Stud bolts for flanges consist of a fully threaded steel rod and two heavy hexagonal steel nuts. Stud bolts are inserted in the flange holes and tightened to seal a flanged joint. The number, length, the diameter of the stud bolts required for a flanged connection depend on the flange type, diameter, and rating (as per the ASME flange bolt chart).

STUD BOLT FOR FLANGES

WHAT IS A STUD BOLT?

A stud bolt is a long rod that is threaded on both ends; the thread may extend along the complete length of the rod. Designed to be used in tension, stud bolts are a key component in flanged connections such as those found in piping systems, where they are used to join the flanges and provide a seal for the system.

Stud bolts are typically paired with two hexagonal nuts on either end, which apply pressure to the flange faces holding gaskets in place, thus ensuring a tight seal. They are commonly used in the oil and gas, petrochemical, and construction industries where a secure bolted joint is required.

The threads on a stud bolt are made to be compatible with standard nuts and are defined by various thread standards, such as UNC (Unified Coarse), UNF (Unified Fine), or metric.

Stud bolts are available in multiple diameters and lengths combinations, metric and imperial, and they are made from a variety of materials such as carbon steel, stainless steel, or alloy steel to match different environmental conditions and mechanical requirements (common grades are: ASTM A193 B7, L7, B8, B8M, B16, Alloy 20, Monel, Hastelloy, Inconel, 17-4PH, titanium, etc.). All such grades are discussed below in this article.

The selection of stud bolts for a particular application depends on several factors, including the required bolt strength, the materials being joined, environmental factors, and the pressures and temperatures the connection will need to withstand.

STUD BOLT: A THREADED ROD + 2 HEX NUTS

A stud bolt consists of one threaded steel rod (the stud) and two matching hexagonal heavy steel nuts which are tightened on the stud to execute the sealing of the main & companion flanges (the hex nuts). Stud bolts and nuts are essential components of flanged joints for piping systems and shall be purchased together.

Nuts for stud bolts are the hardware components that are threaded onto the ends of the stud bolts to secure two flanges together. They work in tandem with the stud bolts to create a tight seal on a gasket between the flanges.

The ASME B16.5 specification covers stud bolts and nuts for ASME flanges (number, diameter, and the length of required stud bolts, i.e “flange bolt chart”) by flange diameter, pressure class, and face finish (RF, FF, RTJ).

THE THREADED ROD

Stud bolt length (OAL/FTF)

In the context of stud bolts, “OAL” stands for “Overall Length,” which is the total length of the stud bolt from end to end. On the other hand, “FTF” stands for “First-to-First,” referring to the length measured from the first full thread on one end to the first full thread on the opposite end, excluding the points.

Stud OAL (Overall Length):

- It encompasses the entire length of the stud bolt, including the unthreaded portion (if any) and the threads.

- OAL is used when specifying the manufacturing length of a stud bolt.

- It is crucial when you need to account for the entire length of the bolt that will fit into the entire assembly, including the nuts and washers.

Stud FTF (First-to-First):

- FTF measurement excludes the chamfers or incomplete threads at the ends of the bolt, providing a length measurement that is useful for ensuring thread engagement.

- It’s the effective length of the bolt to thread into a nut or tapped hole.

- FTF is often considered when the concern is ensuring that the nuts will thread onto the bolt correctly and achieve the desired preload.

- The FTF length can be calculated by subtracting a quarter of an inch from the OAL length, and it is the standard stud length measurement for piping applications.

When specifying stud bolts for flange connections, both OAL and FTF are important. The OAL ensures that the bolt is long enough to accommodate the flanges, gaskets, washers, and nuts, with enough thread protrusion to ensure secure fastening. The FTF measurement is important to ensure that the bolts can be adequately engaged with the nuts for a proper and secure assembly.

In the assembly of piping systems, the accurate measurement of stud bolt lengths is critical to ensure the structural integrity and leak-tightness of flange connections, especially in pressurized systems. It’s essential to refer to engineering standards or specifications to determine the appropriate lengths for specific flange sizes and pressure ratings.

Flanges of different diameters and ratings require studs of different lengths and diameters.

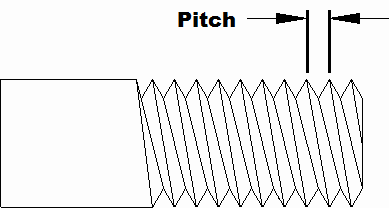

Stud bolt “thread pitch” and “thread series”

Studs are threaded according to the specifications set forth by the ASME B1.1 specification.

