598 covers the inspection and testing of all types of valves, including check valves. It outlines the testing methods and acceptance criteria for pressure testing to ensure valve integrity and leak tightness.

API 620: Forged check valves

American Society of Mechanical Engineers (ASME)

ASME B16.34: Valves – Flanged, Threaded, and Welding End

- This standard establishes requirements for materials, pressure-temperature ratings, dimensions, tolerances, and markings for gate, globe, check, ball, and butterfly valves. It includes criteria that check valves must meet for design and construction.

ASME B16.10: Face-to-Face and End-to-End Dimensions of Valves

- ASME B16.10 specifies the face-to-face and end-to-end dimensions of valves, including check valves. This standard ensures compatibility and interchangeability in valve replacements and installations.

ASME B16.25: Buttweld ends

Adherence to these BS, API, and ASME specifications is essential for the proper selection, installation, and maintenance of check valves in various industrial applications. Compliance with these standards guarantees that check valves meet the necessary quality, safety, and performance requirements for their intended use.

CHECK VALVE TYPES

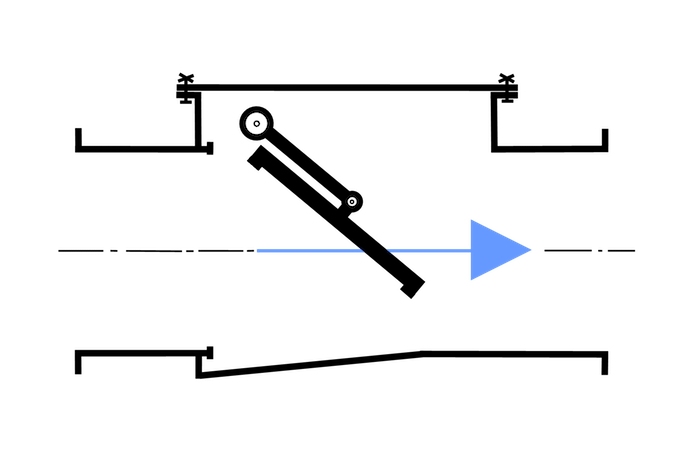

SWING CHECK VALVE

Swing check valves are a type of non-return valve used in piping systems to prevent backflow. They operate automatically, allowing fluid to flow through in one direction and preventing reverse flow. The design and operation of swing check valves make them suitable for a wide range of applications, particularly where low-pressure drop and self-acting backflow prevention are required.

Swing Check Valve Design

The primary components of a swing check valve include:

- Body: The outer casing of the valve, which contains the internal components. It can be made from various materials, including cast iron, steel, stainless steel, and PVC, depending on the application requirements.

- Disc: A movable door-like element that swings on a hinge or a shaft. The disc opens with forward flow and swings back to its closed position when the flow stops or reverses, blocking the flow.

- Seat: The surface against which the disc seals when the valve is closed. The seat can be integral to the valve body or replaceable, and it is often designed to ensure a tight seal to prevent backflow.

- Hinge or Shaft: Enables the swinging motion of the disc. In some designs, a lever and weight or spring mechanism may be added to assist in closing the valve more rapidly or controlling the swing to reduce the water hammer.

Operation

In operation, the pressure of the forward flow pushes the disc open, allowing fluid to pass through the valve. When the flow stops or reverses, the disc swings back to its closed position, either due to gravity or assisted by a lever and weight mechanism, preventing backflow. The simplicity of this mechanism ensures reliability and minimal maintenance.

Advantages

- Low-Pressure Drop: When fully open, swing check valves provide a relatively straight flow path, resulting in a low-pressure drop across the valve.

- Simple and Reliable: The design is straightforward, with few moving parts, contributing to the valve’s reliability and ease of maintenance.

- Versatility: Suitable for a wide range of fluids, including water, oil, and gas, and can be used in various applications, from low to high-pressure systems.

Applications

Swing check valves are commonly used in:

- Water Supply Systems: To prevent backflow and protect equipment like pumps.

- Wastewater Treatment: Where preventing reverse flow is crucial for process integrity.

- Industrial Processes: In chemical, petrochemical, and other industrial plants where backflow prevention is necessary.

Considerations

While swing check valves are suitable for many applications, proper selection involves considering factors like the risk of water hammer (sudden closing can lead to pressure surges), the need for rapid closure, and the compatibility of valve materials with the fluid. Additionally, they are not recommended for pulsating flows as the constant opening and closing may lead to premature wear or failure.

