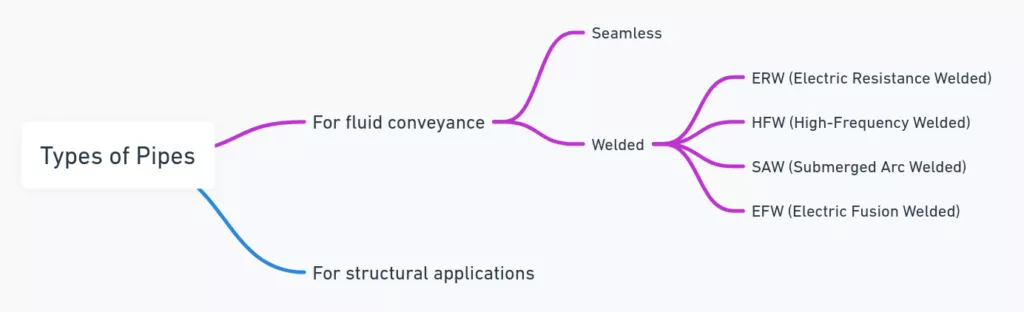

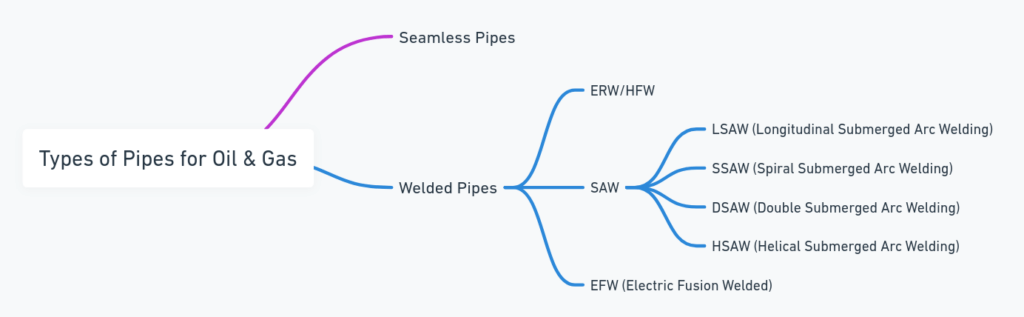

Seamless pipes are produced without a seam, making them a go-to for high-pressure scenarios due to their uniform strength throughout. They’re formed by stretching a solid steel billet into a pipe shape, perfect for when integrity under pressure is non-negotiable.

Welded pipes come into play when length and diameter flexibility outweigh the seamless advantage. They fall into categories based on their welding process: Electric Resistance Welded (ERW) pipes are produced by forming steel — usually, a steel coil, strip, or sheet — into a tubular shape by applying high-frequency electrical currents (ERW pipes are ideal for moderate-pressure applications). HFW (High-Frequency Welded) pipes utilize a similar process but with higher frequencies, resulting in a finer weld seam, enhancing the pipe’s strength and efficiency.

SAW (Submerged Arc Welded) pipes are named for their fabrication process, where the weld is the submerged type. This category splits further into LSAW (Longitudinal), where the arc welds along the length; DSAW (Double Submerged Arc Welded), which involves double welding for extra thickness; and SSAW (Spiral), where the weld spirals around the pipe, lending it strength and flexibility, suitable for water applications. Besides these types of pipes used to convey fluids, another category is the “structural type” – i.e. pipes and tubes used for construction purposes. All these types of pipes are examined in this article.

Introducing Steel Pipes

Steel pipes are essential components in various industries and applications, serving as either conduit for fluids, gases, and solids and/or for structural applications.

Their versatility, durability, and strength make them indispensable in sectors ranging from construction and infrastructure to oil and gas exploration. This chapter delves into the characteristics, types, uses, and manufacturing processes of steel pipes, seamless (SMLS), electrically welded (ERW/HFW), electrical-fusion welded (EFW), and longitudinally welded (LSAW, DSAW, SSAW), shedding light on their importance in modern society.

Steel pipes find extensive applications across diverse industries and sectors, contributing to infrastructure development, transportation, energy production, and manufacturing processes. Some common uses include:

- Fluids Conveyance: Steel pipes serve as conduits for transporting liquids, gases, and solids in industries such as oil and gas, water supply, sewage systems, and chemical processing.

- Structural Support: Steel pipes provide structural support in buildings, bridges, tunnels, and offshore platforms, withstanding heavy loads, seismic forces, and environmental stresses.

- Industrial Processes: In manufacturing and industrial processes, steel pipes facilitate the conveyance of raw materials, products, and by-products, playing vital roles in material handling, heating, cooling, and ventilation systems.

- Utilities and Infrastructure: Steel pipes are integral components of utilities infrastructure, including water distribution networks, gas pipelines, telecommunications systems, and power generation facilities, ensuring reliable and efficient operations.

Steel pipes for the oil & gas industry specifically, the topic of this article, come in four main categories, each designed to serve specific purposes and applications:

- Seamless Steel Pipes (SMLS): Manufactured without welding seams, seamless steel pipes offer uniformity, strength, and reliability, making them ideal for high-pressure and critical applications such as oil and gas transmission, power generation, and automotive manufacturing.

- Electrically Welded Pipes (ERW/HWF): this category includes ERW and HFW pipes, both fabricated starting from steel coils or sheets and an electrical welding process

- Electrical Fusion Welded Pipes (EFW): pipes are fabricated through a process that involves heating and combining steel materials through electric fusion. This method utilizes either a high-energy electric arc or a high-pressure electric resistance method to melt and fuse materials together to form a coherent structure. EFW pipes are recognized for their strong welds and are typically used in high-pressure and high-temperature applications

- Submerged Arc-Welded Steel Pipes (SAW): Fabricated by welding plates, submerged arc-welding pipes come in various forms, including longitudinal (LSAW), spiral (HSAW), and double weld (DSAW). They find applications in construction, infrastructure, water distribution, and industrial processes.

Types of pipes for oil & gas (fluids conveyance: Oil, Gas, Derivative Products)

Let’s now delve into the characteristics of the three main types of steel pipes for the oil & gas industry, namely seamless steel pipes, ERW steel pipes, and SAW steel pipes:

Seamless Pipe

Seamless pipes are produced starting from steel billets, that are heated and perforated to create the tubular section. The word “seamless” means the absence of seam welds.

Seamless pipes are widely renowned for their exceptional durability and superior efficiency in fluid flow. Due to their seamless surface and absence of welds or joints, they exhibit outstanding resistance to leaks, high pressure, and extreme temperatures.

These qualities make them an ideal choice not only in the oil and gas sector but also in fields ranging from fluid transportation (oil, gas, slurry pipelines) to construction and medical equipment, where they have proven vital for withstanding heavy loads and resisting corrosion.

Seamless steel pipes are used for different applications within the oil & gas industry:

- Upstream operations (OCTG pipes)

- Midstream (transmission and distribution of fluids, such as oil, gas, steam, acids, and slurries)

- Downstream (process piping to refine oil and gas in derivative products)

- General plumbing applications for utility services

The most common types of pipes used in the oil&gas industry are (ASTM pipe specifications):

- ASTM A53, A106, A333, and API 5L (types of carbon steel pipes for high and low-temperature carbon steel)

- ASTM A335 Grades P5 to P91 (chrome-moly alloy steel pipes for high temperature and pressure, for refinery and power plant applications)

- ASTM A312 Series 300 and 400 (stainless steel pipes in grades 304, 316, 321, 347)

- ASTM A790/A928 (duplex and super duplex pipes with double ferritic and austenitic structure)

- Various nickel alloys material specifications (Inconel, Hastelloy, Cupronickel, Monel, Nickel 200)

- Specifications for non-ferrous pipes (aluminum, copper, brass, cupro-nickel)

Some specifications cover seamless pipes only (for example ASTM A106), while others apply both to seamless and welded pipes (for example ASTM A53).

Carbon steel pipes (A53, A333, A106, and API 5L) have the largest market share, as they can be used for most high and low-temperature applications; the main application of stainless steel pipes is for corrosive services (and higher grades are used as the temperature and the pressure increase, or when the conveyed fluid is more and more aggressive).

In the upstream oil & gas industry, API 5CT is the key specification covering OCTG pipes (oil country tubular goods).

Seamless steel pipes shall not be confused with seamless tubes. Indeed, there are a few important differences between pipes and tubes, which are not only semantic.

In general, the word “pipe” applies to any tubular used to convey fluids, whereas the word “tube” applies to tubular sections (of various shapes, round, oval, squared) used for structural/mechanical applications, instrumentation systems, and the construction of pressure equipment like boilers, heat exchangers, and superheaters.

Seamless Pipe Price

Seamless pipes have a higher price per ton than ERW pipes, generally 20 to 30% higher, due to their fairly complex production process (more articulated than the manufacturing process of ERW and LSAW pipes) and because the number of seamless pipe manufacturers is rather limited (the market has an oligopolistic nature).

For specific sizes and specifications (for example a 20-inch pipe or a high wall thickness pipe in special or exotic materials, for example, ASTM A335 P91 pipes), there are few global pipe suppliers, and prices per ton (or per meter) are, as a consequence, impacted.

Due to this fact, it is a wrong practice to estimate pipe prices using a standard price per ton for all “carbon steel” or “stainless steel” pipes, regardless of the actual diameter, wall thickness, and specific grade: all these factors shall be taken into consideration to prevent cost overruns during the execution of the project at a later stage. Moreover, prices fluctuate daily (especially for alloyed pipes, which contain chemical elements like Molybdenum, Nickel, Copper, and Chromium traded daily on the London Metal Exchange or the Ferro-Alloy markets).

