ASME B36.10 (sizes chart for carbon and alloy steel pipes like A53, A106, A333, A335) and ASME B36.19 (sizes chart for stainless, duplex, nickel alloy pipes like A312, A790, A928, B161, etc): NPS x WT and weight in kgs./lbs. per meter/foot.

ASME B36.10 PIPE SIZE CHART (FOR CARBON/ALLOY PIPES)

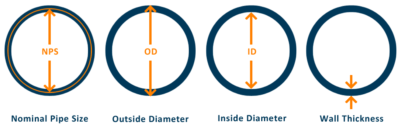

The ASME B36.10 pipe size chart is a standardized chart developed by the American Society of Mechanical Engineers (ASME) that details the dimensions and physical properties of welded and seamless wrought steel pipes for high and low temperatures and pressures (carbon and alloy only). This comprehensive chart includes essential information such as the pipe’s outside diameter (OD), wall thickness (expressed in schedule numbers or, for very thick-walled pipes, in inches or millimeters), weight per unit length, and the pipe’s inside diameter (ID) for various nominal pipe sizes (NPS). The ASME B36.10 chart applies to carbon steel pipes and alloy steel pipes. For stainless steel, duplex, super duplex, and nickel alloy pipes (as well as other non-ferrous pipes), the ASME B36.19 pipe size chart must be applied.

ASME B36.10 WEIGHTS IN KG/METER

First line: wall thickness in mm; second line: pipe weight (in Kilograms per meter)

| NPS | OD mm | Sch. 5 | Sch. 10 | Sch. 20 | Sch. 30 | Sch. 40 | Sch. STD | Sch. 60 | Sch. 80 | Sch. XS | Sch. 100 | Sch. 120 | Sch. 140 | Sch. 160 | Sch. XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 10.287 | 0.089 0.21 | 1.24 0.28 | – | – | 1.73 0.37 | 1.73 0.37 | – | 2.41 0.47 | 2.41 0.47 | – | – | – | – | – |

| 1/4 | 13.716 | 1.24 0.38 | 1.65 0.49 | – | – | 2.24 0.63 | 2.24 0.63 | – | 3.02 0.80 | 3.02 0.80 | – | – | – | – | – |

| 3/8 | 17.145 | 1.24 0.49 | 1.65 0.63 | – | – | 2.31 0.84 | 2.31 0.84 | – | 3.20 1.10 | 3.20 1.10 | – | – | – | – | – |

| 1/2 | 21.34 | 1.65 0.80 | 2.11 1.00 | – | – | 2.77 1.62 | 2.77 1.62 | – | 3.73 0.80 | 3.73 0.80 | – | – | – | 4.78 1.95 | 7.47 2.55 |

| ¾ | 26.67 | 1.65 1.03 | 2.11 1.28 | – | – | 2.87 1.69 | 2.87 1.69 | – | 3.91 2.20 | 3.91 2.20 | – | – | – | 5.56 2.90 | 7.82 3.64 |

| 1 | 33.401 | 1.65 1.30 | 2.77 2.09 | – | – | 3.38 2.50 | 3.38 2.50 | – | 4.55 3.24 | 4.55 3.24 | – | – | – | 6.35 4.24 | 9.09 5.45 |

| 1 1/4 | 42.164 | 1.65 1.65 | 2.77 2.70 | – | – | 3.56 3.39 | 3.56 3.39 | – | 4.85 4.47 | 4.85 4.47 | – | – | – | 6.35 5.61 | 9.70 7.77 |

| 1 1/2 | 48.26 | 1.65 1.91 | 2.77 3.11 | – | – | 3.68 4.05 | 3.68 4.05 | – | 5.08 5.41 | 5.08 5.41 | – | – | – | 7.14 7.25 | 10.15 9.56 |

| 2 | 60.325 | 1.65 2.40 | 2.77 3.93 | – | – | 3.91 5.44 | 3.91 5.44 | – | 5.54 7.48 | 5.54 7.48 | – | – | – | 8.74 11.11 | 11.07 13.44 |

| 2 1/2 | 73.025 | 2.11 3.69 | 3.05 5.26 | – | – | 5.16 8.63 | 5.16 8.63 | – | 7.01 11.41 | 7.01 11.41 | – | – | – | 9.53 14.92 | 14.02 20.39 |

| 3 | 88.9 | 2.11 4.51 | 3.05 6.45 | 3.96 8.29 | 4.78 9.92 | 5.49 11.29 | 5.49 11.29 | – | 7.62 15.27 | 7.62 15.27 | – | – | – | 11.13 21.35 | 15.24 27.68 |

| 3 1/2 | 101.6 | 2.11 5.18 | 3.05 7.40 | – | – | 5.74 13.57 | 5.74 13.57 | – | 8.08 18.63 | 8.80 18.63 | – | – | – | 16.15 34.20 |

|

| 4 | 114.3 | 2.11 5.84 | 3.05 8.36 | 4.78 12.91 | 5.56 14.91 | 6.02 16.07 | 6.02 16.07 | 7.14 18.87 | 8.56 22.32 | 8.56 22.32 | – | 11.13 28.32 | – | 13.49 33.54 | 17.12 41.03 |

