The article shows the ASME B16.5 dimensions of Slip-On Flanges Classes from 150 to 2500 (NPS, ID, OD, Thickness, and bolting details, tolerances) – in millimeters.

ASME SLIP-ON FLANGE DIMENSIONS & WEIGHTS

The article shows the ASME B16.5 dimensions and weights for slip-on flanges.

SLIP-ON FLANGE SIZES IN MILLIMETERS

SLIP-ON CLASS 150

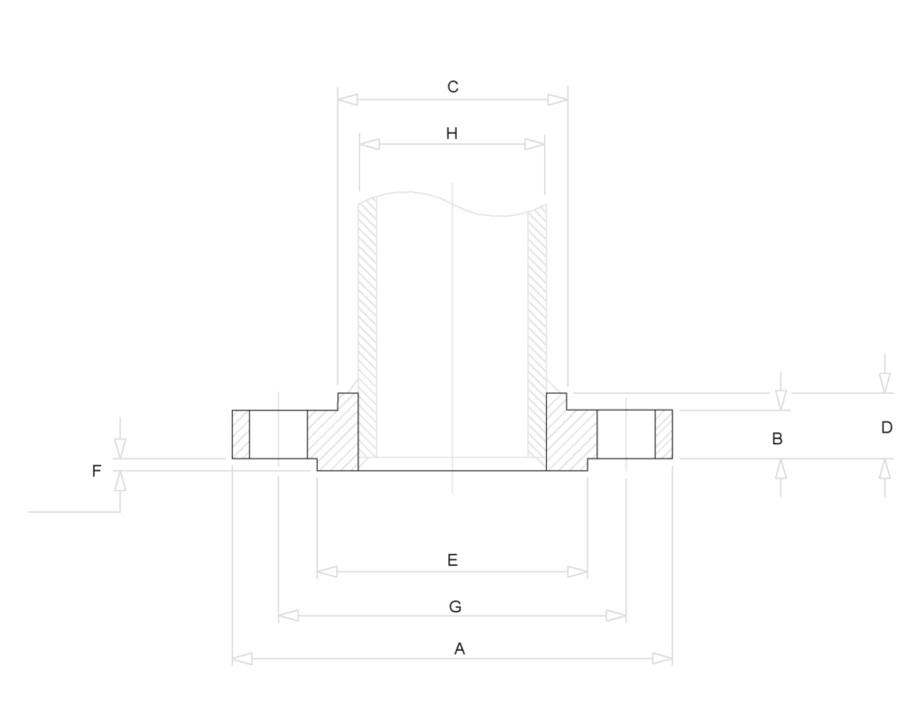

| NPS | DN | OD (mm) | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

SLIP-ON CLASS 300

| NPS | DN | OD (mm) | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21 | 34.9 | 2 | 66.7 | 22.2 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 14.3 | 48 | 24 | 42.9 | 2 | 82.6 | 27.7 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 54 | 25 | 50.8 | 2 | 88.9 | 34.5 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 25 | 63.5 | 2 | 98.4 | 43.2 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 29 | 73 | 2 | 114.3 | 49.5 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 84 | 32 | 92.1 | 2 | 127 | 61.9 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 37 | 104.8 | 2 | 149.2 | 74.6 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 27 | 117 | 41 | 127 | 2 | 168.3 | 90.7 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 43 | 139.7 | 2 | 184.2 | 103.4 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 7.7 |

| 4 | 100 | 255 | 30.2 | 146 | 46 | 157.2 | 2 | 200 | 116.8 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 10 |

| 5 | 125 | 280 | 33.4 | 178 | 49 | 185.7 | 2 | 235 | 144.4 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 12.7 |

| 6 | 150 | 320 | 35 | 206 | 51 | 215.9 | 2 | 269.9 | 171.4 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 17.7 |

| 8 | 200 | 380 | 39.7 | 260 | 60 | 269.9 | 2 | 330.2 | 222.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 26 |

| 10 | 250 | 445 | 46.1 | 321 | 65 | 323.8 | 2 | 387.4 | 277.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 36 |

