Throughout the lifecycle of an EPC project, from its inception through to commissioning and the startup of the plant, various documents are generated at each project phase. These documents include project tenders, bids, bonds, Requests for Information (RFIs), bid tabulations, commercial and technical offers, Request for Proposal (RFP), Request for Quote (RFQ), Purchase Orders (POs), Order Confirmations (OCs), status reports, commissioning reports, Factory Acceptance Tests (FAT), among others. This article provides an overview of the key documents associated with each stage of an EPC project, aiming to clarify the commonly used terminology.

COMMERCIAL DOCUMENTS CREATED DURING THE EXECUTION OF AN EPC PROJECT

WHAT IS AN EPC PROJECT?

An Engineering, Procurement, and Construction (EPC) project is a common form of contracting arrangement within the construction, infrastructure, and energy sectors. In an EPC project, a single contractor is responsible for all aspects of the design, procurement, construction, and commissioning of a project.

This turnkey solution means the contractor delivers a completed project ready for operation to the project owner or client, based on agreed performance criteria and specifications.

Key Features of EPC Projects

- Comprehensive Scope: The EPC contractor handles the detailed engineering and design of the project, procures all necessary materials and equipment, and then constructs to deliver a functioning facility or asset.

- Single Point of Responsibility: The client contracts with a single entity (the EPC contractor) for the delivery of the project. This consolidates responsibility and minimizes risks related to coordinating between different parties, making the contractor the single point of contact for all project-related issues.

- Turnkey Delivery: EPC projects are often referred to as “turnkey” projects because they are delivered in a state ready for immediate use, just like turning a key in a lock. The client essentially steps into a fully operational facility.

- Fixed Price Contracts: Many EPC contracts are fixed-price, meaning the contractor agrees to deliver the project within a predetermined budget. This can provide financial certainty to the client but places the risk of cost overruns on the contractor.

- Performance Specifications: The contract typically specifies the performance criteria the project must meet, linking payment and completion to achieving these benchmarks.

Advantages of EPC Projects

- Efficiency and Time Savings: With a single contractor managing all project phases, there is a streamlined decision-making process, which can lead to more efficient project delivery.

- Cost Certainty: Fixed-price contracts provide the client with clear visibility of project costs upfront, aiding in budget control and financial planning.

- Risk Management: Transferring the responsibility of design, procurement, and construction to the EPC contractor mitigates a significant amount of risk for the client.

- Quality Assurance: EPC contractors, having comprehensive control over the project, can ensure a high standard of quality and compliance with the project specifications.

Challenges of EPC Projects

- Contract Complexity: The comprehensive nature of EPC contracts can make them complex to negotiate and manage, requiring detailed specifications and performance standards.

- Risk Allocation: While EPC contracts transfer significant risk to the contractor, managing these risks, especially in projects with uncertain elements, can be challenging and potentially increase costs.

- Less Flexibility: Changes to the project scope or design initiated by the client after the contract has been awarded can be difficult and expensive to implement.

EPC projects are particularly suitable for large-scale, complex projects where the client seeks to offload project risks to a contractor capable of handling the comprehensive scope of project delivery. This model is prevalent in sectors such as energy, infrastructure, industrial plants, and utilities, where expertise, efficiency, and effective risk management are critical to project success.

WHAT ARE THE TYPICAL STEPS OF AN EPC PROJECT?

Embarking on a new Engineering, Procurement, and Construction (EPC) project, especially in complex industries such as oil & gas, involves a series of critical steps.

These steps are designed to ensure that the project progresses from conception to completion in a structured, efficient manner, aligning with the client’s objectives, budget, and timeline while adhering to regulatory and safety standards.

Here’s an overview of the typical steps involved in the lifecycle of an EPC project:

EARLY STAGES

The journey begins with the identification of a project need or opportunity. This phase involves preliminary studies to assess the project’s feasibility, including technical feasibility, market analysis, environmental impact assessments, regulatory approval, and financial modeling to ensure the project’s viability and sustainability. Several RFI (Request for Information) documents may be sent out to contractors, suppliers, and service providers during this stage to help clarify the scope of the project, gather technical insights, and make some informed project decisions. If the project is deemed technically and commercially viable by the end user, a “Tender Package” is generated and submitted to the designated EPC Contractors for bidding.

Key documents:

- Feasibility studies, analysis, and reports

- RFIs to suppliers (EPC contractors, equipment manufacturers, etc)

- Tender Package (including bid bonds requirements)

PROJECT AWARD

As the designated EPC Contractors receive the “Tender Package”, each of them analyzes the requirements, formulates their technical and commercial bids, and submits them to the end-user (or their consultants) within the predefined bidding due date. Submission may happen in two stages, typically: submission of the technical offer, and submission of the commercial offer. As the technical and commercial bids of the competing EPCs have been thoroughly analyzed and compared, the short-listed EPCs (generally 2 or 3) are invited for a final negotiation that leads to the award of the project to a specific Contractor. At this stage, a final contract is signed that details the project scope, deliverables, timelines, costs, payment schedules, and legal terms. These documents must be thorough to ensure clear understanding and agreement between parties.

Key documents:

- EPC’s Technical/Commercial Offers

- Contract between End-User and Awarded EPC Contractor

- Performance Bond

PROJECT EXECUTION

As a project is awarded to a specific EPC contractor, or to a joint venture of multiple EPCs, or EPCs and vendors, the project moves into the execution phase. The execution of the project involves several steps, as outlined below:

Engineering and Design

This phase involves detailed engineering and design work to develop technical specifications for the project. It includes creating architectural designs, engineering drawings, and other technical documents necessary for construction (for example plant layout, piping isometrics, P&ID, etc). This step is crucial for planning the project layout, selecting materials, and defining systems and processes.

Procurement

Concurrent with the engineering phase, the procurement process begins. This involves sourcing and purchasing materials, equipment, and services required for the project. Effective procurement strategies are essential for ensuring that the right quality of materials is available at the right time and at the best cost, thereby avoiding delays and staying within budget.

Construction

With designs in hand and materials procured, the construction phase commences. This is where the project physically takes shape. Activities include site preparation, foundation laying, structural assembly, and installation of systems and equipment. Effective project management is critical during this phase to ensure safety, quality, and adherence to timelines.

Testing and Commissioning

After construction, the next step is testing and commissioning, where all systems and components are methodically checked to ensure they operate according to design specifications. This phase ensures that the project is safe, functional, and ready for operational use.