| 5 | 141.3 | 2.77 9.47 | 3.40 11.57 | 4.78 16.09 | 5.56 18.61 | 6.55 21.77 | 6.55 21.77 | 7.14 23.62 | 9.53 30.97 | 9.53 30.97 | – | 12.70 40.28 | – | 15.88 49.11 | 19.05 57.43 |

| 6 | 168.275 | 2.77 11.32 | 3.40 13.84 | 4.78 19.27 | 6.35 25.38 | 7.11 28.26 | 7.11 28.26 | 9.53 37.31 | 10.97 42.56 | 10.97 42.56 | 12.70 48.73 | 14.27 54.20 | – | 18.26 67.56 | 21.95 79.22 |

| 8 | 219.075 | 2.77 14.78 | 3.76 19.96 | 6.35 33.31 | 7.04 36.81 | 8.18 42.55 | 8.18 42.55 | 10.31 53.08 | 12.70 64.64 | 12.70 64.64 | 15.09 75.92 | 18.26 90.44 | 20.62 100.27 | 23.01 111.27 | 22.23 107.92 |

| 10 | 273.05 | 3.40 22.63 | 4.19 27.78 | 6.35 41.77 | 7.80 51.03 | 9.27 60.31 | 9.27 60.31 | 12.70 81.55 | 15.09 96.01 | 12.70 81.55 | 18.26 114.75 | 21.44 133.06 | 25.40 155.15 | 28.58 172.33 | 25.40 155.15 |

| 12 | 323.85 | 3.96 31.25 | 4.57 36.00 | 6.35 49.73 | 8.38 65.20 | 10.31 79.73 | 9.53 73.88 | 14.27 108.96 | 17.48 132.08 | 12.70 97.46 | 21.44 169.91 | 25.40 186.97 | 28.58 208.14 | 33.32 238.76 | 25.40 186.97 |

| 14 | 355.6 | 3.96 34.36 | 6.35 54.69 | 7.92 67.90 | 9.53 81.33 | 11.13 94.55 | 9.53 81.33 | 15.09 126.71 | 19.05 158.10 | 12.70 107.39 | 23.83 194.96 | 27.79 224.65 | 31.75 253.56 | 35.71 281.70 | – |

| 16 | 406.4 | 4.19 41.56 | 6.35 62.64 | 7.92 77.83 | 9.53 93.27 | 12.70 123.30 | 9.53 93.27 | 16.66 160.12 | 21.44 203.53 | 12.70 123.30 | 26.19 245.66 | 30.96 286.64 | 36.53 333.19 | 40.49 365.35 | – |

| 18 | 457.2 | 4.19 46.81 | 6.35 70.57 | 7.92 87.71 | 11.13 122.38 | 14.27 155.80 | 9.53 105.16 | 19.05 205.74 | 23.83 254.55 | 12.70 139.15 | 29.36 309.62 | 34.93 363.56 | 39.67 408.26 | 45.24 459.37 | – |

| 20 | 508 | – | 6.35 78.55 | 9.53 117.15 | 12.70 155.12 | 15.09 183.42 | 9.53 117.15 | 20.62 247.83 | 26.19 311.17 | 12.70 155.12 | 32.54 381.53 | 38.10 441.49 | 44.45 508.11 | 50.01 564.81 | – |

| 22 | 558.8 | – | 6.35 86.54 | 9.53 129.13 | 12.70 171.09 | 9.53 129.13 | 22.23 294.25 | 28.58 373.83 | 12.70 171.09 | 34.93 451.42 | 41.28 527.02 | 47.63 600.63 | 53.98 672.26 | – | |

| 24 | 609.6 | – | 6.35 94.53 | 9.53 141.12 | 14.27 209.64 | 17.48 255.41 | 9.53 141.12 | 24.61 355.26 | 30.96 442.08 | 12.70 187.06 | 38.89 547.71 | 46.02 640.03 | 52.37 720.15 | 59.54 808.22 | – |

| 26 | 660.4 | 6.35 102.36 | 7.92 127.36 | – | – | – | 9.53 152.87 | 10.31 165.18 | 12.70 202.72 | 14.27 227.23 | – | – | – | – | |

| 28 | 711.2 | 6.35 110.34 | 7.92 137.32 | – | – | – | 9.53 164.85 | 12.70 218.69 | – | – | – | – | – | ||

| 30 | 762 | 6.35 118.31 | 7.92 147.28 | 12.70 234.67 | 15.88 292.18 | – | 9.53 176.84 | 10.31 191.11 | 11.13 206.09 | 12.70 234.67 | – | – | – | – | – |

| 32 | 812.8 | 6.35 126.31 | 7.92 157.24 | – | – | – | 9.53 188.82 | 10.31 204.08 | 11.13 220.08 | 12.70 250.64 | – | – | – | – | – |

| 34 | 863.6 | 6.35 134.30 | 7.92 167.20 | – | – | – | 9.53 200.31 | 10.31 217.05 | 11.13 234.08 | 12.70 266.61 | – | – | – | – | – |

| 36 | 914.4 | 6.35 142.13 | 7.92 176.96 | 12.70 282.27 | 15.88 351.70 | 19.05 420.42 | 9.53 212.56 | 10.31 229.76 | 11.13 247.31 | 12.70 282.27 | – | – | – | – | – |

| 40 | 1016 | – | – | – | – | – | 9.53 236.53 | 12.70 314.22 | – | – | – | – | – | ||

| 42 | 1066.8 | 7.92 207.92 | – | – | – | – | 9.53 248.52 | 12.70 330.19 | – | – | – | – | – | ||

| 48 | 1219.2 | – | – | – | – | – | 9.53 284.24 | 12.70 377.79 | – | – | – | – | – |

ASME B36.10 WEIGHTS IN LBS/FT.