In summary, swing check valves offer a simple, efficient solution for preventing backflow in piping systems, combining low-pressure drop with reliable operation across a broad range of applications.

STOP CHECK VALVE

Stop check valves are specialized valves that combine the features of a check valve and a globe valve, offering both backflow prevention and the ability to manually stop the flow of fluid in a piping system. They provide a unique functionality that allows operators to control the valve’s position, acting as a check valve when left to operate automatically or as an isolation valve when manually adjusted.

Design of Stop Check Valves

The key components of a stop check valve include:

- Body: The outer casing that houses the valve’s internal mechanisms. It can be made of various materials suited to the application’s needs, such as cast iron, stainless steel, or other alloys.

- Disc: A movable element that lifts away from the valve seat to allow flow in one direction and seats back to block flow in the opposite direction. Unlike standard check valves, the disc in a stop check valve can also be manually positioned to fully close, regardless of flow direction.

- Stem: Connected to the disc, the stem can be moved manually (e.g., via a handwheel or actuator) to lift the disc from the seat or to firmly press it against the seat, effectively stopping flow.

- Seat: The area against which the disc seals to prevent backflow or to stop flow entirely when the valve is manually closed.

- Bonnet: The top part of the valve that contains the stem and, in some designs, may house packing material to prevent leaks along the stem.

Operation

In its default mode, a stop check valve functions as a check valve, allowing flow in one direction and automatically preventing backflow by seating the disc against the valve seat under reverse flow conditions. However, the key feature of a stop check valve is its ability to be manually closed by an operator, overriding the automatic function. This is accomplished by turning the handwheel or actuator, which moves the stem and disc into a closed position against the seat, regardless of flow direction or pressure.

Advantages

- Dual Functionality: Provides the benefits of a check valve and a globe valve in a single unit, offering flexibility in applications that require both backflow prevention and flow isolation.

- Manual Override: The ability to manually stop flow, irrespective of system pressure or flow direction, enhances control over the system.

- Safety and Protection: Helps protect against reverse flow that could damage equipment, while also allowing for system maintenance by isolating parts of the system.

Applications

Stop check valves are commonly used in high-pressure and high-temperature applications, such as:

- Boilers: To prevent the backflow of water or steam that could damage the boiler or other equipment in steam systems.

- Power Generation: In feedwater lines, to control flow to steam generators and allow for system isolation for maintenance.

- Process Industries: Where process safety requires both the prevention of backflow and the ability to isolate sections of the system for maintenance or emergency shutdowns.

Considerations

When selecting a stop check valve, it’s essential to consider the fluid characteristics, pressure and temperature conditions, and the specific requirements for flow control and isolation. Additionally, like all valves, regular maintenance is necessary to ensure reliability, especially given the critical safety functions these valves often serve.

In summary, stop check valves offer a versatile solution for systems requiring both backflow prevention and the capability to manually stop flow, making them invaluable in various industrial applications where safety, control, and maintenance are paramount.

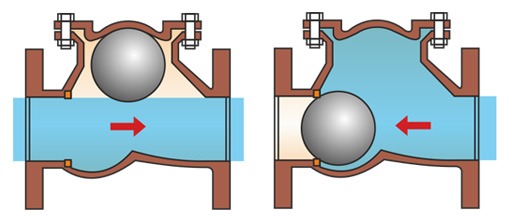

BALL CHECK VALVE

A ball check valve is a type of check valve that uses a ball to prevent backflow in a piping system. It operates automatically, allowing fluid to flow through it in one direction and preventing reverse flow by utilizing a ball that moves within the valve body. Ball check valves are simple, reliable, and effective for a wide range of applications, particularly where viscous fluids or fluids with suspended solids are present.

Design

The key components of a ball check valve include:

- Body: The outer casing of the valve, which can be made from various materials such as cast iron, stainless steel, PVC, or other corrosion-resistant alloys, depending on the fluid characteristics and application requirements.

- Ball: The movable element inside the valve that seals against reverse flow. The ball is typically made of metal, rubber, or plastic. Its material and density are chosen based on the fluid type and the required sealing capability.

- Seat: The surface inside the valve body against which the ball seals when the valve is closed. The seat is often designed to match the contour of the ball for a tight seal and can be made from materials similar to or compatible with the ball.

- Cover or Bonnet: A removable part that provides access to the interior of the valve for maintenance, inspection, or replacement of the ball and seat.

