Buttweld fittings are pipe fittings used to change the pathway of a pipeline (elbows), reduce/increase the pipe bore size (reducers), branch (tees, cross), or blind a pipeline (butt weld cap). ASME B16.9 (and MSS-SP 43) Buttweld fittings are used for piping systems above 2 inches in diameter, whereas socket weld and threaded fittings (“forged fittings”) are used for smaller size pipes (ASME B16.11)

BUTTWELD FITTINGS

WHAT ARE BUTTWELD FITTINGS?

Buttweld fittings are a category of pipe fittings used to change the direction, branch off, or mechanically join piping systems. These fittings are typically welded to pipes to ensure a tight and seamless connection, providing a continuous flow within the piping system.

Buttweld fittings are widely used in various industries such as oil and gas, power generation, chemical processing, and wastewater treatment due to their strength, durability, and leak-proof nature. Understanding the types, materials, and applications of buttweld fittings can help in selecting the right fitting for specific piping needs.

Bear in mind that for piping systems below 2 inches in diameter, socket weld and threaded (forged fittings) covered by the ASME B16.11 Specification, are used instead.

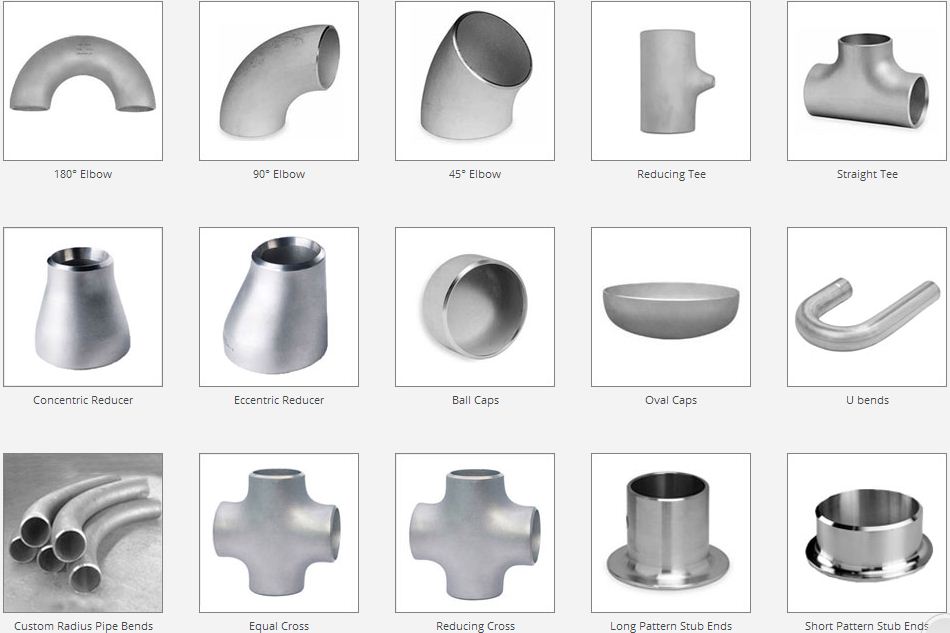

Buttweld fittings are available in multiple shapes (elbows, tees, reducers, crosses, caps, stub ends), material grades (carbon, high-yield carbon, low-alloy, stainless, duplex, and nickel alloys, non-ferrous metals), and dimensions (2 to 24 inches in seamless execution, and welded for larger pipe sizes).

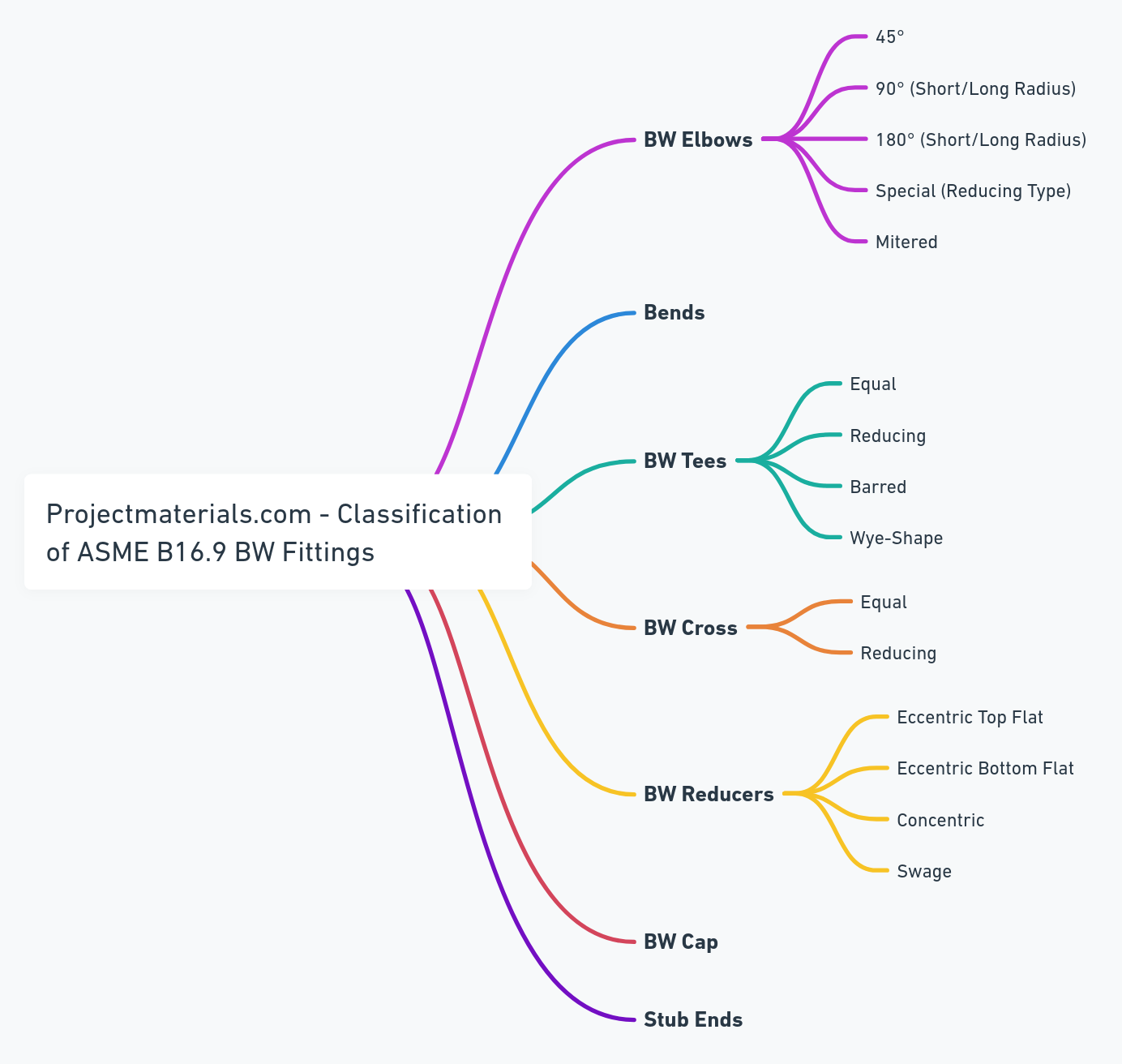

COMMON SHAPES OF BUTTWELD FITTINGS

Elbows

Used to change the direction of the flow in a piping system. Elbows are available in various degrees, with 45° and 90° elbows being the most common (180° are also available, but less used).

Tees

Tees are T-shaped fittings that split or combine the flow in a piping system. They come in two types: equal tees, where the size of all three ends is the same, and reducing tees, where the branch has a smaller diameter.