Thread Pitch:

The concept of “thread pitch” refers to the distance between thread peaks and is typically measured in millimeters or threads per inch (TPI) in the imperial system. For example, a pitch of 1.5 mm means that each thread is 1.5 mm apart from the next. In the imperial system, you might have 13 TPI, where each thread peak is 1/13th of an inch apart.

The most used thread pitch is the symmetrical thread pitch type with a “V-profile” (a 60-degree angle), as it is easier for the manufacturer to inspect compared to the non-symmetrical types.

Thread Series:

Thread series relate to the diameter and pitch combinations, measured by the number of threads per inch (“TPI”) applied to a single diameter:

- Coarse thread series (UNC/UNRC): UNC is the most common type for screws, bolts, and nuts. Coarse threads are used for threads in low-strength materials such as iron, mild steel, copper softer alloy, aluminum, etc. The coarse thread is also more tolerant of adverse conditions and it facilitates quick assembly

- Fine thread series (UNF/UNRF): UNF is widely used for precision duties and when higher tensile strength is required (vs. the coarse thread series)

- 8-Thread series (8UN) is the elective threading method for several ASTM standards including A193 B7, A193 B8/B8M, and A320. This series is widely used for diameters from one inch upwards

Stud bolts covered by the ASTM A193 or A320 Specifications use 8UN for all diameters 1” and above, which means that there are 8 threads per inch for these sizes. For any other material grade, the buyer shall specify the thread pitch unless it is given by the applicable ASTM norm.

Selection of thread pitch/series:

When selecting a stud bolt, it’s important to choose the thread pitch and series that best match the mechanical and environmental requirements of the application, as well as the nuts that will be used with the bolt. Specifications will often refer to both the diameter and the TPI for imperial measurements (like 1/2″-13 for a 1/2 inch diameter bolt with 13 TPI UNC threads), or the diameter and pitch in millimeters for metric measurements (like M12 x 1.75 for a 12 mm diameter bolt with a 1.75 mm pitch).

The points to consider in the selection of thread pitches/series are:

- Strength and Precision: Fine threads (UNF) provide greater resistance to loosening and are stronger in tension than coarse threads (UNC) due to the larger stress area.

- Ease of Assembly: Coarse threads (UNC) are less likely to cross-thread, are more durable, and are typically easier to assemble and disassemble, especially in dirty or rough environments.

- Material Thickness: Fine threads are better suited for threading into thinner materials, as coarse threads could strip out the material.

- Vibration Resistance: UNF threads, due to their finer pitch, are generally better at resisting vibration, making them suitable for applications such as aircraft and military.

HEX NUTS FOR STUD BOLTS

To fasten a stud bolt, two heavy hex steel nuts have to be bolted at the opposite ends of the rod. The stud and the steel nuts join perfectly due to the friction existing between their respective threads, by a slight stretching of the bolt, and the compression of the two joined parts.

Function of the hex nuts:

- Compression: When tightened, nuts apply compressive force to the flanges, clamping them together and compressing the gasket to prevent leaks.

- Tension: They also create tension in the stud bolts, which contributes to the robustness of the sealed joint.

Features:

- Hexagonal Shape: Nuts are typically hexagonal to provide multiple angles for wrenches to tighten or loosen them.

- Material Compatibility: They are often made from the same material as the stud bolt (like carbon steel, stainless steel, or alloy steel) to ensure uniform thermal expansion and prevent galvanic corrosion.

- Thread Matching: The internal threads of the nuts must match the thread type and size of the stud bolts for a proper fit.

Types:

- Heavy Hex Nuts: Thicker and wider than standard hex nuts, providing a larger contact surface (this is the type used in conjunction with studs to implement stud bolt connections for flanges)

- Lock Nuts: Used in high-vibration environments to prevent loosening.

- Jam Nuts: Often used in tandem with standard nuts to lock the bolt’s position.

In the past, steel nuts for stud bolts had a squared head. Nowadays, the hexagonal head shape (featuring 6 sides instead of 4) has fully replaced the older shape as they ensure quicker and more effective screwing on the stud.

Standards:

Nuts are designed according to specific standards that dictate their size, thread pitch, and material properties, such as:

- ISO: International standards for dimensions and tolerance.

- ASME: American standards commonly used in industrial applications.

- DIN: German standards, widely recognized and used in Europe.

