Discover the essential ASTM material standards for valves. Valves larger than 2 inches typically have cast valve bodies, created by casting molten metals into molds. Forged valve bodies, suitable for smaller or high-pressure valves, are made by shaping and machining solid steel. The principal material specifications for cast steel valve bodies include ASTM A216 (WCA, WCB, WCC) for standard conditions, ASTM A352 LCB/LCC for low temperatures, and ASTM A351 CF8/CF8M for stainless steel valves. For forged valve bodies, the relevant ASTM standards are A105, A350, and A182.

CAST STEEL VALVES (ASTM GRADES)

DEFINITION OF CAST VALVE

DEFINITION OF CAST VALVE

Cast valves are valves whose bodies have been formed by pouring molten metal into a mold where it solidifies into the desired shape. This casting process allows for the creation of complex shapes and sizes, making it possible to produce valve bodies with intricate internal geometries that would be challenging or impossible to achieve through forging or machining alone. Cast valves are widely used across various industries due to their versatility in design, the ability to work with a wide range of materials, and their cost-effectiveness for producing large or complex valves. They are suitable for numerous applications, handling everything from water and steam to chemicals and gas, depending on the material used in the casting process.

Therefore, cast valves are characterized by a body made through casting, whereas forged valves possess a body created by forging. Essentially, the difference between cast and forged valves lies in the method used to construct the valve body material, specifically whether it involves steel forging or casting.

Let’s now delve into the most common cast valve body materials according to ASTM.

ASTM A216 WCA, WCB, WCC (CARBON STEEL FOR HIGH-TEMPERATURE)

ASTM A216 is a specification established by the American Society for Testing and Materials (ASTM) that covers carbon steel castings for valves, flanges, fittings, and other pressure-containing parts for high-temperature service. The standard is divided into three grades: WCA, WCB, and WCC, with WCB being the most commonly used grade.

These 3 grades covered by the ASTM A216 specification differ mainly in their mechanical properties and temperature capabilities:

- WCA is the grade with the lowest strength and temperature tolerance.

- WCB is the intermediate grade, offering a good balance of strength and ductility across a wide range of temperatures.

- WCC has higher strength and impact properties at low temperatures compared to WCB.

ASTM A216 specifies the chemical composition, mechanical properties, heat treatment, and testing requirements to ensure the material’s quality and durability under high-temperature conditions. This standard is commonly applied in the manufacturing of components for industrial boilers, pressure vessels, and other equipment where robust performance at elevated temperatures is required.

The ASTM A216 specification applies to cast valves that match carbon steel pipes in grades A53, A106, and API 5L.

ASTM A216 steel castings shall be heat treated and can be manufactured in annealed, normalized, or normalized tempered conditions. The surface of steel castings shall be free of adhering elements such as sand, cracks, hot tears, and other defects.

| ASTM A216 carbon steel valves (cast), material chart | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A216 GRADE | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| WCA UNS J02502 | 0.25(1) | 0.70(1) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

| WCB UNS J03002 | 0.30(2) | 1.00(2) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

| WCC UNS J02503 | 0.25(3) | 1.20(3) | 0.04 | 0.045 | 0.60 | 0.30 | 0.50 | 0.50 | 0.20 | 1.00 |

Notes:

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% of manganese above the specified maximum is allowed up to a maximum of 1.10%.

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% Mn above the specified maximum is allowed up to a maximum of 1.28%.

- For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.04% of manganese above the specified maximum is allowed to a maximum of 1.40%.

ASTM A352 LCB/LCC (CARBON STEEL FOR LOW-TEMPERATURE)

ASTM A352 is an ASTM (American Society for Testing and Materials) standard specification that covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for low-temperature service. The standard includes several grades of carbon and alloy steel castings that vary in their mechanical properties and chemical compositions to suit different environmental conditions and temperature ranges.

The grades under ASTM A352 are designed to perform reliably in environments where temperatures may fall below freezing, making them suitable for applications in cold climates or in processes requiring cryogenic temperatures.

Key grades within this specification include:

- LCB: A grade of carbon steel castings suitable for low-temperature applications where temperatures can go as low as -46°C (-50°F).

- LCC: Similar to LCB but with improved impact strength at lower temperatures, making it suitable for even more demanding low-temperature environments.

- LC1, LC2, LC3, LC4: These are alloy steel grades within ASTM A352, each designed for specific low-temperature ranges and applications, with LC3, for example, being nickel steel castings intended for service down to -101°C (-150°F).

Each grade specified in ASTM A352 has defined requirements for chemical composition, mechanical properties (such as tensile strength, yield strength, and elongation), and toughness to ensure the castings perform adequately under the specified service conditions. The standard also outlines requirements for heat treatment, quality, and test methods to verify the properties of the castings.

ASTM A352 is widely used in the oil and gas industry, petrochemical plants, and other applications where materials are exposed to low temperatures and require a high level of toughness to prevent brittle fracture.

The ASTM A352 specification applies to cast valves that match carbon steel pipes for low-temperature applications in grades A333.

Chemical composition of A352 cast valves Gr. LCA/LCB/LCC (valve material chart):

| GRADE | C | Si | Mn | Cr | Mo | Ni | Cu | Nb | V |

| ASTM A352 LC3 | 0.15 | 0.6 | 0.65 | 3.5 | |||||

| ASTM A352 LCA | 0.25 | 0.6 | 0.7 | 0.5 | 0.2 | 0.5 | 0.3 | 0.03 | |

| ASTM A352 LCB | 0.3 | 0.6 | 1 | 0.5 | 0.2 | 0.5 | 0.3 | 0.03 | |

| ASTM A352 LCC | 0.25 | 0.6 | 1.2 | 0.5 | 0.2 | 0.5 | 0.03 |

ASTM A351 CF8/CF8M (STAINLESS STEEL FOR HIGH-TEMP. & CORROSIVE SERVICE)

ASTM A351 is a standard specification established by the American Society for Testing and Materials (ASTM) that covers castings of austenitic steel for valves, flanges, fittings, and other pressure-containing parts. This specification is particularly focused on stainless steel castings that are intended for high-temperature service. The ASTM A351 standard includes several grades, each with specific chemical compositions and mechanical properties to suit different environments and applications.

Key grades under ASTM A351 include:

- CF8: Equivalent to 304 stainless steel, this grade is known for its good corrosion resistance and is widely used in general applications.

- CF8M: Equivalent to 316 stainless steel, CF8M offers enhanced corrosion resistance due to its molybdenum content, making it suitable for more corrosive environments such as those encountered in chemical processing.

- CF3 and CF3M: These are the low-carbon versions of CF8 and CF8M, respectively, offering similar corrosion resistance but with improved weldability and reduced susceptibility to intergranular corrosion after welding or heating.

The standard specifies requirements for chemical composition, mechanical properties, heat treatment, and testing procedures to ensure the quality and performance of the castings. ASTM A351 stainless steel castings are commonly used in applications requiring good corrosion resistance at both ambient and elevated temperatures, including the chemical industry, food processing, and petrochemical operations, among others.