Reducers

These fittings are used to connect two sections of pipe of different sizes. There are two types of reducers:

- Concentric reducers: which have a central axis of symmetry, tapering uniformly, and are used where the pipe size changes significantly.

- Eccentric reducers: which have an off-center tapering line used in applications requiring the maintenance of the same top or bottom level in the piping.

Caps

Used to seal the end of a pipe, effectively stopping the flow. Caps are a critical component when future expansions or connections might be needed.

Stub Ends

Stub ends are used in conjunction with lap joint flanges. They provide a means for quick disconnection of pipes for inspection or maintenance.

All these shapes for buttweld fittings are explored in greater detail below in this article.

MATERIALS FOR BW FITTINGS

Buttweld fittings are manufactured from a variety of materials, each selected based on the application’s specific requirements for strength, temperature, piping system pressure, and corrosion resistance. Common materials include:

- Carbon Steel: Widely used due to its strength and durability. It’s suitable for high-temperature and high-pressure applications.

- Stainless Steel: Offers excellent corrosion resistance. It is used in applications involving aggressive fluids or in environments prone to corrosion.

- Alloy Steel: Used in applications requiring higher strength and resistance to heat and corrosion.

- Duplex Stainless Steel: Combines the qualities of austenitic and ferritic stainless steel, offering high strength and resistance to corrosion.

- Nickel Alloy Steel: Used for the most demanding applications in terms of process temperature, pressure, and corrosion.

- Non-Ferrous Materials (Aluminium, Bronze, Cupronickel, Copper): Used for demanding applications in the field of water management, seawater, desalinization, etc.

The material specifications for buttweld fittings are often defined by other ASME standards, such as the ASME SA/A 234 specification for piping fittings of wrought carbon steel and alloy steel for moderate and high-temperature service and by ASTM.

These specifications ensure that buttweld fittings are manufactured and installed with the highest level of integrity and safety in mind. They cover a range of applications, from general low-pressure service to high-pressure and high-temperature applications in critical service environments. Adherence to these standards is crucial for the safety, reliability, and efficiency of piping systems. They serve as a guide for manufacturers, engineers, and end-users in the selection, application, and maintenance of buttweld fittings.

BW FITTINGS: FIELDS OF APPLICATION

Buttweld fittings are preferred in applications requiring a strong, seamless pipe connection that can withstand high pressure, high/low temperatures, or corrosive substances. Their use spans across:

- Petrochemical and Refineries: Due to their ability to withstand high pressures and corrosive materials.

- Power Plants: Especially in systems where high-pressure steam and hot water are involved.

- Water Treatment Plants: For their durability and leak-proof nature, essential in systems managing large volumes of water.

- Food and Beverage Industry: Stainless steel buttweld fittings are used for their hygienic properties and resistance to corrosion.

ADVANTAGES OF BUTTWELD FITTINGS

- Strength and Durability: The welded connection offers a strong bond, making the pipeline more secure and durable.

- Leak-Proof: Provides a seamless flow path that is leak-proof, which is crucial in high-pressure and high-temperature applications.

- Flow Efficiency: The smooth inner surface minimizes friction and turbulence, improving flow efficiency.

SPECIFICATIONS FOR BW FITTINGS (ASME/MSS)

The American Society of Mechanical Engineers (ASME) and the Manufacturers Standardization Society (MSS) have established specifications and standards to ensure the quality, compatibility, and safety of buttweld fittings used in piping systems. These specifications cover dimensions, material grades, tolerances, manufacturing processes, testing, and marking of buttweld fittings. When selecting buttweld fittings and planning their installation in a piping system, it’s important to consult the relevant ASME and MSS specifications to ensure compliance with the required standards for the specific application.

Here’s an overview of some key ASME and MSS specifications related to buttweld fittings:

ASME Specifications

ASME B16.9 – Factory-Made Wrought Buttwelding Fittings:

This standard covers overall dimensions, tolerances, ratings, testing, and markings for wrought carbon and alloy steel buttwelding fittings of NPS 1/2 through NPS 48 (DN 15 through DN 1200). It includes fittings like elbows, tees, reducers, lap joint stub-ends, and caps.

ASME B16.28 – Wrought Steel Buttwelding Short Radius Elbows and Returns:

Specifies the design, dimensions, tolerances, and material requirements for short-radius elbows and returns. This standard is intended for fittings that do not require the use of the full range of material grades and design pressures covered in ASME B16.9.

ASME B16.25 – Buttwelding Ends:

Details the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It specifies types of welds, dimensions, and finishes for weld ends.

MSS Specifications

MSS SP-43 – Wrought Stainless Steel Butt-Welding Fittings:

Covers the dimensions, tolerances, and material requirements for stainless steel, wrought, seamless, and welded butt-welding fittings in nominal pipe sizes 1/2 through 24 inches. It’s focused on low-pressure corrosion-resistant applications.

MSS SP-75 – Specification for High-Test, Wrought, Butt-Welding Fittings:

Provides specifications for high-strength, seamless, and welded butt-welding fittings for high-pressure, high-temperature service, such as in oil and gas pipelines. It covers fittings of carbon steel and alloy steel materials.

MSS SP-97 – Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends:

Addresses standards for branch outlet fittings that are intended to be butt welded, socket welded, or threaded to the run pipe. It covers design, dimensions, material, and testing requirements.

TYPES OF BUTTWELD FITTINGS

BUTTWELD ELBOW 45/90/180 DEG.

ASME B16.9 buttweld elbows are manufactured in a wide range of dimensions (combinations of outside diameter and wall thickness) to fit ASME B36.10 and ASME B36.19 carbon, alloy, and stainless steel pipes of any size between 2 and 48 inches (and above).

Buttweld elbows below 24 inches in diameter are produced by cutting, heating, and bending seamless steel pipes; pipe elbows of larger sizes are manufactured, instead, from welded pipes or steel plates.

The three most common types of elbows in piping are the 45, 90, and 180 degrees (or return elbow), as shown in the image:

SPECIAL TYPES OF BW ELBOWS

Some special types of pipe elbows are:

Reducing elbow

A reducing elbow is a specific type of pipe fitting used in piping systems to change the direction of flow while simultaneously reducing the pipe size. It combines the functionality of an elbow, which alters the direction of the flow, typically by 90 degrees or 45 degrees, with that of a reducer, which transitions the piping system to a smaller diameter.

This type of fitting is particularly useful in areas with limited space where a separate elbow and reducer would be impractical due to spatial constraints or when aiming to reduce the number of fittings used, thereby simplifying the system and potentially reducing costs.

Key Features of a Reducing Elbow

- Direction Change and Size Reduction: Allows for a directional change in the piping system while transitioning to a smaller pipe size in a single fitting.

- Angle: Most commonly available in 90-degree and 45-degree angles, although custom angles can be manufactured for specific applications.

- End Connections: The ends of a reducing elbow are designed to match the differing pipe sizes they connect. These ends can be prepared for buttwelding, threaded connections, or other types of joining methods depending on the application requirements.

- Material Variety: Manufactured from a wide range of materials, including carbon steel, stainless steel, alloy steel, and others, to suit different pressure, temperature, and corrosion resistance needs.

Applications

Reducing elbows are utilized across various industries where piping systems transport fluids, gases, or slurries and there is a need to change direction and reduce pipe size within the same fitting. Common applications include, but are not limited to:

- Chemical Processing: For managing the flow of chemicals within reactors, separators, and other process equipment.

- Oil and Gas: In pipelines and refining processes where changes in pipe size are required to manage pressure or flow rates.

- Water Treatment Facilities: Within treatment plants to modify the direction and flow rate of water through the treatment process.

- HVAC Systems: For air distribution networks where the system transitions to smaller ducts.

Advantages

- Space Efficiency: Reducing elbows is particularly advantageous in tight spaces where combining two functions into one fitting saves space and simplifies the design.