Project Handover

Upon successful testing and commissioning, the project is formally handed over to the client. This step includes transferring documents, training client personnel, and finalizing any outstanding contractual obligations. A successful handover signifies that the project is complete and operational.

Operations and Maintenance

Although not always directly handled by EPC contractors, the operations and maintenance phase is crucial for the long-term success of the project. In some contracts, the EPC contractor may provide support during the initial operational period or engage in long-term maintenance agreements.

Project Closure and Review

Finally, the project closure phase involves evaluating project performance, documenting lessons learned, and conducting final financial settlements. This step is crucial for both the contractor and the client to assess the project’s success and areas for improvement.

Each step in the lifecycle of an EPC project is interdependent, requiring careful planning, coordination, and execution to ensure the project’s success. From the initial idea to the project’s operational handover, a disciplined approach to project management can help mitigate risks, control costs, and achieve the desired outcomes within the established timeframe.

Key Documents (focusing on procurement activities):

- Request for Information (“RFI”)

- Request for Proposal (“RFP”)

- Request for Quote (“RFQ”)

- Suppliers’ technical & commercial offers

- Bid tabulations

- Purchase Order (“PO”)

- Purchase Order Confirmation (POC or “OC”)

- Status reports (for suppliers providing services)

- Non Conformity Reports (“NC”)

- Shipping documents (Invoice, packing list, mill test certificates)

- Supplier’s assessment reports

TYPICAL DOCUMENTS BY EPC PROJECT STAGE

EARLY STAGES

The initiation and feasibility study phase of an EPC (Engineering, Procurement, and Construction) project is critical, laying the groundwork for the project’s scope definition, tendering process, award, and continuation into the execution stage. This phase assesses the viability of the project from technical, economic, legal, and operational perspectives and culminates with the issuance of a “Tender Package” submitted to EPC designated to bid competitively on the project.

The end user of the project (for example an Oil & Gas player like Saudi Aramco), with the help of their technical/financial/regulatory consultants, generally drafts all the documents of this stage before moving into the execution stages of the project.

Here is an overview of the typical documents that emerge during this initial phase:

Feasibility studies, analysis, and reports

This category encompasses all the documents produced in the early stages of the project:

1. Project Proposal

The project proposal is a preliminary document that outlines the project’s objectives, scope, and potential impact. It includes an initial assessment of the project’s feasibility, required resources, and a high-level timeline.

2. Feasibility Study Report

A comprehensive document that details the findings of the feasibility study. It assesses various aspects of the project, including technical feasibility, economic viability, market analysis, environmental impact, legal compliance requirements, and potential risks. The report concludes with recommendations on whether or not to proceed with the project.

3. Initial Environmental Impact Assessment (EIA)

This report evaluates the potential environmental impacts of the project, considering factors like biodiversity, water and air quality, and socio-economic effects. It also outlines mitigation strategies for any identified negative impacts.

4. Risk Assessment Report

Identifies potential risks to the project, including technical, financial, operational, and environmental risks. This document also suggests mitigation strategies to manage these risks effectively.

5. Market Analysis Report

Provides an analysis of the current market conditions, demand forecasts, competition analysis, and the economic justification for the project. This report is crucial for understanding the project’s commercial viability.

6. Technical Scope Document

Outlines the technical requirements and specifications of the project, including preliminary designs, technology options, and infrastructure needs. This document serves as a foundation for more detailed engineering work in later phases.

7. Cost Estimate Reports

Include initial cost estimates for the project, covering capital investment, operational expenses, and potential financial returns. These estimates are crucial for budgeting and financial planning.

8. Funding Proposal

If external financing is required, a funding proposal may be prepared to present to potential investors or lenders. This document includes the feasibility study report, cost estimates, and financial projections to demonstrate the project’s financial viability.

9. Regulatory Compliance Checklist

A document listing all regulatory approvals and permits required for the project, based on the initial environmental, legal, and technical assessments. This checklist helps ensure that the project meets all legal and regulatory requirements.

10. Stakeholder Engagement Plan

Outlines a strategy for communicating with and engaging stakeholders, including local communities, governmental bodies, and potential project partners. Effective stakeholder engagement is crucial for gaining project support and facilitating smooth project execution.

Request for Information (RFI)

A Request for Information (RFI) is a common business process document used in various industries, including construction, manufacturing, and technology, to gather detailed information from suppliers, contractors, or service providers. It’s a preliminary document issued early in the project lifecycle, often before formal procurement processes like Request for Proposal (RFP) or Request for Quotation (RFQ).

Purpose of an RFI:

- Clarification: RFIs are used to clarify project specifications, and product details, or to understand the capabilities of potential vendors or partners. It helps in gathering necessary information that might not be readily available.

- Decision Making: The information gathered through an RFI can aid in decision-making processes, helping to determine project feasibility, refine project requirements, or select the right vendors for further engagement.

- Scope Definition: It helps in defining the scope of work more accurately by understanding the market’s offerings, leading to more detailed and targeted RFQs or RFPs.

- Cost Estimation: While not a bidding document, an RFI can provide preliminary information that assists in budgeting and cost estimation.

- Vendor Pre-Qualification: RFIs can help in pre-qualifying vendors based on their responses, ensuring that subsequent RFQs or RFPs are sent to vendors capable of meeting project requirements.

Characteristics of an RFI:

- Non-binding: Responses to an RFI are generally non-binding and used for informational purposes only. They don’t typically result in a direct contract or purchase order.

- Open-ended Questions: RFIs often contain open-ended questions designed to gain comprehensive insights into the capabilities, products, or services of potential suppliers or partners.

- Broad Distribution: RFIs may be sent to a wide array of potential vendors to cast a wide net for gathering information.

Process of Issuing an RFI:

- Preparation: The issuing party prepares the RFI document, outlining the information needed.

- Distribution: The RFI is distributed to potential respondents, which can include vendors, contractors, or consultants.

- Response: Respondents provide the requested information by a specified deadline.

- Analysis: The issuing party analyzes the responses to inform their project planning, scope definition, or vendor selection processes.

An RFI is a crucial tool in the early stages of project planning and vendor selection, serving as a foundation for gathering essential information. It facilitates better-informed decisions, ensuring projects are well-defined and aligned with organizational goals before moving forward with more formal procurement processes.

Tender Package (Project Tender)

A project tender issued by an end user to award a project to EPC (Engineering, Procurement, and Construction) contractors is a formal invitation to submit bids for the design, procurement, construction, and commissioning of a project. This tender process is a critical component in the procurement strategy of organizations, especially those operating in industries like oil & gas, power generation, infrastructure, and construction, where projects are large-scale, complex, and require specialized skills and resources.