The material of the hex steel nuts shall match the material of the threaded rod (generally, stud materials ASTM A193 match with nuts materials ASTM A194).

Nuts for petrochemical applications are tightened to a specific torque using special torque wrenches. The mechanical strength of the steel nut material shall be compatible with the strength of the mated bolt.

The dimensions and weights of heavy steel nuts for stud bolts are covered by the ASME B18.2.2 specification.

DIFFERENCE BETWEEN “STUD” VS. “BOLT”

A common question is: what is the difference between the concepts “stud” vs. “bolt”?

Stud

A stud:

- is a fully threaded metal rod that requires two heavy hexagonal nuts to be tightened

- does not have a head, unlike a bolt

- is installed into a tapped hole on one end and receives a nut on the opposite end. It’s often used where one of the components to be joined is permanently fitted with a tapped hole.

- is commonly used in situations where frequent assembly and disassembly are not required. They are ideal for mounting engines, large equipment, and in piping systems where the use of a bolt may not be feasible due to space constraints.

- is often preferred (to bolts) when uniform tensioning across the joint is necessary because they are less likely to be over-torqued.

A bolt:

- is a threaded fastener with a head designed to be inserted through holes in the assembled parts and is intended to be tightened or released by torquing the head.

- is used with a nut and often a washer. They pass through all components to be joined before the nut is fitted on the threaded end.

- is versatile and used in a wide variety of applications. They are suitable for connections that require regular assembly and disassembly.

- is more susceptible to loosening under vibration unless special measures are taken.

STUD BOLT MATERIALS (THREADED ROD)

The most common materials for the threaded rod of stud bolts are ASTM A193 (grade B7, B8, B8M, B8T), ASTM A453 (grade 660), ASTM A320 (grade L7, L7M), and ASTM A182 (duplex and super duplex bolting). For aggressive fluids and environments, stud bolts can be coated with Xylan, Xylar, and other materials.

Let’s dive into the most common grades for the rod of a stud bolt assembly (the materials for the hex nuts are examined in this article).

ASTM A193 (HIGH-TEMP. SERVICE)

The ASTM A193 specification covers low-alloy steel and stainless steel stud bolt materials for high-temperature or high-pressure service.

ASTM A193 stud bolts are available in national coarse (UNC) thread pitches, generally used in traditional applications, which means that there are 8 threads per inch (“thread per inch”) for rod diameters above 1 inch.

The main grades covered by the ASTM A193 specification are:

- ASTM A193 B7 is a chromium-molybdenum steel alloy that is a common choice for high-strength applications like pressure vessels and flanges in the oil and gas industry.

- ASTM A193 B8/B8M are grades of stainless steel bolts and studs. Grade B8 is made from 304 stainless steel and B8M from 316 stainless steel, providing corrosion resistance, and are used in applications where exposure to corrosive elements is a concern.

- ASTM A193 Grade B6: Made of 410 stainless steel, these bolts are heat-treated and used for applications requiring high strength and a certain level of corrosion resistance.

- ASTM A193 Grade B7M: Similar properties to B7 but with controlled hardness and intended for applications where there’s a need for resistance to stress corrosion cracking.

- ASTM A193 Grade B8C/B8T/B8R: These are grades of stainless steel with different compositions such as 347 (B8C), 321 (B8T), and Alloy 20 (B8R), used for corrosive environments.

The most common stud bolts materials covered by ASTM A193 are:

- ASTM A193 B5

- ASTM A193 B6

- ASTM A193 B7: Alloy steel, AISI 4140/4142 quenched and tempered

- ASTM A193 B7M

- ASTM A193 B16

- ASTM A193 B8: Class 1 Stainless steel, AISI 304, carbide solution treated.

- ASTM A193 B8A

- ASTM A193 B8M: Class 1 Stainless steel, AISI 316, carbide solution treated.