Operation

In operation, forward fluid pressure pushes the ball away from the seat, allowing fluid to flow through the valve. When the fluid flow stops or reverses direction, the ball rolls or is pushed back against the seat by the reverse flow, effectively sealing the valve and preventing backflow. In some designs, a spring or external weight may assist in closing the valve, especially in horizontal installations where gravity alone may not be sufficient to seal the valve.

Advantages

- Versatility: Effective for a broad range of fluids, including liquids and gases, and particularly suitable for viscous fluids and slurries.

- Low Maintenance: The simple design has few moving parts, reducing the risk of malfunction and the need for maintenance.

- Durability: When made with appropriate materials, ball check valves can be highly durable and resistant to wear and corrosion.

- Self-Cleaning: The rolling action of the ball can help dislodge small particles, preventing clogging and ensuring reliable operation.

Applications

Ball check valves are used in various applications, including:

- Wastewater and Sewage Systems: For preventing backflow in sewage lines and treatment facilities.

- Chemical Processing: In systems handling viscous chemicals or fluids with suspended solids.

- Pumping Systems: To prevent reverse flow and protect pumps in water, oil, and other liquid transfer systems.

- Agricultural Irrigation: In irrigation systems to maintain water flow direction and prevent contamination.

Selection Considerations

When selecting a ball check valve, consider:

- Fluid Characteristics: Ensure compatibility with the valve materials to prevent corrosion or degradation.

- Pressure and Temperature: Choose a valve rated for the system’s maximum pressure and temperature conditions.

- Installation Orientation: While ball check valves are versatile, confirm the valve’s suitability for the intended orientation, especially in horizontal lines.

- Valve Sizing: Proper sizing is crucial to minimize pressure drop while ensuring effective backflow prevention.

Ball check valves offer a practical solution for preventing backflow in a wide range of applications. Their simplicity, reliability, and effectiveness make them a preferred choice in systems where maintenance should be minimal, and fluid characteristics are challenging.

Ball check valves belong to the family of “lift valves”, and have a seat design similar to globe valves.

A variant of the ball design is the so-called piston type. This type of valve is used for high-pressure services where the fluid can change direction suddenly and with good force (this because the disc is precisely guided and fits perfectly into the seat).

Ball and piston check valves can be installed both horizontally and vertically.

DUAL PLATE CHECK VALVE

A dual plate check valve, also known as a double door check valve or a butterfly check valve, is an advanced design of the traditional check valve. It operates automatically to prevent the backflow of fluid in a piping system, ensuring flow in only one direction. The valve features two spring-loaded plates (or discs) that open with forward flow and close rapidly to prevent reverse flow, making it an efficient and reliable choice for a wide range of applications.

Design

The key components and design features of a dual plate check valve include:

- Body: The outer shell of the valve that houses the internal components. It can be made from various materials, including cast iron, stainless steel, carbon steel, and other alloys, depending on the application’s specific requirements for pressure, temperature, and corrosion resistance.

- Plates (Discs): Two semi-circular plates are hinged on either side of the valve body, allowing them to swing open or close. The plates are typically lightweight, enhancing their ability to respond quickly to changes in flow direction.

- Springs: Each plate is equipped with a spring that facilitates quick closing of the plates when the forward flow stops or when there is a reversal in flow direction. The springs help in minimizing the risk of water hammer and valve slam.

- Seat: A sealing surface inside the valve body against which the plates close. The seat can be integral to the valve body or replaceable and is designed to ensure a tight seal when the valve is closed.

- Hinge Pins: Pins around which the plates pivot. They are designed to ensure smooth and reliable operation of the plates.

Operation

In operation, forward flow exerts pressure on the plates, causing them to swing open and allow fluid to pass through the valve. The design of the plates and the presence of springs ensure that they open with minimal pressure drop. When the flow decreases or reverses, the springs assist in quickly closing the plates, preventing backflow. The rapid response of the plates helps to significantly reduce the potential for water hammer.

Advantages

- Compact and Lightweight: Dual plate check valves are more compact and lighter than traditional swing check valves, making them easier to install and requiring less support structure.

- Low-Pressure Drop: The design allows for a smoother flow path when open, resulting in a lower pressure drop compared to other types of check valves.

- Quick Closure: The spring-loaded plates close rapidly, reducing the risk of water hammer and backflow.

- Versatility: Suitable for a wide range of applications and can be installed in both horizontal and vertical orientations with upward flow.

Applications

Dual plate check valves are used in various industrial applications, including:

- Water and Wastewater Treatment: To prevent backflow in treatment plants and distribution systems.

