Stub ends are pipe fittings that can be used (in combination with a lap joint flange) alternatively to weld neck flanges to make flanged connections. The use of stub ends has two advantages: it can reduce the total cost of flanged joints for piping systems in high material grades (as the lap joint flange does not need to be of the same material as the pipe and the stub end but can be a lower grade); it speeds up the installation process, as the lap joint flange can be rotated to facilitate the alignment of the bolt holes. Stub ends are available in short and long patterns (ASA and MSS stub ends), in sizes up to 80 inches.

STUB END

WHAT IS A STUB END?

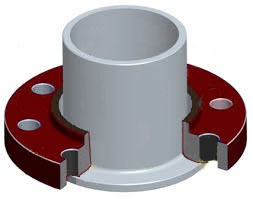

A stub end is a type of fitting used in conjunction with lap joint flanges to facilitate the connection and disassembly of flanged pipe sections in piping systems. It consists of two components: the stub end itself, which is essentially a short length of pipe with one flared end, and a lap joint flange that slides over the plain end of the stub end and rests against the flared end.

This setup allows for the easy removal of the flange without disturbing the welded connection of the stub end to the pipeline, offering significant advantages during maintenance or system modification.

It’s noteworthy that stub ends are increasingly being adopted for high-pressure applications, marking a significant shift from their traditional use solely in low-pressure settings.

Design and Features:

- Flared End: The flared end of the stub end is designed to match the facing of the lap joint flange, providing a smooth and continuous surface for sealing. This end is butt-welded to the pipe.

- Plain End: The other end of the stub end, which is not flared, is left plain and is typically the part that slides into the lap joint flange. The outer diameter of the plain end matches the inner diameter of the flange, ensuring a snug fit.

- Material Compatibility: Stub ends are made from various materials, including carbon steel, stainless steel, alloy steel, and others, to match the piping system’s material and ensure compatibility with the transported medium.

Types of Stub Ends:

Stub ends are available in different types based on their construction and design, commonly classified as Type A, Type B, and Type C, each offering different advantages and suited to specific applications and piping configurations. These 3 types of stub ends are reviewed in detail later in this article.

Applications:

- Ease of Assembly and Disassembly: The use of stub ends with lap joint flanges is particularly advantageous in systems where frequent disassembly and reassembly of pipe sections are required, such as in processing plants with extensive cleaning and maintenance schedules.

- Cost-Effective Material Use: In systems using expensive or specialty materials, stub ends allow for the use of costlier materials only where necessary (at the sealing face), while the flange, which does not come into contact with the process medium, can be made from a standard or less expensive material.

- Flexibility in Alignment: Lap joint flanges can rotate around the stub end, making it easier to align bolt holes when connecting flanges, thus simplifying the installation process.

Installation Considerations:

- Welding: The stub end is butt-welded to the pipe, requiring proper welding techniques to ensure a secure and leak-proof connection.

- Sealing: The joint between the flared end of the stub end and the back face of the lap joint flange must be properly sealed, typically using a gasket, to prevent leaks.

- Dimensional Compatibility: It’s essential to ensure that the dimensions of the stub end, the lap joint flange, and the pipe all match to achieve a proper fit and seal.

STUB END WITH LAP JOINT FLANGE

A stub end and a lap joint flange can work in tandem as an effective alternative to using weld neck flanges for creating a flanged connection. In this setup, two main components are involved:

The Stub End: This component is essentially a length of pipe that has been modified on one end to flare outward. The other end is designed to be butt-welded to a pipe with the same nominal pipe size (NPS), material composition, and wall thickness. The flaring of the pipe’s end is typically achieved using a flaring machine, which not only flares the end of the pipe but also trims it to the necessary length.

The Lap Joint Flange: This flange serves as the mechanism for bolting two sections of pipe together. Unlike standard flanges that are welded directly to the pipe, the lap joint flange loosely fits over the flared end of the stub end. When the flange is bolted to another flange on an adjacent pipe section, it compresses the flared end of the stub end against the second flange, creating a seal.

This combination offers a versatile and efficient means of assembling a flanged connection, providing the benefits of ease of alignment, accessibility for inspection or modification, and the adaptability to accommodate different types of piping systems. It is particularly useful in applications where frequent disassembly may be required or in systems that utilize lined or non-metallic pipes.

BENEFITS OF USING LAP JOINT STUB ENDS

The use of stub ends has these two key advantages and some other minor ones. The 2 key advantages of using stub ends instead of welding neck flanges are:

- Reduces the overall cost of the flanged joint: Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Example:

For an SS316 pipe, instead of using a full 316 welding neck flange, a combination of an SS316 stub end and a carbon steel lap joint flange would do the same exact job, but the total weight of SS316 material would be lower, and the cost as well.