- ASTM A193 B8MA

- ASTM A193 B8T (SS 321)

- ASTM A193 B8cl2: Class 2 Stainless steel, AISI 304, carbide solution treated, strain hardened

- ASTM A193 B8Tcl2

- ASTM A193 B8Mcl2: Class 2 Stainless steel, AISI 316, carbide solution treated, strain hardened

ASTM A193: Chemical Composition

| Physical Element | ASTM A193 grade B7 (AISI 4140) | ASTM A193 grade B8 (AISI 304) | ASTM A193 grade B8M (AISI 316) |

|---|---|---|---|

| Carbon | 0.38 – 0.48% | 0.08% max | 0.08% max |

| Manganese | 0.75 – 1.00% | 2.00% max | 2.00% max |

| Phosphorus, max | 0.035% | 0.045% | 0.045% |

| Sulfur, max | 0.040% | 0.030% | 0.030% |

| Silicon | 0.15 – 0.35% | 1.00% max | 1.00% max |

| Chromium | 0.80 – 1.10% | 18.0 – 20.0% | 16.0 – 18.0% |

| Nickel | absent | 8.0 – 11.0% | 10.0 – 14.0% |

| Molybdenum | 0.15 – 0.25% | absent | 2.00 – 3.00% |

ASTM A193: Mechanical Properties

| ASTM A193 | Size | Min Tensile Strength, in ksi | Min Yield Strength, in ksi | Min Elongation, in % | RA % min | Max HBW | Max HRC |

|---|---|---|---|---|---|---|---|

| ASTM A193 grade B7 | Up to 2-1/2 | 125 | 105 | 16 | 50 | 321 | 35 |

| 2-5/8 – 4 | 115 | 95 | 16 | 50 | |||

| 4-1/8 – 7 | 100 | 75 | 18 | 50 | |||

| ASTM A193 grade B8 Class 1 | All | 75 | 30 | 30 | 50 | 223 | 35 |

| ASTM A193 grade B8M Class 1 | All | 75 | 30 | 30 | 50 | 223 | 96 |

| ASTM A193 grade B8 Class 2 | Up to 3/4 | 125 | 100 | 12 | 35 | 321 | 35 |

| 7/8 – 1 | 115 | 80 | 15 | 35 | |||

| 1-1/8 – 1-1/4 | 105 | 65 | 20 | 35 | |||

| 1-3/8 – 1-1/2 | 100 | 50 | 28 | 45 | |||

| ASTM A193 grade B8M Class 2 | Up to 3/4 | 110 | 95 | 15 | 45 | 321 | 35 |

| 7/8 – 1 | 100 | 80 | 20 | 45 | |||

| 1-1/8 – 1-1/4 | 95 | 65 | 25 | 45 | |||

| 1-3/8 – 1-1/2 | 90 | 50 | 30 | 45 |

The material chosen for the threaded stud and the hex nuts should be compatible. Materials for bolting sets shall be selected based on the process’s working temperatures, as shown in the table below:

| TEMPERATURE °C ( °F ) | ||

| STUD BOLTS MATERIALS | MIN. | MAX. |

| CARBON STEEL | -29 (-20) | 300 (572) |

| A193 B7, L7 | -73 (-100) | 400 (752) |

| A193 B6 | 0 (32) | 500 (932) |

| A193 B8 | -200 (-325) | 575 (1067) |

| A193 B16 | 0 (32) | 520 (968) |

| A193 B17B | -29 (-20) | 650 (1202) |

| A913 Inconel 718 | 0 (32) | 750 (1382) |

| A453 Gr. 660 | -29 (20) | 538 (1000) |

Stud bolts can be produced also with “dual certification,” i.e. they conform to multiple sets of ASTM standards (A193 B7 stud bolts can meet the requirements of A320 L7; B8 and B8m stud bolts also typically conform to both A193 and A320).

ASTM A453 (HIGH-TEMP.)

The ASTM A453 specification covers standards for Grade 660 (Class A, B, C, and D), Grade 651 (Class A and B), Grade 662 (Class A and B), and Grade 665 (Class A and B) of bolting materials, with ten classes of yield strength ranging from 50 to 120 KSI [345 to 827 MPa], for use in high-temperature service such as fasteners, pressure vessels and flanges.

Bolting materials in ASTM A453 are covered rolled, forged, or hot-extruded bars, and also bolts, nuts, screws, washers, studs, and stud bolts.

Materials shall adhere to specified contents of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, tungsten, titanium, columbium, aluminum, vanadium, boron, and copper.

According to ASTM A453, materials shall be subjected to tension, stress-rupture, and hardness tests. Materials shall conform to yield strength, tensile strength, elongation, reduction of area, Brinell hardness, and Rockwell hardness requirements.

