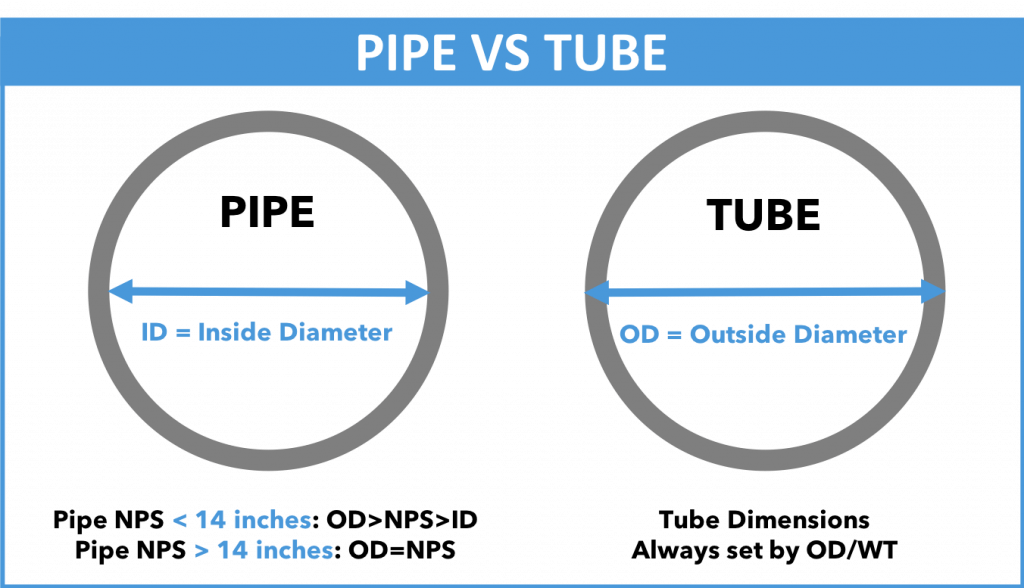

This article addresses two frequently asked questions: “What is the difference between ‘pipe’ and ‘tube’,” and “What distinguishes ‘tube’ from ‘tubing’?” In summary: A PIPE refers to a round tubular section designed for the transport of fluids and gases, identified by nominal pipe size (NPS or DN), which gives an approximate measure of the pipe’s fluid carrying capacity; a TUBE can be round, rectangular, square, or oval in shape, and its dimensions are specified by the outside diameter (“OD”) and wall thickness (“WT”), measured in inches or millimeters; TUBING generally denotes the broader category encompassing various types of tubes.

“PIPE” VS “TUBE” VS “TUBING”

The terms “pipe,” “tube,” and “tubing” are often used interchangeably in casual conversation, but they refer to distinct entities in engineering and industrial contexts. Understanding the differences is crucial for selecting the right material and specification for specific applications.

Here’s a concise differentiation:

PIPE

- Shape: A pipe is a cylindrical hollow section.

- Purpose: Primarily used for transporting fluids, gases, and/or solids from one location to another.

- Dimensions: Specified by its nominal size (NPS), which correlates to the pipe’s inner diameter (ID) but isn’t its actual dimension. The schedule number indicates the wall thickness. In the oil & gas industry, ASME B36.10 and ASME B36.19 specify standard sizes for carbon, alloy, and stainless steel pipes.

- Shape and Customization: Generally available in circular cross-sections and less flexible in terms of custom shapes and sizes.

- Material: Common materials include steel, nickel alloys, non-ferrous materials (like copper), and PVC.

- Application: Pipes are used in industries such as oil and gas, water distribution, plumbing, HVAC (heating, ventilation, and air conditioning), and process piping.

TUBE

- Shape and Customization: Can be found in a variety of shapes beyond circular, including square, rectangular, and oval hollow sections, allowing for more customization in design and engineering projects.

- Purpose: Mainly used for structural applications, but can also be used for the conveyance of fluids and gases. Tubes can serve both functional and aesthetic purposes.

- Dimensions: Specified by the exact outer diameter (OD) and wall thickness (WT), in inches or mm, providing precise dimensions.

- Material: Manufactured from a wide range of materials, including metal, plastic, and glass.

- Application: Tubes are used in a wide range of industries and applications, including construction, manufacturing, automotive, aerospace, instrumentation, and structural engineering.

TUBING

- Purpose: The term “tubing” often refers to flexible or smaller-diameter applications, though it can be used more broadly to describe any tube-like structure used for fluid transport or structural purposes.

- Measurement: Like tubes, tubing is also described by its outer diameter and wall thickness. However, the term is more often associated with flexible materials.

- Shape and Customization: Tubing offers flexibility in both application and material, able to be bent or fitted around structures as needed.

- Material: Includes soft metals, plastics, rubber, and more, accommodating a range of flexibility and durability needs.