- Oil and Gas: In pipelines and processing facilities for protecting equipment and ensuring unidirectional flow.

- HVAC Systems: To prevent reverse flow in heating and cooling systems.

- Process Industries: In chemical, petrochemical, and food and beverage processing plants to protect sensitive equipment and maintain process integrity.

Selection Considerations

When selecting a dual plate check valve, it’s important to consider:

- Fluid Characteristics: Compatibility with the valve materials to prevent corrosion and ensure durability.

- Operating Conditions: The valve’s rating must match the system’s maximum pressure and temperature.

- Installation Space: The compact design is advantageous in tight spaces, but the orientation and location should still be considered for optimal performance.

- Maintenance Requirements: Though generally low maintenance, access for inspection or replacement of components should be considered.

In summary, dual plate check valves offer an efficient and reliable solution for preventing backflow in piping systems, combining compact design with quick operation and low-pressure drop. Their versatility and performance advantages make them suitable for a broad range of applications across various industries.

TITLING DISC CHECK VALVE

A tilting disc check valve is a type of check valve designed to allow fluid to flow in one direction and prevent backflow. It features a disc that tilts on a hinge or pivot point, opening in response to forward flow and closing when the flow stops or reverses. This design offers improved dynamics over traditional swing check valves, making it particularly effective in applications where rapid closure is needed to prevent reverse flow and minimize the risk of water hammering.

Design Features

- Disc Mechanism: The disc in a tilting disc check valve is mounted such that it tilts around a point or axis that is offset from the center of the disc. This allows the disc to open with a smaller amount of fluid pressure compared to swing check valves and to close more quickly as the flow diminishes.

- Seat: The valve seat is designed to provide a tight seal when the disc closes. The seating arrangement can be configured to reduce wear and enhance the sealing capability.

- Body: The valve body can vary in design but is typically streamlined to facilitate smooth fluid flow and minimize pressure drop across the valve.

Operational Advantages

- Quick Response: The tilting mechanism allows for rapid opening and closing of the valve, which helps in preventing the backflow more effectively and reduces the potential for water hammer, a pressure surge caused when a fluid in motion is forced to stop or change direction suddenly.

- Low-Pressure Drop: When open, the valve offers minimal obstruction to the flow, resulting in a lower pressure drop compared to some other check valve designs.

- Long Service Life: The design of the tilting disc check valve, including the way the disc interacts with the flow, can contribute to reduced wear on the valve components, leading to a longer service life.

Applications

Tilting disc check valves are suitable for a wide range of applications, particularly in systems where rapid valve closure is necessary to protect equipment and ensure system integrity. Common applications include:

- Water Supply Systems: Used in high-rise buildings and municipal water distribution networks to prevent backflow.

- Power Generation: Installed in cooling water systems, feedwater systems, and condensate pump discharge lines to prevent reverse flow.

- Process Industries: Utilized in chemical and petrochemical plants, where the prevention of backflow is critical to process safety and efficiency.

- HVAC Systems: Implemented heating and cooling systems to maintain directional flow and system balance.

Selection Considerations

When selecting a tilting disc check valve, consider the following:

- Fluid Characteristics: Ensure the valve materials are compatible with the fluid, including considerations for temperature, pressure, and potential corrosiveness.

- Installation Orientation: While versatile, the specific design of the tilting disc check valve may make it more suitable for certain orientations. Consult manufacturer recommendations.

- Maintenance Requirements: Consider the ease of maintenance and access to internal components, as regular inspection may be necessary to ensure optimal performance.

Tilting disc check valves offer an efficient solution for preventing backflow in fluid systems, combining quick response, durability, and effective operation across a variety of applications.

FOOT CHECK VALVE

A foot check valve is a specific type of check valve designed to be installed at the bottom of a pump suction line, primarily used to maintain the pump’s prime by preventing the backflow of fluid. These valves are typically submerged in the source fluid, such as a well or a tank. Foot check valves are essential components in pumping systems where the pump is located above the fluid level, ensuring a steady and reliable supply of fluid to the pump and preventing the system from running dry.

Design Features

- Body: Foot check valves are commonly made from durable materials such as cast iron, stainless steel, PVC, or bronze, depending on the application and the type of fluid being handled.

- Screen or Strainer: A key feature of foot check valves is the integrated screen or strainer at the inlet. This screen prevents debris, sediment, and other particulates from entering the pump suction line, protecting the pump and the system from damage.