Any ASTM A351 cast part shall receive heat treatment followed by a quench in water or rapid cooling. The steel shall conform to the chemical and mechanical requirements set by the specification. The steel shall be made by the electric furnace process with or without separate refining such as argon-oxygen decarburization.

The ASTM A351 specification applies to cast valves that match stainless steel pipes for high-temperature and corrosive applications applications in ASTM A312.

ASTM A351 stainless steel valves, chemical composition

| ASTM A351 GRADE | UNS | C | Mn | Si | S | P | Cr | Ni | Mo | Nb | V | N | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CF3+CF3A | J9270 | 0.03 | 1.5 | 2 | 0.04 | 0.04 | 17.0-21.0 | 8.0-11.0 | 0.5 | ||||

| CF8+CF8A | J9260 | 0.08 | 1.5 | 2 | 0.04 | 0.04 | 18.0-21.0 | 8.0-11.0 | 0.5 | ||||

| CF3M+CF3MA | J9280 | 0.03 | 1.5 | 1.5 | 0.04 | 0.04 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | ||||

| CF8M | J9290 | 0.08 | 1.5 | 1.5 | 0.04 | 0.04 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | ||||

| CF3MN | J92804 | 0.03 | 1.5 | 1.5 | 0.04 | 0.04 | 17.0-21.0 | 9.0-13.0 | 2.0-3.0 | 0.10-.20 | |||

| CF8C | J92710 | 0.08 | 1.5 | 2 | 0.04 | 0.04 | 18.0-21.0 | 9.0-12.0 | 0.5 | -1 | |||

| CF10 | J92950 | 0.04-0.10 | 1.5 | 2 | 0.04 | 0.04 | 18.0-21.0 | 8.0-11.0 | 0.5 | ||||

| CF10M | J92901 | 0.04-0.10 | 1.5 | 1.5 | 0.04 | 0.04 | 18.0-21.0 | 9.0-12.0 | 2.0-3.0 | ||||

| CH8 | J9340 | 0.08 | 1.5 | 1.5 | 0.04 | 0.04 | 22.0-26.0 | 12.-15.0 | 0.5 | ||||

| CH10 | J93401 | 0.04-0.10 | 1.5 | 2 | 0.04 | 0.04 | 22.0-26.0 | 12.-15.0 | 0.5 | ||||

| CH20 | J93402 | 0.04-0.20 | 1.5 | 2 | 0.04 | 0.04 | 22.0-26.0 | 12.0-15.0 | 0.5 | ||||

| CK20 | J94202 | 0.04-0.20 | 1.5 | 1.75 | 0.04 | 0.04 | 23.0-27.0 | 19.0-22.0 | 0.5 | ||||

| HK30 | J94203 | 0.25-0.35 | 1.5 | 1.75 | 0.04 | 0.04 | 23.0-27.0 | 19.0-22.0 | 0.5 | ||||

| HK40 | J94204 | 0.35-0.45 | 1.5 | 1.75 | 0.04 | 0.04 | 23.0-27.0 | 19.0-22.0 | 0.5 | ||||

| HT30 | N08030 | 0.25-0.35 | 2 | 2.5 | 0.04 | 0.04 | 13.0-17.0 | 33.0-37.0 | 0.5 | ||||

| CF10MC | 0.1 | 1.5 | 1.5 | 0.04 | 0.04 | 15.0-18.0 | 13.0-16.0 | 1.7-2.25 | -2 | ||||

| CN7M | N0807 | 0.07 | 1.5 | 1.5 | 0.04 | 0.04 | 19.0-22.0 | 27.5-30.5 | 2.0-3.0 | 3.0-4.0 | |||

| CN3MN | J94651 | 0.03 | 2 | 1 | 0.01 | 0.04 | 20.0-22.0 | 23.5-25.5 | 6.0-.0 | 0.18-.26 | 0.75 | ||

| CE8MN | 0.08 | 1 | 1.5 | 0.04 | 0.04 | 22.5-25.5 | 8.0-11.0 | 3.0-.5 | 0.10-.30 | ||||

| CG-6MMN | J93790 | 0.06 | 4.0-6.0 | 1 | 0.03 | 0.04 | 20.5-23.5 | 11.5-13.5 | 1.50-3.0 | 0.10-.30 | 0.10-.30 | 0.20-.40 | |

| CG8M | J9300 | 0.08 | 1.5 | 1.5 | 0.04 | 0.04 | 18.0-21.0 | 9.0-13.0 | 3.0-4.0 | ||||

| CF10SMnN | J92972 | 0.1 | 7.0-9.0 | 3.50-.50 | 0.03 | 0.06 | 16.0-18.0 | 8.0-9.0 | 0.08-.18 | ||||

| CT15C | N08151 | 0.05-0.15 | 0.15-.50 | 0.50-.50 | 0.03 | 0.03 | 19.0-21.0 | 31.0-.0 | 0.50-.50 | ||||

| CK-3MCuN | J93254 | 0.025 | 1.2 | 1 | 0.01 | 0.045 | 19.5-20.5 | 17.5-19.5 | 6.0-7.0 | 0.18-.24 | 0.50-1.0 | ||

| CE20N | J92802 | 0.2 | 1.5 | 1.5 | 0.04 | 0.04 | 23.0-26.0 | 8.0-.0 | 0.5 | 0.08-.20 | |||

| CG3M | J92999 | 0.03 | 1.5 | 1.5 | 0.04 | 0.04 | 18.0-21.0 | 9.0-.0 | 3.0-4.0 |

Notes:

- Grade CF8C shall have a Niobium content 8 times above the Carbon but not over 1.00%.

- Grade CF10MC shall have a Niobium content 10 times above the Carbon but not over 1.20%.

MECHANICAL PROPERTIES CAST STEEL VALVES CHART

The mechanical properties of cast steel valves are critical to their performance, durability, and suitability for specific applications. These properties depend on the material specifications, such as those outlined by ASTM standards for cast steel. While the exact mechanical properties can vary depending on the specific grade of cast steel and the heat treatment it undergoes, here is an overview of the key mechanical properties typically considered for cast steel valves:

Tensile Strength

- Definition: The maximum stress that a material can withstand while being stretched or pulled before failing or breaking.

- Importance for Valves: High tensile strength is crucial for valves in high-pressure applications to prevent rupture or failure under stress.

Yield Strength

- Definition: The stress at which a material begins to deform plastically. Beyond this point, the material will not return to its original shape automatically.

- Importance for Valves: Adequate yield strength ensures that the valve maintains its integrity and shape under operational pressures, contributing to its reliability and longevity.

Elongation

- Definition: A measure of ductility, specifically the extent to which a material can be stretched before breaking, expressed as a percentage of the original length.

- Importance for Valves: Elongation indicates the valve’s ability to withstand deformation without cracking, important in handling thermal expansions and contractions.

Reduction of Area

- Definition: A measure of ductility determined by the reduction in the cross-sectional area of a material specimen after fracture compared to its original cross-sectional area.

- Importance for Valves: This property helps assess the material’s toughness and resistance to catastrophic failure.

