The term “forged fittings” refers to two families of pipe fittings (socket weld and threaded) used for small bore pipes and piping systems (generally below 4 inches in diameter for Class 3000, and below 2 inches for fittings in Class 6000 and 9000). These fittings are manufactured by forging and machining solid steel and are available in a multitude of shapes like elbows, tees, reducers, unions, and couplings. The ASME B16.11 specification covers socket and threaded fittings for oil and gas applications. For larger pipe sizes, ASME B16.9 buttweld fittings (instead of forged) shall be used.

FORGED FITTINGS ASME B16.11

WHAT ARE FORGED FITTINGS?

ASME B16.11 is a standard that specifies the dimensions, tolerances, ratings, and material requirements for forged fittings, both socket-welding and threaded, used in piping systems.

These fittings are designed for use in areas involving high pressure, temperatures, and potentially corrosive conditions. Forged fittings are made through a process that involves shaping metal under high pressure, usually at room temperature, which enhances their strength, fatigue resistance, and durability compared to cast fittings.

SOCKET/THREADED FITTINGS in ASME B16.11

Socket-Weld Fittings: These fittings are connected to pipes by inserting the pipe into the recess of the fitting (the “socket”) and then applying fillet weld around the top. This method provides a strong, leak-proof connection suitable for high-pressure applications. Common socket-weld fittings include elbows, tees, couplings, and caps.

Threaded Fittings: These fittings are connected to pipes via threads. Threaded fittings are easier to install and remove than socket-weld fittings but are typically used in lower-pressure applications. Common threaded fittings include elbows, tees, couplings, and bushings.

Common Materials for ASME B16.11 Forged Fittings

- Carbon Steel: Widely used due to its strength and versatility in varying temperatures and pressures.

- Stainless Steel: Offers excellent resistance to corrosion and oxidation, making it suitable for corrosive environments.

- Alloy Steel: Used for applications requiring higher strength and resistance to wear and tear.

- Duplex and Super Duplex Stainless Steel: Provide higher strength and corrosion resistance, suitable for harsh environments.

- Nickel Alloys: Ideal for extreme temperature and corrosive applications.

Sizes and Pressure Ratings

- ASME B16.11 covers fittings in sizes from 1/8 inch to 4 inches (NPS).

- The pressure ratings (“Class”) vary based on the type of fitting and the material, generally ranging from Class 3000, Class 6000, to Class 9000 for high-pressure applications.

Applications of ASME B16.11 Forged Fittings

- Oil and Gas: Used in both upstream extraction and downstream processing where high pressure and corrosive conditions are common.

- Chemical Processing: Forged fittings are used to handle various chemicals and solvents, requiring resistance to corrosion and high pressures.

- Power Generation: In power plants, especially in systems involving steam, where temperature and pressure conditions are high.

- Manufacturing and Industrial: Forged fittings are used in machinery, equipment, and processes that involve high pressures and temperatures.

ASME B16.11 forged fittings are crucial components in ensuring the integrity and safety of piping systems under high-stress conditions. Their durability and resistance to high pressure and temperatures make them an essential choice for critical applications across various industries.

What does “Class” mean for Forged Fitting?

The “class” of a forged fitting in piping systems refers to the pressure rating of the fitting, indicating the maximum pressure that the fitting can withstand at a specified temperature. This classification system helps ensure the safe operation of piping systems by matching the pressure capabilities of all components to the system’s requirements.

Understanding Pressure Classes

Pressure classes for forged fittings are defined by several standards organizations, including the American Society of Mechanical Engineers (ASME) and the Manufacturers Standardization Society (MSS). The class designation is a numerical value that typically ranges from 2000, 3000, 6000, to 9000 for forged steel fittings, with each number roughly correlating to the maximum pressure (in pounds per square inch, psi) that the fitting can handle at room temperature. For example:

- Class 2000: Suitable for systems operating at up to 2000 psi.

- Class 3000: Suitable for systems operating at up to 3000 psi.

- Class 6000: Suitable for systems operating at up to 6000 psi.

- Class 9000: Suitable for systems operating at up to 9000 psi.

It’s important to note that the actual maximum pressure rating can vary based on the material of the fitting and the operating temperature of the system. ASME B16.11, for example, provides detailed tables that specify the maximum allowable pressure for different materials and temperature ranges.

Material Considerations

The class of a forged fitting not only indicates its pressure rating but also implies certain material qualities. For example, higher-class fittings, capable of withstanding greater pressures, are typically made from materials with higher strength and durability.

Application

Selecting the correct class of forged fitting is critical for ensuring the integrity and safety of a piping system. The choice of class should be based on:

- The maximum operating pressure of the system.

- The temperature conditions under which the system will operate.

- The compatibility of the fitting material with the fluid being transported.

In summary, the class of a forged fitting is a critical specification that determines its suitability for use in a particular pressure environment, contributing to the overall safety and reliability of piping systems in various industrial applications.

Forged vs. Buttweld Fittings

The main differences between forged and buttweld fittings relate to piping system sizes (smaller for forged, larger for BW), applicable ASME specifications, and manufacturing process/raw materials.

Piping system bore size

Forged fittings are used for piping systems below 2 or 4 inches in diameter (4″ for 2000#/3000# fittings, 2″ for 6000#/9000# fittings), whereas buttweld fittings are used for larger diameter piping.

ASME specifications

The ASME B16.11, MSS SP 75, MSS SP 83, and MSS SP 95 specifications cover forged fittings (socket weld and threaded) to fit ASME B36.10 and ASME B36.19 carbon, alloy, stainless steel, and nickel alloy pipes of small bore size.

Raw materials/manufacturing process

Forged fittings are manufactured from solid blocks of steel, that are machined to obtain the final required shape within the tolerances set by the applicable specifications mentioned above. This is different from buttweld fittings, which are manufactured by cutting, bending, and shaping seamless or welded steel pipes.

Applicable Specifications (ASME/MSS)

The American Society of Mechanical Engineers (ASME), Manufacturers Standardization Society (MSS), and the American Petroleum Institute (API) provide specifications for forged fittings used in piping systems. These specifications define the standards for the design, dimensions, material, and testing of forged fittings to ensure reliability, safety, and interoperability in various industrial applications. Here’s an overview of key specifications from ASME, MSS, and API for forged fittings:

ASME Specifications

ASME B16.11: This standard covers forged steel fittings, including socket welding and threaded types. It specifies dimensions, tolerances, marking, and material requirements for fittings in sizes NPS 1/8 through NPS 4 and pressure ratings from Class 2000 to Class 9000. Common materials include carbon steel, stainless steel, and alloy steel.