Seamless Pipes Sizes

The ASME B36.10 and B36.19 specifications cover the dimensions and weights of seamless pipes for the petrochemical industry (the specs apply to welded pipes too):

- The ASME B36.10 specification covers carbon and low-alloy seamless pipe sizes (dimensions and weights) between 1/8 and 24 inches

- The ASME B36.19 specification, instead, covers the dimensions and weights of stainless steel, duplex, nickel-alloy seamless, and welded pipes

Commercial seamless pipes are designated with a nominal pipe size (representing the approximate fluid conveyance capacity of the pipe) and with a “schedule”, which refers to the thickness of the pipe (the most common are schedule 40, STD, XS, XXS for carbon/alloy pipes, and 10S, the 40S and 80S for stainless and nickel alloy pipes).

The ASME pipe size specifications can be purchased online from the ASME website or from the IHS online store.

Seamless Pipes Manufacturing Process

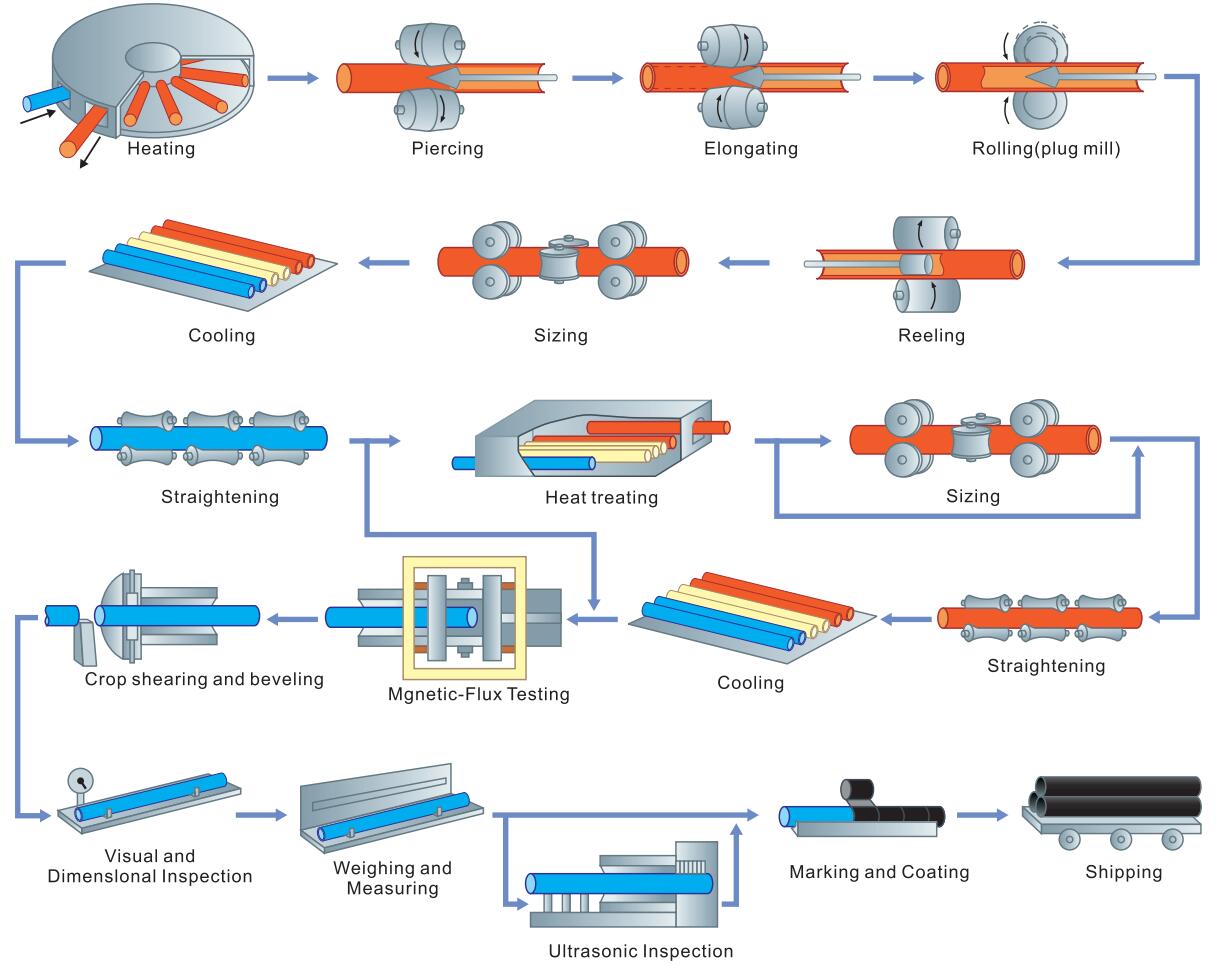

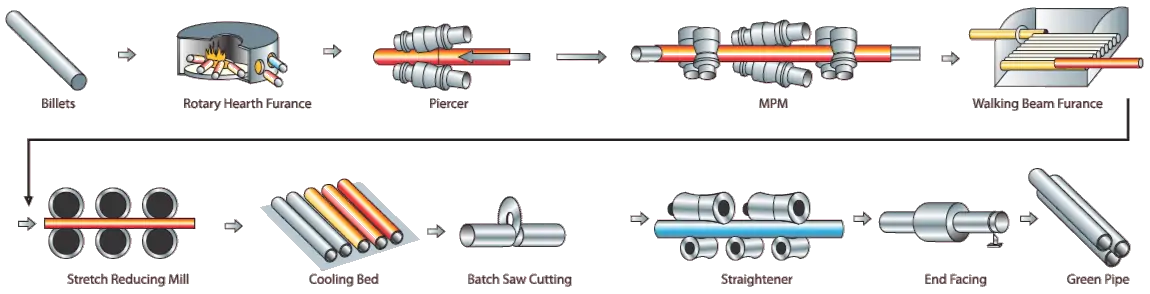

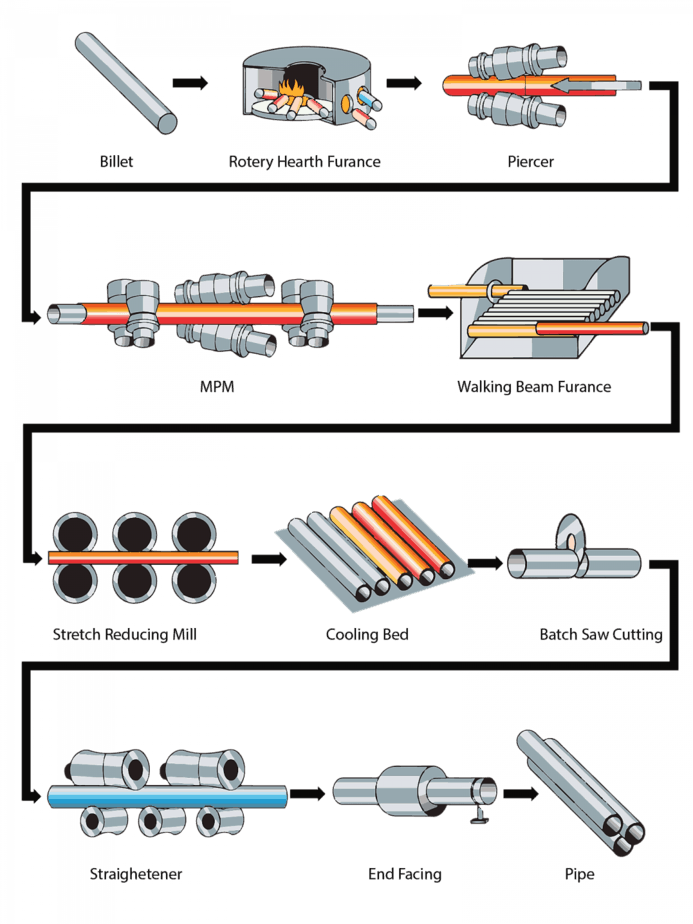

Mild steel seamless pipes from 1/8 to 6 inches. are manufactured with the so-called “plug mill process” or the “extrusion process” (used for smaller diameters), whereas the “mandrel mill process” is used for larger diameters.

In general, the manufacturing process of seamless pipes involves several steps, each crucial for ensuring the integrity, quality, and consistency of the final product. Here’s an overview of the seamless pipe manufacturing process:

- Steel Billet Preparation: The process begins with the preparation of steel billets, which are solid cylindrical bars of steel. These billets are typically made from carbon steel or alloy steel and are produced through methods such as continuous casting or hot rolling.

- Heating: The steel billets are heated to the required temperature in a furnace. This heating process helps to soften the steel, making it more malleable and easier to work with during subsequent manufacturing steps.

- Piercing: Once heated to the appropriate temperature, the steel billets are pierced to form a hollow tube. This piercing process is typically done using a mandrel mill or a rotary piercing mill. The mill contains a rotating mandrel or piercing plug, which pierces through the center of the heated billet to create a hollow tube.

- Rolling and Sizing: After piercing, the hollow tube undergoes rolling and sizing processes to achieve the desired dimensions and wall thickness. The tube is passed through a series of rolling stands, where it is gradually reduced in diameter and wall thickness to meet the specifications of the final seamless pipe.

- Heat Treatment: Once the seamless pipe is formed and sized, it may undergo heat treatment processes such as annealing, quenching, or tempering to improve its mechanical properties, microstructure, and overall performance. Heat treatment helps to relieve internal stresses, enhance strength, and achieve the desired metallurgical structure.

- Finishing: After heat treatment, the seamless pipe may undergo additional finishing processes to meet specific requirements. This may include processes such as straightening, cutting to length, end finishing (e.g., beveling, threading), and surface treatment (e.g., coating, painting).

- Testing and Inspection: Throughout the manufacturing process, seamless pipes undergo rigorous testing and inspection to ensure quality and conformance to specifications. This may include non-destructive testing methods such as ultrasonic testing, eddy current testing, and visual inspection, as well as destructive testing methods such as tensile testing and impact testing.