| 12 | 300 | 520 | 49.3 | 375 | 71 | 381 | 2 | 450.8 | 328.2 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 52 |

| 14 | 350 | 585 | 52.4 | 425 | 75 | 412.8 | 2 | 514.4 | 360.2 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 75 |

| 16 | 400 | 650 | 55.6 | 483 | 81 | 469.9 | 2 | 571.5 | 411.2 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 86 |

| 18 | 450 | 710 | 58.8 | 533 | 87 | 533.4 | 2 | 628.6 | 462.3 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 113 |

| 20 | 500 | 775 | 62 | 587 | 94 | 584.2 | 2 | 685.8 | 514.4 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 143 |

| 24 | 600 | 915 | 68.3 | 702 | 105 | 692.2 | 2 | 812.8 | 616 | 24 | 1 1/2 | 205 |

SLIP-ON CLASS 400

| NPS | DN | OD (mm) | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.5 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 255 | 35 | 146 | 51 | 157.2 | 7 | 200 | 116.1 | 8 | 7/8 | 140 | 1 | M24 | 11.8 |

| 5 | 125 | 280 | 38.1 | 178 | 54 | 185.7 | 7 | 235 | 143.8 | 8 | 7/8 | 145 | 1 | M24 | 14.1 |

| 6 | 150 | 320 | 41.3 | 206 | 57 | 215.9 | 7 | 269.9 | 170.7 | 12 | 7/8 | 150 | 1 | M24 | 20 |

| 8 | 200 | 380 | 47.7 | 260 | 68 | 269.9 | 7 | 330 | 221.5 | 12 | 1 | 170 | 1 1/8 | M27 | 31 |

| 10 | 250 | 445 | 54 | 321 | 73 | 323.8 | 7 | 387.4 | 276.2 | 16 | 1 1/8 | 190 | 1 1/4 | M30 | 42 |

| 12 | 300 | 520 | 57.2 | 375 | 79 | 381 | 7 | 450.8 | 327 | 16 | 1 1/4 | 205 | 1 3/8 | M33 | 59 |

| 14 | 350 | 585 | 60.4 | 425 | 84 | 412.8 | 7 | 514.4 | 359.2 | 20 | 1 1/4 | 210 | 1 3/8 | M33 | 82 |

| 16 | 400 | 650 | 63.5 | 483 | 94 | 469.9 | 7 | 571.5 | 410.5 | 20 | 1 3/8 | 220 | 1 1/2 | M36 | 107 |

| 18 | 450 | 710 | 66.7 | 533 | 98 | 533.4 | 7 | 628.6 | 461.8 | 24 | 1 3/8 | 230 | 1 1/2 | M36 | 130 |

| 20 | 500 | 775 | 69.9 | 587 | 102 | 584.2 | 7 | 685.8 | 513.1 | 24 | 1 1/2 | 240 | 1 3/4 | M39 | 157 |

| 24 | 600 | 915 | 76.2 | 702 | 114 | 692.2 | 7 | 812.8 | 616 | 24 | 1 3/4 | 265 | 1 7/8 | M45 | 232 |

SLIP-ON CLASS 600

| NPS | DN | OD (mm) | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 275 | 38.1 | 152 | 54 | 157.2 | 7 | 215.9 | 116.1 | 8 | 7/8 | 145 | 1 | M24 | 16.8 |

| 5 | 125 | 330 | 44.5 | 189 | 60 | 185.7 | 7 | 266.7 | 143.8 | 8 | 1 | 165 | 1 1/8 | M27 | 29 |

| 6 | 150 | 355 | 47.7 | 222 | 67 | 215.9 | 7 | 292.1 | 170.7 | 12 | 1 | 170 | 1 1/8 | M27 | 36 |

| 8 | 200 | 420 | 55.6 | 273 | 76 | 269.9 | 7 | 349.2 | 221.5 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 52 |