- Cost-Effective: Reduces the number of fittings needed, which can lower material costs and reduce installation time.

- Streamlined Flow: Minimizes the number of joints in the system, which can reduce the potential for leaks and pressure drops, contributing to a more efficient system.

Selection Considerations

When selecting a reducing elbow for a piping system, several factors should be considered to ensure optimal performance:

- Material Compatibility: The material of the reducing elbow should be compatible with the fluid being transported and the operating conditions (e.g., temperature, pressure, corrosive properties) of the system.

- Size and Angle: The size reduction and angle of the elbow must meet the system’s design requirements for flow direction change and pipe size transition.

- Standards and Specifications: The fitting should conform to relevant industry standards and specifications to ensure quality and safety.

In conclusion, reducing elbows are essential components in the design and implementation of efficient, space-saving piping systems across a wide range of industrial and commercial applications.

Mitered elbow

Mitered elbows are a type of pipe fitting used to change the direction of flow in a piping system, constructed by cutting and joining pipe sections at angles. Unlike standard elbows, which are manufactured as single, seamless fittings, mitered elbows are fabricated from several pipe segments, or “miters,” welded together.

This method allows for custom angles and sizes that might not be readily available or cost-effective in standard elbow fittings. Mitered elbows can be designed to accommodate any angle required for the piping system, making them versatile for a wide range of applications.

Construction and Design

The design of a mitered elbow typically involves several straight pipe sections being cut at specific angles and then welded together to achieve the desired change in direction. The number of miters or cuts can vary based on the elbow’s required angle and the bend radius. More segments generally allow for a smoother flow transition but require more welding and fabrication effort.

Key Characteristics

- Customization: Mitered elbows can be tailored to specific angle requirements, offering flexibility for unique or complex piping layouts.

- Cost-effectiveness: For large-diameter pipes or uncommon angles, mitered elbows can be more economical than purchasing specially cast or manufactured fittings.

- Versatility: They can be made from a variety of materials, matching the piping system’s requirements for pressure, temperature, and corrosion resistance.

Applications

Mitered elbows are used in both commercial and industrial applications, including:

- Water Supply and Distribution: Where large diameter pipes are common, and custom angles may be required.

- HVAC Systems: For custom ductwork that requires specific angles for optimal airflow.

- Process Piping: In industries such as chemical, petrochemical, and power generation, where complex piping routes are necessary.

Advantages and Disadvantages

Advantages:

- Flexibility in design to meet specific system requirements.

- Cost-effective for large-diameter pipes or when standard elbows are not available.

- Ability to match the material with the existing piping system.

Disadvantages:

- Increased potential for leaks due to multiple welds.

- Potential for turbulent flow or pressure drops if not properly designed, especially in systems with high flow rates.

- Requires precise fabrication and welding, impacting the overall quality and performance of the elbow.

Design Considerations

When designing or selecting a mitered elbow, several factors need to be considered to ensure optimal performance:

- Flow Requirements: The elbow design should minimize turbulence and pressure drops to maintain efficient flow.

- Number of Miters: More miters can provide a smoother flow path but increase fabrication complexity. The choice depends on the application’s specific requirements for flow characteristics and pressure integrity.

- Weld Quality: High-quality welding is crucial to prevent leaks and maintain the structural integrity of the elbow.

- Inspection and Testing: Due to their fabricated nature, mitered elbows should undergo thorough inspection and testing to ensure they meet the necessary standards and specifications.

Mitered elbows offer a practical solution for custom or large-scale piping systems where standard elbows cannot meet specific requirements. Their design and fabrication require careful consideration to balance the benefits of customization with the need for reliable performance and flow efficiency.

Short Vs. Long-Radius BW Elbows

Buttweld (BW) elbows are integral components of piping systems, used to change the direction of the flow. They come in various angles, materials, and types, including short-radius (SR) and long-radius (LR) elbows. Understanding the difference between short and long-radius elbows is essential for selecting the appropriate fitting for a given application, based on factors like flow requirements, space constraints, and pressure drop considerations.

The center-to-face distance of a long-radius pipe elbow is always 1.5 times the nominal pipe size, whereas, for a short-radius pipe elbow, the center-to-face distance is equal to the nominal pipe size.

Example:

- For a 4 inches long radius (LR) butt weld elbow, the center-to-face distance is 4 x 25.4 x 1.5 = 152.4 mm;

- For a short radius butt weld elbow, the center-to-face distance is instead 4 x 25.4 x 1 = 101.6 mm. Short-radius pipe elbows are available only for the 90 and 180-degree configuration (and not for the 45 degrees); instead, long-radius elbows are available for all degrees.

Short-Radius (SR) Elbows

- Radius: The radius of a short-radius elbow is equal to the nominal pipe diameter. For example, for a 4-inch pipe, the radius of a short-radius elbow would also be 4 inches.

- Angle: While available in various angles, 90-degree SR elbows are the most common.

- Application: SR elbows are typically used in tight areas where space is a significant constraint. Their compact design allows for sharper turns in the piping system.

- Pressure Drop: Due to their tighter curvature, short-radius elbows generally induce a higher pressure drop compared to long-radius elbows. This aspect needs to be considered, especially in systems where maintaining a lower pressure drop is crucial.

Long-Radius (LR) Elbows

- Radius: The radius of a long-radius elbow is typically 1.5 times the nominal pipe diameter. So, for a 4-inch pipe, the radius of an LR elbow would be approximately 6 inches.

- Angle: Like SR elbows, LR elbows are also available in various angles, with 90-degree and 45-degree angles being the most common.

- Application: Long-radius elbows are the standard in most piping systems due to their gentle curve, which minimizes pressure drop and allows for smoother flow. They are used in a wide range of applications, from water supply and HVAC systems to chemical and petrochemical processing.

- Pressure Drop: The broader curve of LR elbows results in a lower pressure drop, making them more suitable for applications where maintaining flow efficiency is important.

Key Differences Summarized (SR Vs. LR Elbows)

- Design and Space Requirements: SR elbows have a tighter curve and are more suited to applications with limited space, whereas LR elbows have a gentler curve, requiring more space but providing a smoother flow.

- Pressure Drop: SR elbows generally cause a higher pressure drop due to the sharp turn in the flow path, whereas LR elbows promote a more efficient flow with a lower pressure drop.

- Application Suitability: The choice between SR and LR elbows depends on the specific requirements of the piping system, including space constraints, flow dynamics, and pressure considerations.

When designing or modifying a piping system, it’s crucial to select the appropriate type of elbow based on these differences to ensure optimal performance, efficiency, and longevity of the system. The selection should align with the system’s operational requirements, taking into account the fluid dynamics, space availability, and overall design specifications.

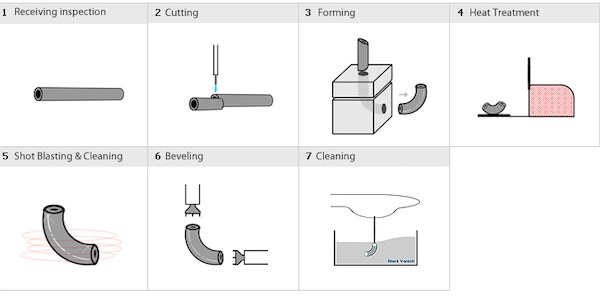

Pipe Elbows Manufacturing Process

The manufacturing process of buttweld elbows involves several steps designed to transform raw materials into a finished product that meets specific standards for size, shape, and material composition. These elbows are crucial components in piping systems, allowing for directional changes of the flow with minimal loss of pressure. Here’s an overview of the manufacturing process typically used to produce buttweld elbows:

1. Material Selection

The process begins with the selection of the appropriate material, which is usually a section of pipe or a solid cylindrical steel billet. The choice of material depends on the intended application of the elbow and factors such as temperature, pressure, and corrosive properties of the fluid being transported.