Hardness

- Definition: A measure of a material’s resistance to deformation when subjected to a constant load. It’s often measured using scales such as Brinell, Rockwell, or Vickers.

- Importance for Valves: Hardness affects wear resistance and durability, particularly in valves handling abrasive or corrosive fluids.

Impact Toughness

- Definition: The ability of a material to absorb energy and plastically deform without fracturing. It is typically measured by impact tests, such as the Charpy V-notch test.

- Importance for Valves: High impact toughness is essential for valves in environments where they are subjected to sudden shocks or in low-temperature applications where materials become more brittle.

Creep Strength

- Definition: The resistance of a material to deformation under prolonged exposure to high stress and temperature.

- Importance for Valves: Critical for valves used in high-temperature applications, ensuring they can maintain their shape and functionality over time.

The selection of a cast steel valve with the appropriate mechanical properties is essential for ensuring that the valve can withstand the operational demands of pressure, temperature, and flow media it will encounter in service. These properties are influenced by the material’s composition, the casting process, and any subsequent heat treatments, highlighting the importance of choosing the right material specification and manufacturing processes for each application.

The table summarizes the key mechanical properties of each common grade of ASTM cast steel valves:

| Minimum Steel Mechanical Properties | Modulus | Approximate | ||||

|---|---|---|---|---|---|---|

| ASTM CAST GRADE | Tensile strength (psi) | Yield strength (psi min) | Elongation (at 2 inches) | Reduction of Area (%) | ||

| ASTM A216 Grade WCB | 70,000 | 36,000 | 22 | 35 | 27.9 | 137-1 87 |

| ASTM A352 Grade LCB | 65,000 | 35,000 | 24 | 35 | 27.9 | 137-1 87 |

| ASTM A217 Grade C5 | 90,000 | 60,000 | 18 | 35 | 27.4 | 241 Max. |

| ASTM A217 Grade WC1 | 65,000 | 35,000 | 24 | 35 | 29.9 | 215 Max. |

| ASTM A217 Grade WC6 | 70,000 | 40,000 | 20 | 35 | 29.9 | 215 Max. |

| ASTM A217 Grade WC9 | 70,000 | 40,000 | 20 | 35 | 29.9 | 241 Max. |

| ASTM A352 Grade LC3 | 65,000 | 40,000 | 24 | 35 | 27.9 | 137 |

| ASTM A217 Grade C12 | 90,000 | 60,000 | 18 | 35 | 27.4 | 180-240 |

| ASTM A351 Grade CF-8 | 65,000 | 28,000 | 35 | – | 28 | 140 |

| ASTM A351 Grade CF-8M | 70,000 | 30,000 | 30 | – | 28.3 | 156-170 |

| ASTM A126 Class B | 31,000 | – | – | – | – | 160-220 |

| ASTM A126 Class C | 41,000 | – | – | – | – | 160-220 |

| ASTM A395 Type 60-45-15 | 60,000 | 45,000 | 15 | – | 23-26 | 143-207 |

| ASTM A439 Type D-2B | 58,000 | 30,000 | 7 | – | – | 148-211 |

| ASTM B62 | 30,000 | 14,000 | 20 | 17 | 13.5 | 55-65* |

| ASTM B143 Alloy 1A | 40,000 | 18,000 | 20 | 20 | 15 | 75-85* |

| ASTM B147 Alloy 8A | 65,000 | 25,000 | 20 | 20 | 15.4 | 98* |

| ASTM B148 Alloy 9C | 75,000 | 30,000 | 12 min. | 12 | 17 | 150 |

| (Weldable Grade) | 65,000 | 32,500 | 25 | – | 23 | 120-170 |

| ASTM A494 (Hastelloy B) | 72,000 | 46,000 | 6 | – | – | – |

| ASTM A494 (Hastelloy C) | 72,000 | 46,000 | 4 | – | – | – |

| Stellite No. 6 | 121,000 | 64,000 | 01.feb | – | 30.4 | – |

| ASTM B211 Alloy 20911-T3 | 44,000 | 36,000 | 15 | – | 10.2 | 95 |

| ASTM B16 1/2 Hard | 45,000 | 15,000 | 7 | 50 | 14 | – |

| ASTM B21 Alloy 464 | 60,000 | 27,000 | 22 | 55 | – | – |

| AISI 12L 14 | 79,000 | 71,000 | 16 | 52 | – | 163 |

| ASTM A108 Grade 1018 | 69,000 | 48,000 | 38 | 62 | – | 143 |

| (Suitable for ASTM A193 Grade B7 bolt material) | 135,000 | 115,000 | 22 | 63 | 29.9 | 255 |

| ASTM A276 Type 302 | 85,000 | 35,000 | 60 | 70 | 28 | 150 |

| ASTM A276 Type 304 | 85,000 | 35,000 | 60 | 70 | – | 149 |

| ASTM A276 Type 316 | 80,000 | 30,000 | 60 | 70 | 28 | 149 |

| ASTM A276 Type 316L | 81,000 | 34,000 | 55 | – | – | 146 |

| ASTM A276 Type 410 | 75,000 | 40,000 | 35 | 70 | 29 | 155 |

| ASTM A461 Grade 630 | 135,000 | 105,000 | 16 | 50 | 29 | 275-345 |

| Alloy K500 (K Monel) | 100,000 | 70,000 | 35 | – | 26 | 175-260 |

| ASTM B335 (Hastelloy B) | 100,000 | 46,000 | 30 | – | – | – |

| ASTM B336 (Hastelloy C) | 100,000 | 46,000 | 20 | – | – | – |

ASTM CAST STEEL GRADE SELECTION

Choosing the correct ASTM cast steel grade for valves involves several key considerations to ensure that the valve performs effectively and reliably under the intended service conditions. The selection process must account for factors such as the operating environment, temperature, pressure, fluid characteristics, and specific industry requirements.

Here’s a structured approach to selecting the appropriate ASTM cast steel grade for valves:

1. Assess Operating Conditions

- Temperature: Determine the minimum and maximum temperatures the valve will encounter. For high-temperature applications, grades like ASTM A216 WCB are commonly used, while low-temperature services may require ASTM A352 LCB or LCC.

- Pressure: Consider the pressure range within the system. Higher pressure levels demand materials with greater strength and durability.

2. Identify Fluid Characteristics

- Corrosiveness: If the fluid is corrosive, select a material with high corrosion resistance, such as ASTM A351 CF8M (stainless steel).

- Abrasion: For abrasive fluids, choose a grade with good wear resistance or consider additional treatments like hard facing.

- Toxicity and Cleanliness Requirements: In applications like food processing or pharmaceuticals, materials must not only be resistant to corrosion but also meet strict hygiene standards.

3. Consider Mechanical and Chemical Properties

- Tensile and Yield Strength: Ensure the material has adequate strength to withstand operational stresses.

- Impact Toughness: For applications in colder environments, the material must possess good low-temperature toughness (e.g., ASTM A352 grades).

- Chemical Composition: The alloying elements in the cast steel grade should be compatible with the fluid medium to prevent corrosion and degradation.