Hardening and solution treatment requirements for each material class are also given. The most common grades under ASTM A453 are:

- ASTM A453 660A

- ASTM A453 660B

- ASTM A453 660C

- ASTM A453 660D

ASTM A453 Chemical Composition

| ELEMENT | ASTM A453 Grade 660 | ASTM A453 Grade 651 | ASTM A453 Grade 662 | ASTM A453 Grade 665 | ASTM A453 Grade 668 |

| % | % | % | % | % | |

| Carbon | 0.08 max | 0.28-0.35 | 0.08 max | 0.08 max | 0.08 max |

| Manganese | 2.00 max | 0.75-1.5 | 0.40-1.00 | 1.25-2.00 | 2.00 max |

| Phosphorus, max | 0.040 max | 0.040 max | 0.040 max | 0.040 max | 0.040 max |

| Sulfur, max | 0.030 max | 0.030 max | 0.030 max | 0.030 max | 0.030 max |

| Silicon | 1.00 max | 0.30-0.80 | 0.40-1.00 | 0.1-0.80 | 1.00 max |

| Nickel | 24.0-27.0 | 8.0-11.0 | 24.0-28.0 | 24.0-28.0 | 17.5-21.5 |

| Chromium | 13.5-16.0 | 18.0-21.0 | 12.0-15.0 | 12.0-15.0 | 13.5-16.0 |

| Molybdenum | 1.00-1.50 | 1.00-1.75 | 2.0-3.50 | 1.25-2.25 | 1.50 max |

| Tungsten | … | 1.00-1.75 | … | … | … |

| Titanium | 1.9-2.35 | 0.1-0.35 | 1.80-2.10 | 2.70-3.30 | 2.20-2.80 |

| Columbium * | … | 0.25-0.6 | … | … | … |

| Aluminum | 0.35 max | 0.35 max | 0.25 max | 0.50 max | |

| Vanadium | 0.10-0.50 | … | … | 0.50 max | |

| Boron | 0.001-0.010 | 0.001-0.010 | 0.01-0.07 | 0.001-0.010 | |

| Copper | 0.50 max | 0.50 max | 0.25 max | … |

ASTM A453: Mechanical Properties

| ASTM A453 Grade | Class | Tensile, Mpa | Yield, Mpa | Elong. %, min | RA %, min |

| ASTM A453 Grade 660 | A, B , & C | 895 min | 585 min | 15 | 18 |

| D | 895 min | 725 min | 15 | 18 | |

| ASTM A453 Grade 651 | A | 690 min | 485 min | 18 | 35 |

| 415 min | |||||

| B | 655 min | 415 min | 18 | 35 | |

| 345 min | |||||

| ASTM A453 Grade 662 | A | 895 min | 585 min | 15 | 18 |

| B | 860 min | 550 min | 15 | 18 | |

| ASTM A453 Grade 665 | A | 1170 min | 830 min | 12 | 15 |

| B | 1070 min | 830 min | 12 | 15 | |

| ASTM A453 Grade 665 | A & B | 895 min | 858 min | 15 | 18 |

ASTM A453: Heat Treatment Requirements

| ASTM A453 | Class | Solution Treatment | Hardening Treatment |

| 660 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool | |

| C | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and oil quench | 1425 +/- 25 °F [775 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool | |

| D | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench OR | 1325 +/- 25 °F [720 +/- 14 °C] hold 16h, air cool followed by 1200 +/- 25 °F [650 +/- 14 °C], hold 16h, air cool if necessary to achieve properties, second age : 1200 +/- 25 °F [650 +/- 14 °C] hold 16h, air cool | |

| 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | |||

| 651 | A | hot-cold worked at 1200 °F[650] min with a 15% min reduction in cross-sectional area, stress-relief anneal at 1200 °F [650 °C] min or 4h, min | |

| B | hot-cold worked at 1200 °F[650] min with a 15% min reduction in cross-sectional area, stress-relief anneal at 1350 °F [730 °C] min or 4h, min | ||

| 662 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 1950 +/- 25 °F [1065 +/-14 °C], hold 2 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 665 | A | 1800 +/- 25 °F [980 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool |

| B | 2000 +/- 25 °F [1095 +/-14 °C], hold 3 h, min and liquid quench | 1350 to 1400 °F [730 to 760 °C], hold 20h, furnace cool to 1200 +/- 25 °F [650 +/- 14 °C], hold 20h, air cool | |

| 668 | A | 1650 +/- 25 °F [900 +/-14 °C], hold 2 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

| B | 1800 +/- 25 °F [980 +/-14 °C], hold 1 h, min and liquid quench | 1325 +/- 25 °F [720 +/- 14 °C] 16h, air cool |

A453: Time to Rupture and Elongation

| Grade | Class | Test Temperature | Stress, Min | Time to Rupture | Elongation | |

| Deg F [ Deg C ] | Ksi | Mpa | Min, h* | Min % | ||

| 660 | A, B & C | 1200 [650] | 56 | 385 | 100 | 5 |

| 651 | A & B | 1200 [650] | 40 | 275 | 100 | 5 |

| 662 | A & B | 1200 [650] | 55 | 380 | 100 | 5 |

| 665 | A | 1200 [650] | 75 | 515 | 100 | 3 |

| B | 1200 [650] | 70 | 485 | 100 | 5 | |

ASTM A320 (LOW-TEMP.)