- Packaging and Shipping: Once the seamless pipes have passed all quality checks and inspections, they are carefully packaged and prepared for shipping to customers or distribution centers. Proper packaging helps to protect the pipes during transit and storage, ensuring they arrive in optimal condition.

Overall, the manufacturing process of seamless pipes requires precision, expertise, and attention to detail to produce high-quality pipes that meet the demanding requirements of various industries and applications. By following stringent quality control measures and employing advanced manufacturing technologies, seamless pipe manufacturers can deliver reliable and durable products that contribute to the infrastructure, construction, and industrial development of society.

Mandrell vs. Mannesmann Manufacturing Process for Seamless Pipes

The Mandrel Mill Process and the Mannesmann Process are two distinct methods for producing seamless pipes, each with its own characteristics and advantages. Here’s an explanation of the differences between these two processes:

Mandrell Mill Process

- Description: The Mandrel Mill Process is a hot extrusion process used to produce seamless pipes with precise dimensions and enhanced mechanical properties. In this process, a solid steel billet is heated to high temperatures and then pierced by a rotating mandrel or piercing plug.

- Piercing: The piercing operation involves forcing the heated billet through a series of dies and rollers, with the mandrel or piercing plug acting as a guide to form the inner diameter of the pipe. This results in the formation of a hollow tube with a uniform wall thickness and a smooth inner surface.

- Rolling: After piercing, the hollow tube is elongated and reduced in diameter through a series of rolling passes. The tube is gradually elongated and shaped to achieve the desired dimensions and mechanical properties.

- Advantages: The Mandrel Mill Process allows for the production of seamless pipes with tight dimensional tolerances, smooth surface finish, and improved mechanical properties. It offers high production efficiency and versatility, making it suitable for a wide range of applications in industries such as oil and gas, automotive, and aerospace.

Mannesmann Process (Plug-Mill)

- Description: The Mannesmann Process, also known as the Plug Mill Process or the Continuous Rolling Process, is a hot extrusion process used to produce seamless pipes in large volumes. This process was developed by German engineer Friedrich Mannesmann in the late 19th century.

- Plug Rolling: In the Mannesmann Process, a solid cylindrical billet is heated to high temperatures and then pierced by a stationary plug or mandrel. The pierced billet is then elongated and reduced in diameter through a series of rolling passes.

- Mandrelless Rolling: Unlike the Mandrel Mill Process, the Mannesmann Process does not require a rotating mandrel during piercing. Instead, the billet is pierced by a stationary plug, and the subsequent rolling passes elongate and shape the tube without the need for additional mandrels.

- Advantages: The Mannesmann Process offers high production rates and cost efficiency, making it suitable for the mass production of seamless pipes. It is particularly well-suited for producing large-diameter and heavy-wall pipes used in applications such as oil and gas transmission, infrastructure, and construction.

Forged Seamless Pipes

Forged seamless pipes are a specialized type of seamless pipe that undergoes an additional manufacturing process known as forging.

While traditional seamless pipes are typically produced using methods such as hot extrusion or piercing, forged seamless pipes are manufactured through a combination of forging and machining processes.

The critical information to know about forged pipes are:

Forging Process:

- Initial Billet: The manufacturing process begins with a solid cylindrical billet of steel, which is heated to high temperatures in a furnace to make it more malleable and ductile.

- Forging: The heated billet is then placed under a forging press or hammer, where it is subjected to high compressive forces to deform it into the desired shape. The forging process may involve multiple stages of deformation to achieve the desired dimensions and properties.

- Forming: During forging, the billet is shaped into a rough cylindrical form resembling a pipe. However, additional machining processes are required to refine the shape and dimensions to meet the final specifications.

- Machining: After forging, the rough forged blank undergoes machining operations such as turning, boring, and threading to achieve the final dimensions, surface finish, and tolerances required for the seamless pipe.

Advantages of Forged Seamless Pipes:

- Enhanced Strength: The forging process imparts superior strength and toughness to the material, resulting in forged seamless pipes with enhanced mechanical properties compared to conventionally produced seamless pipes.

- Improved Grain Structure: The controlled deformation and shaping during forging promote a refined and uniform grain structure in the steel, which enhances its resistance to fatigue, stress corrosion, and other forms of mechanical degradation.

- Customizable Shapes: Forged seamless pipes can be manufactured in a wide range of sizes, shapes, and configurations to meet specific design requirements and performance criteria. This flexibility allows for the production of complex geometries and custom-made components for various industrial applications.

Applications of Forged Seamless Pipes:

- Oil and Gas Industry: Forged seamless pipes are commonly used in the oil and gas industry for applications such as drilling, production, transportation, and refining. Their superior strength, durability, and resistance to harsh operating conditions make them ideal for handling high-pressure and corrosive fluids.

- Aerospace and Defense: Forged seamless pipes find applications in aerospace and defense applications, including aircraft components, missile systems, and military vehicles, where lightweight yet strong materials are required to withstand extreme environments and dynamic loads.

- Power Generation: Forged seamless pipes are used in power generation facilities such as thermal power plants, nuclear reactors, and renewable energy installations for conveying steam, water, and other fluids in boiler systems, heat exchangers, and piping networks.

In summary, forged seamless pipes offer enhanced strength, durability, and customizability compared to conventionally produced seamless pipes. They are used in industries such as oil and gas, aerospace, defense, and power generation, where high-performance materials are essential for reliable operations.

Learn more about forged steel pipes.

ERW & HFW Pipes (Electric Resistance Welding/High Frequency Welding)

ERW pipes are manufactured starting from steel coils: the coil is first uncoiled, then smoothed, cut and, finally formed into a pipe shape by joining its two extremities electrically.

ERW pipes are available in sizes between 1/2 and 20 inches, in carbon steel (ASTM A53 is the most common specification) and stainless steel (ASTM A312). In terms of dimensions, ASME B36.10 and ASME B36.19 are the key reference specifications (API 5L for welded ERW line pipes).

The ASME and API dimensional charts show typical combinations of pipe nominal size and wall thickness (designated as “schedule”) and show ERW pipe weight in kg (or pounds).

In the last few years, ERW pipes have become an efficient alternative to seamless pipes, both in terms of price and performance, due to the modern welding technologies adopted by ERW pipe manufacturers (for example HFI and HFW, high-frequency welding). These advancements in welding technologies have reduced, over time, the technical superiority of seamless pipes vs ERW pipes, making them interchangeable at least in some applications (low/medium pressure and temperature). Of course, seamless pipes will always benefit from the intrinsic superior mechanical strength of steel billets vs. coils and plates.

ERW Pipe Manufacturing Process

ERW pipes are manufactured starting from steel coils, that are at first uncoiled, cut, processed, welded, and tested as shown in the picture below.

The most common welding technique used for oil and gas pipes is the so-called “high-frequency induction technology” (ERW-HFI), consisting of the application of an induction current on the outer surface of the pipe able to generate a robust seam weld and joining the two sides of the steel coil very tightly.

The manufacturing process of Electric Resistance Welded (ERW) pipes involves several steps, each crucial for ensuring the quality, integrity, and dimensional accuracy of the final product. Here’s an overview of the ERW pipe manufacturing process:

- Steel Coil Preparation: The process begins with the preparation of steel coils, which are flat strips of steel rolled into coils. These coils are typically made from carbon steel or low-alloy steel and are sourced from steel mills or manufacturers. The coils may undergo surface treatment processes such as pickling or coating to remove impurities and improve corrosion resistance.

- Uncoiling and Straightening: The steel coils are uncoiled and straightened to prepare them for the welding process. This may involve passing the coils through a series of rollers and straightening machines to ensure uniformity and alignment of the steel strip.

- Forming and Edge Preparation: The straightened steel strip is then passed through a series of forming rolls to shape it into a cylindrical tube. The edges of the strip are prepared for welding by removing any burrs, oxides, or surface contaminants. This edge preparation helps to ensure a clean and consistent weld seam.

- Welding: The formed and prepared steel strip is then fed into an ERW welding machine, where it undergoes the welding process. ERW welding involves the application of electrical resistance to generate heat, which fuses the edges of the steel strip together to form a welded seam. The welding process may utilize high-frequency induction welding, rotary contact welding, or other specialized techniques to achieve a strong and reliable weld.

- Heat Treatment: After welding, the welded tube may undergo heat treatment processes such as annealing or stress relieving to improve its mechanical properties, reduce residual stresses, and enhance weld integrity. Heat treatment helps to achieve the desired metallurgical structure and properties in the welded seam and surrounding material.

- Sizing and Shaping: Once the welded tube has been formed and welded, it may undergo sizing and shaping processes to achieve the desired dimensions and wall thickness. This may involve passing the tube through a series of sizing rolls or stretch-reducing mills to achieve the final dimensions and tolerances.

- Cutting and Finishing: After sizing, the ERW tube is cut to length and undergoes finishing processes to meet specific requirements. This may include processes such as end facing, beveling, threading, or surface treatment (e.g., coating, painting).

- Testing and Inspection: Throughout the manufacturing process, ERW pipes undergo rigorous testing and inspection to ensure quality and conformance to specifications. This may include non-destructive testing methods such as ultrasonic testing, eddy current testing, and visual inspection, as well as destructive testing methods such as tensile testing and hydrostatic testing.

- Packaging and Shipping: Once the ERW pipes have passed all quality checks and inspections, they are carefully packaged and prepared for shipping to customers or distribution centers. Proper packaging helps to protect the pipes during transit and storage, ensuring they arrive in optimal condition.

Overall, the ERW pipe manufacturing process requires precision, expertise, and attention to detail to produce high-quality pipes that meet the demanding requirements of various industries and applications.