MSS Specifications

- MSS SP-79: This standard specifies requirements for insert-type socket-welding fittings made from bar stock for sizes NPS 1/2 through NPS 4.

- MSS SP-83: Covers the design and dimensions of class 3000 and class 6000 threaded and socket-welding steel pipe unions.

- MSS SP-97: Provides standards for integrally reinforced forged branch outlet fittings (such as Weldolets, Threadolets, and Sockolets) for butt-weld, socket welding, and threaded connections.

API Specifications

- API 602: This specification covers compact steel gate valves, globe valves, and check valves in sizes DN 4 (NPS 1/8) through DN 100 (NPS 4) for use in refinery and petrochemical service.

- API 6D: Although primarily for pipeline valves, API 6D can be relevant for forged fittings used in conjunction with pipeline valves in the oil and gas industry.

Considerations for Selecting Forged Fittings

- Material Compatibility: The selection of material for forged fittings should match or exceed the performance requirements of the piping system, taking into account factors such as temperature, pressure, and corrosion resistance.

- Pressure Ratings: Fittings must be chosen based on the pressure rating required for the application, ensuring they can withstand the system’s maximum operating pressure.

- Industry and Application: The choice between ASME, MSS, or API specifications may depend on the specific industry (e.g., oil and gas, chemical processing, power generation) and the application requirements, including regulatory compliance.

These specifications are crucial for ensuring the quality and safety of forged fittings used in piping systems. They provide a framework for manufacturers, engineers, and end-users to specify and utilize fittings that meet the necessary standards for performance, reliability, and safety in various industrial applications.

TYPES OF FORGED FITTINGS

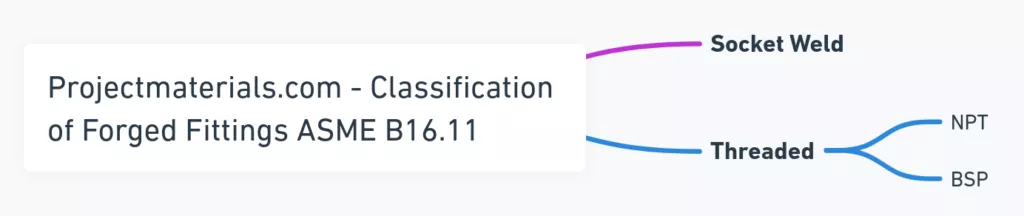

Forged fittings can be classified by connection type and shape:

- connection type: in this case, the key dichotomy is between socket weld and threaded fittings

- fitting shape: this classification is based on the body shape of the fitting (elbows, tees, caps, adapters, couplings, etc)

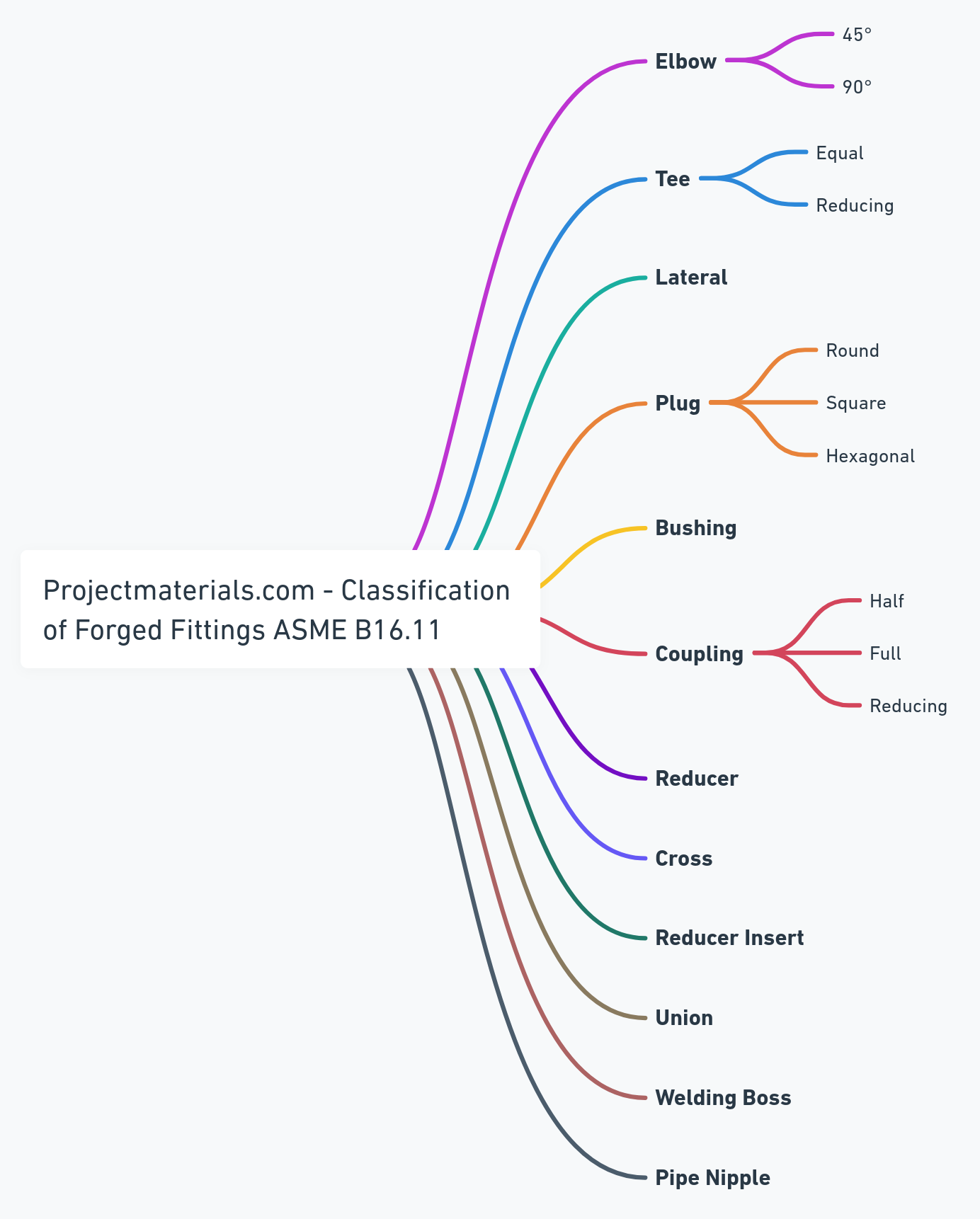

SOCKET WELD VS. THREADED FITTINGS TYPES

The difference between socket-weld and threaded fittings is the first concept to grasp when discussing the available types of forged fittings. These two types, mentioned in the ASME B16.11 specification, differ in the way the fitting is connected to the piping system. The two types (SW, and THD) are shown in the image below:

SOCKET WELD FITTINGS (“SW”)

Socket-Weld fittings: Key Concepts

Socket weld fittings are a type of pipe fitting designed for use in high-pressure piping systems. These fittings allow for a pipe to be inserted into a recessed area of the fitting, known as the “socket,” and then welded around the top to secure the connection.

Socket weld fittings are available in sizes from 1/8 to 4 inches and in classes between 2000# and 9000#.

Socket weld fittings are preferred for applications where strong and long-lasting connections are required. Socket weld fittings are very reliable but are time-consuming to install in a piping system (due to the heavy workload caused by welding operations on small parts).

Socket weld fittings are connected to pipes by fillet welds, whereas threaded fittings are screwed onto the pipe (or vice-versa).

Socket weld fittings are commonly used in the petrochemical, oil and gas, and power generation industries, among others, where high-pressure conditions are prevalent.

Characteristics of Socket Weld Fittings:

- High Integrity Connection: Socket weld fittings provide a strong, high-integrity connection that is crucial for high-pressure applications. The internal weld helps prevent leakage and ensures a smooth flow of fluids.

- Ease of Installation: These fittings are easier to install compared to butt weld fittings, especially in tight or confined spaces, since they require less precision in cutting the pipe to length.

- Reduced Turbulence: The smooth transition from pipe to fitting minimizes turbulence and erosion inside the piping system.

- Size Range: Socket weld fittings are typically used for small pipe diameters, generally up to NPS 2 (DN 50), although larger sizes are available.

- Materials: They are available in a variety of materials, including carbon steel, stainless steel, alloy steel, and others, to suit different operational environments and media.

Common Types of Socket Weld Fittings:

- Elbows: Used to change the direction of flow in the piping system. Available in 45° and 90° angles.

- Tees: Allow for the branch connection of three sections of pipe. Available as equal (straight) tees and reducing tees.

- Couplings: Utilized to connect two pieces of pipe together.

- Caps: Used to seal the end of a pipe.

- Reducers: Enable the connection of pipes of different diameters in a straight line.

- Unions: Similar to couplings but designed for quick disconnection and connection without cutting.

Advantages:

- Strong and leak-proof connection suitable for high-pressure applications.

- Requires less space around the pipe for welding, making it ideal for use in restricted spaces.

- The risk of weld splatter entering the pipe is minimized since the weld is outside the flow path.

Installation Considerations:

- Proper alignment and gap: A small gap (typically 1/16″ or 1.6 mm) is required between the end of the pipe and the bottom of the socket to allow for thermal expansion of the welded metal.

- Welding: Requires skilled welding to ensure the integrity of the connection. The weld should be inspected to confirm it meets the necessary standards for pressure and temperature resistance.

The typical applications for socket weld fittings are:

- Steam

- Explosive fluids and gases

- Acids and toxic fluids

- Long service / durable installations

Socket weld fittings are a reliable choice for high-pressure applications where a durable and leak-proof connection is essential. Their design and installation flexibility make them suitable for a wide range of industrial applications.

Difference between Socket-Weld fittings and Butt-Weld fittings

The key differences between BW and SW fittings can be summarized as follows:

- Pressure and Size: Socket weld fittings are generally preferred for high-pressure systems with smaller pipe sizes, while buttweld fittings are suitable for larger pipes and a wide range of pressures.

- Leakage Risk: Buttweld fittings offer a more gradual transition that minimizes the risk of leakage and is preferred in critical applications where fluid integrity is paramount.

- Installation: Socket weld fittings can be easier and quicker to install, especially in tight spaces, compared to buttweld fittings, which require precise alignment and welding.

- Flow Dynamics: Buttweld fittings provide better flow characteristics due to their smooth and continuous interior surface.

Fillet weld vs. Butt Weld: a butt welding connection fills the gaps between two devices, that are beveled at 30 degrees.

THREADED FITTINGS (“THD” or “THDD”)

Threaded fittings: Key Concepts

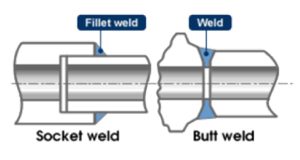

Threaded fittings are a type of pipe fitting used to connect and secure different components within a piping system through threaded connections. These fittings are designed with internal or external threads that align with the threads on the end of a pipe, allowing for a screwed connection without the need for welding.

Threaded fittings are commonly used in low-pressure, low-temperature, and non-critical applications due to their ease of installation and the ability to disassemble and reassemble when necessary for maintenance or system modification.

Threaded fittings are used for less-critical piping systems than socket-weld fittings, such as water distribution, fire protection, and cooling, or for low-pressure installations not subject to vibration, elongation, and bending forces. Threaded pipe fittings are not suited for fluids with constantly changing temperatures, as sudden changes may crack the connection.

Types of Threaded Fittings:

- Elbows: Used to change the direction of flow within the piping system. Threaded elbows are typically available in 45-degree and 90-degree angles.

- Tees: Allow for the connection of three pieces of piping. A straight tee connects pipes of the same diameter, while a reducing tee connects pipes of different diameters.

- Couplings: Used to connect two pieces of pipe. Full couplings join pipes of the same diameter, and reducing or half couplings connect pipes of different diameters.

- Caps: Designed to close off the end of a pipe.

- Nipples: Short lengths of pipe with threads on both ends, used to connect two other fittings.