First line: wall thickness in inches; second line: pipe weight (in lbs./foot)

| NPS | OD Inch. | 5S | 5 | 10S | 10 | 20 | 30 | 40S/STD. | 40 | 60 | 80S/XS | 80 | 100 | 120 | 140 | 160 | XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.405 | .035 .1383 | .049 .1863 | .049 .1863 | .068 .2447 | .068 .2447 | .095 .3145 | .095 .3145 | |||||||||

| 1/4 | 0.54 | .049 .2570 | .065 .3297 | .065 .3297 | .088 .4248 | .088 .4248 | .119 .5351 | .119 .5351 | |||||||||

| 3/8 | 0.675 | .049 .3276 | .065 .4235 | .065 .4235 | .091 .5676 | .091 .5676 | .126 .7338 | .126 .7338 | |||||||||

| 1/2 | 0.84 | .065 .5383 | .065 .5383 | .083 .6710 | .083 .6710 | .109 .8510 | .109 .8510 | .147 1.088 | .147 1.088 | .187 1.304 | .294 1.714 |

||||||

| 3/4 | 1.05 | .065 .6838 | .065 .6838 | .083 .8572 | .083 .8572 | .113 1.131 | .113 1.131 | .154 1.474 | .154 1.474 | .218 1.937 | .308 2.441 |

||||||

| 1 | 1.315 | .065 .8678 | .065 .8678 | .109 1.404 | .109 1.404 | .133 1.679 | .133 1.679 | .179 2.172 | .179 2.172 | .250 2.844 | .358 3.659 |

||||||

| 1-1/4 | 1.66 | .065 1.107 | .065 1.107 | .109 1.806 | .109 1.806 | .140 2.273 | .140 2.273 | .191 2.997 | .191 2.997 | .250 3.765 | .382 5.214 |

||||||

| 1-1/2 | 1.9 | .065 1.274 | .065 1.274 | .109 2.085 | .109 2.085 | .145 2.718 | .145 2.718 | .200 3.631 | .200 3.631 | .281 4.859 | .400 6.408 |

||||||

| 2 | 2.375 | .065 1.604 | .065 1.604 | .109 2.638 | .109 2.638 | .154 3.653 | .154 3.653 | .218 5.022 | .218 5.022 | .343 7.444 | .436 9.029 |

||||||

| 2-1/2 | 2.875 | .083 2.475 | .083 2.475 | .120 3.531 | .120 3.531 | .203 5.793 | .203 5.793 | .276 7.661 | .276 7.661 | .375 10.01 | .552 13.70 |

||||||

| 3 | 3.5 | .083 3.029 | .083 3.029 | .120 4.332 | .120 4.332 | .216 7.576 | .216 7.576 | .300 10.25 | .300 10.25 | .437 14.32 | .600 18.58 |

||||||

| 3-1/2 | 4 | .083 3.472 | .083 3.472 | .120 4.973 | .120 4.973 | .226 9.109 | .226 9.109 | .318 12.51 | .318 12.51 | .636 22.85 |

|||||||

| 4 | 4.5 | .083 3.915 | .083 3.915 | .120 5.613 | .120 5.613 | .237 10.79 | .237 10.79 | .281 12.66 | .337 14.98 | .337 14.98 | .437 19.01 | .531 22.51 | .674 27.54 |

||||

| 4-1/2 | 5 | .247 12.53 | .355 17.61 | .710 32.53 |

|||||||||||||

| 5 | 5.563 | .109 6.349 | .109 6.349 | .134 7.770 | .134 7.770 | .258 14.62 | .258 14.62 | .375 20.78 | .375 20.78 | .500 27.04 | .625 32.96 | .750 38.55 |

|||||

| 6 | 6.625 | .109 7.585 | .109 7.585 | .134 9.290 | .134 9.290 | .280 18.97 | .280 18.97 | .432 28.57 | .432 28.57 | .562 36.39 | .718 45.3 | .864 53.16 |

|||||

| 7 | 7.625 | .301 23.57 | .500 38.05 | .875 63.08 |

|||||||||||||

| 8 | 8.625 | 0.109 | 0.109 | .148 13.40 | .148 13.40 | .250 22.36 | .277 24.70 | .322 28.55 | .322 28.55 | .406 35.64 | .500 43.39 | .500 43.39 | .593 50.87 | .718 60.93 | .812 67.76 | .906 74.69 | .885 72.42 |

| 9 | 9.625 | .342 33.9 | .500 48.72 | ||||||||||||||

| 10 | 10.75 | .134 15.19 | .134 15.19 | .165 18.65 | .165 18.65 | .250 28.04 | .307 34.24 | .365 40.48 | .365 40.48 | .500 54.74 | .500 54.74 | .593 64.33 | .718 76.93 | .843 89.20 | 1.000 104.1 | 1.125 115.7 | |