Purpose of the Tender:

The primary purpose of issuing a project tender is to select an EPC contractor who can deliver the project within the specified parameters of cost, time, quality, and safety. The tendering process ensures a competitive and transparent mechanism for awarding contracts, aiming to achieve the best value for money and adherence to project specifications.

Components of a Project Tender:

A typical project tender for EPC contracts includes the following components:

- Invitation to Tender (ITT): A document that formally invites potential contractors to participate in the bidding process, outlining the project scope and submission guidelines.

- Tender Documents: A comprehensive package that provides detailed information about the project, including:

- Project Scope: Detailed description of the project, including technical specifications, project objectives, and expected outcomes.

- Bid Submission Requirements: Instructions on how the bid should be structured, including any specific formats or templates to be used.

- Evaluation Criteria: The criteria against which bids will be evaluated, such as price, technical capability, project delivery approach, and past performance.

- Contract Terms and Conditions: Draft a contract outlining the legal, commercial, and technical terms and conditions that will govern the project execution.

- Request for Proposal (RFP) or Request for Quotation (RFQ): These documents ask contractors to provide detailed proposals or quotations based on the project requirements outlined in the tender documents.

- Instructions for Prequalification: For projects requiring specialized skills or significant financial commitment, an end user may include a prequalification process to identify contractors capable of delivering the project.

Tender Process:

The tender process typically involves several key stages:

- Preparation and Issuance: The end user prepares and issues the tender documents to potential EPC contractors.

- Pre-Bid Meetings: Optional meetings to clarify project requirements and answer potential bidders’ questions.

- Submission of Bids: Contractors submit their bids following the tender instructions.

- Evaluation: The end user evaluates the bids based on the predefined criteria.

- Award: The contract is awarded to the EPC contractor whose bid is determined to offer the best overall value, considering the price, technical expertise, and capability to deliver the project.

The issuance of a project tender by an end user is a critical step in the procurement of EPC services. It facilitates a structured and competitive process for selecting a contractor capable of meeting the project’s requirements efficiently and effectively. This process ensures transparency, fairness, and the selection of a contractor who can deliver the project to the end user’s satisfaction, within budget and on schedule.

Bid Bond

A bid bond is a type of surety bond that EPC (Engineering, Procurement, and Construction) contractors often need to submit along with their bid for a project. This bond serves as a financial guarantee issued by a third party (such as a bank or an insurance company) on behalf of the contractor to the end user (the project owner). The primary purpose of a bid bond is to ensure that the contractor is serious and financially capable of accepting the contract at the bid price if they are awarded the project.

Key Aspects of a Bid Bond:

- Commitment Assurance: It assures the end user that the contractor will enter into a contract and furnish the required performance and payment bonds if awarded the bid. This prevents contractors from submitting frivolously low bids or withdrawing their bids before a contract is signed.

- Compensation in Case of Withdrawal: If the winning bidder fails to proceed as per the terms, the bond compensates the end user for the difference between the winning bid and the next highest bid, up to the bond’s value, or covers the cost of re-tendering the project.

- Bid Security: Acts as a form of security for the end user, protecting against the risk of a contractor’s inability to commit to the project after being selected based on their bid.

- Value: The value of a bid bond is typically a percentage of the bid amount, often ranging from 1% to 5%, depending on the project’s requirements and the perceived risk by the end user.

- Cost and Validity: The cost of obtaining a bid bond varies depending on the contractor’s financial health and the bond’s amount. The bond is valid until the bidding process is complete, and either a contract is awarded and the required performance bonds are issued, or the bid is rejected.

Why a Bid Bond is Important in EPC Projects:

- Ensures Serious Bidders: It filters out non-serious bidders, ensuring that only financially stable and committed contractors compete for the project.

- Protects the End User: Provides financial protection to the end user if the winning contractor fails to honor the terms of the bid, thereby mitigating the risk and potential costs associated with bid withdrawal or failure to execute a contract.

- Facilitates Fair Competition: Encourages fair and competitive bidding by ensuring that contractors are held accountable for their bids, contributing to a more transparent and reliable tendering process.

In EPC projects, a bid bond is a crucial requirement during the tender process, offering a safeguard for the end user against the potential default or withdrawal of a bidder after being awarded a project. It underscores the bidder’s commitment and financial capability to carry out the project according to their bid, enhancing the integrity and efficiency of the bidding process.

PROJECT AWARD

EPC’s Technical/Commercial Offers

During the tendering stage of an EPC (Engineering, Procurement, and Construction) project, submitting technical and commercial offers to the end user is a critical process. These offers form the core of the bidding process, where EPC contractors outline how they plan to meet the project requirements and at what cost. Here’s an overview of what these offers typically include:

Technical Offer

The technical offer, or proposal, details the contractor’s engineering and technical solutions designed to meet the project specifications outlined by the end user. This document is crucial for demonstrating the contractor’s understanding of the project scope, their approach to design, and how they intend to execute the project. Key components include:

- Project Understanding and Methodology: An overview of how the contractor interprets the project requirements and their proposed methodology for project execution.

- Design and Engineering Solutions: Detailed descriptions of the engineering designs, technical solutions, and innovations the contractor proposes to use.

- Project Management Approach: Outline of the project management structure, including timelines, quality control measures, safety protocols, and communication strategies.

- Compliance with Specifications: Demonstrates how the proposed solutions meet or exceed the project’s technical specifications and regulatory requirements.

- Technology and Equipment: Information on the technology and equipment to be used, including any novel tools or techniques that offer advantages over standard practices.

Commercial Offer

The commercial offer focuses on the financial aspects of the proposal. It provides a detailed cost breakdown of the project, terms of payment, and any financial terms and conditions. Key elements include:

- Price Breakdown: Detailed cost estimates for all project components, including material costs, labor, equipment rental, and any other direct or indirect costs.

- Terms of Payment: Schedule and conditions under which payments will be made, including any advance payments, milestone-based payments, and retention fees.

- Validity Period: The timeframe for which the offer remains valid, giving the end user a deadline by which they need to make a decision.

- Bonds and Guarantees: Information on performance bonds, advance payment bonds, and warranties offered as part of the bid to ensure project completion and quality standards.

- Risk and Contingency Plans: Assessment of potential risks and the associated costs or contingencies included in the price to manage those risks.