Essentially, stub ends allow for the minimization of the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

- Facilitates the installation of the flange: The lap joint flange can be rotated on the pipe and simplify the alignment of the bolt holes of the mating flanges

Besides the two key advantages mentioned above (ease of alignment/installation, and cost efficiency for high-grade piping systems), using stub ends in conjunction with lap joint flanges instead of weld neck flanges offers other remarkable benefits, making them a preferred choice for certain piping system applications. These advantages include:

- Simplified Installation and Maintenance: The assembly and disassembly of flanged connections using stub ends are straightforward, facilitating easier installation, inspection, and maintenance. The lap joint flange can be easily removed for access to the system without cutting the flange or pipe, saving time and reducing labor costs.

- Weight Reduction: Stub ends are generally lighter than weld neck flanges, contributing to an overall reduction in the weight of the piping system. This can be particularly advantageous in applications where weight is a critical factor, such as in offshore platforms or in suspended piping systems.

- Material Compatibility: The use of stub ends allows the flanged connection to match the material of the pipeline, ensuring compatibility and corrosion resistance where it is most needed, while the flange itself can be made from a standard material like carbon steel. This is beneficial in systems handling corrosive media.

- Thermal Expansion Accommodation: The design of stub ends and lap joint flanges accommodates thermal expansion more easily than fixed flanges. The lap joint flange can slide over the stub end, allowing for some movement without placing excessive stress on the piping system.

- Reduced Risk of Leakage: As the sealing face of the stub end can be made from the same material as the pipe, it ensures a high-quality seal with the gasket. The risk of leakage is minimized, especially in applications where fluid compatibility and corrosion resistance are critical.

APPLICABLE SPECIFICATIONS

Stub ends, crucial components in piping systems for facilitating flanged connections, especially with lap joint flanges, are manufactured and utilized according to specific industry standards. These standards ensure uniformity, reliability, and safety across various applications. Key standards applicable to stub ends include:

ASME Standards

- ASME B16.9: This standard covers factory-made wrought buttwelding fittings for sizes NPS ½ through NPS 48 (DN 15 through DN 1200). It includes dimensions, tolerances, and material requirements for stub ends, providing a basis for their manufacture and use in piping systems.

- ASME B16.5: While primarily focused on pipe flanges and flanged fittings, ASME B16.5 also includes references to the use of stub ends with lap joint flanges, specifying the types of stub ends suitable for different flange facings and pressure classes.

MSS Standards

MSS SP-43: Titled “Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications,” this standard complements the ANSI/ASME standards by providing detailed specifications for stub ends used in low-pressure, corrosion-resistant applications, particularly those made from stainless steel and other alloy materials. It describes stub ends in Types A, B, and C, addressing their dimensions and application in specialized settings.

International Standards

ISO 15590-3: ISO standards also cover fittings for the petroleum and natural gas industries. ISO 15590-3 specifies requirements for induction bends, flanges, and fittings, including stub ends, for pipeline transportation systems.

Industry-Specific Standards

Various industries may have their own standards or specifications for stub ends, especially when unique materials, pressures, or temperatures are involved. For example, the petroleum, chemical, and pharmaceutical sectors might have specific requirements that go beyond the general standards.

ASA/ANSI VS. MSS STUB ENDS

ASA (American Standards Association) and MSS (Manufacturers Standardization Society) stub ends refer to types of stub ends that are defined and standardized by different organizational standards. These standards specify dimensions, tolerances, material types, and other critical manufacturing details. It’s important to note that ASA has evolved into what is now known as ANSI (American National Standards Institute), but the term ASA might still be encountered in some contexts relating to historical standards or in common usage.

ASA (ANSI) Stub Ends

ASA (ANSI) stub ends are manufactured by standards originally established by the American Standards Association, which has transitioned to ANSI. ANSI standards for stub ends, like ANSI B16.9 for factory-made wrought buttwelding fittings, specify dimensions for seamless and welded construction stub ends used in conjunction with lap joint flanges. These stub ends are commonly used in systems requiring standardized connectivity and are available in various materials and sizes to accommodate different piping requirements.

MSS Stub Ends

MSS stub ends are defined by the Manufacturers Standardization Society, particularly in standards such as MSS SP-43, “Standard Practice for Light Weight Stainless Steel Butt-Welding Fittings.” This standard covers stub ends suitable for use with lap joint flanges in low-pressure corrosion-resistant applications. MSS SP-43 specifies dimensions for stub ends in types A, B, and C, focusing primarily on stainless steel materials and catering to applications where corrosion resistance is a priority.

Key Differences

- Scope and Application: ASA (ANSI) stub ends are broadly used across various industries and applications, offering standard dimensions for a wide range of piping systems. MSS stub ends, while also widely applicable, have a specific focus on stainless steel materials and are often selected for their corrosion resistance in lower-pressure environments.

- Standardization and Compatibility: Both ASA (ANSI) and MSS standards provide detailed specifications to ensure compatibility with lap joint flanges and to facilitate uniformity in the manufacturing and application of stub ends. The choice between ASA (ANSI) and MSS stub ends may depend on the specific requirements of the application, including material preferences, pressure ratings, and industry standards.

- Types and Designs: MSS standards explicitly define Types A, B, and C stub ends, each with unique design characteristics for different applications. ASA (ANSI) standards cover a broader range of stub end designs without the specific type designations found in MSS SP-43.