| 11 | 11.75 | .375 45.55 | .500 60.07 | ||||||||||||||

| 12 | 12.75 | .156 21.07 | .165 22.18 | .180 24.17 | .180 24.17 | .250 33.38 | .307 34.24 | .365 40.48 | .365 40.48 | .500 54.74 | .500 54.74 | .593 64.33 | .718 76.93 | .843 89.20 | 1.000 104.1 | 1.125 115.7 | |

| 14 | 14 | .156 23.07 | .188 27.73 | .250 36.71 | .312 45.38 | .375 54.57 | .375 54.57 | .437 63.37 | .593 84.91 | .500 72.09 | .750 106.1 | .937 130.7 | 1.093 150.7 | 1.250 170.2 | 1.406 189.1 | ||

| 16 | 16 | .165 27.90 | .188 31.75 | .250 42.05 | .312 52.36 | .375 62.58 | .375 62.58 | .500 82.77 | .656 107.5 | .500 82.77 | .843 136.5 | 1.031 164.8 | 1.218 192.3 | 1.427 223.5 | 1.593 245.1 | ||

| 18 | 18 | .165 31.43 | .188 35.76 | .250 47.39 | .312 59.03 | .437 82.06 | .375 70.59 | .562 104.2 | .750 138.2 | .500 93.45 | .937 170.8 | 1.156 208.0 | 1.375 244.1 | 1.562 274.2 | 1.781 308.5 | ||

| 20 | 20 | .188 39.78 | .218 46.05 | .250 52.73 | .375 78.6 | .500 104.1 | .375 78.6 | .593 122.9 | .812 166.4 | .500 104.1 | 1.031 208.9 | 1.280 256.1 | 1.500 296.4 | 1.750 341.1 | 1.968 379.0 | ||

| 22 | 22 | .188 43.8 | .218 50.71 | .250 58.07 | .375 86.61 | .500 114.81 | .375 86.61 | .875 197.41 | .500 114.81 | 1.125 250.81 | 1.375 302.88 | 1.625 353.61 | 1.875 403.0 | 2.125 451.06 | |||

| 24 | 24 | .218 55.37 | .250 63.41 | .250 63.41 | .375 94.62 | .562 140.8 | .375 94.62 | .687 171.2 | .968 238.1 | .500 125.5 | 1.218 296.4 | 1.531 367.4 | 1.812 429.4 | 2.062 483.1 | 2.344 542.13 | ||

| 26 | 26 | .312 85.60 | .500 136.17 | .375 102.63 | .500 136.17 | ||||||||||||

| 28 | 28 | .312 92.26 | .500 146.85 | .625 182.73 | .375 110.64 | ||||||||||||

| 30 | 30 | .250 79.43 | .312 98.93 | .312 98.93 | .500 157.53 | .625 196.08 | .375 118.65 | .500 157.53 | |||||||||

| 32 | 32 | .312 105.59 | .500 168.21 | .625 209.43 | .375 126.66 | .688 230.08 | .500 168.21 | ||||||||||

| 34 | 34 | .312 112.25 | .500 178.89 | .625 222.78 | .375 134.667 | .688 244.77 | |||||||||||

| 36 | 36 | .312 118.92 | .625 236.13 | .375 142.68 | .750 262.35 | .500 189.57 |

⚠️ If you are interested in charts showing only the wall thickness of carbon & alloy steel pipes in inches or in mm by NPS or DN, consult this article.

ASME B36.19 PIPE SIZE CHART (FOR STAINLESS/NICKEL ALLOY PIPES)

The ASME B36.19 pipe size chart is a standardized chart developed by the American Society of Mechanical Engineers (ASME) that specifies the dimensions and physical properties of stainless steel pipes (and higher alloyed grades) intended for high-temperature, high-pressure applications, as well as for corrosive or high-purity applications. Similar to the ASME B36.10 chart for carbon and alloy steel pipes, the B36.19 chart focuses specifically on stainless steel pipes, including seamless and welded types.

ASME B36.19 WEIGHTS IN KG/METER

| Sch. 5S | Sch 10S | Sch 40S | Sch 80S | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OD mm | OD inch | WT mm (WT in) | kg/m | WT mm (WT in) | kg/m | WT mm (WT in) | kg/m | WT mm (WT in) | kg/m | |

| 1/8 | 10.3 | 0.405 | – | – | 1.25 (0.049) | 0.28 | 1.73 (0.068) | 0.37 | 2.42 (0.095) | 0.47 |

| 1/4 | 13.7 | 0.54 | – | – | 1.66 (0.065) | 0.49 | 2.24 (0.088) | 0.63 | 3.03 (0.119) | 0.8 |

| 3/8 | 17.2 | 0.675 | – | – | 1.66 (0.065) | 0.63 | 2.32 (0.091) | 0.85 | 3.20 (0.126) | 1.1 |

| 1/2 | 21.3 | 0.84 | 1.65 (0.065) | 0.81 | 2.11 (0.083) | 1 | 2.77 (0.109) | 1.27 | 3.74 (0.147) | 1.62 |

| 3/4 | 26.7 | 1.05 | 1.65 (0.065) | 1.02 | 2.11 (0.083) | 1.28 | 2.87 (0.113) | 1.68 | 3.92 (0.154) | 2.2 |

| 1 | 33.4 | 1.315 | 1.65 (0.065) | 1.3 | 2.77 (0.109) | 2.09 | 3.38 (0.133) | 2.5 | 4.55 (0.179) | 3.24 |