2. Cutting

For elbows made from pipes, the first step is to cut the pipe section to the required length. If a billet is used, it’s cut into discs of a thickness that corresponds to the desired elbow diameter.

3. Heating

The pipe section or disc is then heated to a high temperature to make it more pliable. This is usually done in a furnace that’s carefully controlled to ensure uniform temperature and prevent overheating, which could alter the steel’s properties.

4. Forming

- Mandrel Method: The heated pipe section is placed over a mandrel (a shaped die), which mimics the inner radius of the elbow. The assembly is then pushed through a forming die, which bends the pipe into the elbow shape. This method is often used for manufacturing long-radius elbows.

- Hot Pushing Method: Widely used for both long-radius and short-radius elbows, the heated pipe or billet is pushed through a shaping die by a hydraulic ram, where it’s bent around a curved mandrel to form the elbow. The pushing and bending occur simultaneously, reducing the amount of stress and potential for cracking.

- Cold Forming: For smaller sizes or specific materials, elbows can be formed at room temperature using a cold forming process. This usually requires more force and may involve additional steps, like cold drawing, to achieve the final dimensions.

5. Heat Treatment

After forming, the elbows are often subjected to heat treatment processes such as normalizing or annealing. These processes relieve stresses induced during forming and improve the mechanical properties of the material, ensuring the elbow can withstand the operational demands of its intended application.

6. Machining

The ends of the elbow are then machined to create a beveled edge, preparing them for the buttwelding process. This step ensures that the elbow can be easily and securely welded to other components in the piping system.

7. Cleaning and Finishing

The elbows undergo cleaning to remove any scale, residue, or contaminants from the surface. They may also be treated with coatings or linings, depending on the requirements of the specific application.

8. Inspection and Testing

The final step involves inspecting the elbows for defects and testing them to ensure they meet the required standards and specifications. This may include visual inspection, dimensional checks, non-destructive testing (NDT) methods like radiography or ultrasonic testing, and pressure testing.

The manufacturing process of buttweld elbows is carefully controlled to ensure that the final product is of high quality, meets industry standards (such as ASME B16.9 for factory-made wrought buttwelding fittings), and is suitable for its intended application in terms of durability, reliability, and performance.

Mandrel Process

Cold forming

PIPE BENDS

Pipe bends are fundamental components in the design and construction of piping systems across various industries, including oil and gas, power generation, and construction. Their primary function is to allow for directional change of the flow within a piping system, facilitating the layout to accommodate obstacles, align with equipment, or meet design requirements without significantly affecting the flow efficiency or inducing unnecessary pressure drops. In this educational exploration, we’ll delve into the types, manufacturing processes, design considerations, and applications of pipe bends.

Types of Pipe Bends

Pipe bends can be classified based on various factors such as the angle of bend, radius of curvature, and manufacturing process. The most common types include:

- Long Radius Bends (LRB): Typically having a radius of curvature of 1.5 times the nominal pipe diameter (1.5D). They are preferred for their smoother flow characteristics and lower pressure drop.

- Short Radius Bends (SRB): With a radius of curvature equal to the nominal pipe diameter (1D). They are used where space is constrained, though they may result in higher pressure drops compared to LRB.

- 3D and 5D Bends: These bends have radii of curvature that are three times (3D) and five times (5D) the nominal pipe diameter, respectively. They are often used in high-pressure applications or where a more gradual directional change is desired to minimize flow resistance.

Manufacturing Processes

The manufacturing of pipe bends involves several techniques, each suitable for different materials, sizes, and specifications. The most common methods include:

- Hot Bending: This involves heating a section of the pipe to a high temperature, and then bending it to the desired angle using a mandrel or die. This method is suitable for large-diameter pipes and allows for tight radius bends.

- Cold Bending: Also known as induction bending, it does not require the pipe to be heated across its entire cross-section. A localized area is heated using an induction coil, and the pipe is bent while being pushed through a bending machine. This process is precise and retains the original strength and integrity of the pipe.

- Welding: For complex shapes or when standard bends are not suitable, pipe segments can be cut and welded to achieve the desired angle. This method, however, may introduce potential points of failure if not executed properly.

Design Considerations

When integrating pipe bends into a piping system, several design considerations must be taken into account to ensure efficiency, durability, and safety:

- Flow Dynamics: The bend angle, radius, and pipe diameter affect the flow velocity, pressure drop, and potential for erosion or cavitation within the bend.

- Material Compatibility: The material of the pipe bend should be compatible with the fluid being transported, considering factors such as corrosion, temperature, and pressure.

- Support and Anchorage: Due to the forces exerted by the flow at bends, proper support and anchorage are crucial to prevent pipe movement or failure.

- Expansion and Contraction: Thermal expansion and contraction can stress pipe bends. Design solutions may include the use of expansion loops, joints, or specific materials that can accommodate temperature variations.

Applications

Pipe bends find applications across a wide range of industries due to their versatility and functionality:

- Oil and Gas Industry: Used extensively for routing pipelines across terrain, under obstacles, or within processing facilities, where changes in direction are required.

- Power Generation: Critical in the layout of cooling systems, steam conduits, and exhaust pipelines, where efficiency and flow dynamics are paramount.

- Construction: Employed in heating, ventilation, and air conditioning (HVAC) systems, water supply, and drainage systems, adapting the piping layout to the architectural constraints of buildings.

In conclusion, pipe bends are indispensable components that contribute significantly to the efficiency, safety, and design flexibility of piping systems. Understanding the types, manufacturing processes, and design considerations of pipe bends is crucial for engineers and designers in selecting the most appropriate solutions for their specific applications, thereby ensuring the longevity and reliability of the piping infrastructure.

BUTTWELD TEE

EQUAL TEE

An equal tee, otherwise called a straight tee, is a buttweld fitting used to branch a pipeline, or any other pipework, at 90 degrees.

A pipe tee is defined as “equal” when the bore size at the run and branch sides have the same diameter. An equal tee is, therefore, used to connect two pipes of the same nominal diameter.

Equal tees are available in sizes from half an inch to 48 inches (or larger) and in seamless and welded execution (seamless up to 24 inches, welded for tee sizes above 24 inches).

Buttweld tees are manufactured according to ASME B16.9 (carbon and alloy) and MSS-SP 43 (stainless steel and nickel alloy).

REDUCING TEE

A reducing tee features a smaller bore size at the branched pipe side (generally 2/3 sizes smaller).

In case a larger bore size reduction is necessary, then a reinforced branch connection (such as a Weldolet) shall be preferred to prevent turbulence and have a smoother flow reduction.

The standard dimensions and tolerances of equal and reducing pipe tees are covered by the ASME B16.19 specification (carbon and alloy steel) and by the MSS SP 43 spec (for stainless steel and nickel alloy tees).

BARRED TEE

A barred tee is a special type of (equal) tee used for pigging operations (reducing barred tees does not exist, as the pig would not pass through the reduced area anyway).

A barred tee features a welded restriction on the branch pipe side that prevents the pig from flowing from the run pipe into the branched pipe.

Such barred restriction is welded on the internal side of the fitting and looks like a steel cage.