4. Compliance with Standards and Regulations

Ensure the selected material grade meets any relevant industry standards and regulatory requirements, such as API specifications for oil and gas applications or FDA guidelines for food contact materials.

5. Evaluate Availability and Cost

Consider the availability of the desired material grade and its cost-effectiveness for the project. While higher grades may offer superior performance, they also tend to be more expensive and may have longer lead times.

6. Consult with Experts

When in doubt, consult with material engineers or valve manufacturers. Their expertise can provide valuable insights into the most suitable material choice for your specific application.

7. Review Past Applications and Case Studies

Look into case studies or historical data from similar applications to understand the performance of different material grades in comparable environments.

By thoroughly evaluating these factors, you can make an informed decision on the most appropriate ASTM cast steel grade for your valve application. This ensures not only the reliability and safety of the valve in its intended service but also its longevity and cost-effectiveness over its operational life.

ASTM CAST STEEL GRADE RECOMMENDED SERVICE

The table shows the most common materials for cast valves and their recommended service:

| MATERIAL GROUP | MATERIAL GRADE | RECOMMENDED SERVICE |

|---|---|---|

| High-temperature Carbon Steel | ASTM A216 Grade WCB | Non-corrosive fluids such as water, oil, and gases at temperatures range -20°F (-30°C) and +800°F (+425°C) |

| Low-temperature Carbon Steel | ASTM A352 Grade LCB | Low temperature to -50°F (-46°C). Use excluded above +650°F (+340°C). |

| Low-temperature Carbon Steel | ASTM A352 Grade LC1 | Low temperature to -75°F (-59°C). Use excluded above +650°F (+340°C). |

| Low-temperature Carbon Steel | ASTM A352 Grade LC2 | Low temperature to -100°F (-73°C). Use excluded above +650°F (+340°C). |

| 3.1/2% Nickel Steel | ASTM A352 Grade LC3 | Low temperature to -150°F (-101°C). Use excluded above +650°F (+340°C). |

| 1.1/4% Chrome 1/2% Moly Steel | ASTM A217 Grade WC6 | Non-corrosive fluids such as water, oil, and gases at temperatures range -20°F (-30°C) and +1100°F (+593°C). |

| 2.1/4% Chrome | ASTM A217 Grade C9 | Non-corrosive fluids such as water, oil, and gases at temperatures range -20°F (-30°C) and +1100°F (+593°C). |

| 5% Chrome 1/2% Moly | ASTM A217 Grade C5 | Mild corrosive or erosive applications and non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C). |

| 9%Chrome 1% Moly | ASTM A217 Grade C12 | Mild corrosive or erosive applications and non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C). |

| 12% Chrome Steel | ASTM A487 Grade CA6NM | Corrosive application at temperatures between -20°F (-30°C) and +900°F (+482°C). |

| 12% Chrome | ASTM A217 Grade CA15 | Corrosive application at temperatures up to +1300°F (+704°C) |

| Stainless steel 316 | ASTM A351 Grade CF8M | Corrosive or either extremely low or high-temperature non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater. |

| Stainless steel 347 | ASTM 351 Grade CF8C | Mainly for high-temperature, corrosive applications between -450°F (-268°C) and +1200°F (+649°C). Above +1000°F (+540°C) specify carbon content of 0.04% or greater. |

| Stainless steel 304 | ASTM A351 Grade CF8 | Corrosive or extremely high temperatures non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater. |

| Stainless steel 304L | ASTM A351 Grade CF3 | Corrosive or non-corrosive services to +800F (+425°C). |

| Stainless steel 316L | ASTM A351 Grade CF3M | Corrosive or non-corrosive services to +800F (+425°C). |

| Alloy-20 | ASTM A351 Grade CN7M | Good resistance to hot sulfuric acid to +800F (+425°C). |

| Monel | ASTM 743 Grade M3-35-1 | Weldable grade. Good resistance to corrosion by all common organic acids and salt water. Also highly resistant to most alkaline solutions to +750°F (+400°C). |

| Hastelloy B | ASTM A743 Grade N-12M | Well suited for handling hydrofluoric acid at all concentrations and temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C). |

| Hastelloy C | ASTM A743 Grade CW-12M | Good resistance to span oxidation conditions. Good properties at high temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C). |

| Inconel | ASTM A743 Grade CY-40 | Very good for high-temperature service. Good resistance to spangly corrosive media and atmosphere to +800°F (+425°C). |

| Bronze | ASTM B62 | Water, oil, or gas: up to 400°F. Excellent for brine and seawater service. |

We recommend purchasing the ASTM A216 specification from the ASTM website or the IHS store to get a complete understanding of this topic.

FORGED STEEL VALVES (ASTM GRADES)

DEFINITION OF FORGED VALVE

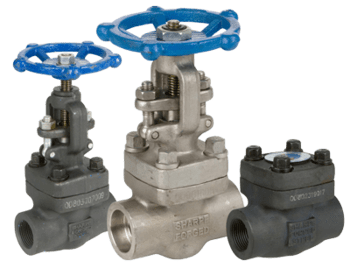

A forged valve is a type of valve whose body is made from forged steel. Forging involves heating a piece of metal until it becomes malleable and then applying force to shape it into the desired form, often using a hammer or press. This process aligns the grain structure of the metal, enhancing its strength, durability, and resistance to impact and fatigue compared to casting. Forged valves are known for their robust construction and are especially valued in applications requiring high pressure and temperature conditions. They are commonly used in the oil and gas, petrochemical, power generation, and marine industries, among others, where safety and performance are critical. The forging process allows for the production of valves with fewer defects and more consistent properties throughout the material, providing a reliable solution for controlling fluid flow under demanding operational conditions.

Forged valves feature a body obtained by forging monolithic blocks of steel.

Forged bodies are common for smaller-diameter valves (generally, below 2 inches) or for high-pressure valves that require extreme robustness and solidity (regardless of the valve bore size). Forged bodies are less prone to leakages than cast valve body materials.

The ASTM A105, ASTM A350, and ASTM A182 specifications cover materials for carbon, low-alloy, and stainless steel forged valves (the same specifications apply to other forged piping components, such as flanges for example).

ASTM A105 (CARBON STEEL FOR HIGH-TEMPERATURE)

ASTM A105 stands out as a critical specification for carbon steel forgings, including forged valves, in piping systems. This standard, established by the American Society for Testing and Materials (ASTM), outlines the chemical composition, mechanical properties, and other critical criteria for forgings used in high-temperature service. This article delves into the specifics of ASTM A105, highlighting its significance, applications, and key characteristics that make it suitable for forged valves in demanding industrial environments.

The Significance of ASTM A105

ASTM A105 specifies the manufacturing process, chemical composition, mechanical properties, and testing requirements for carbon steel forgings for piping applications. It is designed for components that will operate in ambient and higher-temperature service conditions. Given its robustness and versatility, ASTM A105 is widely recognized and utilized across various sectors, including oil and gas, chemical processing, power generation, and more.