| 1 1/4 | 42.2 | 1.66 | 1.65 (0.065) | 1.66 | 2.77 (0.109) | 2.69 | 3.56 (0.140) | 3.39 | 4.86 (0.191) | 4.47 |

| 1 1/2 | 48.3 | 1.9 | 1.65 (0.065) | 1.91 | 2.77 (0.109) | 3.11 | 3.69 (0.145) | 4.06 | 5.08 (0.200) | 5.41 |

| 2 | 60.3 | 2.375 | 1.65 (0.065) | 2.4 | 2.77 (0.109) | 3.93 | 3.92 (0.154) | 5.45 | 5.54 (0.218) | 7.49 |

| 2 1/2 | 73 | 2.875 | 2.11 (0.083) | 3.69 | 3.05 (0.120) | 5.26 | 5.16 (0.203) | 8.64 | 7.01 (0.276) | 11.4 |

| 3 | 88.9 | 3.5 | 2.11 (0.083) | 4.52 | 3.05 (0.120) | 6.46 | 5.49 (0.216) | 11.3 | 7.62 (0.300) | 15.3 |

| 3 1/2 | 101.6 | 4 | 2.11 (0.083) | 5.18 | 3.05 (0.120) | 7.41 | 5.74 (0.226) | 13.6 | 8.08 (0.318) | 18.6 |

| 4 | 114.3 | 4.5 | 2.11 (0.083) | 5.84 | 3.05 (0.120) | 8.37 | 6.02 (0.237) | 16.1 | 8.56 (0.337) | 22.3 |

| 5 | 141.3 | 5.563 | 2.77 (0.109) | 9.46 | 3.41 (0.134) | 11.6 | 6.56 (0.258) | 21.8 | 9.53 (0.375) | 31 |

| 6 | 168.3 | 6.625 | 2.77 (0.109) | 11.3 | 3.41 (0.134) | 13.9 | 7.12 (0.280) | 28.3 | 10.98 (0.432) | 42.6 |

| 8 | 219.1 | 8.625 | 2.77 (0.109) | 14.8 | 3.76 (0.148) | 20 | 8.18 (0.322) | 42.5 | 12.70 (0.500) | 64.6 |

| 10 | 273.1 | 10.75 | 3.41 (0.134) | 22.7 | 4.20 (0.165) | 27.8 | 9.28 (0.365) | 60.4 | 12.70 (0.500) | 81.5 |

| 12 | 323.9 | 12.75 | 3.97 (0.156) | 31.3 | 4.58 (0.180) | 36.1 | 9.53 (0.375) | 73.9 | 12.70 (0.500) | 97.4 |

ASME B36.19 WEIGHTS IN LBS/FT.

| NPS | OD (mm) | OD (inch) | Sch 5S | Weight | Sch 10S | Weight | Sch 40S | Weight | Sch 80S | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm (inch) | lbs/ft. | mm (inch) | lbs/ft. | mm (inch) | lbs/ft. | mm (inch) | lbs/ft. | |

| 1/8 | 10.3 | 0.405 | – | – | 1.25 (0.049) | 0.19 | 1.73 (0.068) | 0.25 | 2.42 (0.095) | 0.32 |

| 1/4 | 13.7 | 0.54 | – | – | 1.66 (0.065) | 0.33 | 2.24 (0.088) | 0.42 | 3.03 (0.119) | 0.54 |

| 3/8 | 17.2 | 0.675 | – | – | 1.66 (0.065) | 0.42 | 2.32 (0.091) | 0.57 | 3.20 (0.126) | 0.74 |

| 1/2 | 21.3 | 0.84 | 1.65 (0.065) | 0.54 | 2.11 (0.083) | 0.67 | 2.77 (0.109) | 0.85 | 3.74 (0.147) | 1.09 |

| 3/4 | 26.7 | 1.05 | 1.65 (0.065) | 0.69 | 2.11 (0.083) | 0.86 | 2.87 (0.113) | 1.13 | 3.92 (0.154) | 1.48 |

| 1 | 33.4 | 1.315 | 1.65 (0.065) | 0.87 | 2.77 (0.109) | 1.4 | 3.38 (0.133) | 1.68 | 4.55(0.179) | 2.18 |

| 1 1/4 | 42.2 | 1.66 | 1.65 (0.065) | 1.12 | 2.77 (0.109) | 1.81 | 3.56 (0.140) | 2.28 | 4.86 (0.191) | 3 |

| 1 1/2 | 48.3 | 1.9 | 1.65 (0.065) | 1.28 | 2.77 (0.109) | 2.09 | 3.69 (0.145) | 2.73 | 5.08 (0.200) | 3.64 |

| 2 | 60.3 | 2.375 | 1.65 (0.065) | 1.61 | 2.77 (0.109) | 2.64 | 3.92 (0.154) | 3.66 | 5.54 (0.218) | 5.03 |

| 2 1/2 | 73 | 2.875 | 2.11 (0.083) | 2.48 | 3.05 (0.120) | 3.53 | 5.16 (0.203) | 5.81 | 7.01 (0.276) | 7.66 |

| 3 | 88.9 | 3.5 | 2.11 (0.083) | 3.04 | 3.05 (0.120) | 4.34 | 5.49 (0.216) | 7.59 | 7.62 (0.300) | 10.28 |