HFW Pipes

HFW pipes, or High-Frequency Welded pipes, are a type of welded steel pipe manufactured using high-frequency electric resistance welding (ERW) technology. This process involves passing a high-frequency electric current through the edges of the rolled steel strips that are being formed into a pipe shape. The high-frequency current heats the edges to the point where they can be fused together to form a strong, longitudinal weld seam. HFW pipe manufacturing is distinguished by its use of high-frequency (typically in the range of hundreds of kHz to several MHz) electric currents, which make the welding process more efficient and result in a high-quality weld.

Key Characteristics of HFW Pipes

- Efficient Welding Process: The high-frequency electric resistance welding process is highly efficient, allowing for faster welding speeds compared to lower-frequency welding methods. This efficiency makes HFW pipes suitable for large-scale production.

- Strong Weld Seam: The HFW process produces a weld seam with a narrow heat-affected zone (HAZ), which enhances the strength and durability of the weld area. The narrow HAZ also minimizes the grain coarsening effect, preserving the steel’s mechanical properties.

- Versatility in Applications: HFW pipes can be used in a wide range of applications, from low-pressure fluid transport to structural and mechanical uses. They are particularly favored in the oil and gas industry for line pipes, as well as in construction for structural and scaffolding purposes.

- Material and Size Range: HFW pipes can be manufactured from a variety of materials, including carbon steel, alloy steel, and stainless steel, and are available in a wide range of diameters and wall thicknesses to suit different applications.

Manufacturing Process

- Uncoiling and Flattening: The process starts with uncoiling the steel coil and flattening it into a strip.

- Edge Milling: The edges of the strip are then milled to prepare them for welding, ensuring clean, parallel surfaces that will form the weld seam.

- Forming: The strip is gradually formed into a cylindrical shape by passing it through a series of rollers.

- Welding: As the edges of the formed cylinder come together, a high-frequency electric current is applied to heat and fuse the edges, creating the longitudinal weld seam.

- Cooling, Sizing, and Cutting: After welding, the pipe is cooled, and then passed through sizing rollers to ensure it meets the specified diameter and roundness requirements. Finally, the pipe is cut to the desired length.

Applications of HFW Pipes

HFW pipes find applications across various sectors, including:

- Oil and Gas Industry: For transporting crude oil, natural gas, and refined products.

- Water and Wastewater Management: For water mains, distribution pipelines, and sewage systems.

- Construction and Infrastructure: Used in structural applications, scaffolding, fencing, and as conduits for electrical and communication cables.

- Automotive and Mechanical: For manufacturing structural components and precision mechanical parts.

HFW pipes are valued for their high quality, efficiency of production, and versatility, making them a preferred choice for many industries requiring welded steel pipes.

ERW vs. Seamless Pipes

The question “Shall I use ERW or seamless pipes for my project?” is coming up over and over. Each of the two has different advantages and disadvantages, which should be pondered to make a proper decision:

Seamless Pipe Pros and Cons

- Seamless pipes are manufactured out of a solid block of steel and do not have any weld seam, which may represent a weak area (subject to corrosion, erosion, and, general failure)

- Seamless pipes have more predictable and precise shapes, in terms of roundness and ovality, compared to welded pipes.

- The main disadvantage of seamless pipes is that their cost per ton is higher than the cost of ERW pipes of the same size and grade (Seamless vs ERW pipe compete in the range 2 to 20 inches)

- Delivery times may be longer, as there are fewer manufacturers of seamless pipes than welded pipes (lower entry barriers exist for welded pipes vs. seamless pipes)

- Seamless pipes may have an inconsistent wall thickness across their length, indeed the general tolerance is +/- 12.5%

ERW Pipe Pros and Cons

- Welded pipes are cheaper than seamless (ERW HFI type), as they are manufactured using steel coils as feedstock in less complex manufacturing plants

- Welded pipes have shorter lead times than seamless pipes, as the manufacturing base is larger

- Welded pipes have a consistent wall thickness, as they are manufactured using coils (ERW) or plates (LSAW), both subject to tight tolerance control

- The major “defect” attributed to welded pipes is that the presence of a weld seam constitutes a weakness factor. Whereas this may have been true in the past, this is becoming less and less true with the advances in welding technologies in the last ten years.

Conclusion: modern ERW-HFI welded pipes are absolutely a valid alternative to seamless pipes and help end-users reduce prices and lead times between 20 and 25%.

Pipes are, with valves, the most impactful piping cost element in plant construction (as a rule of thumb, piping covers 5-7% of the total plant cost, and pipes represent circa 60 to 70% of this cost, valves 15 to 25%). These figures are average values that refer to the oil & gas industry and refer to carbon steel materials (the weight of piping may be higher for stainless steel, duplex, and nickel-alloy piping classes).

The last point: pipes may have different colors (painted on the outer surface) to represent the type of fluid they carry.

LSAW Pipe (Longitudinal Submerged Arc Welding)

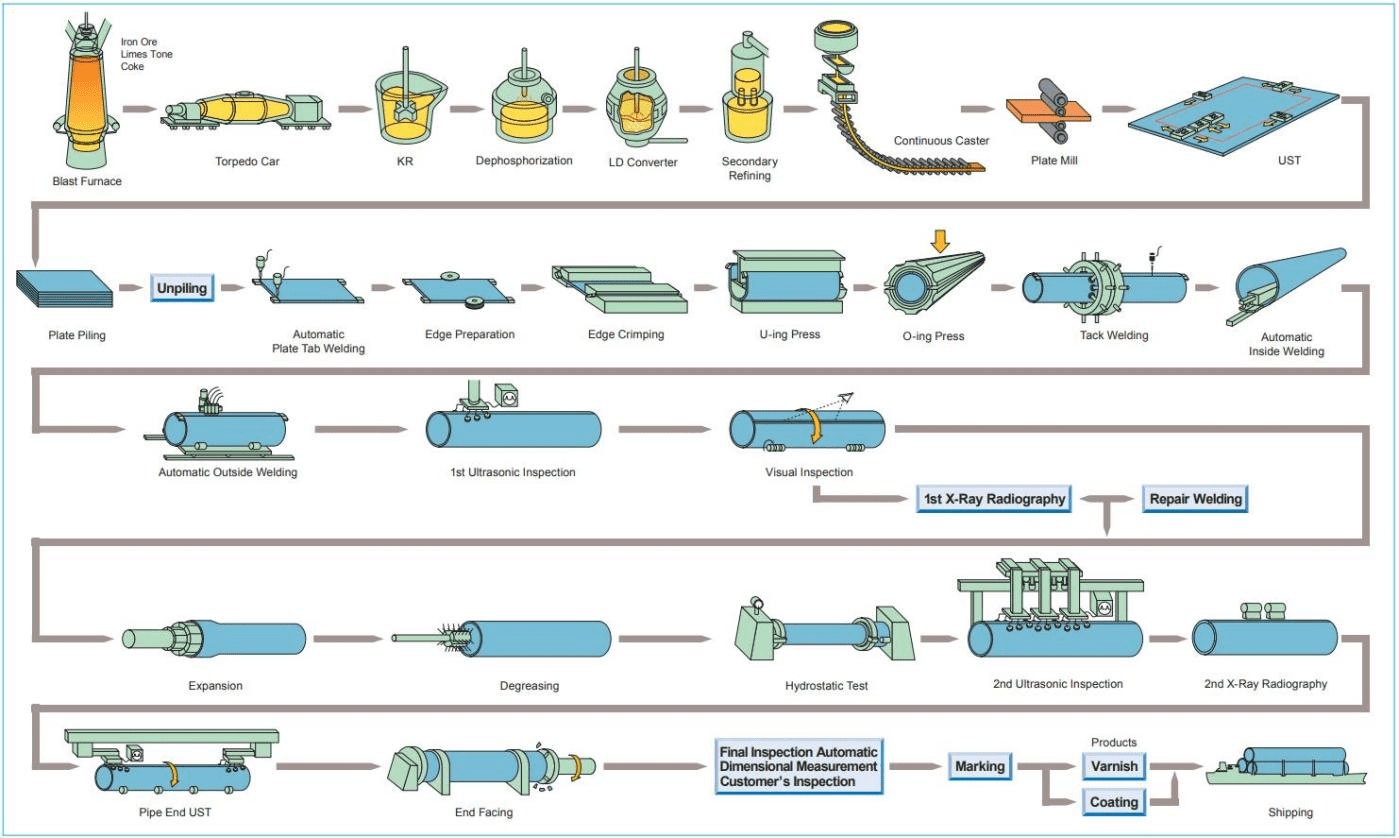

An LSAW pipe (“submerged arc welding”) is manufactured by cutting, bending, and welding steel plates (JCOE process).

LSAW pipes compete with seamless and ERW pipes in the size range between 16 and 24 inches but are a “must-go” option for pipelines above 24 inches (as 24 inches is the maximum size for commercial seamless pipes).

The two main types of LSAW pipes are the longitudinal (with a single or double straight seam weld, DSAW) and the spiral type (called, HSAW, SSAW, or SAWL pipe). Therefore, the difference between DSAW vs. LSAW is that DSAW pipes have a seam weld on the inside and outside of the pipe, whereas LSAW pipes have a single seam weld on the outer surface.

The difference between LSAW and ERW pipes is that LSAW pipes are produced using steel plates, and ERW pipes are manufactured starting from steel coils.

In the oil and gas industry, large-diameter API 5L LSAW pipes are used to transport hydrocarbons over long distances efficiently.

HSAW/SSAW spiral weld pipes are used for non-critical applications, such as water transmission and distribution (not for oil & gas).

