ASME B16.9 Buttweld Fittings for Pipes: Elbow, Tee, Cross, Reducers, Caps Explained

Dive into ASME B16.9 buttweld fittings for piping: types, manufacturing, comparison between seamless and welded, and leading manufacturers…

Dive into ASME B16.9 buttweld fittings for piping: types, manufacturing, comparison between seamless and welded, and leading manufacturers…

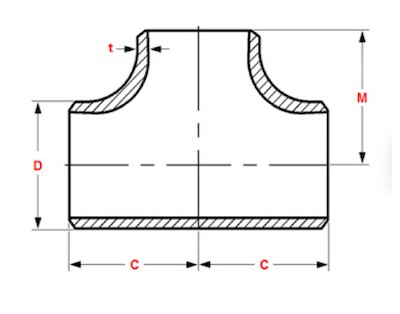

Explore dimensions and weights of ASME B16.9 buttweld fittings: 45/90-degree elbows, equal/reducing tees, pipe caps, concentric/eccentric reducers…

Learn about ASME B16.11 forged fittings: types (socket weld, threaded), difference vs. BW fittings, types, materials…

Explore the essentials of compression fittings for tubing: types, materials, installation, and applications in various industries…

Stub ends are pipe fittings that can be used (in combination with a lap joint flange) alternatively to weld neck flanges to make flanged connections. The use of stub ends has two advantages: it can reduce the total cost of flanged joints for piping systems in high material grades (as the lap joint flange does not need to be of the same material as the pipe and the stub end

Unlock Success in Your EPC, Engineering, or Consulting Job: Dive into Our Free Knowledge on Piping, Process Equipment, Oil & Gas Tech, and More. Dedicated to Project Buyers, Managers, and Engineers, carefully written by Industry Experts!

by Envestis SA Lugano, Switzerland

Swiss Trade Registry # CHE-339.253.743

Registered Capital 100.000 CHF

Our Mission

We are dedicated to exploring the vast and diverse product landscape in various industries that include oil & gas, construction, shipbuilding, energy, and renewable energy. Our comprehensive content encompasses a wide range of products, such as piping products, instrumentation, structural steel, process equipment, field safety systems, and pipeline equipment. Our goal is to provide upcoming piping and process engineers with free, top-tier information to help them thrive in the project plant industry. With our extensive knowledge and resources, we strive to equip the next generation of engineers with the skills and knowledge necessary to succeed.

Subscribe to Newsletter

Read our Legal Terms and Policies before using our website

Terms of Use • Privacy Policy • Cookies Policy • Other Policies

Hi, ready for your questions