- Unions: Similar to couplings but designed for quick disconnection and reconnection, featuring two threaded ends that join with a middle nut.

Common Materials:

- Carbon Steel: Widely used for its strength and versatility. Suitable for a broad range of temperatures and pressures.

- Stainless Steel: Preferred for its resistance to corrosion and oxidation. Ideal for use in chemical processing and food processing industries.

- Brass: Known for its corrosion resistance and ductility. Commonly used in plumbing applications.

- Alloy Steel: Used in applications requiring higher strength and resistance to wear and tear.

Advantages:

- Ease of Installation: Threaded fittings can be quickly and easily installed without special tools or welding equipment.

- Maintainability: They can be disassembled and reassembled, allowing for easier maintenance and inspection of the piping system.

- Cost-Effectiveness: Generally less expensive than welded fittings, especially in terms of installation labor costs and equipment.

Limitations:

- Leak Potential: Threaded connections may be more prone to leaks compared to welded connections, especially under high pressure or in applications involving hazardous fluids.

- Strength Limitations: Not suitable for high-pressure applications due to the risk of thread damage under high stress.

- Size Restrictions: Typically used for smaller pipe diameters, as larger threaded connections can be difficult to seal and handle.

Threaded fittings offer a practical solution for many piping applications, particularly where the system requires frequent disassembly or where welding is not feasible. Their selection depends on the specific requirements of the application, including the nature of the fluids being transported, operating pressures and temperatures, and maintenance needs.

The two major types of threads are the BSP and NPT, which are not compatible one with the other:

Types of Threads for Threaded Fittings

BSP means “British Standard Pipe” and can be further divided into the BSPT (tapered) and BSPP (parallel) variations. The threads have a 55° angle in this case. BSP threaded fittings are less common than NPT threaded fittings in the oil and gas industry.

Let’s review these two types of threading more in detail.

BSP Fittings (BSPT/BSPP)

BSP threaded fittings are pipe fittings that use the British Standard Pipe (BSP) thread standard for connecting and securing components within a piping system. BSP is one of the most widely used thread types globally, especially in the United Kingdom, Europe, Asia, Australia, and other parts of the world, excluding North America where NPT (National Pipe Thread) is more commonly used. BSP threads come in two main types:

Types of BSP Threads

- BSP Parallel (BSPP): Also known as G-thread, these have a constant diameter, allowing the thread to run parallel to the pipe. BSPP fittings create a seal through a bonded or metal seal that is compressed between the mating surfaces, which are typically the end of the pipe and the flat surface of the fitting. They are commonly used in applications where a fluid-tight seal is required on the threads’ periphery and are often found in water and gas piping systems.

- BSP Tapered (BSPT): Similar to NPT threads, BSPT threads are designed to provide a seal through thread interference. The diameter of the threads tapers down towards the end of the fitting, allowing for a tighter seal as the threads are engaged. BSPT fittings are commonly used in applications requiring a pressure-tight seal on the threads themselves, without the need for an additional sealing mechanism.

Common Applications

- Water Supply: BSPP threads are commonly used in water supply fittings, where a watertight seal is essential.

- Pneumatic Systems: Both BSPP and BSPT fittings are used in pneumatic systems for air connections.

- Hydraulic Systems: Hydraulics extensively use BSPP fittings due to their ability to maintain a fluid-tight seal under high pressure.

- Oil and Gas: BSPT fittings are utilized in the oil and gas industry for pipes carrying gases or liquids under pressure.

Advantages

- Interchangeability: BSP threads are standardized, making fittings interchangeable across different systems and manufacturers.

- Global Availability: Widely used and recognized outside of North America, making sourcing and replacement easier in those regions.

- Versatility: Available in both parallel and tapered forms, allowing for use in a wide range of applications.

When selecting BSP threaded fittings, it’s important to choose the correct type (parallel or tapered) for the application and to ensure that the materials are compatible with the fluids being transported. Additionally, the correct sealing methods should be used to ensure leak-proof connections, especially in high-pressure systems.

NPT Fittings

NPT threaded fittings are a type of fitting used in piping systems, characterized by their National Pipe Taper (NPT) threads. NPT is a standard used in North America, defined by the American National Standard Institute (ANSI) and it specifies the technical requirements for the design and use of tapered threads on pipe fittings and pipes.

The taper on NPT threads allows for a tighter and more secure seal as the fittings are threaded together, making them suitable for conveying fluids and gases under pressure.

Characteristics of NPT Threaded Fittings:

- Tapered Threads: NPT threads are tapered at a rate of 1°47’24” (1.7899°) per side, which means the diameter of the threads decreases towards the end of the fitting. This design allows for a better seal through interference fit.

- Sealing Mechanism: The seal on NPT threaded connections is achieved through the deformation of the threads when tightened, which requires the use of thread sealant (like Teflon tape or pipe dope) to ensure a leak-proof connection.

- Versatility: NPT fittings are used in a wide range of applications, from residential plumbing to industrial fluid handling systems, due to their ability to create a tight seal under a wide range of pressures and temperatures.

- Standards Compliance: Fittings that use NPT threads must conform to ANSI/ASME B1.20.1 specifications.

Applications:

NPT threaded fittings are commonly used in:

- Plumbing and heating systems

- Gas lines

- Oil and fluid transmission systems

- Any application requiring a reliable seal for the transport of liquids or gases under pressure

Installation Considerations:

- Sealant Use: Since the sealing of NPT threads relies on the deformation of the threads, applying a suitable thread sealant is essential to prevent leaks.

- Tightening: Over-tightening NPT fittings can cause damage to the threads or the fittings themselves. It’s important to follow proper torque specifications during installation.

- Reusability: While NPT fittings can be reused, care must be taken to ensure that the threads are not damaged and that new sealant is applied each time.

NPT threaded fittings are a reliable and widely used solution for creating leak-proof connections in piping systems, offering ease of installation and broad applicability across various industries and applications.

NPT threading is covered by the ASME B1.20.1 specification and is based on 60° thread flank angles (vs. 55° of the BSP type).

FORGED FITTINGS BY SHAPE

This section of the article covers the types of forged fittings based on their body shape.