- Valve Mechanism: The valve mechanism can vary but often includes a ball, disc, or flap that opens under the pressure of incoming fluid when the pump operates. When the pump stops, the mechanism seals against a seat to prevent fluid from flowing backward.

Operational Advantages

- Maintains Prime: By preventing the backflow of fluid, foot check valves help maintain the pump’s prime, which is crucial for efficient pump operation and to avoid pump damage due to dry running.

- Filtration: The built-in screen or strainer filters out debris, ensuring that the fluid entering the pump is free from particulates that could cause wear or clogs.

- Versatility: Suitable for a wide range of applications, including water, chemicals, and other fluids, depending on the construction materials.

Applications

Foot check valves are used in various applications where pumps need to draw fluid from a source below the pump, such as:

- Water Supply Systems: In wells, cisterns, or tanks where pumps supply water to residential, agricultural, or industrial systems.

- Irrigation Systems: To ensure a constant supply of water and prevent contamination of the water source by soil or debris.

- Flood Control and Drainage: In pumping stations that remove water from low-lying areas.

- Industrial Processes: Where liquid ingredients or products are transferred from storage tanks into processing systems.

Selection Considerations

When choosing a foot check valve, it’s essential to consider:

- Fluid Compatibility: Select materials that are compatible with the fluid to prevent corrosion or chemical degradation.

- Screen Mesh Size: The mesh size of the screen should be suitable for filtering out debris while allowing sufficient flow to meet the system’s demands.

- Pressure and Flow Requirements: Ensure the valve can handle the system’s pressure and flow rate without causing excessive pressure drop or hindering pump performance.

- Maintenance Accessibility: Consider how easily the valve can be accessed for cleaning or maintenance, especially since foot check valves are often submerged.

In summary, foot check valves play a critical role in pumping systems, providing both a non-return function to maintain the pump prime and a filtration role to protect the pump and the system. Their selection and maintenance are vital for the reliability and efficiency of fluid transfer operations.

PRESSURE SEAL CHECK VALVE

Pressure seal check valves are a type of check valve designed for high-pressure and high-temperature applications, commonly found in power generation, oil and gas, and industrial process systems. Unlike traditional bolted bonnet check valves, pressure seal check valves use a pressure seal bonnet design that ensures a tighter seal as system pressure increases. This design is particularly effective in environments where safety and efficiency are paramount, and where operating conditions can exceed pressures of 600 psi and temperatures above 1000°F (538°C).

Design

The key components of a pressure seal check valve include:

Body: The main structure that contains the internal components. It can be made of materials suited for high pressure and temperature, such as carbon steel, alloy steel, or stainless steel.

Bonnet: Instead of being bolted to the body, the bonnet in a pressure seal valve is sealed using a pressure seal gasket. As system pressure rises, the gasket is further compressed, enhancing the seal between the bonnet and the valve body.

Pressure Seal Gasket: A unique component of pressure seal valves, this gasket is usually made of flexible graphite for high-temperature applications or metal for extremely high pressures. It is designed to ensure a tight seal that improves with increased pressure.

Disc: The movable part that opens to allow flow in the forward direction and seats against the valve seat to prevent backflow. The design of the disc can vary but typically mirrors that of swing or lift check valves.

Seat: The surface against which the disc seals when the valve is closed. It can be integral to the valve body or replaceable, depending on the design.

Operation

In operation, forward flow pressure pushes the disc away from the seat, allowing fluid to pass through the valve. When flow stops or reverses, the disc moves back to the seat, preventing backflow. The unique pressure seal design ensures that as system pressure increases, the seal between the bonnet and the body becomes tighter, which is particularly advantageous in high-pressure applications where ensuring a reliable seal is challenging.

Advantages

- High-Pressure and Temperature Capability: Designed to operate reliably in conditions where standard check valves might fail, making them ideal for critical applications.

- Improved Seal Integrity: The pressure seal design ensures that the valve’s sealing capability improves under higher pressures, providing a robust solution for high-pressure systems.

- Compact Design: Pressure seal valves tend to be more compact than their bolted bonnet counterparts, beneficial in systems where space is limited.

Applications

Pressure seal check valves are used in applications that demand reliable operation under high pressure and temperature, such as:

- Power Generation: In steam, feedwater, and other high-pressure systems within power plants.

- Oil and Gas Production: For high-pressure drilling and production systems.

- Chemical Processing: In processes involving high-pressure reactions or transfers.

Selection Considerations

When selecting a pressure seal check valve, consider:

- System Pressure and Temperature: Ensure the valve material and design are rated for the system’s maximum operating pressure and temperature.