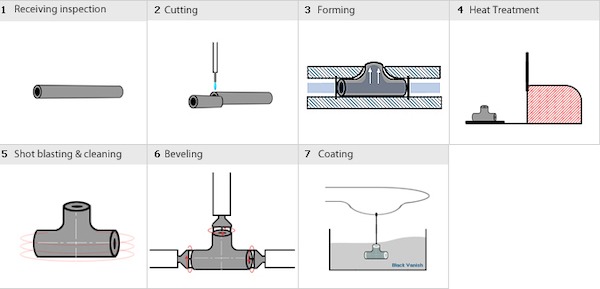

PIPE TEE MANUFACTURING PROCESS

The manufacturing process of buttweld tees, crucial components in piping systems for branching off or combining fluid flow, involves several steps. These fittings must meet stringent standards for size, shape, material, and strength to ensure they perform reliably under various operational conditions. The process typically involves the following stages:

1. Material Selection

The process begins with selecting a suitable material that matches the application’s requirements for temperature, pressure, and corrosion resistance. Common materials include carbon steel, stainless steel, alloy steel, and others, depending on the specific service conditions.

2. Cutting and Shaping

Pipe Cutting: The initial step is to cut the pipe or tube to the required length from which the tee will be formed. This is usually done using sawing or cutting machines designed for precise cutting.

Forming the Run: The main body of the tee, known as the run, is formed either by extrusion or by bending the pipe. Extrusion involves heating a section of the pipe and then pushing it through a die to form the desired shape. Bending is less common for tees but can be used for certain material types and sizes.

3. Branch Formation

Punching or Drilling: For the branch (the perpendicular part of the tee), a hole is created on the run. This can be achieved through punching (in the case of hot-formed tees) or drilling (for cold-formed tees).

Branch Insertion: A piece of pipe with a diameter matching the branch size is prepared and inserted into the hole. This piece can be either directly formed from the main pipe in the case of extruded tees or separately manufactured and welded onto the run.

4. Welding (if necessary)

In cases where the branch is not formed integrally with the run (i.e., not extruded), welding is required to join the branch pipe to the run. The welding process must be carefully controlled to ensure the joint’s integrity and strength. Common welding methods include gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW).

5. Heat Treatment

After forming and welding, the tee may undergo heat treatment to relieve stresses, improve toughness, and ensure the material meets the required mechanical properties. The specific heat treatment process (such as annealing, normalizing, or stress relieving) depends on the material and the application requirements.

6. Finishing and Inspection

Finishing: The external and internal surfaces of the tee are finished to meet the specifications. This may include removing weld excess, grinding to smooth out surfaces, and applying surface treatments or coatings for corrosion resistance.

Inspection: The final step involves rigorous inspection and testing to ensure the tee meets all dimensional, material, and performance standards. This includes visual inspections, dimensional checks, non-destructive testing (NDT) methods like radiography or ultrasonic testing for welds, and hydrostatic testing to verify pressure resistance.

7. Marking and Packaging

Once the tees pass all inspections, they are marked according to standards (such as ASME, ASTM, or ANSI) with information including size, material, heat number, and manufacturer. They are then packaged for shipping to ensure they arrive at their destination without damage.

Manufacturing buttweld tees is a complex process that requires precision and control at every step to produce reliable and high-quality fittings that meet the demands of industrial piping systems.

BUTTWELD CROSS

A buttweld cross is a type of pipe fitting used in piping systems to create a four-way branch, allowing fluid flow to be diverted in multiple directions. This fitting is designed for buttwelding, a process where the fitting is welded directly to the pipe to ensure a strong, seamless connection that minimizes the risk of leaks.

Buttweld crosses are commonly used in industries where piping systems need to distribute or collect fluid from multiple directions, such as in chemical processing, petrochemical, wastewater treatment, and oil and gas distribution.

The buttweld cross has one inlet and three outlets (or vice versa), forming a cross shape. The ends are beveled to allow for welding to pipes of similar diameters. This design ensures a smooth transition of fluids with minimal disruption to the flow. The central section of the cross where the branches meet is typically reinforced to withstand the pressures and stresses involved in diverging or converging flows.

ASME B16.9 and MSS SP43 define the pipe cross dimensions and tolerance. There are no specific limitations in terms of available sizes and schedules for butt weld crosses.

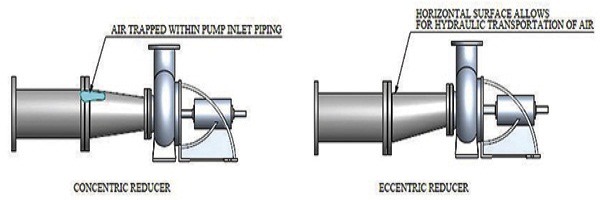

BUTTWELD REDUCERS

Concentric and eccentric reducers are both types of pipe fittings used to connect pipes of different diameters in a piping system, facilitating a smooth transition between the varying pipe sizes. While both serve the same primary purpose, their designs are suited to different applications and operational needs, based on the requirements for fluid flow, air entrapment, and installation considerations.

CONCENTRIC REDUCER

Concentric reducers are the most common type of buttweld reducers. They feature the following characteristics:

- Design: A concentric reducer is shaped like a cone and is used to align the centerline of the pipeline as it reduces in size. Both ends of a concentric reducer are centered along the same axis, providing a symmetrical reduction in size.

- Application: They are commonly used in vertical piping systems and in situations where maintaining the same centerline across piping sections is necessary. Concentric reducers are preferred in pipelines carrying fluids at a low velocity, where there is less concern about turbulence or the accumulation of air pockets.

- Advantages: The symmetrical design minimizes the risk of erosion due to the uniform distribution of fluid flow. It is also easier to insulate due to its regular shape.

The open ends of a concentric reducer are aligned and centered one to the other. Generally, this type of pipe reducer is used to modify the bore size of the pipeline by two (maximum three) measures, to avoid an excessive pressure drop in the pipeline.

If a larger reduction is needed, then a sequence of reducers shall be used to have a smooth and gradual adjustment of the pipeline bore size (vs. a drastic change).

For small bore size reductions, reducing flanges may be an alternative to buttweld reducers.

ECCENTRIC REDUCER

Eccentric reducers are used, generally, for pipelines installed in a horizontal position (whereas concentric reducers are used for pipelines installed vertically or for the inlets of suction pumps, as top flat eccentric reducers).

Alternatively, to the concentric reducer, the open ends of an eccentric reducer are in an “offset” position from one to the other.

Eccentric reducers’ key features are:

- Design: An eccentric reducer has an edge that is parallel to the connecting pipe, creating an off-center reduction. This design allows one side of the reducer to maintain the same bottom (or top) level of the pipeline, facilitating a smooth flow of liquids or gases.

- Application: Eccentric reducers are essential in horizontal pipelines, especially for liquid lines or gas lines where it is important to avoid trapping air. They are used when it is necessary to maintain a flat top or bottom in the piping system, as in pump suction lines to prevent air from being drawn into the pump.

- Advantages: The offset design prevents the accumulation of air or gas at the top or sediment at the bottom of the pipe, ensuring a smoother flow and reducing maintenance issues related to air pockets or blockages.

TOP AND BOTTOM FLAT ECCENTRIC REDUCER

CONCENTRIC VS ECCENTRIC REDUCER

The key difference between concentric and eccentric reducers is the centricity of the inlet vs. the outlet of the fitting, which is perfect for a concentric reducer and offset of an eccentric reducer. More in detail, the key differences between concentric vs. eccentric reducers can be summarized as follows:

- Alignment: Concentric reducers align the centerline of the pipes, making them suitable for vertical piping or when a symmetrical reduction is needed. Eccentric reducers have an offset that aligns the bottom or top of the pipes, ideal for horizontal piping where air or sediment accumulation is a concern.

- Application: The choice between concentric and eccentric reducers depends on the flow characteristics of the material being transported, the orientation of the piping (vertical or horizontal), and the need to prevent air or sediment accumulation.

- Flow Dynamics: Concentric reducers can handle both turbulent and laminar flow well but may introduce air pockets in horizontal lines. Eccentric reducers are designed to manage issues related to air entrapment in liquids or sediment in gases, ensuring a continuous flow in horizontal applications.