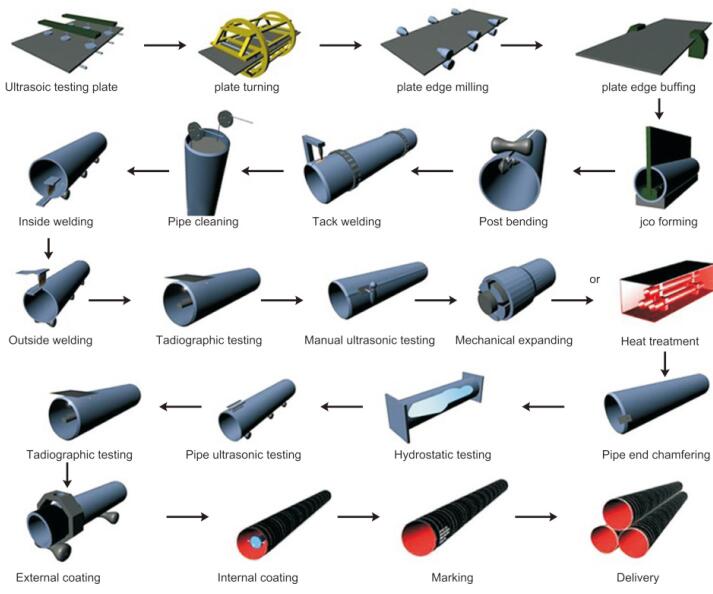

LSAW Pipe Manufacturing Process

LSAW pipes are manufactured with the so-called JCOE process, starting from steel plates as illustrated below.

The manufacturing process of Longitudinal Submerged Arc Welded (LSAW) pipes involves several steps, each crucial for ensuring the quality, integrity, and dimensional accuracy of the final product. Here’s an overview of the LSAW pipe manufacturing process:

- Plate Preparation: The process begins with the preparation of steel plates, which are flat sheets of steel cut to the desired dimensions. These plates are typically made from carbon steel or low-alloy steel and are sourced from steel mills or manufacturers. The plates may undergo surface treatment processes such as shot blasting or coating to remove impurities and improve corrosion resistance.

- Edge Milling and Pre-Bending: The edges of the steel plates are milled to achieve a smooth and uniform surface, ensuring proper fit-up during welding. The plates are then pre-bent to the desired curvature to facilitate the forming process and reduce residual stresses in the weld zone.

- Forming: The pre-bent steel plates are formed into cylindrical shells using a bending machine or a press brake. The plates are gradually shaped and welded together along their longitudinal edges to form a continuous pipe body. This forming process may involve cold forming or hot forming, depending on the material thickness and specifications.

- Submerged Arc Welding: Once the pipe body is formed, it undergoes submerged arc welding to create a longitudinal seam weld. In this process, an electric arc is generated between a welding electrode and the workpiece, while a layer of granular flux covers the welding zone to shield it from atmospheric contamination. The arc melts the edges of the steel plates, forming a fused weld seam along the length of the pipe.

- Ultrasonic Testing: After welding, the welded seam undergoes ultrasonic testing to detect any defects or imperfections in the weld zone. Ultrasonic waves are passed through the welded seam, and the reflected waves are analyzed to identify any discontinuities or flaws that may affect the integrity of the pipe.

- Expansion and Sizing: After welding and testing, the pipe may undergo expansion and sizing processes to achieve the desired dimensions and wall thickness. This may involve passing the pipe through a series of sizing rolls or stretch-reducing mills to achieve the final specifications and tolerances.

- Straightening and Cutting: Once the pipe has been sized, it undergoes straightening to remove any residual deformation and ensure straightness. The pipe is then cut to the desired length using saws or flame-cutting equipment.

- End Facing and Beveling: After cutting, the ends of the pipe are faced and beveled to achieve a smooth and uniform surface finish and facilitate welding during installation. This may involve machining or grinding the ends of the pipe to the required angle and surface finish.

- Surface Treatment: Finally, the LSAW pipes may undergo surface treatment processes such as coating, painting, or galvanizing to improve corrosion resistance, aesthetics, and environmental compatibility. This helps to protect the pipes from corrosion and extend their service life in various applications.

- Testing and Inspection: Throughout the manufacturing process, LSAW pipes undergo rigorous testing and inspection to ensure quality and conformance to specifications. This may include non-destructive testing methods such as ultrasonic testing, radiographic testing, and magnetic particle testing, as well as destructive testing methods such as tensile testing and hydrostatic testing.

- Packaging and Shipping: Once the LSAW pipes have passed all quality checks and inspections, they are carefully packaged and prepared for shipping to customers or distribution centers. Proper packaging helps to protect the pipes during transit and storage, ensuring they arrive in optimal condition.

Overall, the LSAW pipe manufacturing process requires precision, expertise, and attention to detail to produce high-quality pipes that meet the demanding requirements of various industries and applications. By following stringent quality control measures and employing advanced welding technologies, LSAW pipe manufacturers can deliver reliable and cost-effective products that contribute to the infrastructure, construction, and industrial development of society.

SSAW/DSAW Types

SSAW Pipes

SSAW pipes, or Spiral Submerged Arc Welded pipes, are a specific type of welded steel pipe manufactured by coiling a hot-rolled steel plate and then welding it in a spiral seam. This process uses the submerged arc welding technique, where the welding arc is submerged under a flux layer. This method provides excellent protection for the welding area from atmospheric contamination, ensuring high-quality, durable welds. SSAW pipes are recognized for their spiral weld seam, which significantly contributes to their strength and allows for greater flexibility in sizes and lengths compared to some other welded pipe manufacturing processes.

Key Characteristics of SSAW Pipes

- Spiral Weld Seam: The hallmark of SSAW pipes is their spiral seam, which results from the helical welding process. This seam enhances the pipe’s ability to withstand internal pressure and distributes stress more evenly across the pipe structure.

- Manufacturing Process: SSAW pipes are produced by first uncoiling and flattening the steel coil. The edges are then bent to form a cylindrical shape, and the edges are welded together in a spiral fashion using the submerged arc welding process.

- Material Efficiency: The spiral welding process allows for considerable material efficiency, making it possible to produce pipes of varying diameters and wall thicknesses from the same width of the steel strip.

- Large Diameter and Length: SSAW pipes can be manufactured in large diameters and lengths, which, combined with their material efficiency, makes them suitable for a wide range of large-scale applications, particularly where lengthy, large-diameter pipes are required.

Applications of SSAW Pipes

SSAW pipes are used across various industries and for a broad range of applications, including:

- Water and Wastewater Transportation: Due to their large diameter and strength, SSAW pipes are often used in water mains, sewage systems, and stormwater drainage systems.

- Oil and Gas Pipeline: SSAW pipes are suitable for the transportation of oil and gas over long distances, especially in non-critical applications.

- Structural and Piling Purposes: Their strength and flexibility make them ideal for structural applications, including in the construction of bridges and buildings, as well as for piling to support foundations in construction projects.

- Industrial Applications: In plants and facilities, SSAW pipes are used for various applications, including the conveyance of raw materials and waste products.

Advantages and Considerations

While SSAW pipes offer advantages like material efficiency, strength, and versatility in size, they also have certain limitations. The quality of the weld seam is critical, and the spiral weld requires a thorough inspection to ensure integrity. Additionally, the helical nature of the seam may affect the pipe’s roundness and straightness, factors that are critical in certain applications.

DSAW Pipes (or HSAW)

DSAW pipes, or Double Submerged Arc Welded pipes, represent a specific category of welded steel pipes manufactured using the double-submerged arc welding process. This technique involves forming an arc between a continuously fed consumable electrode and the workpiece, with the welding zone being submerged under a layer of flux. The process is conducted from both the inside and outside of the pipe, hence the term “double.” This dual-welding approach enhances the strength, quality, and integrity of the weld seam, making DSAW pipes suitable for high-stress and high-pressure applications.

Key Characteristics of DSAW Pipes

- High-Quality Welds: The double-submerged arc welding process ensures deep penetration and a high-quality weld seam, contributing to the overall strength and durability of the pipe.

- Large Diameter and Thickness: DSAW manufacturing allows for the production of large-diameter pipes with significant wall thicknesses, making them ideal for heavy-duty applications.

- Smooth Internal Surface: The interior weld seam can be very smooth, depending on the manufacturing process, which is advantageous for fluid flow and reduces the risk of corrosion and accumulation of deposits.

- Structural Integrity: The double welding process, conducted on both the inside and outside surfaces, ensures uniform structural integrity throughout the pipe, making it capable of withstanding higher pressures and stresses compared to single-welded pipes.

Manufacturing Process

- Plate Preparation: The process starts with steel plates that are cut to the required width and length, depending on the intended diameter and length of the pipe.

- Forming: The plates are then formed into a cylindrical shape, either through rolling or pressing.

- Welding: The key stage in DSAW pipe manufacturing is the welding process. The edges of the cylinder are first preheated and then welded using the submerged arc welding technique from both the inside and outside, ensuring thorough penetration and a strong, uniform weld seam.

- Inspection and Testing: After welding, the pipes undergo rigorous inspection and testing, including non-destructive testing methods like X-ray or ultrasonic testing, to ensure the weld’s integrity and the pipe’s overall quality.

- Finishing: Finally, any additional processing, such as cutting to length, hydrostatic testing, or end finishing, is performed according to the application’s requirements.

Applications of DSAW Pipes

DSAW pipes are widely used in applications that require robust and high-quality welded pipes, including:

- Oil and Gas Transmission Lines: For transporting crude oil, natural gas, and other fluids over long distances.

- Structural Applications: In construction and infrastructure projects, such as bridge construction, where high strength and durability are essential.

- Water and Wastewater Projects: For main water supply lines, sewage systems, and large-scale drainage projects.

- Offshore and Subsea Pipelines: In the oil and gas industry offshore drilling rigs and subsea pipelines, where the pipes are exposed to high pressures and corrosive environments.

DSAW pipes’ combination of strength, durability, and capacity to handle high pressures and stresses makes them a preferred choice for critical applications across various industries.