| 10 | 250 | 510 | 63.5 | 343 | 86 | 323.8 | 7 | 431.8 | 276.2 | 16 | 1 1/4 | 215 | 1 3/8 | M33 | 77 |

| 12 | 300 | 560 | 66.7 | 400 | 92 | 381 | 7 | 489 | 327 | 20 | 1 1/4 | 220 | 1 3/8 | M33 | 91 |

| 14 | 350 | 605 | 69.9 | 432 | 94 | 412.8 | 7 | 527 | 359.2 | 20 | 1 3/8 | 235 | 1 1/2 | M36 | 105 |

| 16 | 400 | 685 | 76.2 | 495 | 106 | 469.9 | 7 | 603.2 | 410.5 | 20 | 1 1/2 | 255 | 1 5/8 | M39 | 150 |

| 18 | 450 | 745 | 82.6 | 546 | 117 | 533.4 | 7 | 654 | 461.8 | 20 | 1 5/8 | 275 | 1 3/4 | M42 | 182 |

| 20 | 500 | 815 | 88.9 | 610 | 127 | 584.2 | 7 | 723.9 | 513.1 | 24 | 1 5/8 | 285 | 1 3/4 | M42 | 232 |

| 24 | 600 | 940 | 101.6 | 718 | 140 | 692.2 | 7 | 838.2 | 616 | 24 | 1 7/8 | 330 | 2 | M48 | 332 |

SLIP-ON CLASS 900

| NPS | DN | OD (mm) | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.6 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 104.8 | 7 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.5 |

| 3 | 80 | 240 | 38.1 | 127 | 54 | 127 | 7 | 190.5 | 90.7 | 8 | 7/8 | 145 | 1 | M24 | 12 |

| 4 | 100 | 290 | 44.5 | 159 | 70 | 157.2 | 7 | 235 | 116.1 | 8 | 1 1/8 | 170 | 1 1/4 | M30 | 24 |

| 5 | 125 | 350 | 50.8 | 190 | 79 | 185.7 | 7 | 279.4 | 143.8 | 8 | 1 1/4 | 190 | 1 3/8 | M33 | 38 |

| 6 | 150 | 380 | 55.6 | 235 | 86 | 215.9 | 7 | 317.5 | 170.7 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 50 |

| 8 | 200 | 470 | 63.5 | 298 | 102 | 269.9 | 7 | 393.7 | 221.5 | 12 | 1 3/8 | 220 | 1 1/2 | M36 | 78 |

| 10 | 250 | 545 | 69.9 | 368 | 108 | 323.8 | 7 | 469.9 | 276.2 | 16 | 1 3/8 | 235 | 1 1/2 | M36 | 112 |

| 12 | 300 | 610 | 79.4 | 419 | 117 | 381 | 7 | 533.4 | 327 | 20 | 1 3/8 | 255 | 1 1/2 | M36 | 148 |

| 14 | 350 | 640 | 85.8 | 451 | 130 | 412.8 | 7 | 558.8 | 359.2 | 20 | 1 1/2 | 275 | 1 5/8 | M39 | 182 |

| 16 | 400 | 705 | 88.9 | 508 | 133 | 469.9 | 7 | 616 | 410.5 | 20 | 1 5/8 | 285 | 1 3/4 | M42 | 193 |

| 18 | 450 | 785 | 101.6 | 565 | 152 | 533.4 | 7 | 685.8 | 461.8 | 20 | 1 7/8 | 325 | 2 | M48 | 258 |

| 20 | 500 | 855 | 108 | 622 | 159 | 584.2 | 7 | 749.3 | 513.1 | 20 | 2 | 350 | 2 1/8 | M52 | 317 |

| 24 | 600 | 1040 | 139.7 | 749 | 203 | 692.2 | 7 | 901.7 | 616 | 20 | 2 1/2 | 440 | 2 5/8 | M64 | 608 |

SLIP-ON CLASS 1500

| NPS | DN | OD (mm) | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | Bolts # | Bolt Size UNC | RF Stud Length | Hole Size | Metric Studs | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.7 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 9.8 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 104.8 | 7 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.4 |

SLIP-ON FLANGE TOLERANCE

ASME B16.5 provides specific tolerances for slip-on flanges across various dimensions to ensure proper fit, alignment, and sealing capability within piping systems. While it’s important to refer directly to the ASME B16.5 standard for comprehensive and specific tolerance values due to variations across different flange sizes and pressure classes, below are general examples of tolerances for slip-on flanges as outlined in the standard:

Diameter of Bolt Circle (P):

The tolerance for the diameter of the bolt circle is typically ±1.6 mm (±1/16 inch) for flanges up to and including NPS 24.