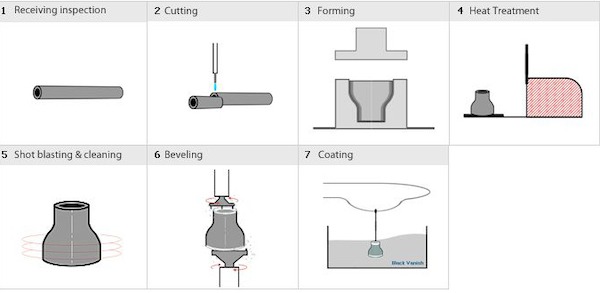

BW REDUCER MANUFACTURING PROCESS

The manufacturing process of buttweld reducers, which are pivotal in connecting pipes of different diameters within a piping system, involves several steps. These components ensure a smooth transition for the fluid flow, minimizing turbulence and pressure drops. The process combines metallurgical principles with precision engineering to produce reducers that meet specific standards for strength, durability, and leak-proof performance. Below is an overview of the key stages involved in manufacturing buttweld reducers:

1. Material Selection

The process starts with selecting a suitable material that matches the reducer’s required mechanical properties and chemical resistance. Common materials include carbon steel, stainless steel, and alloy steels, chosen based on the application’s specific needs regarding temperature, pressure, and corrosive environments.

2. Cutting and Shaping

Pipe Cutting: The selected material, often in the form of a pipe or a plate, is cut to the required size using cutting methods such as sawing, shearing, or plasma cutting.

Forming the Reducer: There are two primary methods to form the reducer shape:

Extrusion: The cut piece is heated and then extruded to form the reducer’s tapered shape. This method is generally used for seamless reducers.

Pressing: For welded reducers, plates are pressed into the reducer shape in a die and then welded along a seam. This method allows for the production of large-size reducers.

3. Heat Treatment

Depending on the material used and the forming process, the reducer may undergo heat treatment to enhance its mechanical properties, such as toughness and ductility. Common heat treatment processes include annealing, normalizing, quenching, and tempering.

4. Machining and Finishing

After forming, the reducers undergo machining to achieve the precise dimensions and surface finish required. This step may involve facing the ends to ensure they are square and smooth, which is critical for a successful butt weld.

Additional finishing processes, such as sandblasting or pickling, may be applied to improve the surface quality and enhance corrosion resistance.

5. Inspection and Testing

Rigorous inspection and testing are performed throughout the manufacturing process to ensure the reducer meets all specifications and quality standards. This includes dimensional checks, visual inspection for defects, and non-destructive testing methods like radiography or ultrasonic testing to detect any internal flaws.

Pressure testing may also be conducted to verify the reducer’s integrity under operational conditions.

6. Marking and Packaging

Once the reducers pass all inspections and tests, they are marked with essential information such as size, material grade, heat number, and manufacturer’s identification. This information aids in traceability and quality assurance.

Finally, the reducers are packaged securely to protect them during storage and transport, ensuring they arrive at their destination in perfect condition.

PIPE CAP

A buttweld pipe cap is used to blind or isolate the pipeline, permanently or temporarily (for example during the execution of maintenance and reparation works).

Buttweld pipe caps are manufactured using steel plates for most sizes and materials. The shape of a pipe cap is ellipsoidal and conforms to the requirements set by the «ASME Boiler and Pressure Vessel» code.

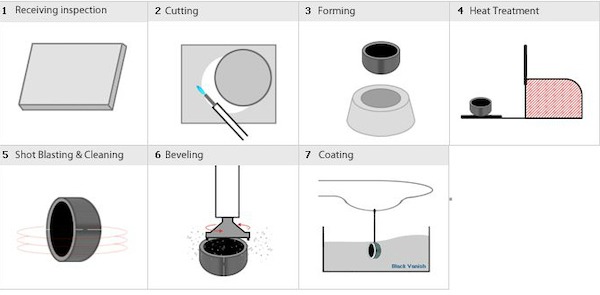

PIPE CAP MANUFACTURING PROCESS

The manufacturing process of buttweld pipe caps, essential components used to seal the end of a piping system, involves precision engineering and quality control to ensure the cap fits securely and provides a leak-proof seal. These caps are used in a wide range of applications, including oil and gas, chemical processing, and water treatment systems, to close off pipelines and enable future extensions or connections. Here’s an overview of the key steps involved in manufacturing buttweld pipe caps:

1. Material Selection

The process begins with selecting the appropriate material for the pipe cap, which is typically the same as the pipe material to ensure compatibility. Common materials include carbon steel, stainless steel, and alloy steel, chosen based on the requirements for pressure, temperature, and corrosion resistance of the application.

2. Cutting and Shaping

Blank Cutting: Material in the form of plates or sheets is cut into circular blanks. The size of the blank depends on the nominal size of the pipe cap to be manufactured.

Forming: The circular blank is then formed into the hemispherical shape of the pipe cap. This can be achieved through several methods:

Deep Drawing: A mechanical press uses a punch and die to stretch the blank into a hemispherical shape. This method is suitable for smaller caps and does not involve any seams.

Spinning: The blank is rotated at high speed and formed into shape using a roller or mandrel. This method is also used for seamless caps and can be applied to larger diameters.

Pressing: For larger sizes, segments may be pressed into shape and then welded together to form the full hemisphere. This method involves a seam that is fully welded and then inspected for quality.

3. Heat Treatment

Depending on the material and forming process, the pipe cap may undergo heat treatment to relieve stresses induced during forming and to achieve the desired mechanical properties. Common heat treatments include annealing and normalizing.

4. Machining and Finishing

After forming, the cap’s edges are machined to ensure a smooth and precise surface for welding. This involves facing the edges to create the bevel required for buttwelding to the pipe.

The cap may also undergo surface finishing processes, such as sandblasting or pickling, to remove scale and improve corrosion resistance.

5. Inspection and Testing

The finished pipe cap undergoes thorough inspection and testing to ensure it meets all specifications and quality standards. This includes dimensional checks, visual inspection for surface defects, and non-destructive testing (NDT) such as radiography or ultrasonic testing to detect any internal flaws.

For certain applications, pressure testing might also be conducted to verify the cap’s integrity under operational pressures.

6. Marking and Packaging

Approved pipe caps are marked with essential information such as size, material grade, schedule, manufacturer’s identification, and any applicable standard specifications (e.g., ASTM, ASME).

Finally, the caps are packaged appropriately to protect them from damage during storage and transport.

SEAMLESS VS WELDED BW FITTINGS

Butt weld fittings are available in seamless and/or welded execution (seamless for bore sizes below 24 inches, welded for sizes above 24 inches).

Seamless buttweld fittings have no seam welds and are therefore considered superior to welded BW fittings (a weld is always a weak point on the metal, prone to corrosion).

Seamless and welded buttweld fittings are two main categories of fittings used in piping systems to change direction, branch off, or change pipe diameter. Each type has its unique manufacturing process, characteristics, applications, and advantages, making them suitable for different operational conditions and requirements. Understanding the differences between these two types of fittings is crucial for selecting the right component for a specific application.

Seamless Buttweld Fittings

Manufacturing Process:

Seamless fittings are made from a single piece of metal that is heated and then pushed or pulled over a form until the desired shape is achieved. This process does not involve any welding and produces a fitting with a uniform structure throughout.

Characteristics:

- Uniformity in structure and strength across the entire fitting.

- Generally available in smaller sizes (commonly up to 24 inches in diameter).

- Higher pressure ratings due to the absence of weld seams.

Applications:

- Preferred in high-pressure applications.

- Used in industries where highly corrosive materials are handled, or extreme temperatures are encountered, as they offer enhanced integrity and reliability.

Advantages:

- Better strength and resistance to corrosion and high temperatures due to the homogeneous material structure.