HSAW vs. DSAW

HSAW (Helical Submerged Arc Welding) and SSAW (Spiral Submerged Arc Welding) pipes are often considered synonyms in the context of welded pipes used in the oil and gas industry. Both terms refer to a method where the steel pipe is formed by spiral welding the steel coil. The terms “helical” and “spiral” in this context describe the same helical seam shape created during the manufacturing process. This method is distinguished from other welded pipe production methods, such as LSAW (Longitudinal Submerged Arc Welding), which involves welding along the length of the pipe.

In practice, the terms HSAW and SSAW might be used interchangeably by professionals in the industry to refer to pipes produced using a helical (or spiral) welding process.

EFW PIPES (Electric Fusion Welding)

WHAT ARE EFW PIPES?

EFW pipe stands for Electric Fusion Welded pipe. It’s a type of welded pipe manufactured by using high-temperature electric arcs to fuse metal and create a strong bond.

The process involves heating the steel to a molten state and then using pressure to forge the metal together along the seam, creating a full penetration weld.

EFW technology is particularly suited for the fabrication of pipes from plate material, allowing for the production of large-diameter pipes and the use of various types of steel, including carbon steel, stainless steel, and alloy steel.

KEY FEATURES OF EFW PIPES

- Versatility in Materials: EFW pipes can be made from a wide range of materials, offering solutions for industries that require specific properties, such as high strength, corrosion resistance, or heat resistance.

- Large-Diameter Capabilities: The EFW process is well-suited for producing large-diameter pipes, which are often required for major water, oil, and gas transmission lines.

- High-Quality Welds: The electric fusion welding process allows for the creation of high-quality, uniform welds that are integral to the pipe structure, providing excellent mechanical properties and durability.

- Application Flexibility: EFW pipes are used in various applications, including in the oil and gas industry for pipelines, in the construction industry for structural applications, and in the utility sector for water and sewage systems.

EFW VS. ERW/LSAW PIPES

EFW pipes are often compared with ERW (Electric Resistance Welded) pipes and SAW (Submerged Arc Welded) pipes, which are other common types of welded pipes.

As seen above, ERW pipes are made by using electrical resistance to heat the edges of the strip steel to a temperature where it can be shaped and fused together, which is effective for smaller diameters and thinner walls. SAW pipes, on the other hand, use a submerged arc welding process that involves the formation of an arc between a continuously fed electrode and the workpiece to form a weld, suitable for thick-walled and large-diameter pipes.

The choice between EFW, ERW, and SAW pipes depends on the specific requirements of the application, including the desired diameter, wall thickness, material properties, and the environment in which the pipe will be used. EFW pipes offer a robust solution for applications requiring large diameters and high-quality welds in challenging or high-specification environments.

KEY SPECS FOR EFW PIPES

Electric Fusion Welded (EFW) pipes are subject to various specifications that define their manufacturing process, materials, testing requirements, and applications. These specifications ensure that EFW pipes meet the necessary safety, reliability, and performance standards for their intended use. Here are some of the key specifications applicable to EFW pipes:

ASTM Specifications

- ASTM A358: This specification covers electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service, or both. It’s commonly used for EFW pipes in the chemical, petrochemical, and oil refining industries.

- ASTM A672: Specifies requirements for electric-fusion-welded steel pipe for high-pressure service at moderate temperatures. It’s often used for pipelines in power generation, petrochemical, and other industrial applications.

ASME Specifications

- ASME B36.10M: Defines the standard dimensions and weights for welded and seamless wrought steel pipes, including EFW pipes. It covers a wide range of sizes, making it applicable to a variety of industrial and construction applications.

- ASME B36.19M: Similar to ASME B36.10M but specifically for stainless steel pipe, including EFW stainless steel pipes. It provides dimensions and weights for different sizes and schedules of pipes.

API Specifications

API 5L: Specifies requirements for the manufacture of two levels of specification for seamless and welded steel pipes, including EFW pipes, used for pipeline transportation systems in the petroleum and natural gas industries. While API 5L is more commonly associated with seamless and Electric Resistance Welded (ERW) pipes, it can also apply to EFW pipes under certain conditions.

Other Relevant Standards

-

NACE MR0175/ISO 15156: Provides guidelines for the selection of materials for sour service environments in oil and gas production, where hydrogen sulfide is present. This is crucial for ensuring the corrosion resistance of EFW pipes in such conditions.

-

ASTM A691: Covers carbon and alloy steel pipe, electric-fusion-welded for high-pressure service at high temperatures, applicable for high-pressure service at high temperatures.

EFW PIPES MANUFACTURING PROCESS

The manufacturing process of Electric Fusion Welded (EFW) pipes involves several key steps that use high-temperature electric arcs to fuse metal together, creating a strong and durable welded joint. This process is particularly suitable for producing large-diameter pipes from plate material and can be used with a variety of steel types, including carbon steel, stainless steel, and alloy steel. Here’s an overview of the EFW pipe manufacturing process:

1. Material Selection and Preparation

-

The process begins with the selection of the appropriate steel plate material, based on the required chemical composition and mechanical properties for the intended application.

-

The steel plates are then cut to size and cleaned to remove any surface impurities or oxides that could affect the quality of the weld.

2. Forming

-

The cut plates are formed into a cylindrical shape using a press or a rolling machine. This step is crucial for ensuring that the edges align properly for welding.

-

For large-diameter pipes, the plates might be pre-bent at the edges to facilitate better alignment and welding.

3. Edge Preparation

The edges of the formed cylinder are then carefully prepared to ensure that they are clean and properly aligned. This may involve machining or grinding the edges to create a bevel, which helps to achieve a full penetration weld.

4. Welding

-

The primary feature of the EFW process is the use of an electric arc to heat the edges of the steel to a molten state. An electric arc is generated between an electrode and the steel material.

-

The molten steel edges are then fused together using pressure. In some cases, filler material may be added to ensure a strong and uniform weld seam.

-

The welding process may be performed using one or more passes, depending on the thickness of the steel plate and the required properties of the weld.

5. Post-Weld Heat Treatment (PWHT)

After welding, the pipe may undergo post-weld heat treatment to relieve stresses and ensure that the welded area has properties consistent with the rest of the material. This involves heating the entire pipe or the weld area to a specified temperature and then cooling it under controlled conditions.

6. Inspection and Testing

The welded pipe is subjected to various inspections and tests to ensure that it meets the required specifications and quality standards. This includes visual inspection, dimensional checks, non-destructive testing (such as ultrasonic or radiographic testing), and mechanical testing (such as tensile and impact tests).

7. Finishing

Any final processing, such as cutting the pipe to length, beveling the ends, or applying surface treatments, is completed. The pipe is then marked with relevant information, including material grade, size, and heat number, for identification and traceability.

8. Quality Assurance

Throughout the manufacturing process, quality assurance measures are in place to ensure that each step is performed correctly and that the final product complies with all relevant standards and customer requirements.

The EFW pipe manufacturing process is complex and requires precise control at each stage to produce high-quality pipes suitable for critical applications in industries such as oil and gas, chemical processing, and utilities.

STRUCTURAL PIPES

Structural pipes are steel pipes designed and used primarily for structural purposes rather than for conveying fluids. These pipes are utilized in a wide array of construction and engineering applications due to their strength, durability, and versatility.

KEY FEATURES OF STRUCTURAL PIPES

- Strength and Durability: Structural pipes are known for their high strength-to-weight ratio, making them an efficient choice for supporting structures under loads without adding excessive weight.

- Versatility: They can be used in a variety of shapes, sizes, and thicknesses, allowing for flexibility in design and application. They can also be manufactured from different materials, including carbon steel, alloy steel, and stainless steel, to meet specific environmental and mechanical requirements.

- Cost-Effectiveness: Compared to other structural materials like concrete or solid steel bars, structural pipes offer cost savings due to their strength, ease of installation, and lower maintenance requirements.

- Ease of Fabrication and Assembly: Structural pipes can be easily cut, welded, and assembled into various configurations, facilitating quick and efficient construction.

APPLICATIONS OF STRUCTURAL PIPES

- Building and Construction: Used as columns, trusses, and frameworks in buildings, stadiums, bridges, and other structures.

- Infrastructure: Piling for foundations, signposts, and guardrails along roads and highways.

- Industrial and Mechanical: Supports machinery and industrial equipment, conveyance systems, and as part of the structural framework in factories and plants.

- Agricultural: Frames for greenhouses, barns, and fencing.

- Architectural: Aesthetic purposes, such as handrails, balustrades, and architectural features.

PILING PIPES

Piling pipes are structural pipes driven into the ground or seabed to provide foundational support for various structures such as buildings, bridges, piers, and other constructions. These pipes are used as pile foundations, where they transfer the load of the structure to the stronger soil or rock layers deep below the surface, providing stability and support. Piling pipes can be made of steel, concrete, or wood, with steel being the most common due to its strength, durability, and resistance to environmental factors.

Key Characteristics of Piling Pipes

- High Strength: Piling pipes are designed to withstand high stress and loads, making them suitable for supporting heavy structures.

- Durability: They are often treated or manufactured from materials that are resistant to corrosion, wear, and environmental degradation, ensuring long-term structural integrity.

- Versatility: Piling pipes can be used in a variety of soil and environmental conditions. They can be driven into the ground using different methods, including impact hammering, vibration, or pressing, depending on the ground conditions and the project requirements.

- Customizability: These pipes come in various sizes, lengths, and materials to match the specific needs of a project. They can also be filled with concrete to enhance their load-bearing capacity and stability.

Applications of Piling Pipes

- Building Foundations: Piling pipes provide foundational support for high-rise buildings, especially in areas with soft soil that cannot support heavy structures.

- Bridges and Piers: They are used to anchor bridges and piers firmly into the ground or seabed, ensuring stability against environmental and operational loads.

