Learn about Piping, Oil & Gas Equipment, Structural Steel for Free

200+ high-quality educational articles about materials for projects (Piping, Oil & Gas equipment, structural steel) to empower individuals working in the oil and gas, construction, and energy sectors with powerful and free knowledge

The World's #1 Knowledge base

Over 3 million people visit us each year, working for top EPC companies, engineering firms, and oil & gas companies: piping engineers, procurement professionals, quality inspectors, and consultants

Latest Articles

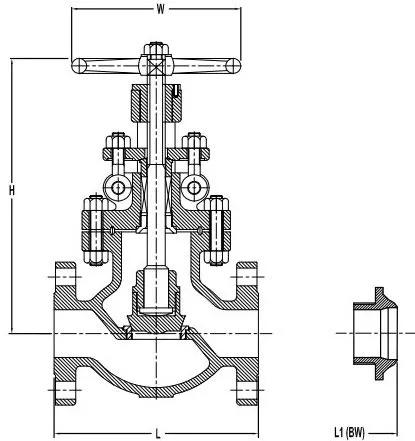

The Most Common Types of Valves in the Oil & Gas Industry (ASME, API)

General overview of valves for oil & gas: what are valves, types, ASME B16.34, and details about control valves…

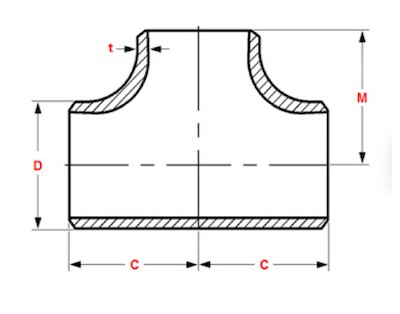

ASME B16.9 Buttweld Fittings for Pipes: Elbow, Tee, Cross, Reducers, Caps Explained

Dive into ASME B16.9 buttweld fittings for piping: types, manufacturing, comparison between seamless and welded, and leading manufacturers…

The 6 Non-Destructive Tests for Piping and Equipment: VI, LP, MP, UT, RX, EC, Eddy Currents

Explore non-destructive testing (NDT) techniques for pipe fittings, ensuring quality and reliability in critical applications (VI, LP, MP, UT, RX, Eddy Currents)…

Buttweld Fittings Materials: Carbon, Alloy, Stainless, Nickel Alloys (ASTM Grades)

Explore ASTM materials for buttweld fittings: Carbon and alloy steel (A234), Stainless Steel (A403), Duplex/Super Duplex (A185), and nickel alloys (B366)…

The Key Valve Components: Exploring Body, Bonnet, Trim, Seats, and Packing

Essential components of valves include body (cast or forged steel), bonnet, trim (wet parts), disc, seat, packing, stem, and various actuation mechanisms…

ASTM Materials for Valves: ASTM A216, A351, A352, A105, and A182 (Cast & Forged Grades)

Explore ASTM valve material specifications like A216 WCB, A352 LCB, A351 CF8/8M for cast steel valves, and A105, A182 for forged ones + trim charts and service recommendations by grade…

Understand Gate Valves (API 600, 602, 603)

Dive into gate valves for piping: definitions, types, distinctions from ball and globe valves, and specifications like API 600/602/603. Explore diagrams and dimensional considerations…

Buttweld Fittings Dimensions & Weights Charts by Type (ASME B16.9)

Explore dimensions and weights of ASME B16.9 buttweld fittings: 45/90-degree elbows, equal/reducing tees, pipe caps, concentric/eccentric reducers…