Importance of Technical/Commercial Offers

The combination of technical and commercial offers enables the end user to assess the feasibility, cost-effectiveness, and compliance of each bidder’s proposal. These documents need to be comprehensive, clear, and aligned with the end user’s requirements to stand a chance of winning the bid. Contractors must meticulously prepare these offers to demonstrate their capability, experience, and competitiveness in delivering the project within the specified budget and timelines.

Conclusion

Technical and commercial offers are integral to the EPC tendering process, providing a basis for the end user to evaluate and select the most suitable contractor for the project. A well-prepared offer not only showcases a contractor’s technical proficiency and financial responsibility but also their commitment to meeting the project’s goals and delivering value to the end user.

Contract between End-User and Awarded EPC Contractor

A contract between an end-user and an awarded EPC (Engineering, Procurement, and Construction) contractor formalizes the agreement for the execution of a project from start to finish under specified terms. This document is crucial as it outlines the responsibilities, scope, timelines, financial details, and legal obligations of both parties. Here’s a comprehensive overview of the key elements typically included in such a contract:

1. Introduction and Background

- Parties Involved: Clearly identify the end-user (client) and the awarded EPC contractor.

- Project Description: Provides a brief overview of the project, including its purpose and expected outcome.

2. Scope of Work

- Detailed Specifications: Outlines in detail the work to be performed by the EPC contractor, including engineering and design, procurement of materials and services, construction activities, and commissioning and start-up of the facility.

- Exclusions: Specifies any services or components not included in the contract scope.

3. Contract Price and Payment Terms

- Total Contract Value: States the total agreed-upon price for the project execution.

- Payment Schedule: Details the payment milestones, including any advance payments, progress payments, and the final payment conditions.

- Adjustment Mechanisms: Conditions under which the contract price can be adjusted, such as changes in scope or unforeseen circumstances.

4. Project Schedule and Milestones

- Timeline: Specifies the project start date, critical milestones, and completion date.

- Delay Penalties: Defines penalties for delays attributable to the contractor and conditions for extensions due to unforeseeable circumstances.

5. Quality and Performance Guarantees

- Standards and Testing: Details the quality standards, testing, and inspections to be adhered to during project execution.

- Warranties and Guarantees: Outlines the performance guarantees and warranties provided by the contractor for the work completed.

6. Risk Management and Insurance

- Liabilities: Describes the liabilities of each party and the indemnities provided.

- Insurance: Specifies the types and levels of insurance coverage that the contractor must maintain.

7. Change Order Procedures

Management of Changes: Defines the process for managing changes in scope, including how change orders are initiated, approved, and priced.

8. Dispute Resolution

Mechanisms for Resolution: Outlines the agreed-upon mechanisms for dispute resolution, which may include negotiation, mediation, arbitration, or litigation.

9. Termination Clauses

Conditions for Termination: Specifies the conditions under which either party may terminate the contract and the associated consequences.

10. Governing Law

Jurisdiction: Identifies the legal jurisdiction and governing law under which the contract will be interpreted and disputes resolved.

11. Miscellaneous Provisions

- Confidentiality: Obligations to maintain the confidentiality of project and contract information.

- Force Majeure: Conditions under which parties are relieved from liability for non-performance due to events beyond their control.

The contract between an end-user and an awarded EPC contractor is the foundation of their partnership on a project. It ensures there is a mutual understanding of expectations, responsibilities, and procedures, aiming to minimize risks and disputes. This comprehensive legal document requires careful consideration and negotiation by both parties to ensure a successful project outcome that meets the end user’s requirements within the agreed timelines and budget.

Performance Bond

A performance bond opened by an EPC (Engineering, Procurement, and Construction) contractor in favor of the end user for an EPC project is a financial guarantee issued by a third party (usually a bank or an insurance company) that ensures the completion of the project according to the contract terms. This bond is a key element in project contracts, particularly in large and complex projects typical of the construction, infrastructure, and energy sectors.

Purpose of a Performance Bond:

The primary purpose of a performance bond is to protect the end user (the project owner) if the contractor fails to fulfill their contractual obligations, such as failing to complete the project on time, within budget, or to the quality standards specified in the contract. If the contractor does default, the bond provides financial compensation to the end user, covering losses up to the bond amount.

Key Features of Performance Bonds:

- Security for End User: Acts as a form of insurance, giving the end user confidence that the contractor has the financial stability and commitment to complete the project as agreed.

- Contractor Qualification: Only contractors who are financially stable and have a good track record are typically able to secure performance bonds, which serve as a qualification criterion.

- Bond Value: The value of the bond is usually a percentage of the total contract value, often ranging from 10% to 20%, depending on the project’s size, complexity, and perceived risk.

- Cost: The contractor usually pays for the performance bond, and the cost depends on the contractor’s creditworthiness and the bond amount.

- Duration: The bond remains in effect until the project is completed and sometimes during the warranty period, ensuring that the contractor rectifies any defects arising after project completion.

Process of Claiming Against a Performance Bond:

If the contractor fails to meet their contractual obligations, the end user can claim compensation up to the bond amount. The process typically involves:

- Notification: The end user notifies the bonding company of the contractor’s default and files a claim.

- Verification: The bonding company investigates the claim to verify the default.

- Compensation: If the claim is valid, the bonding company compensates the end user for losses up to the bond amount.

A performance bond is an essential risk management tool in EPC projects, offering financial protection to the end user against contractor default. By requiring a performance bond, the end user mitigates the risk of project delays, cost overruns, or substandard work, ensuring that the project progresses toward successful completion even in the face of contractor challenges.

PROJECT EXECUTION

During the execution of an EPC project, and focusing on the typical documents issued by the procurement department or the products/equipment/service suppliers involved in the project, the following typical documents are found:

- Request for Information (“RFI”)

- Request for Proposal (“RFP”)

- Request for Quote (“RFQ”)

- Suppliers’ technical & commercial offers

- Bid tabulations

- Purchase Order (“PO”)

- Purchase Order Confirmation (POC or “OC”)

- Status reports (for suppliers providing services)

- Non Conformity Reports (“NC”)

- Shipping documents (Invoice, packing list, mill test certificates)

- Supplier’s assessment reports

Let’s delve into some details for each of these typical EPC documents:

Request for Information

Just as RFIs are utilized in the process of awarding the overall project contract, the procurement department of an EPC contractor, working alongside the engineering department, might also issue RFIs during the project execution phase. For further information on RFIs, refer to the preceding paragraph, as the same principles, and guidelines are applicable.