Forged Elbow 45/90 Degrees

Forged elbows are pipe fittings that facilitate directional changes in piping systems, allowing fluids to change direction at either a 45-degree or a 90-degree angle. They are manufactured through the forging process, which involves shaping metal under high pressure and temperature, resulting in a fitting with superior strength, durability, and resistance to impact, fatigue, and thermal fluctuations compared to cast fittings.

Forged elbows are used in high-pressure applications and in environments requiring solid performance. Forged elbows are manufactured according to ASME B16.11 in various material grades, either with socket weld or threaded pipe connections. The 3 main types of forged elbows are:

45-Degree Elbows: Used to redirect the piping system at a 45-degree angle. They are typically employed where a full 90-degree turn is unnecessary, allowing for a more gradual change in direction which minimizes pressure drops and flow resistance.

90-Degree Elbows: Used to make a quarter turn in the piping, changing the direction of the flow by 90 degrees. This type of elbow is common in piping systems that need to route pipes in different directions or around obstacles.

- Street-Elbow: A street elbow is a type of forged fitting that allows for a change in direction in the piping system. It differs from standard elbows in its configuration; one end of a street elbow is male (external threads), and the other end is female (internal threads). This design enables the street elbow to connect directly to another fitting without requiring a pipe nipple or additional length of pipe between them, making it particularly useful in tight spaces or when minimal piping is desired.

Forged Tee (Equal/Reducing)

Forged tees are pipe fittings used to either combine or split the flow of a fluid. They are essential components in piping systems, allowing for directional change and branching off. Forged tees are made through a forging process, which involves shaping metal under high pressure and heat, resulting in a piece that’s exceptionally strong and durable. There are two main types of forged tees: equal tees and reducing tees, each serving different purposes based on the requirements of the piping system.

Forged tees ASME B16.11 are available with socket weld or threaded connections (NPT or BSP). The dimensions of forged tees are covered by the MSS SP 75 and the ASME B16.11 specifications.

Forged Lateral

A forged lateral fitting is a type of pipe fitting used to branch off from the main line in a piping system at an angle other than 90 degrees, typically at a 45-degree angle (or 30 degrees). It is called “lateral” because it allows for a lateral (side) connection, facilitating a branch line to divert from the main flow path (Y-shape). These fittings are made through the forging process, where metal is heated and then shaped under high pressure, resulting in a very strong and durable fitting.

Forged Plug (Round, Squared, Hex)

Forged plugs are components used to close off (blind) the ends of piping, valves, or fittings, providing a sealed closure. They are commonly used in various industrial applications to temporarily or permanently stop the flow within a pipeline. Forged plugs are manufactured through the forging process, which involves shaping metal under high pressure and heat, resulting in a highly durable and robust component. These plugs come in various shapes, including round, squared, and hexagonal (hex), each serving specific installation and operational needs.

Bushings

A forged bushing is a type of pipe fitting used to connect two pipes of different diameters, acting as a reducer to facilitate the transition between sizes in a piping system. Unlike couplings, which generally connect pipes of the same diameter, bushings are designed to fit inside a larger fitting, valve, or pipe and accommodate a smaller pipe on the other side. They are manufactured through the forging process, where metal is heated and then shaped under high pressure, enhancing the fitting’s strength, durability, and resistance to wear and pressure.

Couplings (Half, Full)

A forged coupling is a type of pipe fitting that allows two pipes to be joined together. It is manufactured through the forging process, where metal is heated and then formed into the desired shape under high pressure. This manufacturing technique enhances the coupling’s strength, making it suitable for high-pressure, high-temperature, and harsh environmental conditions. Forged couplings are used extensively in various industrial piping systems to create a seamless and secure connection between pipe sections.

Forged couplings are available in different shapes:

Full Coupling: Designed to connect two pipes of the same diameter. A full coupling has a socket or threaded end on both sides, allowing it to join two pipes directly.

Half Coupling: Features a socket or threaded end on one side only. It is welded to the end or side of a pipe or tank, providing a connection point for another pipe.

Reducing Coupling: Used to connect two pipes of different diameters. A reducing coupling has differing diameters on each end, accommodating the sizes of the pipes being connected.

Reducers and Reducer Inserts

Forged reducers and reducer inserts are types of fittings used in piping systems to connect pipes of different diameters, facilitating a smooth transition between sizes. These components are crucial for managing flow rates, accommodating system design variations, and integrating equipment with differing connection sizes.

Both are manufactured through the forging process, where metal is heated and then shaped under high pressure to enhance strength, durability, and resistance to wear and environmental factors.

Forged Reducers

Forged reducers come in two primary types, each serving a specific purpose in piping systems:

Concentric Reducers: These have a conical shape, with both the inlet and outlet being aligned along the same central axis. Concentric reducers are used when the pipes to be connected are on the same plane. They are ideal for fluid flow applications where there’s a need to avoid trapping air or sediment within the piping system.

Eccentric Reducers: Eccentric reducers have one off-center side, meaning the pipes are aligned on one side only. This design is used to maintain the same top or bottom pipe level, preventing the accumulation of air or sediment in the system. Eccentric reducers are particularly useful in horizontal piping systems.

Reducer Inserts

Reducer inserts are a specialized type of fitting used to reduce the size of a socket weld connection without the need for extensive reconfiguration or the use of multiple fittings. They are inserted into the larger socket of a coupling, valve, or fitting to accommodate the smaller-sized pipe. Reducer inserts are an economical and space-saving solution for size reduction in socket welding applications.

The American Society of Mechanical Engineers (ASME) B16.11 standard, which covers forged fittings, socket-welding, and threaded, categorizes reducer inserts into two types: Type 1 and Type 2. Understanding the differences between these two types is crucial for selecting the appropriate fitting for a given application.

Reducer Insert Type 1

Type 1 reducer inserts are designed to fit into the larger socket of a fitting, valve, or flange to reduce its effective internal diameter to accommodate a smaller size pipe. The key characteristics of Type 1 reducer inserts include:

- Configuration: The outer diameter of a Type 1 insert matches the inner diameter of the socket, while the inner diameter provides a snug fit for the smaller pipe size.

- Application: They are typically used where the flow direction is from the larger to the smaller size, ensuring a smooth transition that minimizes turbulence and pressure drop.

- Installation: Type 1 inserts are inserted directly into the socket before welding, and they require careful alignment to ensure a proper seal and to maintain flow efficiency.