Diameter of Bolt Holes (Q):

The diameter of bolt holes is generally oversized to allow for ease of alignment and assembly, with a common tolerance of +3 mm (1/8 inch) on the nominal bolt hole size.

Flange Thickness (T):

Tolerance for flange thickness can vary, but a general guideline for flanges up to NPS 24 is ±3 mm (±1/8 inch), depending on the pressure class and size of the flange.

Hub Length (Length through Hub, Y):

For slip-on flanges, the hub length tolerance can be important, especially for alignment during welding. Tolerances can vary but might be around ±1.6 mm (±1/16 inch) for smaller sizes.

Outside Diameter (O):

Tolerance for the outside diameter of a slip-on flange might be around ±1.6 mm (±1/16 inch) for sizes up to NPS 24, ensuring the flange fits within standardized fittings and equipment.

Bore Diameter (B):

The tolerance of the bore diameter ensures the flange does not restrict flow or create turbulence. Tolerances vary by size and class but could be in the range of -0 mm/+3 mm (-0 inch/+1/8 inch) for smaller flanges.

Facing Finish:

The surface finish of the flange face where the gasket seats is critical for ensuring a proper seal. ASME B16.5 specifies the surface finish in terms of Ra (Roughness Average), with specific values depending on the type of gasket and sealing surface.

It’s important to consult the latest edition of the ASME B16.5 standard or work with a qualified engineer to obtain the exact tolerance values for the specific slip-on flanges being used in a project. Adherence to these tolerances is critical for the safety, reliability, and efficiency of piping systems.

SLIP-ON FLANGE WEIGHTS

SLIP-ON FLANGE WEIGHT in KGS.

The table shows the ASME B16.5 slip-on flange weights in Kgs. by Flange NPS and Class (carbon/alloy steel materials; for higher grades, consider adjusting weight using the delta-specific weight carbon/other grades)

| NPS | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 |

| 1/2 | 0.5 | 0.9 | 0.9 | 0.9 | 2.7 | 2.7 |

| 3/4 | 0.9 | 1.4 | 1.4 | 1.4 | 2.7 | 2.7 |

| 1 | 0.9 | 1.4 | 1.6 | 1.8 | 3.4 | 3.6 |

| 1¼ | 1.4 | 2 | 2 | 2.3 | 4.5 | 4.5 |

| 1½ | 1.4 | 2.9 | 2.9 | 3.2 | 6.3 | 6.3 |

| 2 | 2.3 | 3.2 | 3.6 | 4.1 | 9.9 | 11.3 |

| 2½ | 3.6 | 4.5 | 5.4 | 5.9 | 13.9 | 16.2 |

| 3 | 4.1 | 5.9 | 6.8 | 7.2 | 16.2 | 21.6 |

| 3½ | 4 | 7.7 | 9.5 | 9.5 | ||

| 4 | 5.9 | 10.6 | 11.7 | 16.7 | 23.9 | 32.9 |

| 5 | 6.8 | 13 | 13.9 | 28.4 | 37.4 | 59.4 |

| 6 | 8.6 | 17.6 | 19.8 | 36 | 49.5 | 74.3 |

| 8 | 13.5 | 26.1 | 30.2 | 51.8 | 77.4 | 117 |

| 10 | 19.4 | 36.5 | 40 | 79.7 | 110.3 | 196.2 |

| 12 | 28.8 | 51.8 | 58.5 | 96.8 | 146.7 | 300.2 |

| 14 | 40.5 | 74.3 | 85 | 116.6 | 180 | 423 |

| 16 | 47.7 | 94.5 | 113.9 | 164.7 | 206.6 | 562.5 |

| 18 | 58.5 | 113.9 | 139.5 | 214.2 | 291.2 | 731.3 |

| 20 | 74.3 | 141.8 | 170.1 | 275.4 | 356.4 | 922.5 |

| 22 | 83.3 | 166.5 | 182.3 | 265.5 | ||

| 24 | 99 | 220.5 | 242.6 | 394.2 | 666 | 1271 |

SLIP-ON FLANGE WEIGHT in LBS.