In choosing between ASA (ANSI) and MSS stub ends, engineers and designers must consider the specific requirements of their piping systems, including the necessary material properties, pressure and temperature ratings, and compliance with industry standards to ensure safe and efficient operation.

STUB END TYPES

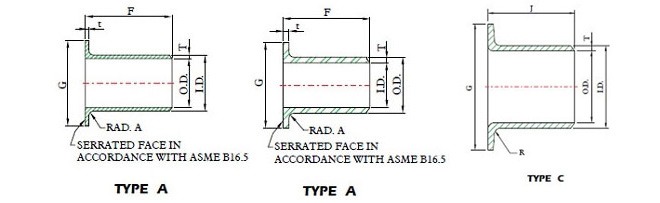

Stub ends are available in three types, named “A”, “B”, and “C”.

Let’s now delve into the details of each type of stub end:

STUB END “TYPE A”

Stub End Type A is one of the common types of stub ends used in piping systems to facilitate flanged connections, particularly in conjunction with lap joint flanges. This specific type is characterized by its design and the method of attachment to the piping system. Here’s a detailed description of Stub End Type A:

Design and Features:

- Geometry: Type A stub ends have a curved radius that matches the bore of the pipe, ensuring a smooth flow transition. The long tapered hub of Type A stub ends provides gradual direction change of the flow, minimizing turbulence and erosion at the joint.

- Material Compatibility: Just like other stub ends, Type A can be manufactured from a variety of materials, including but not limited to carbon steel, stainless steel, and alloy materials, to match the pipeline and fluid requirements.

- Dimensional Standards: The dimensions of Type A stub ends are typically by industry standards such as ASME B16.9, ensuring compatibility with standard lap joint flanges and piping dimensions.

Installation with Lap Joint Flanges:

Type A stub ends are designed for use with lap joint flanges. The process involves:

- Welding: The straight end of the stub end is butt-welded to the pipe, providing a secure and permanent connection. This welding is done in a manner that ensures the flared end (the lap) precisely aligns with the end of the pipe.

- Flanged Connection: The lap joint flange is then slipped over the flared end of the stub end and positioned against the flange’s back face. When bolted to a mating flange, the lap joint flange compresses against the stub end’s lap, creating a seal.

Applications and Advantages:

- Flexibility in Alignment: The combination of Type A stub ends and lap joint flanges allow for easy rotation of the flange, facilitating better alignment during installation and making it easier to bolt up to mating flanges.

- Ease of Inspection and Maintenance: Since the flange is not welded to the pipe and can be detached without affecting the stub end, maintenance, inspection, and flange replacement can be performed with minimal disruption to the piping system.

- Cost-Effectiveness: Type A stub ends can be a more economical solution, especially when the flanges need to be made from a more expensive material than the pipes. Only the stub end needs to match the pipe material, while the flange can be a less costly material since it does not come into contact with the process fluid.

- High-Pressure Applications: Contrary to their traditional use in low-pressure settings, Type A stub ends are now also recognized for their suitability in high-pressure applications, expanding their applicability across a broader range of industrial processes.

STUB END “TYPE B” (MSS SP-43 TYPE B)

Stub End Type B, also known as the MSS SP-43 Type B, is designed specifically for use with lap joint flanges in piping systems. This type of stub end is distinct in its design and application, primarily conforming to the standards set by the Manufacturers Standardization Society (MSS) SP-43, which covers the dimensions, tolerances, and materials for butt-welded stub ends.

Design and Features:

- Geometry: Type B stub ends feature a squared-off lap joint area instead of the tapered hub found in Type A stub ends. This squared lap directly matches the outer diameter of the pipe, creating a flush face that aligns with the back face of the lap joint flange.

- Material and Dimensions: Like Type A, Type B stub ends can be fabricated from various materials, including carbon steel, stainless steel, and alloy materials, to match the pipeline system’s requirements. Their dimensions are governed by MSS SP-43, ensuring compatibility with standard lap joint flanges.

- Welding Interface: The welding end of Type B stub ends typically has a thinner wall thickness than the pipe it attaches to. This is because Type B is designed to be used with lighter schedules of pipe and does not have the same reinforcement found in Type A stub ends.

Installation with Lap Joint Flanges:

The installation process for Type B stub ends involves:

- Welding: The stub end is butt-welded to the pipe with the squared lap facing outward. The welding process must ensure that the end of the stub end and the pipe create a smooth and continuous flow path.

- Assembly with Flange: A lap joint flange is then slipped over the pipe and positioned against the squared lap of the stub end. When bolted to a corresponding flange, the pressure is transmitted from the flange to the stub end’s lap, securing the connection.

Applications and Advantages:

- Cost-Effectiveness for Lighter Applications: Type B stub ends are particularly suitable for applications where lighter pipe schedules are used, providing a cost-effective solution for flanged connections in less demanding environments.

- Ease of Flange Alignment: The squared-off design of the lap allows for easy alignment with lap joint flanges, facilitating the assembly and maintenance of the piping system.