Request for Proposal (“RFP”)

A Request for Proposal (RFP) is a formal document issued by an organization seeking to procure goods or services from external suppliers, during the execution of an EPC project. It invites suppliers to submit comprehensive proposals that not only include pricing details but also provide information on how the supplier intends to meet the project’s requirements. An RFP is typically used when the project or service requirements are complex and cannot be met by a simple bid based solely on price.

Key Components of an RFP:

- Project Overview and Background: Provides context about the project, the issuing organization, and its objectives.

- Scope of Work (SOW): Clearly outlines the specifics of the work or service needed, including tasks, deliverables, timelines, and performance criteria.

- Submission Guidelines: Details the format, deadline, and process for submitting proposals, including any mandatory meetings or presentations.

- Evaluation Criteria: Specifies the criteria against which proposals will be evaluated, such as technical capability, approach, past performance, and cost.

- Terms and Conditions: Includes legal and contractual terms, confidentiality agreements, and requirements for warranties or guarantees.

Purpose of an RFP:

- Clarity and Specification: Ensures that all potential suppliers have a clear understanding of the project requirements and evaluation criteria.

- Fair Competition: Provides a level playing field for all bidders by outlining the same information and expectations.

- Quality and Value: This enables the organization to assess not just the cost but also the quality and value offered by each supplier, considering their approach, methodology, and compliance with the project requirements.

- Informed Decision Making: Facilitates a structured process for comparing proposals and making informed decisions based on comprehensive and comparable data.

When is an RFP Used?

RFPs are particularly useful in situations where:

- The project or service requirements are complex or not fully defined, requiring input or suggestions from suppliers.

- The buyer is looking to evaluate potential suppliers based on criteria other than just price, such as quality, expertise, and innovation.

- There’s a need to establish a long-term partnership with the supplier rather than just make a one-off purchase.

The RFP process is a critical component in the procurement strategy of many organizations, particularly for complex projects or when seeking a partnership approach from suppliers. It allows buyers to compare and contrast different proposals on aspects beyond price, ensuring that the chosen supplier can meet the project’s needs most effectively and efficiently.

Request for Quote (“RFQ”)

A Request for Quote (RFQ) in the context of EPC (Engineering, Procurement, and Construction) procurement is a formal document issued by the EPC contractor (procurement officers, in cooperation with engineering and project management, for high-value materials) to potential suppliers or subcontractors (generally the “approved vendors” either of the EPC itself or the End-User – in case an End-User approved vendor list applies to the project).

The purpose of an RFQ is to invite suppliers to submit a bid to supply specific goods or services at specified prices and terms. Unlike a Request for Proposal (RFP) that seeks detailed proposals on how the work will be done, an RFQ focuses primarily on the price and delivery terms for the required items or services.

RFQs are generally backed by real purchase needs that have to be fulfilled for the execution of the project: an example can be an RFQ issued to pipes manufacturers as a pipeline has to be laid down in the context of the project in execution.

Key Features of an RFQ:

- Specificity: RFQs are used when the requirements, specifications, and quantities of the goods or services are already well-defined, allowing suppliers to provide precise quotes.

- Price Focus: The main objective is to obtain and compare prices from various suppliers to find the best value. While quality and service are still considered, the primary decision factor is often cost (provided the technical features offered by different suppliers are interchangeable).

- Efficiency: RFQs streamline the procurement process, especially for standard or off-the-shelf items, by simplifying the bidding and selection process.

- Terms and Conditions: Besides price, RFQs may also request details on delivery schedules, payment terms, and warranty conditions.

Purpose of an RFQ in EPC Procurement:

- Cost Estimation: RFQs help in estimating the costs of materials and services for budgeting purposes during the initial phases of the project.

- Vendor Selection: They facilitate the selection of suppliers and subcontractors based on price competitiveness and ability to meet delivery schedules and other terms.

- Negotiation Tool: The process of requesting and comparing quotes can serve as a basis for negotiating better prices or terms with suppliers.

- Procurement Efficiency: For items with known specifications, RFQs make the procurement process faster and more efficient, allowing the EPC contractor to focus on critical project activities.

Process of Issuing an RFQ:

- Preparation: The EPC contractor or project owner prepares an RFQ document detailing the specific requirements for the goods or services, including technical specifications, quantities, delivery expectations, and any other relevant information.

- Issuance: The RFQ is issued to potential suppliers or subcontractors, often those pre-qualified or identified through prior research or projects.

- Bid Submission: Suppliers submit their quotes by the specified deadline, outlining their prices and compliance with the terms outlined in the RFQ.

- Evaluation: The EPC contractor evaluates the received quotes, considering the price, supplier reliability, and the ability to meet the specified requirements.

- Award: The contract is awarded to the supplier offering the best value, which may involve further negotiations to finalize the terms.

In the EPC procurement process, an RFQ is a crucial tool for quickly and efficiently obtaining competitive prices for well-defined goods and services. It allows EPC contractors to manage costs effectively, ensuring that projects can be completed within budget and on schedule.

Why are RFQs Used?

RFQs (Request for Quotes) are essential in acquiring goods and services where fixed price lists or prior contractual agreements do not apply. In situations where specific products or services require competitive bidding to determine the most favorable offer, buyers utilize RFQs to solicit bids from various suppliers before issuing purchase orders on an individual basis.

RFQs are particularly vital for procuring items and services characterized by variable commercial conditions—such as price, delivery schedules, and payment terms—or where pricing is not transparent. This includes:

- Products crafted from raw materials whose market prices are subject to fluctuations, like base metals including nickel, chrome, and molybdenum.

- Items available in a range of configurations, necessitating customized quotes based on the specific version selected.

- Goods whose pricing may alter significantly with the quantity ordered, affecting the total cost in a manner not predetermined by standard pricing.

In essence, RFQs provide a structured method for buyers to obtain and compare offers from multiple suppliers for products and services with variable or unclear pricing, ensuring that purchase decisions are made based on competitive and comprehensive bids.

RFQs Typical Content

While the content of an RFQ can vary depending on the industry and the complexity of the request, certain key elements are commonly included:

1. Introduction or Overview

- Brief description of the company issuing the RFQ and the purpose of the request.

- Overview of the project or need for which the goods/services are required.

2. Scope of Work or Specifications

- Detailed description of the products or services needed.

- Specifications such as quantity, size, materials, performance criteria, and any applicable standards.

- Technical drawings or schematics, if applicable.

3. Submission Guidelines

- Instructions on how to submit the quote.