Key Characteristics of ASTM A105

- Chemical Composition: ASTM A105 steel is characterized by a significant amount of carbon, which enhances its strength and heat resistance, making it ideal for high-temperature environments. The standard also specifies allowable contents for manganese, phosphorus, sulfur, and silicon, ensuring a balance between strength, weldability, and ductility.

- Mechanical Properties: ASTM A105 forged valves are known for their high tensile strength and yield strength, enabling them to withstand internal pressures without deforming. The material also exhibits adequate elongation, ensuring it can endure stretching and bending forces during installation and operation.

- Heat Treatment: The forging process followed by heat treatment enhances the material’s mechanical properties. Heat treatment processes, such as normalizing, tempering, or quenching, refine the grain structure of the steel, improving its toughness and resistance to impact and wear.

- Weldability: Despite its high carbon content, ASTM A105 steel maintains good weldability under proper conditions. This allows for the fabrication of complex piping systems where components need to be securely welded together.

Applications of ASTM A105 Forged Valves

ASTM A105 forged valves are employed in a wide array of high-pressure and high-temperature applications. Their durability and resistance to heat make them suitable for:

- Oil and Gas Industry: For controlling the flow of oil, natural gas, and by-products, where pressure and temperature conditions can be extreme.

- Chemical Processing: In environments handling corrosive substances and requiring reliable operation over a broad temperature range.

- Power Generation: For steam and water control in boilers, turbines, and auxiliary systems where operational reliability is critical.

Water Treatment and Distribution: Where valves must withstand varying pressures and temperatures without compromising performance or safety.

Advantages of ASTM A105 Forged Valves

- Durability and Reliability: The forging process, coupled with the material properties of ASTM A105, results in valves that are highly durable and reliable under harsh operating conditions.

- Safety: ASTM A105 forged valves provide a secure and leak-proof solution in high-pressure systems, reducing the risk of accidents and environmental pollution.

- Cost-Effectiveness: Despite their high performance, ASTM A105 forged valves are relatively cost-effective, especially when considering their lifespan and reduced maintenance requirements.

- Standardization: Compliance with ASTM A105 ensures that materials and components meet recognized industry standards, facilitating compatibility and interchangeability in piping systems.

Chemical composition of ASTM A105

| C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | |

| A105 | – | 0.60 | – | – | 0.10 | – | – | – | ||

| 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Mechanical Properties of ASTM A105

| Property | ASTM A105 | ASTM A350-LF2 |

| Tensile Strength Min, psi | 70,000 | 70,000-95,000 |

| Tensile Strength Min, N/mm² | 485 | 485-655 |

| Yield Strength Min, psi | 36,000 | 36,000 |

| Yield Strength Min, N/mm² | 250 | 250 |

| Elongation (%) | 22 | 22 |

| Reduction of Area (%) | 30 | 30 |

| Hardness, maximum | 187 | 15/12 ft-lbs |

| CVN at -50℉ | 20/16 joules | |

ASTM A350 (CARBON STEEL FOR LOW-TEMPERATURE)

ASTM A350 is a specification issued by the American Society for Testing and Materials (ASTM) that covers several grades of carbon and low-alloy steel forged or ring-rolled flanges, forged fittings, and valves intended primarily for low-temperature service and requiring notch toughness testing. These materials are suitable for use in environments where the temperature may go below -29°C (-20°F), making them ideal for applications in cold climates or processes involving cryogenic temperatures.

Key Features of ASTM A350

Notch Toughness: One of the defining characteristics of the ASTM A350 specification is its requirement for notch toughness testing, which ensures that the material possesses adequate resilience and strength at low temperatures. This makes it especially suitable for piping systems that need to remain operational and leak-free even under freezing conditions.

Chemical Composition ASTM A350

ASTM A350 specifies strict chemical composition limits for each grade, ensuring that the steel has the desired properties for low-temperature service. The composition affects the steel’s weldability, toughness, and resistance to corrosion and wear.

| C% | Mn% | Si% | S% | P% | Cr% | Ni% | |

| A350 LF1 | 0.30 max | 0.6/1.35 | .15/.30 | .040 max | .035 max | 0.30 max | 0.40 max |

| A350 LF2 | 0.30 max | 0.6/1.35 | .15/.30 | .040 max | .035 max | 0.30 max | 0.40 max |

| A350 LF3 | 0.20 max | 0.9 | .20/.35 | .040 max | .035 max | 0.30 max | 3.3/3.7 |

Mechanical Properties

The specification outlines minimum mechanical properties, including tensile strength, yield strength, elongation, and impact values. These properties ensure that materials under this specification can withstand the pressures and stresses encountered in low-temperature environments without failing.

| ASTM A105 | ASTM A350-LF2 | |

| Tensile Strength Min, psi | 70,000 | 70,000-95,000 |

| Tensile Strength Min, N/mm² | 485 | 485-655 |

| Yield Strength Min, psi | 36,000 | 36,000 |

| Yield Strength Min, N/mm² | 250 | 250 |

| Elongation (%) | 22 | 22 |

| Reduction of Area (%) | 30 | 30 |

| Hardness, maximum | 187 | 15/12 ft-lbs |

| CVN at -50℉ | 20/16 joules | |

Grades within ASTM A350

ASTM A350 includes several grades, with LF2 and LF3 being among the most commonly used for valve manufacturing. Here’s a brief overview:

- LF1, LF2, LF3: These are low-alloy steels with varying nickel content, designed for different minimum temperature services. LF2 is particularly popular for general low-temperature service, providing a good balance of toughness and strength.

- LF6: Classified under several classes, LF6 is intended for low-temperature applications requiring corrosion resistance.

- LF9: A grade with a higher alloy content, offering improved strength and toughness.

- LF787: A more recent addition, providing enhanced toughness and weldability.

Applications of ASTM A350 Forged Valves

ASTM A350 forged valves are widely used in industries where low-temperature performance and notch toughness are critical. These include:

- Oil and Gas: Especially in areas with cold climates or offshore platforms where temperatures can drop significantly.

- Chemical Processing: In processes involving cryogenic substances or where chemical reactions require low temperatures.

- Power Generation: For systems involving liquified natural gas (LNG) or other cryogenic fluids.

- Cryogenic Services: In applications involving the storage and transportation of liquified gases like nitrogen, oxygen, and argon.

Advantages of ASTM A350 Forged Valves

- Durability in Low Temperatures: These valves maintain their strength and toughness even in extremely low temperatures, reducing the risk of cracks and failures.

- Versatility: The variety of grades within the ASTM A350 specification allows for selection based on specific application requirements, such as desired mechanical properties and environmental conditions.

- Safety: The notch toughness requirement ensures that the valves can handle sudden stresses and shocks without fracturing, enhancing the safety of the system.

Conclusion

ASTM A350 is a critical material specification for forged valves in low-temperature applications, offering a combination of toughness, strength, and resistance to brittle fracture. Its strict requirements ensure that materials used in valve construction are capable of performing reliably in harsh conditions, providing a safe and efficient solution for industries operating in cold environments or with cryogenic processes.