- Reduced risk of leaks since there are no weld seams.

Welded Buttweld Fittings

Manufacturing Process:

- Welded fittings are produced by forming and welding pieces of steel plate or by welding segments or sections of pipe together. The welding process can introduce variability in the properties of the material at the weld seam.

Characteristics:

- The presence of a weld seam can be a factor in the fitting’s overall strength and corrosion resistance.

- Available in a broader range of sizes, including large diameters beyond 24 inches, which are not feasible or economical to produce as seamless fittings.

- Typically, lower pressure ratings compared to seamless fittings, due to the presence of weld seams.

Applications:

- Suitable for moderate-pressure applications and where operational conditions are less severe.

- Commonly used in water supply systems, HVAC, and applications where the benefits of seamless fittings do not justify their higher cost.

Advantages:

- Greater variety of sizes and configurations due to the flexibility of the manufacturing process.

- Generally more cost-effective than seamless fittings, especially in larger diameters or less critical applications.

Smls/Welded BW Fittings Differences Summarized

- Manufacturing Process: Seamless fittings are made from a single piece of material without welds, while welded fittings are constructed from pieces welded together.

- Material Integrity: Seamless fittings offer uniform material properties throughout, whereas welded fittings may have variability at the weld seams.

- Size Range and Pressure Ratings: Seamless fittings are typically available in smaller sizes and higher pressure ratings; welded fittings can be produced in larger sizes but usually have lower pressure ratings.

- Application Suitability: Seamless fittings are preferred for high-pressure, high-temperature, or corrosive environments due to their structural integrity. Welded fittings are more cost-effective for less demanding conditions and larger pipe diameters.

- Cost: Seamless fittings tend to be more expensive due to the manufacturing process and material utilization but offer superior performance in critical applications. Welded fittings provide a more economical choice for a wide range of uses, especially where large diameters or specific configurations are required.

Selecting between seamless and welded buttweld fittings depends on the specific requirements of the piping system, including pressure, temperature, the fluid being transported, and budget constraints.

30 Responses

We are a Chinese leading manufacturer specializing in carbon steel pipe fittings, including elbows, tees, reducers, crosses, caps,and so on. If you have requirement about pipe&fitting from China, pls enquiry to me, competitive price to you.

Thanks and Regards

LI LI

Email: hnxkyib@163.com

Mob/Wechat +8618736287686

We are a Chinese manufacturer specializing in carbon steel pipe fittings,such as elbows, tees, reducers, crosses, caps,an so on.

If you need anything, please contact me.

We are a Chinese manufacturer of carbon steel pipe fittings,such as elbows, tees, reducers, crosses, caps, and so on,look forward to business cooperation with you .Pls contact me(LILI) by email: hnxkyib@163.com

Nice and Fantastic blog Boi! This article is beneficial. To purchase Google Workspace, stop by Google Workspace Business Starter Lite to view the available plans, or go to Fourty60 Infotech for additional information.

Dear Manager

Good day

Nice to know you . I am Jasen hope to be your Piping material vendor . We are a leading steel Pipe &fitting Manufacturer and stockist in China.

Our product include:Tube Elbow Bend Tee Cross Reducer Caps Flange

Material: ASTM SA106B API5L GrB X42 X46 X52X56 X60 X70 X80 A179 NACE MR0175 A210C A333 Gr6 Gr9 13CrMo44 10CrMo910 A335 Gr P1 P5 P9 P11 P12 P22 P91 P92 WB36 ASTM 304 304L 310 310S 316 316L 321 321H 317L 904L S31803 S32205 S32654 S32750

Pipe&Pipe fitting Size: OD 1/4″-80″ WT 2-160mm

Flange: 1/2”-48” Class 150- 2500 or as your drawing.

If you have requirement about pipe&fitting from China, pls enquiry to me, competitive price to you.

—

Thanks and Regards

Jasen Xu

Mob/Whatsapp: +8615076705167

Skype: xujiansheng888

Thank you for sharing such a beautiful information with us. Keep sharing. Additionally, Mehta Metalsmanufacture the best product in the world.

Dear Sirs

Iam Sara from China, we are manufacturer for pipe fittings, including elbow, tee,flange,reducer, act.

you can send your enqiury to my email pipefittings@aliyun.com

thanks

Thanks for sharing this buttweld fittings blog with us; it is really helpful. you might also visit this SS Buttweld Fittings

In this article you have explained about the various kinds of Buttweld Fittings like Stainless Steel Butt Weld Elbow, SS Butt Weld Reducer, Stainless Steel Butt Weld Tee and Stainless Steel Butt Weld Cross. I really learnt a lot from this article and I had a great time reading this article. Thank you.

Thank you for sharing this pipe fitting information with us it is very helpful for us. You may also go here.. Kalikund Steel & Engg Co, Stainless Steel Flanges manufacturer, SS Pipe Fittings Manufacturers in India, SS Pipe Fittings Manufacturer

Thank you for sharing this vital information with us and assisting us in meeting our goal. You may also go here.. Kalikund Steel & Engg Co, Stainless Steel Flanges manufacturer, SS Pipe Fittings Manufacturers in India, SS Pipe Fittings Manufacturer, Stainless Steel Flanges Manufacturers, Stainless Steel Flanges Manufacturer in India

Good blog, learned a lot about buttweld fittings

Great blog. Really informative. Thanks a lot for sharing it. Also check out New Era Pipes & Fittings. We are a leading Pipe Fitting Manufacturer in India and around the world. Visit us now at newerapipefittings.com to buy Pipe Fittings, Flanges and other plumbing products at the best prices.

Thank you for sharing this vital information with us and assisting us in meeting our goal. You may also go here.. Sanjay Metal India, Stainless Steel Flanges manufacturer, SS Pipe Fittings Manufacturers in India, SS Pipe Fittings Manufacturer, Stainless Steel Flanges Manufacturers, Stainless Steel Flanges Manufacturer in India

We specialised ourselves with the blessings of our beloved His Holiness Dr. Syedna Mohammed Burhanuddin Saheb (TUS) and under the guidance of Late S k Mohammed Bhai Calcuttawala, Late Siraj S k Mohammed Bhai Calcuttawala, Fakhruddin Siraj Calcuttawala offers Flanges, Butt Weld Fittings, Forged Fittings, Branch Outlets, G I Pipe Fittings, Pipe & Pipe Fittings, Valves, Boiler Mounting Pipe & Fittings Valves Under One Roof.

If you have any questions or need help, feel free to contact 9339842438.

Our Company was Established in the year 1968 as S. Nomi & Co. to form a house of Industrial products imported from the best sources on the Globe. Later as India developed its resources and steel & allied products, we established ourselves with these indigenous quality products.

9062842438

Email: info@snomi.in

very useful words

nice words

thanks for sharing

Hello, thank you. We used your good article. Please visit my site and read about welding fitting.