- The format in which responses should be provided.

- Contact information for submitting questions or clarifications.

4. Evaluation Criteria

Criteria that will be used to evaluate and compare the quotes, may include price, delivery time, quality standards, and compliance with specifications.

5. Pricing

- Request for detailed pricing information, including unit prices, total cost, taxes, and any discounts.

- Instructions for including shipping or delivery costs.

6. Delivery Terms

- Desired delivery schedule or timeline.

- Preferred delivery location(s).

7. Payment Terms

- Preferred payment terms and conditions.

- Any required payment schedules.

8. Validity Period

The period for which the quoted prices must remain valid.

9. Confidentiality and Non-Disclosure Agreements (if necessary)

Terms regarding the confidentiality of the RFQ details and any responses received.

10. Terms and Conditions

- Legal and contractual terms that will apply to the procurement contract.

- Compliance requirements with local laws and regulations.

11. Requirements for Samples or Demonstrations (if applicable)

Request for samples or demonstration of products/services for evaluation purposes.

The RFQ is a foundational document in the procurement process, designed to ensure that all potential suppliers have a clear understanding of the buyer’s needs and the terms under which they are expected to deliver. By carefully specifying these elements, organizations can facilitate a transparent, fair, and effective bidding process that leads to the selection of the most suitable supplier for their needs.

Difference Between RFQ and RFP/RFI

RFP and RFI stand for Request for Proposal and Request for Information, respectively. These procurement documents are typically issued in the initial phases of project procurement, before the Request for Quotation (RFQ):

- A Request for Information (RFI) is utilized to evaluate suppliers (for purposes such as updating approved vendor lists, incorporating second-source suppliers, or understanding product offerings).

- A Request for Proposal (RFP) is dispatched to suppliers when the procurement team requires detailed information on the technical and commercial specifics of a forthcoming purchase, aiming to gather diverse proposals from several vendors.

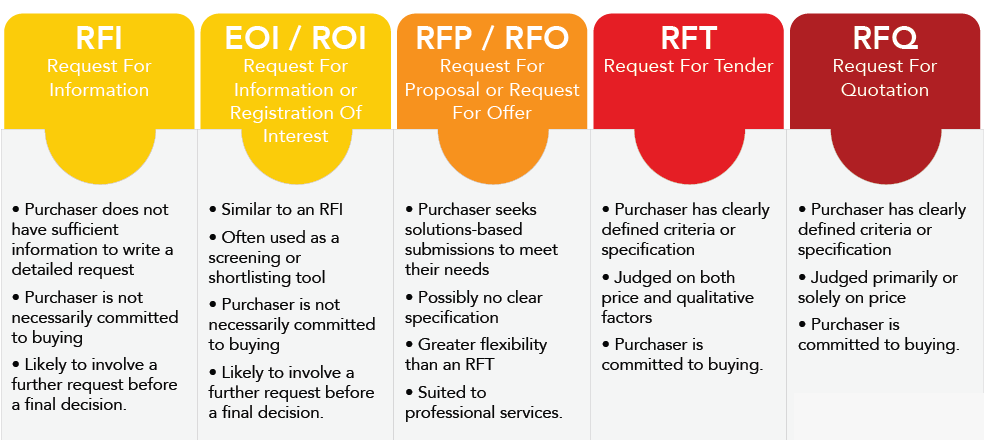

Additionally, EPC contractors and the procurement departments of end-users employ other types of documents, including the “RFT” (Request for Tender) and ROI (Registration of Interest), as illustrated in the provided diagram.

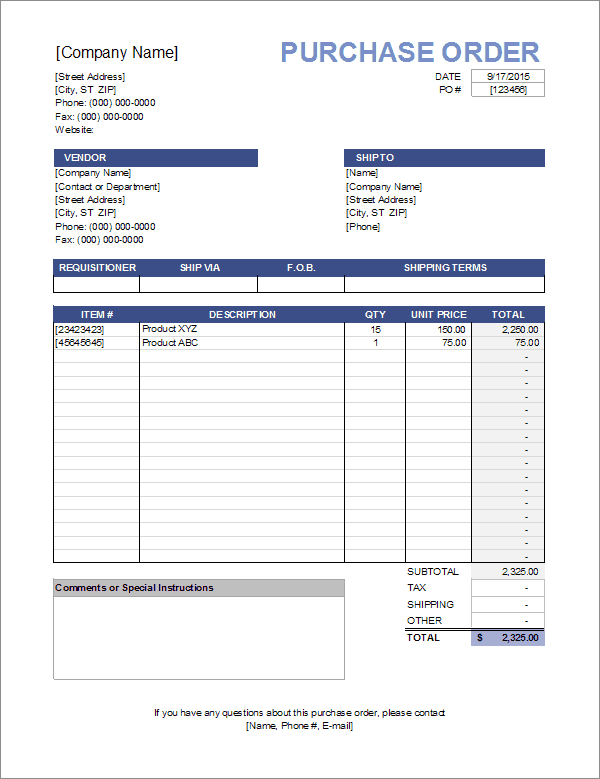

Purchase Order (“PO”)

A Purchase Order (PO) issued by an EPC (Engineering, Procurement, and Construction) contractor during the execution of an EPC project is a formal document sent to a supplier or vendor, authorizing the purchase of goods or services under specified conditions. It is a crucial component of the procurement process in project management, especially in industries like construction, oil and gas, and infrastructure, where large-scale projects necessitate the acquisition of numerous materials, equipment, and subcontracted services.

Key Elements of a Purchase Order:

- PO Number: A unique identifier for tracking and reference purposes.

- Vendor Information: Details of the supplier or service provider.

- Buyer Information: Information about the EPC contractor issuing the PO.

- Description of Goods or Services: A detailed list of the items or services being purchased, including quantities and specifications.

- Prices: The agreed-upon prices for the goods or services.

- Delivery Terms: Instructions on delivery schedules, locations, and logistics.

- Payment Terms: Conditions under which payment will be made, including payment schedules, due dates, and any discounts.

- Quality Requirements: Specifications for quality standards and acceptance criteria.

- Legal and Regulatory Compliance: Any necessary compliance with legal, safety, or regulatory standards.

Purpose of a Purchase Order in EPC Projects:

- Formalizes the Transaction: A PO legally binds the supplier to provide the specified goods or services at the agreed prices and terms.

- Clarifies Orders: It ensures clarity on the order details, reducing the risk of misunderstandings between the EPC contractor and the supplier.