| 3 1/2 | 101.6 | 4 | 2.11 (0.083) | 3.48 | 3.05 (0.120) | 4.98 | 5.74 (0.226) | 9.14 | 8.08 (0.318) | 12.5 |

| 4 | 114.3 | 4.5 | 2.11 (0.083) | 3.92 | 3.05 (0.120) | 5.62 | 6.02 (0.237) | 10.82 | 8.56 (0.337) | 14.98 |

| 5 | 141.3 | 5.563 | 2.77 (0.109) | 6.36 | 3.41 (0.134) | 7.79 | 6.56 (0.258) | 14.65 | 9.53 (0.375) | 20.83 |

| 6 | 168.3 | 6.625 | 2.77 (0.109) | 7.59 | 3.41 (0.134) | 9.34 | 7.12 (0.280) | 19.02 | 10.9 (0.432) | 28.63 |

| 8 | 219.1 | 8.625 | 2.77 (0.109) | 9.95 | 3.76 (0.148) | 13.44 | 8.18 (0.322) | 28.56 | 12.7 (0.500) | 43.41 |

| 10 | 273.1 | 10.75 | 3.41 (0.134) | 15.25 | 4.20 (0.165) | 18.68 | 9.28 (0.365) | 40.59 | 12.7 (0.500) | 54.77 |

| 12 | 323.9 | 12.75 | 3.97 (0.156) | 21.03 | 4.58 (0.180) | 24.26 | 9.53 (0.375) | 49.66 | 12.7 (0.500) | 65.45 |

STEEL PIPES TOLERANCES (ASME B36.10 & B36.19)

DIAMETER TOLERANCE

The American Society of Mechanical Engineers (ASME) provides specifications for pipe diameter tolerances in various ASME standards, including ASME B36.10M for carbon and alloy steel pipes and ASME B36.19M for stainless steel pipes. These tolerances are essential for ensuring that pipes meet the required dimensions for proper fit and function in piping systems. Tolerance levels vary depending on the manufacturing process (seamless or welded), pipe size, and schedule (wall thickness).

ASME B36.10M (Carbon and Alloy Steel Pipes) & ASME B36.19M (Stainless Steel Pipes) Diameter Tolerances:

1. Outside Diameter (OD) Tolerance for Seamless Pipes:

- For NPS 1/8 to NPS 10, inclusive, the tolerance is ±1/64 inch (±0.4 mm).

- For NPS 12 and above, the OD tolerance is ±1% of the nominal diameter.

2. Outside Diameter (OD) Tolerance for Welded Pipes:

- Similar to seamless pipes, for NPS 1/8 to NPS 10, inclusive, the tolerance is ±1/64 inch (±0.4 mm).

- For NPS 12 and above, welded pipes typically follow the same ±1% tolerance of the nominal diameter, but it’s essential to refer to specific standards or manufacturer specifications for precise values, as the tolerance may vary based on the welding method and pipe manufacturing process.

3. Inside Diameter (ID) Tolerance:

Inside diameter tolerances are not typically specified because they are inferred from the OD and wall thickness tolerances. For a specific ID tolerance, it is necessary to control the OD and wall thickness within the prescribed tolerances.

4. Wall Thickness Tolerance:

Wall thickness tolerance varies depending on the NPS and schedule, but it is generally ±12.5% of the nominal wall thickness for most pipe sizes and schedules as per ASME B36.10M and B36.19M.

It’s important to note that these tolerances are general guidelines. Specific applications may require more stringent tolerances, and manufacturers might offer pipes with tolerances tighter than those specified by ASME standards. Always refer to the latest edition of the relevant ASME standard or consult with the pipe manufacturer to obtain the most accurate and applicable tolerances for your project.

WEIGHT TOLERANCE

ASME B36.10 and ASME B36.19 standards specify dimensions and weights for carbon, alloy, and stainless steel pipes, respectively. However, these standards primarily focus on the dimensions such as outside diameter, wall thickness, and length, and do not explicitly define weight tolerances for pipes. The weight of a pipe is a function of its material, outside diameter, wall thickness, and density; therefore, the weight per unit length can be calculated based on these parameters.

While ASME B36.10 and B36.19 provide the formulae and tables for calculating the theoretical weight of pipes, the actual weight can vary due to manufacturing tolerances on the wall thickness and diameter. These variations in dimensions, as a result of production processes, indirectly result in weight tolerances.

For the specific weight tolerance of pipes, one would typically refer to the manufacturer’s standards or the specifications of the material grade being used. Manufacturers might provide their own tolerances based on their manufacturing capabilities and the specific requirements of the project or industry standards.

When precision in weight is crucial for project specifications, such as for critical load-bearing structures or for transport where weight limits are a concern, it’s advisable to consult directly with the pipe manufacturer to understand the expected weight range or tolerance for the pipes being supplied. Additionally, industry practices or project specifications may set acceptable weight tolerance limits to ensure that the delivered pipes meet the structural or design requirements of the application.

Generally accepted weight tolerance for pipes are:

- Pipes of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipes in sizes larger than NPS 4 shall be weighed one by one

- Pipes NPS 12 (DN300, 323.8mm) and under, weight tolerance is: -3.5% / +10%

- Pipes over NPS 12 (DN300, 323.8mm),weight tolerance is: -5% / +10%

QUANTITY TOLERANCE

The American Society of Mechanical Engineers (ASME) standards, such as ASME B36.10M for carbon and alloy steel pipes and ASME B36.19M for stainless steel pipes, primarily focus on the dimensions and weights of pipes and do not specify “quantity tolerances” or the acceptable variation in the number of pipes delivered versus the number ordered. Quantity tolerance typically falls under the purview of procurement contracts, project specifications, or supplier agreements rather than being a part of ASME or similar technical standards.