- Retaining Structures: In constructions such as retaining walls and quay walls, piling pipes are used to withstand lateral forces from earth and water.

- Offshore Structures: Piling pipes form the foundational support for offshore platforms and wind turbines, securing them against the dynamic forces of waves, wind, and other marine challenges.

Manufacturing and Specifications

Piling pipes are manufactured according to specific standards that ensure their suitability for piling applications. Common specifications include ASTM A252 for welded and seamless steel pipe piles and EN 10219 for cold-formed welded structural hollow sections of non-alloy and fine-grain steels. These specifications cover the dimensions, mechanical properties, and other requirements for piling pipes.

MATERIALS FOR STRUCTURAL PIPES

ASTM Materials for Structural Pipes

ASTM International provides several specifications for structural pipes, ensuring they meet defined standards for chemical composition, mechanical properties, dimensions, and other important factors. These specifications help ensure that structural pipes are suitable for their intended structural applications in construction, infrastructure, and various engineering projects. Here are some key ASTM specifications for structural pipes:

ASTM A500

-

Title: Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

-

Description: ASTM A500 is a widely used specification that covers cold-formed welded and seamless carbon steel structural tubing in round, square, and rectangular shapes. It is commonly used in structural applications such as building frames, bridges, and general structural supports. ASTM A500 grades categorize pipes based on their mechanical properties, including Grades A, B, C, or D.

ASTM A53

-

Title: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded, and Seamless

-

Description: Although ASTM A53 is often associated with standard pipes used for fluid conveyance, it is also applicable to structural applications. ASTM A53 covers seamless and welded black and hot-dipped galvanized steel pipe. It includes requirements for the grade, chemical composition, and mechanical properties, making it suitable for structural supports and framing in buildings and infrastructure.

ASTM A252

-

Title: Standard Specification for Welded and Seamless Steel Pipe Piles

-

Description: ASTM A252 covers nominal (average) wall steel pipe piles of cylindrical shape and applies to pipe piles in which the steel cylinder acts as a permanent load-carrying member or as a shell to form cast-in-place concrete piles. It is commonly used in foundation applications, including bridge construction, building foundations, and other structural supports.

ASTM A572

-

Title: Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

-

Description: While ASTM A572 primarily covers structural steel plates, it is relevant to structural pipes as well, particularly when they are made from steel plates rolled into cylindrical shapes and welded. ASTM A572 steel is known for its high strength and is used in high-stress structural applications.

ASTM A618

-

Title: Standard Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing

-

Description: ASTM A618 covers hot-formed welded and seamless high-strength low-alloy square, rectangular, round, or special-shape structural tubing for welded, riveted, or bolted construction of bridges and buildings and for general structural purposes. It emphasizes grade, chemical composition, and tensile properties.

EN Materials for Structural Pipes

European Norms (EN) standards are crucial in defining the specifications for materials used in structural pipes within Europe and many other parts of the world. These standards ensure uniformity, quality, and safety across materials used in construction and engineering projects. Here are some key EN material standards for structural pipes:

EN 10210

-

Title: Hot finished structural hollow sections of non-alloy and fine grain steels

-

Description: EN 10210 specifies the technical delivery conditions for hot-finished hollow sections of circular, square, rectangular, or other shapes. It covers structural pipes made from non-alloy and fine-grain steels, focusing on dimensional tolerances, chemical composition, and mechanical properties. It’s used for construction projects requiring high strength and toughness.

EN 10219

-

Title: Cold-formed welded structural hollow sections of non-alloy and fine-grain steels

-

Description: Similar to EN 10210, EN 10219 specifies requirements for cold-formed welded structural hollow sections of circular, square, or rectangular forms. It applies to pipes formed cold without subsequent heat treatment. EN 10219 is ideal for structural applications that require high strength and resistance to atmospheric corrosion.

EN 10225

-

Title: Weldable structural steels for fixed offshore structures – Technical delivery conditions

-

Description: Although EN 10225 primarily covers plates and sections, it is also relevant for structural pipes used in offshore structures. This standard includes specifications for weldable structural steels with improved resistance to brittle fracture and corrosion in offshore environments.

EN 10025

-

Title: Hot rolled products of structural steels

-

Description: EN 10025 is a broad standard that outlines the specifications for hot-rolled structural steel products, including sections and plates used to manufacture structural pipes. It encompasses several parts that define requirements for various grades and qualities of structural steel, including those with enhanced resistance to atmospheric corrosion (EN 10025-5) and those for high yield strength in quenched and tempered conditions (EN 10025-6).

Conclusion

The key differences between seamless, ERW (Electric Resistance Welded), and LSAW (Longitudinal Submerged Arc Welded) pipes lie in their manufacturing processes, characteristics, and applications. Here’s a comparison of these three types of pipes:

- Manufacturing Process:

– Seamless Pipes: Seamless pipes are manufactured by extruding or piercing solid steel billets to form a hollow tube without any welding seams. This process involves heating the billet and then rolling it to produce the desired dimensions and thickness. Seamless pipes undergo minimal processing and are typically produced using hot or cold drawing techniques.

– ERW Pipes: ERW pipes are manufactured by forming a flat strip of steel into a cylindrical shape and then welding the edges together using electric resistance welding. In this process, the steel strip is passed through a series of rollers and formed into a tube, after which an electric current is passed through the edges to generate heat and form the weld seam.

– LSAW Pipes: LSAW pipes are manufactured by forming and welding steel plates into a cylindrical shape using longitudinal submerged arc welding. In this process, steel plates are bent into a cylindrical shape and then welded along the longitudinal seam using submerged arc welding, where an electric arc is generated between a welding electrode and the workpiece submerged in a granular flux. - Characteristics:

– Seamless Pipes: Seamless pipes have uniformity in composition and structure, with no weld seams, making them stronger and more reliable for high-pressure applications. They exhibit excellent corrosion resistance and are suitable for critical applications where leakage is not acceptable.

– ERW Pipes: ERW pipes have weld seams along the longitudinal axis, which may result in slightly weaker areas compared to seamless pipes. However, ERW pipes offer good dimensional accuracy, surface finish, and cost-effectiveness, making them suitable for a wide range of applications in construction, infrastructure, and manufacturing.

– LSAW Pipes: LSAW pipes have a longitudinal seam weld and offer higher strength and reliability compared to ERW pipes. They are suitable for applications requiring larger diameters and thicker walls, such as oil and gas transmission, piling, and structural support. - Applications:

– Seamless Pipes: Seamless pipes are commonly used in industries such as oil and gas exploration, refining, petrochemicals, power generation, automotive, and aerospace, where high-pressure and critical applications require leak-proof and durable piping systems.

– ERW Pipes: ERW pipes find applications in various industries, including construction, infrastructure, water distribution, plumbing, HVAC (heating, ventilation, and air conditioning), fencing, and agriculture, where cost-effective and readily available piping solutions are required.

– LSAW Pipes: LSAW pipes are used in applications requiring large diameters and heavy wall thicknesses, such as oil and gas transmission pipelines, offshore platforms, structural support in construction, piling for foundations, and transportation of bulk materials.

In summary, the choice between seamless, ERW, and LSAW pipes depends on factors such as the application requirements, budget, availability, and performance characteristics. Each type of pipe offers distinct advantages and limitations, and selecting the appropriate type is essential for ensuring optimal performance and reliability in various industrial and infrastructure projects.

130 Responses

Awesome blog. Thank you for providing this information.

Do you know (Parmanu Dhatu Nigam Manufacturers Of Cerrobend)

Thank you for your kind words, Parmanu Dhatu Nigam Manufacturers Of Cerrobend. We appreciate your positive feedback regarding the blog post on different types of oil and gas pipes. Our aim is to provide valuable information to our readers, and we’re glad to hear that you found it useful.

While we are not specifically familiar with Parmanu Dhatu Nigam or Cerrobend, we welcome any insights or additional information you may have on the topic of oil and gas pipes. Feel free to share your expertise or any relevant details that could further enhance our readers’ understanding. Thank you again for your support and engagement.

Informative article. Need more article like this do you know that biggest manufacturer of titanium ball valve in भारत

Thank you for your feedback, Metal & Alloy. We’re glad to hear that you found the article informative. We strive to provide valuable content on various topics related to oil and gas pipes. While we don’t have specific information on the biggest manufacturer of titanium ball valves in भारत, we appreciate your suggestion for more articles like this. We’ll keep it in mind for future topics. If you have any further questions or if there’s anything else we can assist you with, please feel free to let us know.

Thank you for providing this information. ,For further information – Carbon Steel Plate Manufacturers in India and Carbon Steel Round Bar Manufacturers in India

Thank you for your comment and for sharing additional information on carbon steel plate and round bar manufacturers in India. While the post primarily focuses on the different types of oil and gas pipes, it’s always helpful to have further knowledge about related industries and suppliers. Carbon steel plates and round bars are essential components used in various industries, including oil and gas. Manufacturers play a crucial role in providing high-quality products that meet industry standards. If anyone reading this post is interested in sourcing carbon steel plates or round bars from reliable manufacturers in India, they can refer to the links you shared for more information.

Thank you for providing this information. ,

For further information – Carbon Steel Plate Manufacturers in India and Carbon Steel Round Bar Manufacturer in India

Thank you for giving this useful information. Also, take a look at our Round Bar Manufacturer in India. Go to Tough Alloys for more details.

Thank you for sharing your valuable information and providing additional resources, Tough Alloy. It’s great to see companies like Tough Alloys contributing to the industry. The post primarily focuses on different types of oil and gas pipes, but your round bar manufacturing services in India seem to align with the broader field of materials used in the oil and gas sector. Offering durable and reliable products is crucial in supporting various applications within this industry. I appreciate you sharing your expertise and inviting readers to explore Tough Alloys for more details.

Very nice blog. Thank you very much for your contribution, also Visit Kaliraj Impex we are well known Mexflow Copper Pipe Manufacturers in India.