Reducer Insert Type 2

Type 2 reducer inserts differ from Type 1 primarily in their installation orientation and are used in specific applications where the flow direction or assembly requirements dictate their use. Characteristics include:

- Configuration: Similar to Type 1, the outer diameter of a Type 2 insert matches the inner diameter of the fitting’s socket. However, the design may differ slightly to accommodate reverse flow conditions or specific installation requirements.

- Application: Type 2 inserts can be used in situations where the flow is from the smaller to the larger size, or where Type 1 inserts are not suitable due to design constraints.

- Installation: The installation process for Type 2 inserts is similar to that of Type 1, with an emphasis on ensuring that the insert is properly aligned within the socket for welding.

Union

A forged union is a type of pipe fitting used to connect two pieces of pipe in a piping system, while also allowing for easy disconnection and reconnection without the need for cutting or welding. Unlike couplings, which are used to create a permanent joint between two pipes, unions are designed for situations where piping components may need to be removed or replaced, or where routine maintenance is expected.

The forging process used to manufacture these fittings involves shaping metal under high pressure and heat, resulting in a component with superior strength, durability, and resistance to wear and pressure compared to cast fittings.

Structure of a Forged Union

A typical forged union consists of three parts:

- Male End: A threaded end that connects to one piece of pipe.

- Female End: A threaded counterpart that connects to another piece of pipe.

- Nut: A central component that fits over the male end and screws onto the female end, pulling the two ends together to make a secure connection.

Unions are also available in the male-to-female, female-to-female types, lug-nut, and Rockwood designs. Unions comply with the MSS SP 83 standard.

Welding Boss

A forged welding boss is a type of pipe fitting used to provide a take-off point from the main pipeline, allowing for the connection of auxiliary equipment or the installation of instrumentation, such as pressure gauges or thermowell.

It is called a “boss” because it serves as a mounting point or a reinforced area where additional components can be attached to the piping system. The term “forged” refers to the manufacturing process used to create the boss, where metal is shaped under high pressure and temperature to produce a fitting with superior strength, durability, and resistance to impact and fatigue.

Characteristics of a Forged Welding Boss:

- High Integrity: The forging process enhances the metallurgical properties of the material, resulting in a component that can withstand high pressures, high temperatures, and harsh environments.

- Versatility: Forged welding bosses can be used in a variety of piping materials and designs, accommodating different pipe sizes and schedules.

- Connection Points: They typically have one or more threaded outlets for the attachment of devices or for branching off to smaller pipes.

- Installation: The boss is welded onto the pipe where the connection or attachment is needed. The welding process ensures a strong, leak-proof joint between the boss and the pipe.

Swage Nipple

A swage nipple is a versatile and essential piping component commonly used in the oil and gas, construction, and power generation industries to facilitate the connection between pipes of different diameters.

It serves as a reducer to transition smoothly between pipes of varying sizes, ensuring a reliable and efficient flow path in a piping system. This educational overview will delve into the definition, types, manufacturing processes, design considerations, and applications of swage nipples, shedding light on their importance and utility in various industrial applications.

Definition

A swage nipple, also known as a swage reducer, is a type of fitting used to join two pipes of different diameters, providing a gradual transition that minimizes turbulence and pressure drop in the system. It is typically conical in shape, with one end matching the outer diameter of the larger pipe and the other end the smaller pipe, facilitating a seamless flow transition.

Types

Swage nipples are categorized based on their end connections and manufacturing processes:

Concentric Swage Nipple: Features a uniform conical shape, tapering evenly from the larger to the smaller diameter. It is used where the center lines of the pipes are in alignment, minimizing disruption to flow.

Eccentric Swage Nipple: Has an off-center taper, allowing for the connection of pipes with different diameters without misaligning the bottom of the pipe. This is particularly useful in applications where maintaining a flat bottom is necessary for drainage or flow.

Manufacturing Processes

Swage nipples are manufactured primarily through forging or machining processes:

Forging: Involves shaping the metal under high pressure, usually while it’s hot. Forged swage nipples have enhanced strength and are preferred for high-pressure applications.

Machining: The swage nipple is shaped from a solid bar or pipe using lathes or CNC machines. This method provides precision and is used for specific dimensions and materials.

Design Considerations

When selecting a swage nipple for a piping system, several design considerations should be taken into account:

Material Compatibility: The material of the swage nipple must be compatible with the pipes it connects and the fluid it carries, considering factors like corrosion resistance, temperature, and pressure.

Pressure Rating: Ensure the swage nipple meets the required pressure rating for the application, taking into account the potential for pressure drops across the reducer.

End Connection Type: Choose between threaded or plain/beveled ends based on the connection method (welded or screwed) used in the piping system.

Applications

Swage nipples are used across a wide range of industries due to their functionality and adaptability:

Oil and Gas Industry: Utilized for pipelines and processing equipment to connect pipes of different diameters, facilitating the transport of oil, gas, and processed fluids.

Power Generation: Employed in steam, water, and gas lines within power plants to ensure efficient and controlled flow across systems of varying diameters.

Construction: Used in plumbing and HVAC systems of buildings to adapt piping networks to the required sizes, ensuring effective distribution of water, air, and gas.

In summary, swage nipples play a critical role in the seamless and efficient transition between pipes of different diameters within industrial piping systems. Their design and selection are pivotal in minimizing flow disturbances, maintaining pressure integrity, and ensuring the overall reliability and performance of the piping network. Understanding their types, manufacturing processes, and design considerations is essential for engineers and technicians to optimize piping designs and operations in their respective fields.

FORGED FITTINGS MATERIALS

Carbon steel fittings ASTM A105 (forged)

A105 socket weld and threaded fittings match carbon steel pipes for high-temperature services, like ASTM A53, A106, and API 5L. For low-temperature service, ASTM A350 socket/threaded fittings shall be used instead (to match ASTM A333 pipes).