- Facilitates Financial Planning: By detailing the costs associated with procurement, a PO helps in budgeting and financial management of the project.

- Enables Tracking: Purchase orders facilitate the tracking of orders and deliveries, aiding in project scheduling and logistics management.

- Streamlines Procurement: Standardizing the procurement process with POs helps in managing multiple orders efficiently, ensuring that all purchases are documented and traceable.

In the context of an EPC project, issuing a Purchase Order is a critical step that signifies the formal agreement to buy specific goods or services necessary for project execution. It serves not only as a procurement tool but also as a control mechanism to manage costs, ensure quality, and coordinate the timely delivery of resources, contributing to the smooth progress and successful completion of the project.

UOM (Unit of Measure) in PO

UoM stands for “unit of measurement” or “unit of measure”, i.e. the type of measure to express the quantity of a product (for example meters, eaches, tons, etc.).

UoM is an important indicator in RFQs, bids, contracts, POs, and other commercial documents to make sure the parties agree on an exact quantity of goods to be sold and purchased.

MOQ (Minimum Order Quantity) in PO

MOQ means “minimum order quantity”, i.e. the minimum order that a seller is willing to deliver under a single order.

The minimum order quantity is higher in B2B than in B2C business (1 unit could be a sufficient quantity for retail sales) and is related to the economic batch of production.

MOV (Minimum Order Value) in PO

MOQ differs from MOV, which is the “minimum order value”, i.e. the lowest amount of a purchase order that a seller can accept and confirm. A minimum order value is set to prevent small orders that generate high handling and overhead costs, which may be not compensated.

From RFQ to offers and Purchase Order

The procurement process for materials and services in projects typically unfolds as follows:

- EPC contractors issue Requests for Information (RFIs), Requests for Proposals (RFPs), and Requests for Quotations (RFQs).

- Suppliers respond with their proposals, detailing technical specifications and commercial terms, or submit proforma invoices.

- EPC contractors assess the received offers, engaging in technical and commercial clarifications or negotiations to evaluate the best fit.

- After evaluation, EPC contractors shortlist preferred suppliers and decide on the order’s distribution, which could involve one or several suppliers.

- The EPC contractor then formalizes the agreement by issuing purchase orders to the selected supplier(s).

- The supplier(s) review the purchase order and either confirm acceptance or enter into a negotiation cycle to ensure the PO accurately reflects both parties’ requirements.

Once these steps are concluded, the supplier(s) initiate the delivery of goods or services and proceed to invoice the EPC contractor.

The payment schedule for these invoices is determined by the terms outlined in the purchase order, dictating when payments to suppliers should be made following delivery.

When a buyer issues a Purchase Order (PO) and the seller confirms it, both parties become legally committed to the transaction. As such, a PO often carries the same legal weight as a formal “sales and purchase contract.” Typically, contracts are reserved for transactions that are more complex and detailed than those covered by POs.

Can a Purchase Order be Cancelled?

Yes, a Purchase Order (PO) can be generally canceled, but the process and implications of doing so depend on the terms and conditions outlined in the PO itself, any overarching contract between the parties, and the stage of fulfillment.

Cancellation can be straightforward or complex, influenced by how much work has already been done by the supplier, whether custom materials have been ordered or produced, and the specific cancellation terms agreed upon.

Before Cancellation:

- Review PO Terms: It’s crucial to review the cancellation clauses within the PO or any related contract. These clauses detail the conditions under which a PO can be canceled, including any notice period required and penalties or costs associated with cancellation.

- Communication: Early and clear communication with the supplier is essential. Discussing potential issues as soon as they arise can lead to mutually agreeable solutions, sometimes avoiding the need for cancellation.

Possible Outcomes:

- Mutual Agreement: The best scenario is reaching a mutual agreement for cancellation that minimizes financial impact and maintains business relationships.

- Cancellation Fees: Many POs include terms that require the buyer to pay cancellation fees or reimburse the supplier for expenses already incurred, especially if work has commenced or materials have been ordered.

- Legal Implications: If the cancellation terms are not clearly defined or the supplier disputes the cancellation, legal action could ensue. The enforceability of a cancellation and any associated penalties will depend on the contract law applicable to the PO.

After Cancellation:

- Confirmation in Writing: Any agreement to cancel a PO should be documented in writing to avoid misunderstandings or future disputes.

- Settlement of Obligations: The buyer may need to settle any outstanding obligations, such as paying for work already completed or covering restocking fees for materials ordered by the supplier.

Alternatives to Cancellation:

- Modification: Instead of cancellation, consider whether the PO can be modified to address the issues at hand. This could involve changing the scope, delivery timelines, or other terms.

- Delay: If the issue is temporary, it may be possible to delay delivery or execution rather than cancel the order outright.

Canceling a PO is legally permissible but comes with various considerations, including potential costs, the impact on business relationships, and the specifics of any contractual agreement. Careful review of the PO terms and open communication with the supplier are key steps in the cancellation process.

Purchase Order Confirmation (“OC”)

A Purchase Order Confirmation by a vendor to an EPC (Engineering, Procurement, and Construction) contractor is a formal acknowledgment that the vendor has received and agrees to the terms of the Purchase Order (PO) issued by the EPC for the supply of goods or services.

This confirmation is a crucial step in the procurement process, signifying the vendor’s commitment to fulfilling the order as specified within the PO, including delivery of the specified goods or services, quantities, prices, delivery timelines, and other conditions outlined.

Key Elements of a PO Confirmation:

- PO Details: Reiteration of the PO number, date, and specific details of the goods or services to be supplied.

- Acceptance of Terms: Explicit acceptance of the prices, terms, and conditions specified in the PO.

- Delivery Schedule: Confirmation of the delivery dates or schedule agreed upon, ensuring alignment with the EPC contractor’s project timeline.

- Quantities and Specifications: Verification of the quantities and specifications of the goods or services to be provided.

- Any Modifications or Clarifications: Details of any modifications or clarifications to the original PO terms, if negotiated after the initial issuance.

Importance of PO Confirmation:

- Secures Supply Chain: Ensures that both parties have a mutual understanding and agreement on what is being supplied, safeguarding against misunderstandings.

- Facilitates Project Planning: Confirmed delivery schedules and terms help the EPC contractor in project scheduling and management.

- Legal Clarity: Acts as a legal document that can be referenced in case of disputes regarding order details or fulfillment.

- Financial Planning: With confirmed prices and terms, the EPC contractor can finalize budget allocations and financial planning for the project.