The bog is very informative and well written

This article is very informative

Great content , it is very useful

Dear Sir,

Please share your best prices for the following:

Item End user code Materials Qty: Origin

1 Carbon steel Elbow 10″ 45 degree SCH 40 10

2 Carbon steel Elbow 10″ 90 degree SCH 40 20

3 Carbon steel Elbow 12″ 45 degree SCH 40 8

4 Carbon steel Elbow 12″ 90 degree SCH 40 20

5 Carbon steel Elbow 14″ 45 degree SCH 40 8

6 Carbon steel Elbow 14″ 90 degree SCH 40 10

7 Carbon steel Elbow 16″ 45 degree SCH 40 8

8 Carbon steel Elbow 16″ 90 degree SCH 40 10

9 Carbon steel Elbow 18″ 45 degree SCH 40 8

10 Carbon steel Elbow 18″ 90 degree SCH 40 10

11 Carbon steel Elbow 20″ 45 degree SCH 40 8

12 Carbon steel Elbow 20″ 90 degree SCH 40 10

13 Carbon steel Elbow 24″ 45 degree SCH 40 8

14 Carbon steel Elbow 24″ 90 degree SCH 40 10

15 Carbon steel Elbow 28″ 45 degree SCH 40 8

16 Carbon steel Elbow 28″ 90 degree SCH 40 10

17 Carbon steel Elbow 2″ 45 degree SCH 40 50

18 Carbon steel Elbow2″ 90 degree SCH 40 100

19 Carbon steel Elbow 3″ 45 degree SCH 40 50

20 Carbon steel Elbow 3″ 90 degree SCH 40 100

21 Carbon steel Elbow 4″ 45 degree SCH 40 50

22 Carbon steel Elbow 4″ 90 degree SCH 40 100

23 Carbon steel Elbow 5″ 45 degree SCH 40 10

24 Carbon steel Elbow 5″ 90 degree SCH 40 20

25 Carbon steel Elbow 6″ 45 degree SCH 40 25

26 Carbon steel Elbow 6″ 90 degree SCH 40 50

27 Carbon steel Elbow 8″ 45 degree SCH 40 25

28 Carbon steel Elbow 8″ 90 degree SCH 40 50

Note:

1. Quotation as proforma invoice with details

2. Name & Origin of the manufacturer:

3. Product shall be from G.C.C, USA, UK, Canada, South Korea, Japan, European Country Of Origin

Union Countries, or Australia.

4. Material Test Certificate as per EN10204-3.1 (or) equivalent to be provided along with material delivery.

5. All items to be supply Black Carbon Steel Schedule 40 ASTM A53/A106, should be mentioned in your offer.

6. Total CFR Kuwait Shuwaikh port by sea price & Weight & volume

7. Delivery date to Kuwait port

8. Price validity – 90 days from 17/02/2021

Best regards,

Please contact me – mktg.aristo@gmail.com

Dear Sir,

Asalam wale kum bhaijaan

We Counting upon our excellent sourcing capabilities and rich industry experience, we, Bidasar Forge Industries, have become the foremost choice of a large number of buyers in the national market segment. we have scaled to the newer heights of success owing to our unrelenting efforts and dedication. In two years, we have been able to garner a vast clientele due to the impeccable quality standards of our range of Pipe Fittings. Today, we are well known as a renowned Exporters, Manufacturer, importer, Stockist, and supplier in this cut-throat industry. We are Manufacturing and importing a comprehensive array of Pipe Fittings (Buttweld Fittings, Flanges), Socket Weld Fittings, High-Pressure Fittings, and more.

All these products are at par with superior industrial standards and are widely accepted in various industrial segments. To ensure optimum quality, we procure our entire array from only well-established vendors of the industry. Moreover, our efficient team of procurement personnel makes sure that the products are sourced only after ensuring that those are free from defects. Also, our professionals keep in touch with Our labor Team and ensure that they follow industry recommended guidelines during the entire production process. Furthermore, to ascertain timely deliveries, we have developed a wide distribution network that spans across various locations in the country.

We are able to provide you Quality Material along with the Material Testing Certificate and if required by you we can arrange for Third party Inspection also.

The Products which we can provide for Carbon Steel are as follows:

Pipe Fittings:- Butt weld fittings Tee, Reducers, Caps. (Both seamless and Erw)

In view of the above, we hope you would consider us for requirements in Projects and maintenance by favouring us with your inquires and by registering our name in your approved Vendor’s List.

We once again thank your for your patronage and are looking forward for a long and mutually beneficial relationship with your esteemed organization.

Regards,

Naved Khilji

Bidasar Forge Industries

Direct No:-7339868084

Email:- bidasarforgeind@gmail.co

SUB : REQUEST FOR YOUR REQUIREMENT FOR STAINLESS STEEL, CARBON STEEL, ALLOY STEEL, COPPER ALLOYS & EXOTIC NICKEL ALLOYS IN FORM OF PIPE, TUBE, SHEET, PLATES, FITTINGS & FLANGES

We STELCO INOX INC are Fastest growing International Suppliers & Exporters of Industrial Raw material to world renowned companies in India & abroad, providing them with world class quality material and service. Our products are supplied & accepted by our clients in various sphere of industries ranging from basic industries such as Paper, Textile, Sugar, Dairy, Cement, Engineering to more complex such as Petroleum, Chemicals, Power, Offshore, Onshore & Nuclear Industries.

We have dedicated sources, expertise & full technical know-how to supply quality products as per Client’s basic & special requirements.

We deal in Stainless Steel, Carbon Steel, Alloy Steel, Copper Alloys & Exotic Nickel Alloys in form of Pipe, Tube, Sheet, Plates, Fittings & Flanges. We can fulfill Client’s requirement of all size as we stock huge amount of material from both indigenous & foreign manufactures.

Our major advantage is our qualified workforce, we have pool of specialist in field of Technical, Sales & Logistic, who are fully committed to provide with best solution for your business & can help you solve all your procurement problems.

At STELCO INOX INC Quality is Guaranteed, we take use of innovative & latest available technology to meet client’s full requirements regarding Quality & Value for money.

We hope the information provide on our site to be useful to you & you will forward us your regular enquiry and requirements & provide us with an opportunity to work with your esteem Organisation. If you have any suggestion or query, how we can serve you better please do inform us. your suggestion are heartily welcomed.

Thank you and assuring you our best co-operation always.

Thank you and Warm Regards,

Jayanti K. Metha

+91 922 22 44 084

Description: Description: Description: Description: Description: Description: Description: cid:image001.jpg@01D745B6.2199F020

GST No : 27BBHPM2810H1ZT

STELCO INOX INC

Office No.29, Plot No.156,

2nd Floor,1,Callian Building ,

Khadilkar Road,Kandewadi,

Girgaon,Mumbai-400004

T : +91 92222 44084 / 2381 2828

W : http://www.stelcoinox.com

E : stelcoinox@gmail.com

Dear Sirs

Iam Sara from China, we are manufacturer for pipe fittings, including elbow, tee,flange,reducer, act.

you can send your enqiury to my email pipefittings@aliyun.com

thanks

Dear Manager

Good day

Nice to know you . I am Jasen hope to be your Piping material vendor . We are a leading steel Pipe &fitting Manufacturer and stockist in China.

Our product include:Tube Elbow Bend Tee Cross Reducer Caps Flange

Material: ASTM SA106B API5L GrB X42 X46 X52X56 X60 X70 X80 A179 NACE MR0175 A210C A333 Gr6 Gr9 13CrMo44 10CrMo910 A335 Gr P1 P5 P9 P11 P12 P22 P91 P92 WB36 ASTM 304 304L 310 310S 316 316L 321 321H 317L 904L S31803 S32205 S32654 S32750

Pipe&Pipe fitting Size: OD 1/4″-80″ WT 2-160mm

Flange: 1/2”-48” Class 150- 2500 or as your drawing.

If you have requirement about pipe&fitting from China, pls enquiry to me, competitive price to you.

—

Thanks and Regards

Jasen Xu

Mob/Whatsapp: +8615076705167

Skype: xujiansheng888

We are a Chinese leading manufacturer specializing in carbon steel pipe fittings, including elbows, tees, reducers, crosses, caps,and so on. If you have requirement about pipe&fitting from China, pls enquiry to me, competitive price to you.

Thanks and Regards

LI LI

Email: hnxkyib@163.com

Mob/Wechat +8618736287686

Retrouvez les derniers essais automobiles.

I’m willing to tell you that I appreciated your article, it’s useful for me, and help me have a good sense.

to buy these products please contact me saif@hawkmetalz.com