The ASTM A320 specification covers alloy steel and stainless steel stud bolt materials for low-temperature service.

Each alloy under ASTM A320 shall conform to prescribed chemical requirements. The material, as represented by the tension specimens, shall conform to specific requirements in terms of tensile strength, yield strength, elongation, and hardness. The stud bolt material shall meet the prescribed impact energy absorption requirements and the target test temperature.

According to the ASTM A320 specification, manufacturers shall execute at least the following mechanical tests on the material: impact test, tension test, and hardness test.

The most common stud bolt materials under ASTM A320 are listed below (low-temperature service):

- ASTM A320 L7: Alloy steel, AISI 4140/4142 Quenched and tempered

- ASTM A320 L7M

- ASTM A320 L43: Alloy steel, AISI 4340 Quenched and tempered

- ASTM A320 B8 Class 1: Stainless steel, AISI 304, carbide solution treated

- ASTM A320 B8A

- ASTM A320 B8T

- ASTM A320 B8TA

- ASTM A320 B8C

- ASTM A320 B8M: Class 1 Stainless steel, AISI 316, carbide solution treated

- ASTM A320 B8MA

- ASTM A320 B8cl2: Stainless steel, AISI 304, carbide solution treated, strain hardened

- ASTM A320 B8Mcl2: Stainless steel, AISI 316, carbide solution treated, strain hardened

ASTM A320: Mechanical Properties

| ASTM A320 Grade | Diameter | Tensile, KSI, min | Yield, KSI, min | Charpy Impact 20-ft-LBF @ temp | Elong, %, min | RA, %, min |

|---|---|---|---|---|---|---|

| ASTM A320 Grade L7 | Up to 21⁄2 | 125 | 105 | -150° F | 16 | 50 |

| ASTM A320 Grade L43 | Up to 4 | 125 | 105 | -150° F | 16 | 50 |

| ASTM A320 Grade B8 Class 1 | All | 75 | 30 | N/A | 30 | 50 |

| ASTM A320 Grade B8M Class 1 | All | 75 | 30 | N/A | 30 | 50 |

| ASTM A320 Grade B8 Class 2 | Up to 3⁄4 | 125 | 100 | N/A | 12 | 35 |

| 7⁄8 – 1 | 115 | 80 | N/A | 15 | 35 | |

| 11⁄8 – 11⁄4 | 105 | 65 | N/A | 20 | 35 | |

| 13⁄8 – 11⁄2 | 100 | 50 | N/A | 28 | 45 | |

| ASTM A320 Grade B8M Class 2 | Up to 3⁄4 | 110 | 95 | N/A | 15 | 45 |

| 7⁄8 – 1 | 100 | 80 | N/A | 20 | 45 | |

| 11⁄8 – 11⁄4 | 95 | 65 | N/A | 25 | 45 | |

| 13⁄8 – 11⁄2 | 90 | 50 | N/A | 30 | 45 |

ASTM A182 (Duplex and Super Duplex)

Duplex Steel Grade

Chemical Composition:

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|

| Duplex 2205 (S31803) | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | min: 21.0 max: 23.0 | min: 2.5 max: 3.5 | min: 4.5 max: 6.5 | min: 0.08 max: 0.20 |

| Duplex 2205 (S32205) | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | min: 22.0 max: 23.0 | min: 3.0 max: 3.5 | min: 4.5 max: 6.5 | min: 0.14 max: 0.20 |

Mechanical Properties:

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (HB) MAX |

|---|---|---|---|---|

| 2205 | 90 | 65 | 25 | 217 |

Physical Properties:

| Density lbm/in3 | Electrical Resistivity mW•in | Thermal Conductivity (BTU/hr•ft•°F) | Heat Capacity BTU/lbm•°F | Electrical Resistivity (in x 10-6) |

|---|---|---|---|---|

| at 68°F | 0.278 | 27.6 | 8.7 | 0.112 |

| at 212°F | 26.1 | 9.2 | 0.119 | 35.4 |

| at 392°F | 25.4 | 9.8 | 0.127 | 37.4 |

| at 572°F | 24.9 | 10.4 | 0.134 | 39.4 |

Super Duplex Grade

Chemical Composition:

| C | Cr | Ni | Mo | N | Others |

| 0.02 | 25 | 7 | 4 | 0.27 | S=0.001 |

Mechanical Properties:

| Ultimate Tensile Strength, ksi | 16 min. |

| 0.2% Offset Yield Strength 0.2%, ksi | 80 min. |

| 0.1% Offset Yield Strength 0.2%, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness Rockwell C | 32 max. |

| Impact Energy, ft.-lbs. | 74 min. |

Physical Properties:

| Density | lb/in3 | 0.28 |

| Modulus of Elasticity | psi x 106 | 29 |

| The coefficient of Thermal Expansion | x10-6/°F | 7.2 |

| 68-212°F/°F | ||

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Heat Capacity | Btu/lb/°F | 0.12 |

| Electrical Resistivity | W-in x 10-6 | 31.5 |

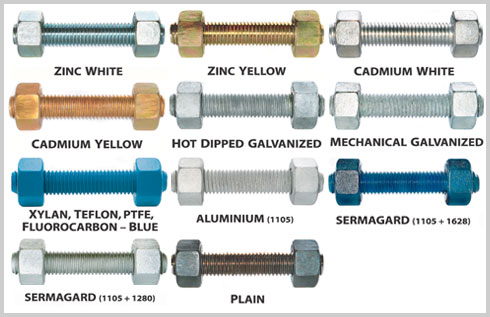

COATINGS FOR STUD BOLTS

Coating materials for stud bolts are used to enhance corrosion resistance, reduce the risk of galling, and sometimes provide electrical insulation or to meet certain aesthetic requirements.

Here’s a look at some commonly used coatings:

1. Zinc Coatings

- Electroplated Zinc: Offers corrosion resistance; however, it can be susceptible to hydrogen embrittlement in high-strength steels.

- Hot-Dip Galvanizing: A process where bolts are dipped into molten zinc, providing thick, durable corrosion protection.

- Zinc Flake Coating (Dacromet, Geomet): A thin, protective coating that provides corrosion resistance without the risk of hydrogen embrittlement.

2. Cadmium Coatings

Excellent corrosion resistance and natural lubricity; however, due to its toxicity, its use is more restricted and often replaced with zinc-nickel and other alternatives.

3. PTFE (Polytetrafluoroethylene) Coatings (Teflon)

Provides excellent chemical resistance and low friction, reducing the torque required to tighten and preventing galling.

4. Phosphate Coatings

Often used as a primer for painting or to provide temporary protection against corrosion; also reduces friction during tightening.

5. Chromium Coatings

- Electroplated Chromium: Used for its hardness and corrosion resistance; it’s relatively rare for stud bolts due to cost.

- Chromium Overlays: Sometimes used for highly corrosive environments but are less common than zinc coatings.

6. Nickel Coatings

- Electroplated Nickel: Provides good corrosion resistance and is used in high-temperature applications.

- Nickel-Alloy Coatings (Nickel-Cobalt, Nickel-Iron): Offer enhanced properties for specific environments.

7. Aluminum Coatings

- Applied through processes like Aluminizing for high-temperature oxidation resistance.

8. Ceramic Coatings

Offer high-temperature resistance and are sometimes used in exhaust systems and similar applications.

9. Silver Coatings

Used in high-temperature and anti-galling applications; silver has excellent conductivity and lubricity.

10. Molybdenum Disulfide Coatings

Often used as a lubricant coating that can withstand high pressures and help prevent galling during tightening.

11. Epoxy Coatings

Durable, corrosion-resistant coatings that can also be used for color coding.

12. Xylan 1070/1024 & Xylar 1

Xylan and Xylar coatings for stud bolts have multiple advantages:

- Lower frictions vs. uncoated bolts (CoF is as low as 0.02)

- Increased wear resistance for the bolt even under extreme pressures.

- Strong corrosion and chemical resistance in most demanding environments

- Increased resistance to adverse weather conditions (such as extreme sunlight, salt-water exposure to chemicals)

- Wider operating range in terms of temperature (from -420° to +550°F, i.e. -250° to 285°C).