- Simplified Fabrication: The simpler geometry of Type B stub ends can offer advantages in terms of fabrication and material costs, especially when dealing with thinner-walled piping systems.

- Application Versatility: While commonly used in lower pressure and temperature applications compared to Type A, Type B stub ends are still versatile and can be found in various industries, including water treatment, chemical processing, and other general industrial applications.

Considerations:

- Pressure and Temperature Limits: Given their design, Type B stub ends are generally more suited to applications with lower pressure and temperature requirements.

- Compatibility with Piping System: It’s essential to ensure that the stub end material and dimensions are compatible with the existing piping system and the fluid being transported.

STUB END “TYPE C” (LAP-JOINT/SLIP-ON FLANGES)

Stub End Type C, also referred to in some contexts as the “Type C Stub End,” is designed for use in conjunction with lap joint flanges, similar to Types A and B stub ends. However, Type C has unique design characteristics that distinguish it from the other types. While not as commonly referenced as Types A and B, understanding the specifics of Type C can be important for certain specialized applications.

Design and Features:

- Geometry: The defining feature of a Type C stub end is its construction, which includes a lap (or collar) that is made separately from the stub end itself. The stub end typically has a straight cut at the end where the lap collar is placed. This design allows for a degree of adjustability in the positioning of the lap joint flange.

- Material Compatibility: Type C stub ends can be manufactured from a variety of materials to match the pipeline system, including carbon steel, stainless steel, and alloy materials. The choice of material is based on the requirements of the application, such as compatibility with the fluid, temperature, and pressure conditions.

- Dimensional Standards: The dimensions and tolerances of Type C stub ends may follow industry standards, but given the variability in their design and application, specific dimensions can also be tailored to meet the needs of a particular piping system.

Installation with Lap Joint Flanges:

The installation process for Type C stub ends involves:

- Assembly: The stub end is butt-welded to the pipe in the same manner as other types of stub end. The separate lap (collar) is then slid over the stub end and positioned for optimal alignment with the lap joint flange.

- Flange Connection: The lap joint flange is slipped over the pipe and positioned against the lap collar of the stub end. When the flange is bolted to a matching flange on an adjacent pipe or fitting, it compresses against the lap collar, securing the connection.

Applications and Advantages:

- Adjustability: The separate lap collar provides flexibility in the positioning of the lap joint flange, which can be advantageous in systems where precise alignment is critical.

- Ease of Maintenance: Like other types of stub ends, Type C allows for easy disassembly of the flanged connection for inspection, maintenance, or replacement without the need for cutting or welding.

- Customization: The design of Type C stub ends can be customized to suit specific application requirements, offering solutions for unique or challenging piping configurations.

Considerations:

- Compatibility and Standardization: It’s important to ensure that the stub end and lap collar are fully compatible with the lap joint flanges used in the system and that they meet any applicable standards or specifications.

- Cost and Availability: Given their specialized design, Type C stub ends might have higher costs or longer lead times compared to more standard stub end types.

DIFFERENCES BETWEEN STUB END TYPE A, B, C

The main differences between stub end Type A, B, and C revolve around their design features, compatibility with various flange types, and specific applications. Here’s a concise comparison without diving into the detailed descriptions of each type:

Design and Geometry

- Type A stub ends feature a long tapered hub that provides a smooth transition for the flow of fluid. This design is intended for use with standard lap joint flanges and is characterized by its ability to accommodate a wide range of piping diameters and wall thicknesses.

- Type B stub ends have a squared-off lap that aligns with the backing flange face. This type is specifically designed for use with lap joint flanges but differs from Type A in that it typically mates with lighter pipe schedules and has a simpler, less tapered design.

- Type C stub ends are unique in that the lap (or collar) is manufactured separately from the stub end itself. This allows for an adjustable fit with the lap joint flange, offering flexibility in alignment and assembly not found in Types A and B.

Compatibility with Flanges

- Type A is versatile and can be used with a wide range of flange sizes, making it suitable for diverse applications.

- Type B is tailored for specific uses where lighter pipe schedules are involved and is compatible with lap joint flanges designed for such applications.

- Type C offers adjustability with lap joint flanges due to its separate lap design, accommodating unique or challenging piping configurations.

Application and Use

- Type A is widely used across various industries for its versatility and ability to handle different piping schedules and diameters.

- Type B is often selected for applications involving lighter pipes and less demanding conditions, where its simpler design and compatibility with lap joint flanges are advantageous.

- Type C provides a solution for applications requiring precise alignment or where the adjustability of the flange connection is beneficial.

Installation Characteristics

- Type A‘s tapered hub facilitates a smooth transition for fluid flow and accommodates a range of piping schedules.

- Type B‘s squared-off lap design simplifies the fabrication process and is suited to lighter pipe schedules with specific dimensional compatibility.

- Type C allows for the lap collar to be adjusted or positioned independently of the stub end, offering flexibility in flange alignment and assembly.