ASTM A182 (STAINLESS STEEL)

ASTM A182 is a specification established by the American Society for Testing and Materials (ASTM) that covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service.

The standard is intended for use in high-pressure and high-temperature environments, offering a wide range of alloys to suit various service conditions, including corrosive and high-temperature applications.

Key Features of ASTM A182

- Versatility: ASTM A182 includes a broad array of alloy compositions, enabling its use across numerous applications requiring high strength, durability, and resistance to harsh environments.

- High-Temperature Service: The materials specified under ASTM A182 are designed to operate efficiently in high-temperature settings, making them suitable for use in the power generation, chemical processing, and oil and gas industries.

- Corrosion Resistance: Many of the stainless steel and alloy grades covered by ASTM A182 offer excellent corrosion resistance, crucial for applications involving corrosive fluids or environments.

Grades within ASTM A182

ASTM A182 specifies several grades of alloy and stainless steel. Some of the most commonly used grades include:

- F304/F304L and F316/F316L: These austenitic stainless steel grades are widely used due to their excellent corrosion resistance and mechanical properties. The “L” denotes a lower carbon content, which enhances corrosion resistance after welding.

- F11, F22, and F91: These are low alloy steels with varying contents of Chromium and Molybdenum, providing different levels of strength, corrosion resistance, and suitability for high temperatures.

- F51, F53, F55: Duplex and super duplex stainless steel grades known for their high strength and excellent resistance to chloride-induced stress corrosion cracking.

Applications of ASTM A182 Forged Valves

Valves manufactured according to ASTM A182 are found in a wide range of applications, including:

- Oil and Gas: Used in both upstream and downstream processes where high strength and corrosion resistance are necessary.

- Chemical Processing: For handling acidic or basic chemicals, as well as organic solvents at high temperatures.

- Power Generation: In steam and water control systems within power plants, including nuclear reactors.

- Marine Applications: Especially in environments where corrosion resistance is critical due to saltwater exposure.

Advantages of ASTM A182 Forged Valves

- Durability: The forging process combined with high-quality alloy steel results in valves with superior strength and durability, capable of withstanding high pressures and temperatures.

- Corrosion Resistance: The specification includes stainless steel and alloys that offer excellent resistance to a wide range of corrosive environments and media.

- Customizability: With a wide variety of grades available, ASTM A182 allows for the selection of materials specifically tailored to the demands of the application, ensuring optimal performance.

Conclusion

ASTM A182 is a comprehensive specification that provides a framework for the production of high-quality forged valves suited for high-temperature and high-pressure applications. Its wide range of alloy and stainless steel grades ensures that there is a material option available for nearly any challenging industrial application, combining strength, corrosion resistance, and durability to meet the rigorous demands of modern industrial environments.

Chemical Composition ASTM A182

| ASTM A182 Forged Steel Valves Materials Composition, % | |||||||||||

| ASTM A182 GRADE | C | Mn | P | S | Si | Ni | Cr | Mo | Nb | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| F304(1) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-13.0 | 18.0-20.0 | ||||

| F304N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F304LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F309H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 12.0-15.0 | 22.0-24.0 | ||||

| F310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310MoLN | 0.030 | 2.0 | 0.030 | 0.015 | 0.40 | 21.0-23.0 | 24.0-26.0 | 2.0-3.0 | N 0.10-0.16 | ||

| F316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316Ti | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | (3) | N 0.10 max | |

| F317 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F317L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (4) | |||

| F321H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (5) | |||

| F347 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | |||

| F347H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | |||

| F348 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | Co 0.20 Ta 0.10 | ||

| F348H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | Co 0.20 Ta 0.10 | ||

Notes:

- Grades F304, F304L, F316, and F316L shall have a maximum Nitrogen of 0.10%.

- Grades F304N, F316N, F304LN, and F316LN shall have a Nitrogen of 0.10 to 0.16%.

- Grade F316Ti shall have a Titanium content five times above the Carbon plus Nitrogen and not more than 0.70%.

- Grade F321 shall have a Titanium content five times above the Carbon and not more than 0.70%.

- Grade F321H shall have a Titanium content four times above the Carbon and not more than 0.70%.

- Grades F347 and F348 shall have a Niobium content ten times above the Carbon and not more than 1.10%.

- Grades F347H and F348H shall have a Niobium content above than eight times the Carbon and not more than 1.10%.

Mechanical Properties ASTM A182

| ASTM A182 Grade | Minimum Tensile Strength in MPa | Minimum Yield point in Mpa | Minimum Elongation in % | Minimum Reduction of in min, % |

| ASTM A182 F304 | 515 | 205 | 30 | 50 |

| ASTM A182 F304L | 485 | 170 | 30 | 50 |

| ASTM A182 F316 | 515 | 205 | 30 | 50 |

| ASTM A182 F316L | 485 | 170 | 30 | 50 |

| ASTM A182 F321 | 515 | 205 | 30 | 50 |

RECOMMENDED SERVICE FORGED STEEL VALVES

The table shows the most common materials for forged valves and their respective recommended service:

Forged Material Grade

| ASTM Grade | Material Name | Recommended Service |

| 304 | 19%Chrome 9%Nickel | Applications at temperatures up to +1000°F (+538°C). |

| 316 | 19%Chrome, 10%Nickel 2%Moly | Applications at temperatures up to +1000°F (+538°C). |

| 321 | 18%Chrome, 10%Nickel with Titanium | Applications at temperatures up to +800°F (+427°C). |

| 347 | 18%Chrome, 10%Nickel with Columbium | 347 has good intergranular-corrosion resistance and is resistant to atmospheric conditions between temperatures of +800°F(+427°C) and +1650°F(+899°C). |

| 400 | Monel | This nickel alloy has good corrosion resistance, good weldability, and, high strength. Great mechanical properties at subzero temperatures up to +1000°F (+538°C). |

| 410 | 13%Chrome 1/2%Moly | 410 is the basic martensitic stainless. It has good impact strength, corrosion, and scaling resistance up to +1200°F (+649°C). |

| 420 | 13%Chrome, 1%Nickel 1/4%Moly | Full corrosion resistance only in the hardened or hardened and stress-relieved conditions. The temperature should be below +800°F (+427°C). |

| 600 | Inconel | This nickel-chromium alloy has good oxidation resistance at higher temperatures to +2000°F (+1093°C) |

| 625 | Inconel | This nickel-chromium alloy has good carburization and oxidation in high resistance at higher temperatures to +2000°F (+1093°C). |

| 825 | Incoloy | Alloy 825 has a high level of corrosion resistance in both reducing and oxidizing environments and good mechanical properties at temperatures up to +1000°F (+538°C). |

| 17-4PH | 15-1/2%Chrome 4-1/2%Nickel | Good corrosive resistance properties at temperatures up to +600°F (+316°C). |

| 304H | 18%Chrome 9%Nickel | Applications at temperatures up to +800°F (+427°C). |

| 304L | 19%Chrome, 10%Nickel Low Carbon | Applications at temperatures up to +800°F (+427°C). |