Process:

After receiving a PO from an EPC contractor, the vendor reviews the document to ensure that they can meet the specified requirements. The vendor then issues a PO Confirmation, which can be in the form of a letter, email, or through a digital procurement platform. This confirmation may also involve negotiation if the vendor needs to request changes to the original PO terms. Once both parties agree on the terms, the confirmation is sent, effectively finalizing the transaction details and enabling the vendor to proceed with fulfilling the order.

Risk management shall be in place before issuing purchase order confirmations, due to the legally binding nature of such documents: learn more about the insidious clauses that EPC contractors and other professional buyers may include/omit in purchase orders and contracts.

Purchase Order Confirmation by a vendor to an EPC contractor is a fundamental step in formalizing the procurement transaction. It not only reinforces the vendor’s commitment to delivering as per the EPC’s requirements but also provides a foundation for effective project execution and management by ensuring that all procurement-related terms are clearly understood and agreed upon by both parties.

EPC PROCUREMENT SOFTWARE

Some of the documents described above, such as RFI, RFPs, RFQ, and POs, are generated by EPC Contractors using dedicated procurement software such as SAP, and/or SAP Ariba, and Oracle (ERP systems).

For EPC (Engineering, Procurement, and Construction) contractors in the oil & gas industry, selecting the right procurement software is crucial for streamlining operations, ensuring supply chain efficiency, and maintaining cost-effectiveness throughout large-scale projects. These software solutions not only facilitate procurement activities but also integrate them with project management and financial systems.

Here are some notable procurement software options tailored to the needs of EPC contractors in the oil & gas sector, and a brief description of their capabilities and uses:

SAP ARIBA

SAP Ariba plays a significant role in facilitating procurement processes within Engineering, Procurement, and Construction (EPC) projects. As a comprehensive cloud-based procurement solution, Ariba offers a suite of tools designed to streamline and enhance the procurement lifecycle, from sourcing and purchasing to invoice management and payment. Its impact on EPC project procurement can be seen in several key areas:

1. Supplier Discovery and Management

Ariba provides access to a global network of suppliers, making it easier for EPC contractors to discover and vet potential vendors for project-specific materials, equipment, and services. It enables efficient management of supplier information, qualifications, and performance metrics, facilitating better supplier selection and collaboration.

2. Sourcing and RFx Processes

Ariba streamlines the sourcing process by allowing EPC contractors to issue Requests for Information (RFIs), Requests for Proposals (RFPs), and Requests for Quotations (RFQs) directly through the platform. This simplifies the management of bidding processes, comparisons of proposals, and the negotiation of terms, ensuring that EPC projects can secure the best value from suppliers.

3. Contract Management

The software provides robust tools for creating, negotiating, and managing contracts with suppliers. By centralizing contract information, Ariba helps EPC contractors maintain compliance, manage risks, and ensure that procurement activities align with project specifications and budgets.

4. Purchase Order Management

Ariba automates the creation, issuance, and tracking of Purchase Orders (POs), facilitating real-time visibility into procurement transactions. This automation helps in reducing errors, speeding up order processing, and improving communication with suppliers.

5. Invoice and Payment Processing

The platform streamlines invoice handling and payment processes, supporting efficient and accurate financial transactions. Ariba’s capability to automate invoice matching and approval workflows significantly reduces processing times and helps manage cash flows more effectively.

6. Collaboration and Communication

Ariba fosters improved communication and collaboration between EPC contractors and their suppliers. The platform’s collaborative features ensure that all parties are aligned on order details, delivery schedules, and any changes or adjustments that may arise during the project lifecycle.

7. Analytics and Reporting

With advanced analytics and reporting features, Ariba provides EPC contractors with valuable insights into their procurement activities. Contractors can analyze spending, supplier performance, and compliance metrics to make informed decisions and identify opportunities for cost savings and efficiency improvements.

SAP Ariba’s software significantly enhances the efficiency, transparency, and effectiveness of procurement processes in EPC projects. By offering a comprehensive set of tools for managing the end-to-end procurement lifecycle, Ariba enables EPC contractors to navigate the complexities of sourcing and managing suppliers, ensuring that projects are delivered on time, within budget, and in compliance with quality standards.

ORACLE PROCUREMENT CLOUD

Part of Oracle Cloud ERP, this solution offers a complete suite of applications for automating and managing procurement processes. It includes modules for supplier qualification management, sourcing, procurement contracts, and purchasing, all designed to enhance efficiency and reduce costs. Oracle Procurement Cloud is well-suited for EPC contractors seeking extensive analytics and integration capabilities.

COUPA

Coupa’s Business Spend Management platform provides a unified suite of cloud applications for procurement, invoicing, and expense management. Its user-friendly interface and comprehensive spend management tools help EPC contractors optimize their procurement processes, achieve cost savings, and enhance supplier collaboration.

IVALUA

Ivalua offers a broad procurement management platform that enables EPC contractors to manage the entire procurement lifecycle on a single platform. It’s known for its flexibility and depth, allowing customization to fit the complex needs of the oil & gas industry, including risk management, contract management, and supplier relationship management.

JAGGAER

JAGGAER’s procurement software specializes in direct and indirect spend management, offering solutions that cover the entire procurement process. It includes advanced features for sourcing, supplier management, contracts, and analytics. JAGGAER is ideal for EPC contractors looking for industry-specific functionalities, such as handling complex categories like equipment and materials unique to the oil & gas sector.

PROCON

Specifically designed for the construction and engineering industries, Procon integrates project cost management with procurement, subcontract management, and financials. It offers a focused solution for EPC contractors in the oil & gas industry, emphasizing cost control and project visibility.

PROCUREWARE

ProcureWare is a procurement and supplier management solution that offers bidding, supplier management, and contract management features. It is suitable for EPC contractors seeking an easy-to-use platform that can be customized to support the unique procurement workflows of oil & gas projects.

4 Responses

Thank you

I get good information,definition and clarification of biased ideas’.

Thank you for your kind words, Sisay. I’m glad to hear that you found the information provided helpful in understanding the concept of RFQ (Request for Quote). It’s always important to have a clear understanding of terms and concepts to avoid any biased ideas or misconceptions. If you have any further questions or if there’s anything else I can assist you with, please feel free to ask.

Hello

In your case , you ought to take part of certain number of commercial events such as trade fairs in order to get known and be seen. ..

Best regards

Doing manufacturer of flanges in automobile sectors.But I don’t know how to get started this.your guidance required so that I can work on it to start.