SHORT VS. LONG PATTERN STUB ENDS

The distinction between short pattern and long pattern stub ends primarily lies in their length and intended use within different piping configurations. These variations accommodate the requirements of various flange types and piping system designs, ensuring proper fit and function.

Short Pattern Stub Ends (MSS):

- Design: Short pattern stub ends are more compact in length. They are designed to be used with standard lap joint flanges and in applications where space constraints exist.

- Applications: Ideal for use in systems that do not require the stub end to accommodate large flange faces or where the piping system design calls for closer flange connections. They are commonly used in systems with space limitations.

- Compatibility: Primarily intended for use with slip-on flanges and lap joint flanges in lower pressure and temperature applications. The compact design helps in tight spaces but may not provide the same flow characteristics as the long pattern.

Long Pattern Stub Ends (ASA/ANSI):

- Design: Long pattern stub ends have a longer length, providing a smoother flow transition from the pipe to the flange. This design is intended to mimic the flow characteristics of a welded neck flange, promoting better fluid dynamics within the piping system.

- Applications: Suited for applications requiring a gradual transition to minimize turbulence and resistance, such as in high-pressure and high-temperature systems, or where fluid flow and erosion concerns are significant.

- Compatibility: These stub ends are typically used with lap joint flanges and in applications where the benefits of a welded neck flange are desired, but the flexibility of a lap joint flange is needed for ease of maintenance and inspection.

Choosing Between Short and Long Pattern Stub Ends:

- System Requirements: The choice between short and long pattern stub ends should be guided by the specific requirements of the piping system, including space constraints, pressure and temperature ratings, and flow dynamics.

- Fluid Dynamics: For applications sensitive to flow turbulence and erosion, long pattern stub ends offer a better solution by providing a smoother transition for the fluid.

- Maintenance and Accessibility: Where frequent disassembly may be required for inspection or maintenance, the choice of stub end pattern may also consider the ease of access and replacement of flanges and gaskets.

END TYPES FOR STUB-ENDS

Stub ends can be ordered with different ends finishing:

Beveled Ends

- Description: Beveled ends on stub ends have an angled cut at the end that is to be welded to the pipe. This bevel aligns with the bevel of the pipe it’s being welded to, allowing for a full penetration weld.

- Applications: Beveled end stub ends are commonly used in butt weld piping systems, where a strong, seamless connection is required. They are suitable for high-pressure applications and systems where the integrity of the weld is critical.

Squared Ends

- Description: Squared ends are cut straight across, creating a flat end surface.

- Applications: These are typically used where the stub end is butted up against a flat surface or another squared end and welded in place. This type might be selected for simpler fabrication processes where precise alignment is necessary.

Flanged Ends

- Description: Flanged end stub ends have a flange manufactured as an integral part of the stub end, allowing for bolted connections without the need for a separate lap joint flange.

- Applications: This configuration is useful in systems that require frequent dismantling for inspection or cleaning, providing the ease of a flanged connection with the integrity of a welded joint.

Grooved Ends

- Description: Grooved ends feature a machined groove around the circumference of the stub end, designed to accept a coupling or gasket for a grooved piping system.

- Applications: Grooved end stub ends are used in systems that utilize grooved couplings for connections, offering rapid assembly and disassembly. This type is favored for moderate-pressure applications and is commonly found in fire protection systems and commercial HVAC.

Threaded Ends (Male Only)

- Description: Threaded end stub ends are machined with male threads that correspond to the female threads of a mating component, such as a valve, fitting, or another pipe.

- Applications: These are used in applications where it is necessary to frequently assemble and disassemble the piping system without welding. Threaded connections are common in low to moderate-pressure systems and provide a convenient method for maintenance or modification.

STUB END MATERIALS

The buttweld fittings material specifications apply also to stub ends.

The table summarizes the most common carbon, stainless, duplex, and nickel-alloy grades. Note that other materials may be used to manufacture stub ends, namely Cupronickel, Titanium, and Copper.

For details about the chemical composition and mechanical properties of BW fittings, please consult this article.

| ASTM Materials for Stub Ends | Grade | UNS Equivalent |

| Carbon Steel [ASTM A234 WPB] | WPA/WPB/WPC | K03006 |

| Stainless Steel [ASTM A403] | 304/304L | S30403 |

| 304H | S30409 | |

| 316/316L | S31603 | |

| 316H | S31609 | |

| 317L | S31703 | |

| 904L | N08904 | |

| 309S/H | S30908 | |

| 310S | S31008 | |

| 321 | S32100 | |

| 6XN | N08367 | |

| 20CB | N08020 | |

| 347 | S34709 | |

| 254SMO | S31254 | |

| Duplex /Super Duplex [ASTM A815] | 2205 | S31803/S32205 |

| Zeron 100 | S32760 | |

| 2507 | S32750 | |

| 410 | S41000 | |

| Nickel Alloys [ASTM A366 – replaced by ASTM A462] | HC22 | N06022 |

| HB-3 | N10675 | |

| HG3 | N06985 | |

| HX | N06002 | |

| HC2000 | N06200 | |

| HC276 | N10276 | |

| NCI | N06600 | |

| NC | N04400 | |

| N | N02200 | |

| NL | N02201 | |

| NCMC | N06625 | |

| NICMC | N08825 | |

| NIC10 | N08810 | |

| NIC11 | N08811 |

STUB ENDS DIMENSIONS

The chart shows the MSS and ANSI stub end dimensions in inches.