- Fluid Compatibility: Choose materials that are compatible with the fluid to prevent corrosion or degradation of the valve components.

- Maintenance Requirements: While durable, pressure seal valves can be more challenging to maintain due to their design. Consider ease of maintenance and access when selecting a valve.

Pressure seal check valves offer a reliable solution for controlling flow in high-pressure and high-temperature systems, ensuring safety and efficiency in demanding industrial environments.

DUCKBILL CHECK VALVE

A duckbill check valve is a unique type of check valve that gets its name from the duckbill-shaped flexible rubber or elastomer flap that acts as the valve mechanism. This design allows the valve to permit fluid flow in one direction while preventing backflow in the opposite direction. Duckbill check valves are known for their simplicity, reliability, and low maintenance, making them an excellent choice for various fluid control applications, especially where backflow prevention is critical.

IN-LINE CHECK VALVE

An inline check valve, also known as an in-line check valve, is a type of check valve designed for simple, direct installation within the pipeline. Its primary function is to allow fluid (liquid or gas) to flow in one direction only, preventing backflow which could potentially cause damage or disrupt the operation of a system. Inline check valves are known for their compact design, which makes them particularly suitable for applications with limited space.

Design Features

- Compact and Simple: Inline check valves have a straightforward and compact design, allowing for easy installation directly into a piping system without the need for special fittings or extensive modifications.

- Body Construction: The valve body is typically cylindrical and can be made from a variety of materials, including metals like brass, stainless steel, and PVC, to suit different application needs and fluid compatibility.

- Closure Mechanism: The closure component inside an inline check valve varies by design but commonly includes a ball, disc, or piston that moves away from the valve seat to allow flow and seals against the seat to prevent backflow. Some designs use a spring to ensure the closure mechanism responds quickly to changes in flow direction.

- Connection Types: Inline check valves are available with various types of end connections, such as threaded, socket weld, or flanged, to match the piping system requirements.

Operational Advantages

- Low Pressure Drop: Many inline check valve designs are optimized to minimize pressure drop across the valve when it is in the open position, maintaining system efficiency.

- Fast Response to Flow Changes: The simplicity of the design often allows for a quick response to stopping backflow, protecting the system from potential damage.

- Versatility: Inline check valves can be used in a wide range of applications and are compatible with many types of fluids and gases.

Applications

Inline check valves are used across various industries and applications, including:

- Water and Wastewater Systems: To prevent backflow and protect pumps and other equipment.

- Chemical Processing: For ensuring unidirectional flow of chemicals in processing lines.

- HVAC Systems: In heating and cooling lines to maintain proper flow direction.

- Hydraulic and Pneumatic Systems: To prevent reverse flow in systems that rely on pressurized fluids or air.

Selection Considerations

When selecting an inline check valve, consider the following:

- Material Compatibility: Choose a valve material that is compatible with the fluid or gas to prevent corrosion or chemical degradation.

- Operating Conditions: Ensure the valve can withstand the system’s pressure and temperature conditions.

- Flow Requirements: Select a valve size and design that meets the flow rate requirements without causing excessive pressure drop.

- Maintenance and Accessibility: Consider how the valve design will impact maintenance needs and whether it can be easily accessed for service if necessary.

Inline check valves offer a convenient and efficient solution for ensuring unidirectional flow in piping systems. Their compact design, ease of installation, and reliability make them a popular choice for many applications where backflow prevention is critical.

SUMP PUMP CHECK VALVE

A sump pump check valve is a critical component in a sump pump system, designed to prevent the backflow of water from the discharge pipe back into the sump pit after the pump has turned off. Sump pumps are commonly used in basements and crawl spaces to remove accumulated water, preventing flooding and water damage. The check valve ensures that once water is pumped out of the pit and through the discharge line, it does not return, thereby enhancing the efficiency of the pump and reducing the risk of flooding.

Design

The design of a sump pump check valve is relatively simple, comprising a few key components:

- Body: Usually made of durable plastic, PVC, or sometimes metal, designed to withstand the water pressure and any debris that might be present in the water.

- Flapper or Ball: The mechanism inside the valve that allows water to flow in one direction and blocks it from flowing backward. In sump pump check valves, a flapper or a ball is common, which moves or tilts to open when water is pumped through and seals shut when the flow stops.

- Connectors: Ends that attach to the discharge pipe of the sump pump and the discharge line leading away from the house. These can be designed for various types of connections, including threaded, slip-on, or barbed, depending on the installation requirements.