The table shows the ASME B16.5 slip-on flange weights in Lbs. by Flange NPS and Class (carbon/alloy steel materials; for higher grades, consider adjusting weight using the delta-specific weight carbon/other grades)

| CLASS 150 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 1 | |

| ¾ | 2 | |

| 1 | 2 | |

| 1¼ | 3 | |

| 1½ | 3 | |

| 2 | 5 | |

| 2½ | 8 | |

| 3 | 9 | |

| 3½ | 11 | |

| 4 | 13 | |

| 5 | 15 | |

| 6 | 19 | |

| 8 | 30 | |

| 10 | 43 | |

| 12 | 64 | |

| 14 | 90 | |

| 16 | 106 | |

| 18 | 130 | |

| 20 | 165 | |

| 22 | 185 | |

| 24 | 220 | |

| CLASS 300 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 2 | |

| ¾ | 3 | |

| 1 | 3 | |

| 1¼ | 4.5 | |

| 1½ | 6.5 | |

| 2 | 7 | |

| 2½ | 10 | |

| 3 | 13 | |

| 3½ | 17 | |

| 4 | 23.5 | |

| 5 | 29 | |

| 6 | 39 | |

| 8 | 58 | |

| 10 | 81 | |

| 12 | 115 | |

| 14 | 165 | |

| 16 | 210 | |

| 18 | 253 | |

| 20 | 315 | |

| 22 | 370 | |

| 24 | 490 | |

| CLASS 400 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 2 | |

| ¾ | 3 | |

| 1 | 3.5 | |

| 1¼ | 4.5 | |

| 1½ | 6.5 | |

| 2 | 8 | |

| 2½ | 12 | |

| 3 | 15 | |

| 3½ | 21 | |

| 4 | 26 | |

| 5 | 31 | |

| 6 | 44 | |

| 8 | 67 | |

| 10 | 91 | |

| 12 | 130 | |

| 14 | 191 | |

| 16 | 253 | |

| 18 | 310 | |

| 20 | 378 | |

| 22 | 405 | |

| 24 | 539 | |

| CLASS 600 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 2 | |

| ¾ | 3 | |

| 1 | 4 | |

| 1¼ | 5 | |

| 1½ | 7 | |

| 2 | 9 | |

| 2½ | 13 | |

| 3 | 16 | |

| 3½ | 21 | |

| 4 | 37 | |

| 5 | 63 | |

| 6 | 80 | |

| 8 | 115 | |

| 10 | 177 | |

| 12 | 215 | |

| 14 | 259 | |

| 16 | 366 | |

| 18 | 476 | |

| 20 | 612 | |

| 22 | 590 | |

| 24 | 876 | |

| CLASS 900 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 6 | |

| ¾ | 6 | |

| 1 | 7.5 | |

| 1¼ | 10 | |

| 1½ | 14 | |

| 2 | 22 | |

| 2½ | 31 | |

| 3 | 36 | |

| 4 | 53 | |

| 5 | 83 | |

| 6 | 110 | |

| 8 | 172 | |

| 10 | 245 | |

| 12 | 326 | |

| 14 | 400 | |

| 16 | 459 | |

| 18 | 647 | |

| 20 | 792 | |

| 24 | 1480 | |

| CLASS 1500 | Nominal Pipe Size | Slip On Weight in Lbs./unit |

| ½ | 6 | |

| ¾ | 6 | |

| 1 | 8 | |

| 1¼ | 10 | |

| 1½ | 14 | |

| 2 | 25 | |

| 2½ | 36 | |

| 3 | 48 | |

| 4 | 73 | |

| 5 | 132 | |

| 6 | 165 | |

| 8 | 260 | |

| 10 | 436 | |

| 12 | 667 | |

| 14 | 940 | |

| 16 | 1250 | |

| 18 | 1625 | |

| 20 | 2050 | |

| 24 | 2825 |