| MSS Stub End | ANSI Stub End | Pipe OD | Pipe WT | Lap OD | Radius | Flange thk | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | Sch | Min | Nom | Max | Min | Nom | Max | Min | Nom | Max | Min | Nom | Max | Min | Max | Min | Nom | Min | Max |

| 1/2″ | 05S | 1.94 | 2 | 2.06 | 2.94 | 3 | 3.06 | 0.809 | 0.84 | 0.896 | 0.057 | 0.065 | 0.073 | 1.35 | 1.38 | 3/32 | 1/8 | 0.065 | 0.127 |

| 10S | 0.073 | 0.083 | 0.093 | 0.083 | 0.145 | ||||||||||||||

| 40S | 0.095 | 0.109 | 0.123 | 0.109 | 0.171 | ||||||||||||||

| 80S | 0.129 | 0.147 | 0.165 | 0.147 | 0.209 | ||||||||||||||

| 3/4″ | 05S | 1.94 | 2 | 2.06 | 2.94 | 3 | 3.06 | 1.019 | 1.05 | 1.106 | 0.057 | 0.065 | 0.073 | 1.66 | 1.69 | 3/32 | 1/8 | 0.065 | 0.127 |

| 10S | 0.073 | 0.083 | 0.093 | 0.083 | 0.145 | ||||||||||||||

| 40S | 0.099 | 0.113 | 0.127 | 0.113 | 0.175 | ||||||||||||||

| 80S | 0.135 | 0.154 | 0.173 | 0.154 | 0.216 | ||||||||||||||

| 1 | 05S | 1.94 | 2 | 2.06 | 3.94 | 4 | 4.06 | 1.284 | 1.315 | 1.376 | 0.057 | 0.065 | 0.073 | 1.7 | 2 | 3/32 | 1/8 | 0.065 | 0.127 |

| 10S | 0.095 | 0.109 | 0.123 | 0.109 | 0.171 | ||||||||||||||

| 40S | 0.116 | 0.133 | 0.15 | 0.133 | 0.195 | ||||||||||||||

| 80S | 0.157 | 0.179 | 0.201 | 0.179 | 0.241 | ||||||||||||||

| 1 1/4 | 05S | 1.94 | 2 | 2.06 | 3.94 | 4 | 4.06 | 1.629 | 1.66 | 1.716 | 0.057 | 0.065 | 0.073 | 2.47 | 2.5 | 5/32 | 3/16 | 0.065 | 0.127 |

| 10S | 0.095 | 0.109 | 0.123 | 0.109 | 0.171 | ||||||||||||||

| 40S | 0.123 | 0.14 | 0.158 | 0.14 | 0.202 | ||||||||||||||

| 80S | 0.167 | 0.191 | 0.215 | 0.191 | 0.253 | ||||||||||||||

| 1 1/2 | 05S | 1.94 | 2 | 2.06 | 3.94 | 4 | 4.06 | 1.869 | 1.9 | 1.965 | 0.057 | 0.065 | 0.073 | 2.85 | 2.88 | 7/32 | 1/4 | 0.065 | 0.127 |

| 10S | 0.095 | 0.109 | 0.123 | 0.109 | 0.171 | ||||||||||||||

| 40S | 0.127 | 0.145 | 0.163 | 0.145 | 0.207 | ||||||||||||||

| 80S | 0.175 | 0.2 | 0.225 | 0.2 | 0.262 | ||||||||||||||

| 2 | 05S | 2.44 | 2.5 | 2.56 | 5.94 | 6 | 6.06 | 2.344 | 2.375 | 2.456 | 0.057 | 0.065 | 0.073 | 3.59 | 3.62 | 9/32 | 5/16 | 0.065 | 0.127 |

| 10S | 0.095 | 0.109 | 0.123 | 0.109 | 0.171 | ||||||||||||||

| 40S | 0.135 | 0.154 | 0.173 | 0.154 | 0.216 | ||||||||||||||

| 80S | 0.191 | 0.218 | 0.245 | 0.218 | 0.28 | ||||||||||||||

| 2 1/2 | 05S | 2.44 | 2.5 | 2.56 | 5.94 | 6 | 6.06 | 2.844 | 2.875 | 2.966 | 0.073 | 0.083 | 0.093 | 3.9 | 4.12 | 9/32 | 5/16 | 0.083 | 0.145 |

| 10S | 0.105 | 0.12 | 0.135 | 0.12 | 0.182 | ||||||||||||||

| 40S | 0.178 | 0.203 | 0.228 | 0.203 | 0.265 | ||||||||||||||

| 80S | 0.242 | 0.276 | 0.311 | 0.276 | 0.338 | ||||||||||||||

| 3 | 05S | 2.44 | 2.5 | 2.56 | 5.94 | 6 | 6.06 | 3.469 | 3.5 | 3.596 | 0.073 | 0.083 | 0.093 | 4.97 | 5 | 11/32 | 3/8 | 0.083 | 0.145 |