When it comes to the supply and procurement of pipes (or any materials), the terms including quantity tolerance are usually negotiated between the buyer and the supplier and should be clearly outlined in the purchase order or contract. These terms can include:

- Overage or Shortage Allowance: An agreed percentage of the total order quantity that the supplier is permitted to deliver over or under the specified quantity.

- Exact Quantity Requirement: Some contracts may require the delivery of the exact quantity specified, with no allowance for overage or underage.

- Penalties for Non-compliance: Contracts may specify penalties or remedial actions if the delivered quantity does not comply with the agreed terms.

For large projects, it’s common to allow a certain percentage of overage to account for potential installation issues, damage, or miscalculations without significantly impacting the project timeline or budget.

It’s crucial for the purchasing documents to clearly define how quantity tolerances are handled, including any specific requirements or exceptions. Effective communication and agreement between the parties involved can help manage expectations and ensure that project needs are met efficiently.

LENGTH TOLERANCE

ASME standards, including ASME B36.10M for carbon and alloy steel pipes and ASME B36.19M for stainless steel pipes, specify dimensions and other physical characteristics of pipes but typically do not provide explicit tolerances for pipe lengths directly within these standards. However, the length of pipes is an important consideration in project planning and execution, and standard practices exist regarding how it is addressed.

Standard Pipe Lengths and Tolerances

1. Fixed Lengths: When pipes are ordered in fixed lengths, the tolerance is usually defined in the purchase order or agreed upon between the manufacturer and the purchaser. Common practice allows for a tolerance of +0 (no positive tolerance) to a certain amount over the ordered length, often around +1/4 inch to +1/2 inch (about +6 mm to +12 mm) for each fixed length, depending on the total length of the pipe.

2. Random Lengths: Pipes supplied in random lengths typically have a range defined, such as 16 to 22 feet (4.9 to 6.7 meters) for single random lengths or 35 to 45 feet (10.7 to 13.7 meters) for double random lengths. The exact tolerance within these ranges can vary and should be specified by the manufacturer or agreed upon in the contract.

3. Cut Lengths: Pipes cut to specific lengths according to project requirements may have tolerances similar to fixed lengths, with the exact values specified in the contract or standards referenced in the project documentation.

Project-Specific Requirements

For projects with specific requirements, it is common for engineering specifications to define length tolerances more strictly than what might be considered standard practice. These specifications take precedence over general practices and are negotiated as part of the contract or purchase agreement.

Reference to Standards

It’s important to reference the latest version of relevant ASME standards or any applicable project specifications for detailed information on pipe length tolerances. In cases where ASME standards do not explicitly define length tolerances, industry practices, manufacturer standards, and project specifications will guide the acceptable tolerances for pipe lengths.

In summary, while ASME B36.10M and B36.19M standards focus on the dimensional characteristics of pipes, length tolerances are typically addressed through manufacturer standards, purchase agreements, and project-specific requirements, rather than directly in these ASME standards.

NPS TO DN CONVERSION

The table shows the conversion between NPS and the pipe outside diameter in inches, mm, and DN (nominal diameter):

| PIPE NPS | Pipe outside diameter in inches | Pipe outside diameter in mm | NPS to DN conversion |

|---|---|---|---|

| 1/8 | 0.404 | 10.26 | 6 |

| 1/4 | 0.54 | 13.72 | 8 |

| 3/8 | 0.675 | 17.15 | 10 |

| 1/2 | 0.84 | 21.34 | 15 |

| ¾ | 1.05 | 26.67 | 20 |

| 1 | 1.315 | 33.40 | 25 |

| 1 ¼ | 1.66 | 42.16 | 32 |

| 1 ½ | 1.9 | 48.26 | 40 |

| 2 | 2.375 | 60.33 | 50 |

| 2 ½ | 2.875 | 73.03 | 65 |

| 3 | 3.5 | 88.90 | 80 |

| 3 ½ | 4 | 101.60 | 90 |

| 4 | 4.5 | 114.30 | 100 |

| 4 ½ | 5 | 127.00 | 115 |

| 5 | 5.563 | 141.30 | 125 |

| 6 | 6.625 | 168.28 | 150 |

| 7 | 7.625 | 193.68 | — |

| 8 | 8.625 | 219.08 | 200 |

| 10 | 10.75 | 273.05 | 250 |

| 12 | 12.75 | 323.85 | 300 |

| 14 | 14 | 355.60 | 350 |

| 16 | 16 | 406.40 | 400 |

| 18 | 18 | 457.20 | 450 |

| 20 | 20 | 508.00 | 500 |

| 22 | 22 | 558.80 | 550 |

| 24 | 24 | 609.60 | 600 |

| 26 | 26 | 660.40 | 650 |

| 28 | 28 | 711.20 | 700 |

| 30 | 30 | 762.00 | 750 |

| 32 | 32 | 812.80 | 800 |

| 34 | 34 | 863.60 | 850 |

| 36 | 36 | 914.40 | 900 |

| 38 | 38 | 965.20 | 950 |

| 40 | 40 | 1016.00 | 1000 |

| 42 | 42 | 1066.80 | 1050 |

| 44 | 44 | 1117.60 | 1100 |

| 46 | 46 | 1168.40 | 1150 |

| 48 | 48 | 1219.20 | 120 |

Sources:

We recommend purchasing the ASME pipe size specifications from the ASME website or from the IHS store to have a complete a proper understanding of the pipe dimensions topic.