Operation

When the sump pump activates, water pressure opens the flapper or moves the ball, allowing water to pass through the valve and into the discharge line. When the pump shuts off, the decrease in pressure allows the flapper or ball to return to its closed position, creating a seal that prevents water from flowing back into the sump pit. This one-way operation is crucial for maintaining the effectiveness of the sump pump system and preventing cycling (where the pump turns on and off frequently), which can lead to premature pump failure.

Advantages

- Prevents Backflow: Keeps pumped water from returning to the sump pit, reducing the workload on the sump pump and minimizing wear.

- Reduces Cycling: By preventing backflow, it reduces the frequency of pump activation, thereby extending the life of the pump.

- Simple Installation: Most sump pump check valves are designed for easy installation and can be added to existing systems without significant modifications.

Applications

Sump pump check valves are used in residential, commercial, and industrial settings where sump pumps are installed to control water accumulation. These include:

- Basements and Cellars: To prevent flooding from groundwater or stormwater intrusion.

- Crawl Spaces: To manage moisture and prevent water damage.

- Outdoor Drainage Systems: Where pumps are used to move water away from buildings or sensitive areas.

Selection Considerations

When choosing a sump pump check valve, consider:

- Compatibility: Ensure the valve fits the discharge pipe diameter of your sump pump system.

- Material: Select a material compatible with the type of water being pumped, especially if debris or chemicals may be present.

- Valve Type: Consider the mechanism (flapper vs. ball) based on the pump’s flow rate and the head pressure.

- Ease of Maintenance: Some designs allow for easier cleaning and maintenance, which can be beneficial in systems that handle debris-laden water.

In summary, a sump pump check valve is an essential component that enhances the efficiency and longevity of a sump pump system by preventing backflow of water into the sump pit, ensuring that once water is removed, it stays out.

CHECK VALVE MATERIALS (ASME, API)

Materials used for check valves in various industries, particularly those handling critical processes, need to meet specific standards to ensure reliability, safety, and longevity. The American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) provide guidelines and standards for materials used in the manufacturing of check valves. These standards help in selecting materials that are suitable for the intended application, especially considering the operational pressures, temperatures, and fluid characteristics. Below are some key materials standards from ASME and API relevant to check valves:

ASME Material Standards

- ASME B16.34 – Valves – Flanged, Threaded, and Welding End

- This standard covers material requirements for ferrous and non-ferrous valve construction, including temperature and pressure ratings for various materials. It is widely referenced for valve materials in piping systems.

API Material Standards

API 600 – Steel Gate Valves – Flanged and Butt-Welding Ends, Bolted Bonnets

- Though primarily focused on gate valves, API 600 includes material specifications applicable to check valves, especially regarding carbon steel, alloy steel, stainless steel, and other materials for high-pressure and high-temperature service.

API 602 – Compact Steel Gate Valves – Flanged, Threaded, Welding, and Extended-Body Ends

- This standard, while focusing on gate valves, also touches on material specifications for smaller size valves that can be relevant to compact check valves in similar service conditions.

Common Materials for Check Valves

- Carbon Steel: Widely used due to its strength and durability, suitable for a broad range of temperatures and pressures. ASME and API standards specify different grades, such as ASTM A216 WCB, for various service conditions.

- Stainless Steel: Offers excellent corrosion resistance and is used in applications involving corrosive fluids or stringent cleanliness requirements. Common grades include ASTM A351 CF8M (316 stainless steel).

- Alloy Steel: Used for applications requiring higher strength and resistance to high temperatures or pressures. Alloys like ASTM A217 WC6 are commonly specified for services with elevated temperatures.

- Bronze and Brass: Offer good corrosion resistance and are commonly used in low to moderate temperature and pressure applications, such as water, gas, and some chemical services.

- Ductile Iron: Provides good strength, durability, and some corrosion resistance, making it suitable for water and other non-corrosive services at lower costs than steel.

Considerations for Material Selection

- Fluid Service: The material must be compatible with the fluid to prevent corrosion or degradation that could lead to valve failure.

- Pressure and Temperature: The material should withstand the maximum expected pressure and temperature in the system.

- Environment: External environmental conditions, such as exposure to corrosive atmospheres, should also be considered.

By adhering to ASME and API material standards, engineers and specifiers can ensure that check valves will perform reliably and safely in their intended applications, maintaining system integrity and protecting against failure.