| 10S | 0.105 | 0.12 | 0.135 | 0.12 | 0.182 | ||||||||||||||

| 40S | 0.189 | 0.216 | 0.243 | 0.216 | 0.278 | ||||||||||||||

| 80S | 0.263 | 0.3 | 0.338 | 0.3 | 0.362 | ||||||||||||||

| 3 1/2 | 05S | 2.94 | 3 | 3.06 | 5.94 | 6 | 6.06 | 3.969 | 4 | 4.096 | 0.073 | 0.083 | 0.093 | 5.47 | 5.5 | 11/32 | 3/8 | 0.083 | 0.145 |

| 10S | 0.105 | 0.12 | 0.135 | 0.12 | 0.182 | ||||||||||||||

| 40S | 0.198 | 0.226 | 0.254 | 0.226 | 0.238 | ||||||||||||||

| 80S | 0.278 | 0.318 | 0.358 | 0.318 | 0.38 | ||||||||||||||

| 4 | 05S | 2.94 | 3 | 3.06 | 5.94 | 6 | 6.06 | 4.469 | 4.5 | 4.593 | 0.073 | 0.083 | 0.093 | 6.16 | 6.19 | 3/8 | 7/16 | 0.083 | 0.145 |

| 10S | 0.105 | 0.12 | 0.135 | 0.12 | 0.182 | ||||||||||||||

| 40S | 0.207 | 0.237 | 0.267 | 0.237 | 0.299 | ||||||||||||||

| 80S | 0.295 | 0.337 | 0.379 | 0.337 | 0.399 | ||||||||||||||

| 5 | 05S | 2.94 | 3 | 3.06 | 7.94 | 8 | 8.06 | 5.532 | 5.563 | 5.683 | 0.095 | 0.109 | 0.123 | 7.28 | 7.31 | 3/8 | 7/16 | 0.109 | 0.171 |

| 10S | 0.117 | 0.134 | 0.151 | 0.134 | 0.196 | ||||||||||||||

| 40S | 0.226 | 0.258 | 0.29 | 0.258 | 0.32 | ||||||||||||||

| 80S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 6 | 05S | 3.44 | 3.5 | 3.56 | 7.94 | 8 | 8.06 | 6.594 | 6.625 | 6.743 | 0.095 | 0.109 | 0.123 | 8.47 | 8.5 | 7/16 | 1/2 | 0.109 | 0.171 |

| 10S | 0.117 | 0.134 | 0.151 | 0.134 | 0.196 | ||||||||||||||

| 40S | 0.245 | 0.28 | 0.315 | 0.28 | 0.342 | ||||||||||||||

| 80S | 0.378 | 0.432 | 0.486 | 0.432 | 0.494 | ||||||||||||||

| 8 | 05S | 3.94 | 4 | 4.06 | 7.94 | 8 | 8.06 | 8.594 | 8.625 | 8.743 | 0.095 | 0.109 | 0.123 | 10.59 | 10.62 | 7/16 | 1/2 | 0.109 | 0.171 |

| 10S | 0.13 | 0.148 | 0.167 | 0.148 | 0.21 | ||||||||||||||

| 40S | 0.282 | 0.322 | 0.362 | 0.322 | 0.384 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 10 | 05S | 4.91 | 5 | 5.09 | 9.91 | 10 | 10.09 | 10.719 | 10.75 | 10.913 | 0.117 | 0.134 | 0.151 | 12.69 | 12.75 | 7/16 | 1/2 | 0.134 | 0.196 |

| 10S | 0.144 | 0.165 | 0.186 | 0.165 | 0.227 | ||||||||||||||

| 40S | 0.319 | 0.365 | 0.411 | 0.365 | 0.427 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 12 | 05S | 5.91 | 6 | 6.09 | 9.91 | 10 | 10.09 | 12.719 | 12.75 | 12.913 | 0.137 | 0.156 | 0.176 | 14.94 | 15 | 7/16 | 1/2 | 0.156 | 0.218 |

| 10S | 0.158 | 0.18 | 0.203 | 0.18 | 0.242 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 14 | 05S | 5.91 | 6 | 6.09 | 11.91 | 12 | 12.09 | 13.969 | 14 | 14.17 | 0.137 | 0.156 | 0.176 | 16.19 | 16.25 | 7/16 | 1/2 | 0.156 | 0.218 |

| 10S | 0.165 | 0.188 | 0.212 | 0.188 | 0.25 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 16 | 05S | 5.91 | 6 | 6.09 | 11.91 | 12 | 12.09 | 15.969 | 16 | 16.18 | 0.144 | 0.165 | 0.176 | 18.44 | 18.5 | 7/16 | 1/2 | 0.165 | 0.227 |