| 316H | 18%Chrome, 8%Nickel with Molybdenum | Applications at temperatures up to +800°F (+427°C). |

| 316L | 19%Chrome, 10%Nickel 2%Moly, Low Carbon | Applications at temperatures up to +800°F (+427°C). |

| 317L | 25%Chrome, 21%Nickel 3/4%Moly | 317L has superior corrosion resistance in difficult environments and can be used at temperatures between +1700°F (+927°C) to +2200°F (+1204°C). |

| 440C | 17%Chrome 3/4%Moly | This grade is used in the hard plus tempered condition. For best corrosion resistance, the tempering temperature should be below +800°F (+427°C). |

| 800H/HT | Incoloy | This nickel-chromium alloy has good carburization and oxidation in high resistance and is normally used in temperatures above +1100°F (+593°C). |

| A105N | 1/4% Max Carbon Steel | Non-corrosive applications include water, oil, and, gases at temperatures between -20°F (-30°C) and +800°F (+427°C). |

| ALLOY 20 | 20%Chrome, 35%Nickel 2-1/2%Moly | Good resistance to hot sulfuric acid to +800°F (+425°C). |

| C276 | Hastelloy | This nickel-molybdenum-chromium alloy has excellent corrosion resistance in a wide range of corrosive media and corrosion resistance to ambient temperatures. |

| F11 | 1-1/4%Chrome 1/2%Moly | Non-corrosive applications include water, oil, and, gases at temperatures between -20°F (-30°C) and +1100°F (+593°C). |

| F22 | 2-1/4%Chrome 1%Moly | Non-corrosive applications include water, oil, and, gases at temperatures between -20°F (-30°C) and +1100°F (+593°C). |

| F5 | 5%Chrome 1/2%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| F51 | 22%Chrome, 5%Nickel 3%Moly | F51 is a super duplex stainless steel. Good Moderate to good corrosion resistance in a variety of environments. Service to +600°F (+316°C). |

| F53 | 25%Chrome, 7%Nickel 4-1/2%Moly | F53 is a super duplex stainless steel. This material has excellent corrosion resistance in a variety of environments. Service to +600°F (+316°C). |

| F55 | 25%Chrome, 7%Nickel 3-1/2%Moly | This material combines high mechanical strength and good ductility with excellent corrosion resistance in environments with temperatures up to +600°F (+316°C). |

| F9 | 9%Chrome 1%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| F91 | 9%Chrome 1%Moly | Non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+650°C). |

| K500 | Monel | This nickel alloy has good corrosion resistance. Monel K500 has great mechanical properties at subzero temperatures up to about +480°C. |

| LF2 | Low-Temp Carbon Steel | Non-corrosive applications at temperatures from -50°F (-46°C) to +800°F (+427°C). |

| X-750 | Inconel | This nickel-chromium alloy has good resistance to corrosion and oxidation along with high tensile and creep-rupture properties at temperatures up to +1300°F (+700°C). |

CROSS REFERENCE CHART: ASTM CAST VS. FORGED MATERIALS

The table shows the equivalent grades for cast and forged steel valve bodies:

| Material Group | Forged Grade | Equivalent Cast Grade |

| Carbon Steel | A181-Gr.1 A181-Gr.2 | |

| Moderate, high temp. service | A105-Gr.1 A105-Gr.2 | A216-WCA WCB WCC |

| Cold temp. service | A350-LF1 A350-LF2 | A352-LCB, LCC |

| Carbon -1/2 Moly Alloy Steel | ||

| High Temp Service | A182-F1 | A217-WC1 |

| Cold Temp Service | A352-LC1 | |

| 1/2Cr-1/2Mo Alloy Steel | A182-F2 | |

| 1/2Cr-1/2Mo-1 Alloy Steel | A217-WC4 | |

| 3/4Cr-1 Mo-3/4NI Alloy Steel | A217-WC5 | |

| 1Cr-1/2Mo Alloy Steel | A182-F12 | |

| 1Cr-1 Mo-Vd Alloy Steel | A404-F24 | A389-C24 |

| 1-1/4Cr-1/2Mo Alloy Steel | A182-F11 | A217-WC6 |

| 1-1/4Cr-1/2Mo-Vd Alloy Steel | A389-C23 | |

| 2-1/4Cr-1/2Mo-Vd Alloy Steel | A182-F22 | A217-WC9 |

| 3Cr-1 Mo Alloy Steel | A182-F21 | |

| 5Cr-1/2Mo Alloy Steel | A182-F5 | |

| 5Cr-1/2Mo-Si Alloy Steel | A217-Gr.C5 | |

| 7Cr-1/2Mo Alloy Steel | A182-F7 | |

| 9Cr-1 Mo Alloy Steel | A182-F9 | A217-Gr.C12 |

| 13Cr Alloy Steel | A182-F6 | A351-CA15 |

| Type 304 Stainless Steel | ||

| Standard | A182-F304 | A351-Gr.CF8 CF8a |

| Low Carbon | A182-F304-L | A351-Gr.CF3 CF3a |

| High Temp Service | A182-F304-H | A351.Gr.CF10 |

| Type 309 Stainless Steel | ||

| Type 310 Stainless Steel | A182-F310 | |

| Type 316 Stainless Steel | ||

| Standard | A182-F316 | A351-Gr.CF8M |

| Low Carbon | A182-F316-L | A351-Gr.CF3M |

| High Temp Service | A182-F316-H | A351.Gr.CF10 |

| Type 317 Stainless Steel | A403-WP317 | |

| Type 321 Stainless Steel | ||

| Standard | A182-F321 | |

| High Temp Service | A182-F321-H | |

| Type 347 Stainless Steel | ||

| Standard | A182-F347 | |

| High Temp Service | A182-F347-H | A351-Gr.CF8C |

| Type 348 Stainless Steel | ||

| Standard | A182-F348 | |

| High Temp Service | A182-F348-H | |

| 20 Ni-8 Cr Alloy | A182-F10 | |

| 2 Nickel Alloy Steel | ||

| Low Temp Service | A352-LC2 |

VALVE TRIM

WHAT IS VALVE TRIM?

The trim of a valve is the collective name for all the (replaceable) parts of a valve in direct contact with the fluid (“wet parts”).

The valve trim includes, generally, the disc/plug, the stem, the cage, the seat ring, the gaskets, and the packing (the trim configuration depends on the type of valve). The API 600 trim chart designates the typical combinations with a conventional number (for example, Trim 8).

API VALVE TRIM CHART

The API 600 specification designates some typical combinations of the valve trim materials with a number (API trim #1, trim #2, etc.).