7 Responses

Dear Sirs

Good Morning

You are kindly requested to send us your best offer for the mentioned as per attached request.

Please send us the related materials test certificates with the offer.

Looking forward to receive your offer as soon as possible.

For any further clarifications, Please do not hesitate to contact us

Dear Sir,

Please we need the urgent quotation for these items:

1) PIPE 14″ NB SEAMLESS, ASME B36.10, API SPEC 5L GRADE B PSL2 , SCHEDULE 20, BEVELLED ENDS, ASME B36.10 (6 METRES IS EQUIVALENT TO A PIECE) TO BE SUPPLIED WITH MATERIAL CERTIFICATE BS EN10204-3.1 ACCORDING TO GS EP PVV 141. Manufacturer Part No : TBA. Manufacturer : NO SPECIFIC MANUFACTURER

QTY 1 PC

2) PIPE,6″NORMINAL BORE SCHEDULE 40 SEAMLESS, BEVELLED END MATERIAL: API 5L GR.B ASME B36.10 MATERIAL CERTS TO BS EN10204-3.1B REQUIRED AS PER GS EP PVV 143. Manufacturer Part No : NO PART NUMBER. Manufacturer : NO SPECIFIC MANUFACTURER CERTIFICATION / DOCUMENTATION REQUIREMENTS Material Certificate to BSEN10204-3.1B

QTY 1 M

3) PIPE 8″ NB C/S API-5L-GR.B(PSL2) ASME B36.10M BE 12M SMLS SCH 20 – (12 METRES IS EQUIVALENT TO A PIECE), TO BE SUPPLIED WITH MATERIAL CERTIFICATE BSEN10204-3.1 ACCORDING TO GS EP PVV 141. Manufacturer Part No : TBA. Manufacturer : NO SPECIFIC MANUFACTURER

QTY 18 PC

4)_FLANGE WELD NECK 16″ NB, 150# RF SCH.20, ASTM A105N C/W316 WELDOVERLAID, ASME B16.5 – BE, AS PER GS PVV 141, TO BE SUPPLIED WITH MATERIAL CERTIFICATE EN10204-3.1 ACCORDING TO GS EP PVV 141. Manufacturer Part No : TBA. Manufacturer : NO SPECIFIC MANUFACTURER

QTY 1 PC

Please include the total weight, and the time of delivery.

Thank you and Kind Regards,

Emelike Mercy

Procurement Officer

CANDIX ENGINEERING NIGERIA LIMITED

10 Azuabie/ Okujagu road

Opposite govt technical College

Off Trans Amadi Industrial Layout,

Port Harcourt, Rivers State.

http://www.candixnigeria.com

+2348130166974

Dear Sir/Madam:

Below is our inquiry and will be thankful to have your offer as soon as possible. At the time of offer, please mention the Country of Origin, delivery time, and give the related data sheets.

ITEM

DESCRIPTION

QTY

UNIT

1- 28 IN,PIPE ASME B36,10M BE S.A.W. API5L GR. B PSL1,100% RT, NACE MR 0175/ISO 15156, RP-2224-999-6300-002,SSCC & HIC, S-STD

6 meter branch (2 LE)

2- 44 IN, PIPE ASME B36,10M BE S.A.W. API5L GR. B PSL1,100% RT, NACE MR 0175/ISO 15156, RP-2224-999-6300-002,SSCC & HIC, THK 14.27

6 meter branch (4 LE)

3- 2 IN,PIPE ASME B36,10M BE SMLS API 5L GR. B PSL1, NACE MR 0175/ISO 15156, RP-2224-999-6300-002,SSCC & HIC, S-80

6 meter branch (1 LE)

4- 1.1/2 IN,PIPE ASME B36,10M PE SMLS API 5L GR. B PSL1, NACE MR 0175/ISO 15156, RP-2224-999-6300-002,SSCC & HIC, S-160

6 meter branch (1 LE)

Laxmi pipe Industries is leading ss pipe manufacturer . We are also manufactures and exporter of steel pipes & tubes.

Dear Sir/Madam,

Please kindly provide us with detailed quote including price, weight/packaging dimension, lead time and shipment cost for the item

stated below;

6.1 PIPE: 1/2 IN, SEAMLESS ASME B36.10M

QTYT:1 Joint

PIPE: 1/2 IN, SEAMLESS ASME B36.10M PLAIN END SCHEDULE 160 STAINLESS STEEL ASTM A312 GRADE TP316/TP316L (DUAL-STAMPED) PPAACABZBKIALZ

Manufacturer (MA) – GENOYER SA

Find Shipping Address below;

10511 Kipp Way, Suite 430

SCL NG1325

Houston, Texas, 77099

Regards,

Chibuzor

Procurement Personnel

Kamax Int. Corp. ltd.

code and std for welded pipe angle

what did “M” stand in ASME B 36.19M?