CHECK VALVE TRIM

Check valve trim refers to the internal components of a check valve that come into direct contact with the process fluid and are critical to the valve’s operation and performance. The trim typically includes parts such as the disc (or ball), seat, stem (if applicable), and any springs or other mechanisms that contribute to the opening and closing of the valve. The material selection and design of the check valve trim are crucial for ensuring proper function, durability, and compatibility with the fluid being handled.

Components of Check Valve Trim

- Disc or Ball: The movable part that seals against the seat to prevent backflow. In ball check valves, a ball acts as the movable element, whereas other types of check valves may use a disc or other shapes.

- Seat: The surface against which the disc or ball seals when the valve is closed. It can be integrated into the valve body or designed as a replaceable component. The seat must provide a tight seal to effectively prevent backflow.

- Stem: In some types of check valves, such as lift check valves, a stem connects the disc to an actuator or mechanism outside the valve body. The stem facilitates the movement of the disc within the valve.

- Spring: Many check valves incorporate a spring to assist in closing the valve, ensuring quick response to flow changes and helping to prevent flow reversal and water hammer.

Material Considerations

The choice of materials for check valve trim is determined by factors such as:

- Fluid Compatibility: The trim materials must be chemically compatible with the process fluid to avoid corrosion, degradation, or contamination.

- Operating Conditions: The materials must withstand the temperature and pressure conditions of the application without losing structural integrity or performance.

- Wear Resistance: Components like the disc and seat are subject to wear due to repeated opening and closing; thus, materials should be selected for their durability and wear resistance.

Common materials used for check valve trim include:

- Stainless Steel: Offers excellent corrosion resistance and strength, suitable for a wide range of applications.

- Brass: Commonly used in low-pressure applications and compatible with many types of fluids.

- Bronze: Provides good corrosion resistance and is often used in water and steam applications.

- Alloy Steels: Selected for high-pressure, high-temperature applications where additional strength and durability are required.

- Plastics and Composites: Used in applications where corrosion resistance is paramount, such as in aggressive chemical environments.

Selection Guidelines

When selecting check valve trim materials, consider the following:

- Review Fluid Service: Analyze the chemical properties of the fluid, including any potential for corrosion or chemical reaction.

- Assess Operating Conditions: Ensure the materials can handle the maximum expected temperature and pressure.

- Consider Flow Characteristics: For applications involving abrasive or viscous fluids, select materials that resist wear and erosion.

- Compliance with Standards: Ensure that the materials meet relevant industry standards and regulations, such as those set by ASME, API, or NACE for specific applications.

Choosing the appropriate trim materials is essential for the reliability and longevity of check valves, ensuring they function correctly under the intended service conditions and minimize maintenance requirements.

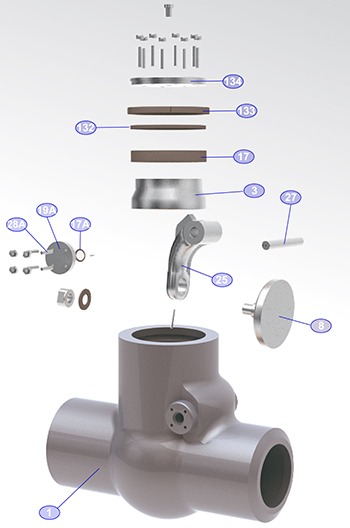

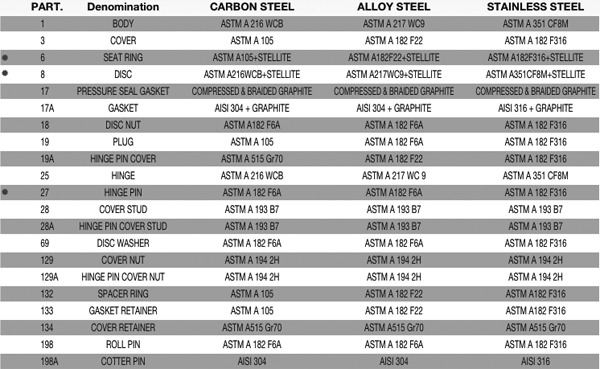

CHECK VALVE GA DIAGRAM

The body of non-return valves below 2 inches is generally made of forged steel (common grades are ASTM A105 for high-temperature service, ASTM A350 for low-temperature service, and, ASTM A182 F304/F316 for corrosive service), whereas the bodies for larger bore sizes check valves are made of cast steel (ASTM A216 WCB for high-temperature service, ASTM A351 for low-temperature conditions and ASTM A351 CF8 and CF8M – i.e. SS304 and SS316).