The selection of the correct combination of trim materials is one of the most important decisions in specifying valves correctly.

| API TRIM # | TRIM MATERIAL | SEAT | DISC/WEDGE | BACKSEAT | STEM |

|---|---|---|---|---|---|

| 1 | 410 | 410 | 410 | 410 | 410 |

| 2 | 304 | 304 | 304 | 304 | 304 |

| 3 | F310 | 310 | 310 | 310 | 310 |

| 4 | Hard 410 | Hard 410 | 410 | 410 | 410 |

| 5 | Hard faced | Stellite | Stellite | 410 | 410 |

| 5A | Hard faced | Ni-Cr | Ni-Cr | 410 | 410 |

| 6 | 410 and Cu-Ni | Cu-Ni | Cu-Ni | 410 | 410 |

| 7 | 410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 |

| 8 | 410 and Hardfaced | Stellite | 410 | 410 | 410 |

| 8A | 410 and Hardfaced | Ni-Cr | 410 | 410 | 410 |

| 9 | Monel | Monel | Monel | Monel | Monel |

| 10 | 316 | 316 | 316 | 316 | 316 |

| 11 | Monel | Stellite | Monel | Monel | Monel |

| 12 | 316 and Hardfaced | Stellite | 316 | 316 | 316 |

| 13 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 |

| 14 | Alloy 20 and Hardfaced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 |

| 15 | 304 and Hardfaced | Stellite | Stellite | 304 | 304 |

| 16 | 316 and Hardfaced | Stellite | Stellite | 316 | 316 |

| 17 | 347 and Hardfaced | Stellite | Stellite | 347 | 347 |

| 18 | Alloy 20 and Hardfaced | Stellite | Stellite | Alloy 20 | Alloy 20 |

VALVE TRIM SELECTION CRITERIA

Selecting the correct valve trim is crucial for ensuring optimal performance, longevity, and safety in valve operations. The valve trim includes components that come into direct contact with the fluid flow, such as the disc, seat, stem, and sleeve. These components play key roles in regulating the flow, sealing, and overall functionality of the valve.

Here’s a guide to selecting the appropriate valve trim for your application:

1. Understand the Application Requirements

- Fluid Characteristics: Identify the type of fluid (liquid, gas, corrosive, abrasive, etc.) the valve will handle. This influences the material selection to ensure compatibility and durability.

- Pressure and Temperature: Consider the operating pressure and temperature ranges. The trim material must withstand these conditions without degrading.

- Flow Control Needs: Determine whether the valve will be used for on/off service, throttling, or both. This affects the choice of trim design for precise flow control.

2. Select the Appropriate Material

- Corrosion Resistance: For corrosive fluids, select materials like stainless steel, Hastelloy, or Monel that offer superior corrosion resistance.

- Wear Resistance: In applications with abrasive fluids or high velocity, opt for hardened materials or coatings, such as Stellite, to resist wear and erosion.

- Temperature Capability: Ensure the trim material can handle the minimum and maximum operating temperatures. For high temperatures, alloys with high-temperature strength and stability are required.

3. Choose the Right Trim Design

- Contoured Plugs: Suitable for throttling applications requiring smooth and precise flow control.

- Balanced Trim: For high-pressure applications, a balanced trim design reduces the force required to operate the valve, improving control and reducing actuator size.

- Soft Seats: Use soft seat materials (such as PTFE) for applications requiring tight sealing with low torque but consider their temperature and pressure limitations.

- Cage-Guided Trim: Offers stability and reduced vibration for high flow rates or applications with significant pressure drops.

4. Consider Trim Characteristics

- Leakage Class: Select a trim that meets the required leakage rate for your application, as defined by standards like ANSI/FCI 70-2.

- Flow Coefficient (Cv): The trim should provide an appropriate Cv value that meets the flow requirements without causing excessive noise, cavitation, or erosion.

5. Evaluate Additional Features

- Noise Reduction: In applications where noise is a concern, consider trims designed to reduce noise levels, such as multi-stage or labyrinth-type trims.

- Cavitation Control: For liquid services prone to cavitation, select anti-cavitation trims that can minimize or eliminate cavitation damage.

6. Review and Test

After selecting a trim, review the selection against all application requirements and, if possible, conduct tests under actual operating conditions to ensure the trim performs as expected.

API VALVE TRIM: RECOMMENDED SERVICE

| TRIM | RECOMMENDED SERVICE |

|---|---|

| 13% Cr, Type 410 Stainless Steel | For oil and oil vapors and general services with heat-treated seats and wedges. |

| 13% Cr, Type 410 plus Hardfacing | Universal trim for general service requiring long service life up to 1100°F (593°C).* |

| Type 316 Stainless | For liquids and gases that are corrosive to 410 Stainless Steel, up to 1000°F (537°C).* |

| Monel | For corrosive service to 842°F (450°C) such as acids, alkalies, salt solutions, etc. |

| Alloy 20 | For corrosive services such as hot acids -49°F to 608oF (-45°C to 320°C). |

| NACE | Specially treated 316 or 410 trim combined optionally with B7M Bolts and 2HM nuts to meet NACE MR-01-75 requirements. |

| Full Stellite | Full hard-faced trim, suitable for abrasive & severe services up to 1200°F (650°C).* |

* Depends upon base material grade

9 Responses

Hello people good morning. Excellent technical article. Very didactic. Do you have any more specific articles for services with Liquid Chlorine?

Thank you, Jarbas Cabral Fagundes, for your kind words about the technical article on valve material specifications. We appreciate your feedback and are glad to hear that you found it useful and didactic.

Regarding your question about more specific articles for services with Liquid Chlorine, we don’t have any additional articles on that specific topic at the moment. However, it is worth noting that when dealing with Liquid Chlorine, it is crucial to consider the corrosive nature of this substance and its potential impact on valve materials.

In general, for applications with corrosive substances like Liquid Chlorine, it is common to use valves made from materials that offer excellent resistance to corrosion, such as certain stainless steels or alloy materials. These materials are specifically designed to withstand the harsh conditions and ensure the integrity of the valve during operation.

Before selecting a valve for Liquid Chlorine service, it is important to consult industry standards and guidelines, such as those provided by organizations like the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API). These standards can provide valuable insights into the appropriate materials, design considerations, and maintenance practices for valves used in such services.

Additionally, engaging with valve manufacturers or industry experts who specialize in handling corrosive substances like Liquid Chlorine can provide valuable guidance and ensure that you select the most suitable valve for your specific application.

While we don’t have a specific article on Liquid Chlorine services at the moment, we hope this information helps in your search for further resources. If you have any more questions or need additional assistance, please feel free to ask.

THANKS FOR INFORMATION add some references in your article

Thanks for Brilliant and briefed post.

What body and trim material selected for propane and butane

This is perhaps one of the most detailed breakdown of valve material specifications that goes right down to the miniscule details for both cast and forged steel valves. Thorough work and thanks for sharing!

Hi, thank you for such a brilliant post. I have been reading some blogs that gives me more knowledge about this topic makenine 2020. I must say this is one of the best among them. You have done a great research for I feel, thanks for sharing.

As you mentioned, forged steel valves are for high pressure situations. My brother recently started working in a factory and there are many valves that need to be working to make things run smoothly. It would be interesting to see everything in action.

Hi Gent:

I have two valves 1.5″ class 800, the material of the first is A105N AACV & Material of second is A350LF2 CL1QT UU4

these valves will be welded on nipple with following material SA / A106B.

Please advise if the second valve will be accepted to weld on this nipple & according any standard please.

Best Regards