- Color coding for easier traceability

- Pliability: Xylan coatings bend easily and repeatedly and do not break

- Machinability: multiple Xylan coatings can be applied to the stud bolts

- Strong adhesion to bolting materials

Stud Bolts Coating Selection Considerations:

When choosing a coating, consider factors such as:

- Corrosion Environment: The presence of moisture, salts, chemicals, and the required lifespan of the bolt in that environment.

- Temperature: High-temperature applications may limit the choice of coatings.

- Friction and Galling: Some coatings reduce friction and prevent galling, especially important for stainless steel fasteners.

- Electrical Conductivity or Insulation: Some applications may require non-conductive or conductive properties.

- Regulatory Compliance: Considerations such as environmental regulations that may restrict the use of certain materials like cadmium or lead.

STUD BOLTS AND NUTS MATERIAL SELECTION

The material to use for stud bolts depends on multiple factors, the main ones are the material of the flanges and the pipeline design temperature:

| DESIGN TEMPERATURE | FLANGE MATERIAL | STUD BOLT | HEAVY HEX STEEL NUTS |

|---|---|---|---|

| -195° to 102°C | ASTM A 182 Gr. F304, F304L, F316, F316L, F321, F347 | A320 Gr. B8 Class 2 | A194 Gr. 8A |

| -101° to -47°C | ASTM A 350 Gr. LF3 | A 320 Gr. L7 | A 194 Gr. 7 |

| -46° to -30°C | ASTM A 350 Gr. LF2 | A 320 Gr. L7 | A 194 Gr. 7 |

| -29° to 427°C | ASTM A 105 | A 193 Gr. B7 | A 194 Gr. 2H |

| 428° to 537°C | ASTM A 182 Gr. F11, F22 | A 193 Gr. B16 | A 194 Gr. 2H |

| 538° to 648°C | ASTM A182 Gr. F11, F22 | A 193 Gr. B8 Class 1 | A 194 Gr. 8A |

| 649° to 815°C | ASTM A182 Gr. F304 H, F316 H | A 193 Gr. B8M Class 1 | A 194 Gr. 8A |

![]()

ASTM stud bolts materials selection.pdf

17 Responses

Welcome

I would like to purchase the materials according to the specifications in the attached picture. Please provide me with the price, origin and processing period

Thanks for Sharing such a great blog about Stud Bolts.

Hi There, Great and informative blog. Thanks for sharing this blog about Stud Bolts and its material. Keep updating your informative thoughts with us.

Hi There, Great and informative blog. Thanks for sharing this blog about Stud Bolts and its material. Keep sharing your informative thoughts with us

Which grade of stud bolt would be considered equivalent to 12.9 grade bolt ?

Hi Ma’am / Sir,

Kindly submit your proposal CIF MANILA, PHILIPPINES for the following:

ADDITIONAL SPECS TO BE FOLLOWED, SEE BELOW AND QUOTE CIF MANILA, PHILIPPINES

THANKS.

ROLLY/MANILA OVERSEAS INC.

TEL;6328804227 FAXC:6328004172

Include price and lead time.

Thank you

Regards,

ROLLYMANILA OVERSEAS INC.

Tel 63-2-88004227

Dear Client

I am Sandra Yang from Cooper and Turner Beck. We are the professional manufacture for Bolt, Studs for Wind, gas, turnel area. Our priority is as below.

• A leading worldwide manufacturer and supplier of industrial fasteners.

• An enviable reputation for quality, service and product innovation.

• Specialist manufacturer in safety critical fasteners.

• Established locations in UK, Denmark, China, India and Dubai.

• Experience in supplying blue chip customers.

• Key global locations

Please feel free to contact us if you have demand.

Very nice blog. Quite helpful.

Very informative blog. Thank you for wonderful explanation.

Very informative blog. Studs are a headless version of bolts. They are either threaded from both ends or are fully threaded. Continuous threaded, tap end stud, double end stud, and flange stud are some studs that Fastener World offers.

I want to know minimum/ maximum torque for 3/4″ Stud bolt SISI 316 (ATM A193 B8M ?

best information in this blog very helpful for me

Do you supply left-handed thread?

yes

Welcome

I would like to purchase the materials according to the specifications in the attached picture. Please provide me with the price, origin and processing period

I want the standard for M8X1.25 stud & nut.

I want to stud cable line stud MOQ 700000. materials grade SAE 1010