A105 Forged Fittings Materials, Chemical Composition %

| Material Grade | Grade or Class | C | Si | Mn | S | P | Cu | Ni | Cr | Mo | V | Cb/Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A105 | 0.35 | 0.10-0.35 | 0.60-1.05 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | ||

| ASTM A181 | 60 | 0.35 | 0.10-0.35 | 1.1 | 0.05 | 0.05 | ||||||

| 70 | 0.35 | 0.10-0.35 | 1.1 | 0.05 | 0.05 | |||||||

| ASTM A266 | 1 | 0.3 | 0.15-0.35 | 0.40-1.05 | 0.025 | 0.025 | ||||||

| 2 | 0.3 | 0.15-0.35 | 0.40-1.05 | 0.025 | 0.025 | |||||||

| 3 | 0.35 | 0.15-0.35 | 0.80-1.35 | 0.025 | 0.025 | |||||||

| 4 | 0.3 | 0.15-0.35 | 0.80-1.35 | 0.025 | 0.025 | |||||||

| ASTM A350 | LF1 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 |

| LF2-1 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 | |

| LF2-2 | 0.3 | 0.15-0.30 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 0.4 | 0.3 | 0.12 | 0.08 | 0.02 | |

| LF3-1 | 0.2 | 0.20-0.35 | 0.9 | 0.04 | 0.035 | 0.4 | 3.30-3.70 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF3-2 | 0.2 | 0.20-0.35 | 0.9 | 0.04 | 0.035 | 0.4 | 3.30-3.70 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF5-1 | 0.3 | 0.20-0.35 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 1.00-2.00 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF5-2 | 0.3 | 0.20-0.35 | 0.60-1.35 | 0.04 | 0.035 | 0.4 | 1.00-2.00 | 0.3 | 0.12 | 0.03 | 0.02 | |

| LF6-1 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF6-2 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF6-3 | 0.22 | 0.15-0.30 | 1.15-1.50 | 0.025 | 0.025 | 0.4 | 0.4 | 0.3 | 0.12 | 0.04-0.11 | 0.02 | |

| LF9 | 0.2 | 0.40-1.06 | 0.04 | 0.035 | 0.75-1.25 | 1.60-2.24 | 0.3 | 0.12 | 0.03 | 0.02 | ||

| LF787-2 | 0.07 | 0.4 | 0.40-0.70 | 0.025 | 0.025 | 1.00-1.30 | 0.70-1.00 | 0.60-0.90 | 0.15-0.25 | 0.03 | 0.02 min | |

| LF787-3 | 0.07 | 0.4 | 0.40-0.70 | 0.025 | 0.025 | 1.00-1.30 | 0.70-1.00 | 0.60-0.90 | 0.15-0.25 | 0.03 | 0.02 min |

A105 Forged Fittings, Mechanical Properties

| Material Grade | Grade or Class | Tensile Strength min, Ksi | Yield Strength Ksi @ 0.2% | Elongation in 2 in, % |

|---|---|---|---|---|

| ASTM A105 | 70 | 36 | 22 | |

| ASTM A181 | 60 | 60 | 30 | 22 |

| 70 | 70 | 36 | 18 | |

| ASTM A266 | 1 | 60-85 | 30 | 23 |

| 2 | 70-95 | 36 | 20 | |

| 3 | 70-95 | 36 | 20 | |

| 4 | 75-100 | 37.5 | 19 | |

| ASTM A350 | LF1 | 60-85 | 30 | 25 |

| LF2-1 | 70-95 | 36 | 22 | |

| LF2-2 | 70-95 | 36 | 22 | |

| LF3-1 | 70-95 | 37.5 | 22 | |

| LF3-2 | 70-95 | 37.5 | 22 | |

| LF5-1 | 60-85 | 30 | 25 | |

| LF5-2 | 70-95 | 37.5 | 22 | |

| LF6-1 | 66-91 | 52 | 22 | |

| LF6-2 | 75-100 | 60 | 20 | |

| LF6-3 | 75-100 | 60 | 20 | |

| LF9 | 63-88 | 46 | 25 | |

| LF787-2 | 65-85 | 55 | 20 | |

| LF787-3 | 75-95 | 65 | 20 |

Low-alloy steel fittings ASTM A182 (forged)

Low-alloy forged fittings match chrome-moly pipes ASTM A335 in grades P5 (for F5 fitting), P9 (for F9 fitting), P11 (for F11 fitting), P22 (for F22 fitting), P91 (for F91 fittings). The chemical composition of these common alloy grades for socket weld and threaded fittings is shown below:

| Low-Alloy Forged Fittings Materials | A182 F5 | A182 F9 | A182 F11 | A182 F22 | A182 F91 |

| C | 0.15 Max | 0.15 Max | 0.10-0.20 (2) | 0.05-0.15 | 0.08-0.12 |

| Mn | 0.30-0.60 | 0.30-0.60 | 0.40-0.65 | 0.30-0.60 | 0.30-0.60 |

| P | 0.035 Max | 0.030 Max | 0.025 Max | 0.035 Max | 0.020 Max |

| S | 0.030 Max | 0.030 Max | 0.040 Max | 0.040 Max | 0.010 Max |

| Si | 0.50 Max | 0.50-1.00 | 0.50-0.80 | 0.50 Max | 0.20-0.50 |

| Ni | 0.50 Max | – | – | 0.40 Max | |

| Cr | 4.0-6.0 | 8.0-10.0 | 1.00-1.50 | 2.00-2.50 | 8.0-9.5 |

| Mo | 0.44-0.65 | 0.90-1.10 | 0.44-0.65 | 0.90-1.10 | 0.85-1.05 |

| V | – | – | – | 0.18-0.25 | |

| Cu | – | – | – | – | |

| Other | – | – | – | Cb, 0.06-0.10; N, 0.03-0.07; Al, 0.04 max. |

Stainless steel fittings ASTM A182 (forged)