It’s a very helpful post. You might also check into Copper Earthing Electrode Manufacturers in India or visit Bombay Earthing House.

Very informative article. Thanks for sharing this. This could be very helpful. Visit: Top ERW Pipe Manufactureres

Awesome blog. incredibly instructive, which is extremely informative. I also suggest checking out Gasco, Inc. A leading gasket manufacturer in India and worldwide. Come visit us at Gasco Inc. to explore our wide range of gaskets and other gasket products, all available at the most competitive prices.

Thank you for your comment, Gasko Gaskets. It’s great to hear that you found the blog post on different types of oil and gas pipes informative. Gasco Inc. sounds like a reputable gasket manufacturer, and it’s always beneficial to have a wide range of gasket options available, especially in the oil and gas industry where gaskets play a crucial role in maintaining safety and preventing leaks.

Having access to competitive prices is also an important factor when considering gasket suppliers. It would be helpful if you could provide more details about the specific types of gaskets Gasco Inc. offers and any unique features or advantages they have. This additional information could further assist readers in making informed decisions when choosing gaskets for their oil and gas projects.

Thank you for suggesting Gasco Inc., and I’m sure readers who are in need of gaskets will appreciate the recommendation.

Awesome blog. incredibly instructive which is extremely informative. I also suggest checking out Manan Steels & Metals. A leading Round Bars manufacturer in India and worldwide. Come visit us at Manan Steels & Metals to explore our wide range of Stainless Steel Round Bars and other stainless steel products, all available at the most competitive prices.

Great Blog! Also read on Aluminium Bronze Round Bar Manufacturer in India or also visit the website of Rajkrupa Metal Industries to learn more.

Fantastic blog. amazingly instructive I appreciate you sharing that. Also research R.H.Alloys. We are one of the top Stainless Steel Sheet Manufacturers in the globe and in India. Visit us now at R H Alloys to buy Stainless Steel Sheet, Stainless Steel Coil and other Stainless Steel products at the best prices.

Hi, Adorable Blog and this is something new I am reading on Blogger, we are Inco Special Alloys We are leading,310 stainless steel pipe manufacturer,ss 310 pipe suppliers in mumbai, inconel 625 tube suppliers,alloy 600 tube manufacturer, inconel 600 tube suppliers,steel pipe size charts,310 stainless steel pipe suppliers, and grade 310 stainless steel pipe

Excellent post and wonderful blog, you can also visit Google Workspace for Lifetime only at $59 USD.

Thanks for the blog loaded with so much information. It’s really informative.

AAC Blocks

tanx

Awesome Blog. Thankyou for this article. We are also manufacturing Metal mesh,Woven wire mesh,Conveyor belt and if you want please visit our website https://www.codinametal.in/ – Metal mesh manufacturer in India

Awesome Blog. Thankyou for this article. We also manufacturing Metal mesh,Woven wire mesh,Conveyor belt and if you want please visit our website

Metal mesh manufacturer in India .

SUB : REQUEST FOR YOUR REQUIREMENT FOR STAINLESS STEEL, CARBON STEEL, ALLOY STEEL, COPPER ALLOYS & EXOTIC NICKEL ALLOYS IN FORM OF PIPE, TUBE, SHEET, PLATES, FITTINGS & FLANGES We STELCO INOX INC are Fastest growing International Suppliers & Exporters of Industrial Raw material to world renowned companies in India & abroad, providing them with world class quality material and service. Our products are supplied & accepted by our clients in various sphere of industries ranging from basic industries such as Paper, Textile, Sugar, Dairy, Cement, Engineering to more complex such as Petroleum, Chemicals, Power, Offshore, Onshore & Nuclear Industries.

We have dedicated sources, expertise & full technical know-how to supply quality products as per Client’s basic & special requirements.

We deal in Stainless Steel, Carbon Steel, Alloy Steel, Copper Alloys & Exotic Nickel Alloys in form of Pipe, Tube, Sheet, Plates, Fittings & Flanges. We can fulfill Client’s requirement of all size as we stock huge amount of material from both indigenous & foreign manufactures.

Our major advantage is our qualified workforce, we have pool of specialist in field of Technical, Sales & Logistic, who are fully committed to provide with best solution for your business & can help you solve all your procurement problems.

At STELCO INOX INC Quality is Guaranteed, we take use of innovative & latest available technology to meet client’s full requirements regarding Quality & Value for money.

We hope the information provide on our site to be useful to you & you will forward us your regular enquiry and requirements & provide us with an opportunity to work with your esteem Organisation. If you have any suggestion or query, how we can serve you better please do inform us. your suggestion are heartily welcomed. Thank you and assuring you our best co-operation always. Thank you and Warm Regards,

—

Rushabh. K. Mehta

STELCO INOX INCCARBON STEEL | ABRASION RESISTANT | ALLOY STEEL | STAINLESSSTEEL | DUPLEX STEEL | HIGH NICKEL ALLOYS PIPES | FITTINGS| FLANGES | TUBES | PLATES | BARS | FASTENERS

Mob: + 9192230 94940 E-mail: stelcopipe@gmail.com cc to. stelcoinox@gmail.com

Thank You for this Wonderful Article, Kindly Check our Products List, We are Valve Manufacturing Company From India, Check our List of Quality Products. We also Offer Valve Repair & Services.

You seem to know a lot about this topic. Your website is incredibly informative and clearly written, making it easy for both experts and novices to understand the precise subject. We work for Farvision ERP which is a top provider of property management system solutions to help you deal with rental properties more efficiently and effectively.

Thank you of such a great information. Visit our site for more information on Stockist of Pipes in Mumbai

Thanks For Sharing this wonderful article. We are Valve Manufacturers in India and also manufacture different types of Industrial Valves; Ball Valve, Gate Valve, Plug Valve, Safety Valve, Butterfly Valve, Pipeline Strainers and Many More.

Nice info, Goyal Steel Tubes, the oldest dealer of MS Pipes and Tubes in Delhi-NCR, deals in all sizes and variety of MS Pipes, stocked from reputed companies like APL Apollo, Jindal, Surya etc.

Send your pipe related queries on 9650705448, call on 9910495448 or find us on google- Goyal Steel Tubes click on the first link.

Awesome blog. really instructive Many thanks for sharing that. Examine New Nakoda Metal Industries as well. We are a well-known manufacturer of stainless steel ferrule fittings both in India and internationally. Visit us now at nakodametalind.com to buy Stainless Steel Ferrule Fittings and other plumbing products at best costs.

Fantastic blog. amazingly instructive I appreciate you sharing it. We at Bhansali Steel really liked it.

Roll-Fast Fasteners Manufacturer bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4″ to 4″.

In this article you have provided a lot of information on various Stainless Steel Seamless Pipes. I also about the various kinds of Seamless pipes such as Stainless Steel 304 Seamless Pipes, Stainless Steel 316 Seamless Pipes, Stainless Steel 321 Seamless Pipes and Stainless Steel 347 Seamless Pipes. I also learn about the various trypes of ERW Pipes. Thank you.

Thanks For Sharing this wonderful article. please visit: https://www.yakshitaengineering.com/

We are manufacturer of all different types of Instrument Valves (Needle Valves, Ball Valves, Check Valves, Non return Valves, Instrument Manifolds Valves) Snubbers, Gauge Cocks, Siphon, and High Precision Products.

Thank you for noting that carbon steel pipes have the biggest market share due to their versatility in both high and low temperatures. My cousin works for a manufacturer. He is doing some studies on industrial welding gas for his factory. I’ll advise him to locate an industrial welding gas supplier to provide the gas to his factory and propose the finest pipes.

Wonderful article you shared. Thanks for sharing such a great blog… I am impressed with you taking time to post a nice info. I really love, keep me up to date, If you want to buy electric scooters, then reach us..

woww!! What a fantastic and informative blog! Thanks Admin for this post, it’s really a good post and followed your blog with great interest. Keep updating stuffs like this. If you are looking for luxury home stay in kodaikanal | hotels in kodaikanal | Villas in Kodaikanal | mountain view room in kodaikanal please reach us…

Nice Blog.. Check our list of products. Valve Dealers & Suppliers, Weir BDK Valve Supplier, Leader Valve Supplier, Audco Plug Valve Supplier, Inline Flame Arrester Dealer

, Level Switch Dealer,

Thank You for this Article, We are Industrial Valve Manufacturers & Exporters, Check our List of Top Quality Products, Gate Valve, Globe Valve, Ball Valve, Check Valve, Butterfly Valve, Control Valve. We also Manufacture Pipeline Strainers

Very Nice and Knowledgeable content. Will create a lot among the people. We are the supplier of Best Plumbing Pipes in India offering piping solutions for water tanks and bath fittings.

Thank you for this information, do visit our blog if you interested in knowing about What is Single Sign-On?, if you want to know JumpCloud vs Okta do visit our website.

Good blog, learnet a lot , Also check out inox steel india one of the best ss seamless pipe manufacturers in india.

This is a very good article for who deal oil and gas.

This is a good article for who deal oil and gas.

Thank you for providing us with this important information and assisting us in reaching our goal. You can visit here: Fasteners Manufacturer In India ,Ss Wire Manufacturers In Mumbai.

Thank you for this exciting blog, visit our website at Aashish Steel. We are the best Inconel Fasteners Manufacturer,Monel Fastener Manufacturer

Thank you for providing this important information. It’s possible that you’d be interested in it as well. Stainless Steel Chequered Plate, Chequered Plates Manufacturer In India and you should also visit our website Maxgrow Corporation

Beautiful blog, very well written. Do also check out our products on aluminium bronze fasteners, Top screw manufacturer in India, Monel Fasteners Manufacturer, Stainless Steel Fasteners Manufacturer in India and many more on our page Ananka Group.