| 10S | 0.165 | 0.188 | 0.212 | 0.188 | 0.25 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 18 | 05S | 5.91 | 6 | 6.09 | 11.91 | 12 | 12.09 | 17.969 | 18 | 18.19 | 0.144 | 0.165 | 0.176 | 20.94 | 21 | 7/16 | 1/2 | 0.165 | 0.227 |

| 10S | 0.165 | 0.188 | 0.212 | 0.188 | 0.25 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 20 | 05S | 5.91 | 6 | 6.09 | 11.91 | 12 | 12.09 | 19.969 | 20 | 20.24 | 0.165 | 0.188 | 0.212 | 22.94 | 23 | 7/16 | 1/2 | 0.188 | 0.25 |

| 10S | 0.191 | 0.218 | 0.245 | 0.218 | 0.28 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 24 | 05S | 5.81 | 6 | 6.19 | 11.91 | 12 | 12.09 | 23.969 | 24 | 24.24 | 0.191 | 0.218 | 0.245 | 27.19 | 27.25 | 7/16 | 1/2 | 0.218 | 0.28 |

| 10S | 0.219 | 0.25 | 0.281 | 0.25 | 0.312 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 26 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 25.969 | 26 | 26.24 | 29.19 | 29.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 28 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 27.969 | 28 | 28.24 | 31.69 | 31.75 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 30 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 29.969 | 30 | 30.24 | 33.69 | 33.75 | 7/16 | 1/2 | |||||

| 10S | 0.273 | 0.312 | 0.351 | 0.312 | 0.374 | ||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 32 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 31.969 | 32 | 32.24 | 35.94 | 36 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.422 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.563 | ||||||||||||||

| 34 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 33.969 | 34 | 34.24 | 37.94 | 38 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 36 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 35.969 | 36 | 36.24 | 40.19 | 40.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 38 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 37.969 | 38 | 38.24 | 42.69 | 42.75 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 40 | 05S | 5.81 | 6 | 6.186 | 11.81 | 12 | 12.19 | 39.969 | 40 | 40.24 | 44.69 | 44.75 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 42 | 05S | 5.81 | 6 | 6.186 | 11.81 | 12 | 12.19 | 41.969 | 42 | 42.24 | 46.94 | 47 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 44 | 05S | 5.81 | 6 | 6.186 | 11.81 | 12 | 12.19 | 43.969 | 44 | 44.24 | 49.19 | 19.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 46 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 45.969 | 46 | 46.24 | 51.19 | 51.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.563 | 0.5 | 0.562 | |||||||||||||||

| 48 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 47.969 | 48 | 48.24 | 53.19 | 53.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 50 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 49.969 | 50 | 50.24 | 55.19 | 55.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 52 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 51.969 | 52 | 52.24 | 57.19 | 57.25 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 | ||||||||||||||

| 54 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 53.969 | 54 | 54.24 | 59.44 | 59.5 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.563 | 0.5 | 0.562 | |||||||||||||||

| 60 | 05S | 5.81 | 6 | 6.19 | 11.81 | 12 | 12.19 | 59.969 | 60 | 60.24 | 65.44 | 65.5 | 7/16 | 1/2 | |||||

| 10S | |||||||||||||||||||

| 40S | 0.328 | 0.375 | 0.422 | 0.375 | 0.437 | ||||||||||||||

| 80S | 0.438 | 0.5 | 0.563 | 0.5 | 0.562 |

10 Responses

We are finding the following materials in urgent,

The company that have this material, pls inform us, ps.kim@lucidcorp.co.kr

B/RGDS

Poseop Kim

Hi Poseop Kim, thank you for reaching out. In order to assist you better, could you please provide more information about the specific materials you are looking for? It will help us to determine if we have them in stock or if we can recommend any reliable sources. Feel free to provide any additional details or specifications so we can better understand your requirements. Thank you.

Thank you for providing us with the stub end flange information; it is quite useful. You might also check. Stainless Steel Ferrule Fittings, SS Ferrule Fittings

Great blog. Really informative. Thanks a lot for sharing it. Also, check out New Era Pipes & Fittings. We are a leading Pipe Fitting Manufacturer in India and around the world. Visit us now at newerapipefittings.com to buy Pipe Fittings, Flanges, and other plumbing products at the best prices.

Thank you for sharing this pipe fitting information with us it is very helpful for us. You may also go here.. Kalikund Steel & Engg Co, Stainless Steel Flanges manufacturer, SS Pipe Fittings Manufacturers in India, SS Pipe Fittings Manufacturer

It’s great to know that rotating the lap joint flange on the pipe makes it easier to line up the bolt holes on the matching flanges. My husband is an industrial worker. He wants to acquire a piece of machinery for his project that can be utilized to fortify the tube’s end. I’ll advise him to acquire rotating tube beading for the pipe for his project.

What are the Standards that covers Stub ends bigger than 24″?

can i get the drawing / dimensions of 3″ nb ring type joint stub end?

flosil bet this is a very amazing comment and I’m very happy to read this comment.

This is a very amazing blog and I’m very happy to read this blog.