Stainless steel forged fittings match ASTM A312 pipes. The chemical composition of stainless steel socket weld and threaded fittings is given below:

| ASTM A182 Forged Fittings Materials in % | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A182 Grade | C | Mn | P | S | Si | Ni | Cr | Mo | Nb | Ti | Others |

| F304(1) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-11.0 | 18.0-20.0 | ||||

| F304L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-13.0 | 18.0-20.0 | ||||

| F304N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F304LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 8.0-10.5 | 18.0-20.0 | ||||

| F309H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 12.0-15.0 | 22.0-24.0 | ||||

| F310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 19.0-22.0 | 24.0-26.0 | ||||

| F310MoLN | 0.030 | 2.0 | 0.030 | 0.015 | 0.40 | 21.0-23.0 | 24.0-26.0 | 2.0-3.0 | N 0.10-0.16 | ||

| F316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316L(1) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316N(2) | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316LN(2) | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | |||

| F316Ti | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | (3) | N 0.10 max | |

| F317 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F317L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 11.0-15.0 | 18.0-20.0 | 3.0-4.0 | |||

| F321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (4) | |||

| F321H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-12.0 | 17.0-19.0 | (5) | |||

| F347 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | |||

| F347H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | |||

| F348 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (6) | Co 0.20 Ta 0.10 | ||

| F348H | 0.04-0.10 | 2.0 | 0.045 | 0.030 | 1.0 | 9.0-13.0 | 17.0-20.0 | (7) | Co 0.20 Ta 0.10 | ||

Socket weld fittings are available, also, in other grades as duplex and super duplex (ASTM A182 F51, F53/F55) and various nickel alloys (Inconel, Incoloy, Monel, Hastelloy).

10 Responses

Great article on ASME B 16.11 Socket Threaded Fittings, very informative! For anyone interested in learning more, check out Duplex Steel F60 Forged Threaded Fittings.

Good work! Thank you for your participation. Look into it as well. Shree Impex Alloys, Stainless Steel Seamless Pipe Manufacturer in India, Stainless Steel Seamless Pipe, Stainless Steel Seamless Pipe Manufacturer, Stainless Steel Seamless Tube Manufacturer in India and Stainless Steel Welded Pipe Manufacturer in India.

Dear Sir/Madam,

Yancheng Xinfujit Machinery Co.,Ltd. is a manufacturer specialized in hydraulic flange and fittings for a variety of

hose,pipe and tube assemblies,The products widely used in petrol, the chemiacal industry, construction machinery and equipment.

Support for the hydraulic piping system.

Our Product group of SAE Flange including:

SAE Split flanges

SAE flange clamps

SAE weld flanges

SAE Butt weld flanges

SAE socket weld flanges

SAE socket weld elbow flanges

SAE threaded flanges/SAE threaded counter flanges

SAE BSPP threaded flanges

SAE NPT threaded flanges

SAE closed flanges/SAE Blind flanges

SAE blocks

All the above products of SAE flanges come in two main series

3000 psi standard pressure series, designed according to standard ISO 6162-1, this is also called code 61 flanges

6000 psi high pressure series, designed according to standard ISO 6162-2, this is also called code 62 flanges.

Materials of SAE hydraulic flanges

Carbon steel:C45,C20,CQ235 or on requests.

Stainless steel:304,304L,316 and 316L or equivalent EN/DIN stainless steel grades,used for connecting stainless steel hydraulic tubing.

other materials also can be supplied on request with some required min. order quantity.

Our products export to more than 30 countries, and get well reputation.

We have our own export licence. We are looking forward to cooperating with you sincerely.

Looking forward to hearing from you.

Best regards

Eileen Jia

Yancheng Xinfujit Machinery Co.,Ltd.

Mobile:00 86 18262378752(wechat)

Fax:00 86 515 86523666

Contact person:Eileen Jia

Website: https://xfjt168.en.alibaba.com/

E-mail:XF80@xfjt-saeflange.com

Address:No.8 2# Road Private Industrial Park Jianhu County,

Yancheng city,Jiangsu Province,China.

Dear Sir,

Greetings.

Please quote your best price and delivery time for the below item:

SK2022030303 – 30 DAYS VALIDITY REQUIRED – LOWEST OFFER TO BE QUOTED – AS PER QP AML – BCD : 07/03/2022

Note

1) Quoted items should be exactly as per specification. If any deviation to be highlighted separately.

2) MTC 3.1 only required.

3) Sea worthy packing cost & attested shipping document cost to be quoted separately.

4) Manufacturer name and origin to be mentioned against each line items

5) Ex-work packed basis quote required.

6) All pipes / fittings / flanges / plates shall be manufactured within 5 years prior to collection or delivery

7) Please provide catalogue / datasheet for the item to be quoted.

8) As per QP AML

Material Description:

00002 10096734 QTY: 30 Piece 24.MAR.2022

NIPPLE,PIPE,HEX,1/4IN,MI,GALV,,

NIPPLE,PIPE

SH_NAME NIPPLE,PIPE

NIPPLE_TYPE HEX

NIPPLE_DIMENSIONS 1/4IN

NIPPLE_MATL MI

NIPPLE_FINISH GALV

NIPPLE_PRESS_RTG 25 BAR AT -20 TO 120 DEGC

NIPPLE_CONN_DATA NPT-M EQUAL

NIPPLE_INSPECTION_CERT ISO 10474-2.1

NIPPLE_DESIGN_SPEC BS 143

NIPPLE_MATL_SPEC ASTM A197M

NIPPLE_COATING_SPEC ASTM A153 CL A

Inspection text

Certificate of Compliance BS EN 10204 / ISO 10474 type 2.1

Your offer the earliest is highly appreciated. Waiting for your prompt reply.

Thanks & Regards,

Heinlyn

Inside Sales Representive – Oil & Gas Division

BECON TRADING & CONTRACTING W.L.L

Building No: 94, D-Ring Road, Street-250, Zone 42, Al-Hilal Area,

PO Box #37312, Doha, Qatar

sayeed@becon.com.qa

2) SP97 A105 SA105N 57008 6-1 ½” x 3/4 6M (Sch 160) BONNY SP97 (B16.11)

What does 57008 mean

Great post to share. very informative content

ELBOW:90 DEG; 1 INCH ONE END MALE & ONE END FEMALE NPT THREAD, F316; ASTM A182, FORGED TYPE 3000 LBS. Qty: 32 pcs

PLEASE QUOTE PRICES IN CIF SINGAPORE.

Dear Sirs,

For a special application I am looking for one(1) piece of:

Y-Filter,socket weld,1/2”,B16.11 with IPS thread delivered Istanbul-Turkey.

my best regards,

Nejat Uner Istanbul-Turkey

Hi , I’m looking for the following prices . 25mm threaded socket working pressure 10bar and threaded 25mm nipples all carbon steel .

Hi,

I have used threaded fittings for steam network then found later that this type of fittings is not reliable for steam application so I have decided to weld around the fittings.

Is this OK?