SUMMARY

While the term “pipe” is predominantly associated with the transportation of fluids and gases and is defined by nominal sizes and schedules (NPS/SCH), “tube” and “tubing” emphasize precise engineering dimensions and material flexibility (OD/WT). “Tube” often pertains to structural and mechanical applications with exact size specifications, whereas “tubing” suggests a broader, sometimes more flexible, application, including both fluid transport and structural usage in diverse materials.

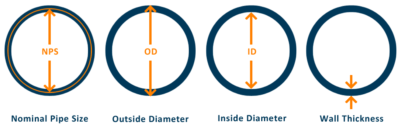

INSIDE DIAMETER VS OUTSIDE DIAMETER

The terms “inside diameter” (ID) and “outside diameter” (OD) refer to measurements of the diameter of a cylindrical object, such as a pipe or tube, and they describe different aspects of the object’s dimensions:

Inside Diameter (ID):

- The inside diameter (ID) is the measurement of the diameter of the inner surface of a cylindrical object, such as the hollow interior of a pipe or tube.

- In the context of pipes or tubes, the inside diameter (ID) represents the distance across the widest part of the inner circular cross-section of the pipe or tube.

- The inside diameter (ID) is often used to determine the flow capacity of a pipe or tube, as it directly affects the volume of fluid or material that can pass through the conduit.

Outside Diameter (OD):

- The outside diameter (OD) is the measurement of the diameter of the outer surface of a cylindrical object, such as the outer circumference of a pipe or tube.

- In the context of pipes or tubes, the outside diameter (OD) represents the distance across the widest part of the outer circular cross-section of the pipe or tube.

- The outside diameter (OD) is commonly used to specify the size and dimensions of pipes or tubes, as it provides a reference for fitting, joining, or connecting the conduit with other components.

In summary, the inside diameter (ID) refers to the measurement of the diameter of the inner surface of a cylindrical object, while the outside diameter (OD) refers to the measurement of the diameter of the outer surface of the object. These measurements are essential for determining the size, dimensions, and flow capacity of pipes, tubes, and other cylindrical components used in various industries and applications.

Now, let’s delve into the details of the differences between pipes and tubes.

WHAT IS A PIPE?

The pipe outside diameter (OD) does not match the nominal size for pipes below NPS 14 inches (a 2-inch pipe, for instance, has an internal flow capacity of approximately 2 inches, but has an outside diameter of 2.375 inches).

For pipes of a given NPS, the pipe outside diameter is fixed, whereas the pipe inside diameter decreases by increasing schedule values (pipe wall thickness).

The most important mechanical parameters for pipes are the pressure rating, the yield strength, and the ductility.

The standard combinations of pipe nominal diameter and wall thickness (schedule) are covered by the ASME B36.10 and ASME B36.19 specifications (respectively, carbon and alloy pipes, and stainless steel pipes).

PIPE INSIDE DIAMETER CALCULATOR

As mentioned, the outside diameter of pipes of a specific NPS is constant but the inside diameter of the pipe (ID) changes depending on the pipe schedule.

The pipe ID can be easily calculated, as long as the pipe NPS and schedule are known.

The pipe ID can be calculated by deducting from the pipe NPS the pipe wall thickness multiplied by 2 (the pipe WT can be taken from the schedule).

Example: for a 12 NPS pipe (DN 300 mm), schedule 40, the pipe outside diameter and the wall thickness are 12.75 inches (324 mm) and 0.406 inches (10.4 mm).

Therefore, the pipe ID (internal diameter) is 12.75 inches – 2 x 0.406 inches = 11.94 inches, or Pipe ID = 324 mm – 2 x 10.4 mm = 303.2 mm.

It should be noted that this calculation is just theoretical, as pipes have a wall thickness tolerance which is generally +/-12.5% for ASME pipes. Hence the actual ID of a given pipe may differ by +/- 12,5% from the theoretical value.

The pipe ID calculator is available on this page.

WHAT IS A TUBE?

The word “tube” refers to round, square, rectangular, and oval hollow sections used for pressure equipment, for mechanical applications, and for instrumentation systems.

Tubes are designated by their outside diameter and wall thickness, which are exact measures in inches or millimeters. For tubes, the difference between the outside diameter and the wall thickness, multiplied by two, defines the inside diameter of the tube.

The most important physical properties of steel tubes are hardness, tensile strength, and low manufacturing tolerances.

PIPE VS TUBE, 10 BASIC DIFFERENCES

| PIPE VS TUBE | STEEL PIPE | STEEL-TUBE | |

| 1 | Key Dimensions (Pipe and Tube Size Chart) | The most important dimension for a pipe is the inside diameter (ID), expressed in NPS (nominal pipe size) or DN (nominal diameter), which defines its fluid conveyance capacity. The NPS does not match the true inside diameter, it is a rough indication | The most important dimensions for a steel tube are the outside diameter (OD) and the wall thickness (WT). These parameters are expressed in inches or millimeters and express the true dimensional value of the hollow section. |

| 2 | Wall Thickness | The thickness of a steel pipe is designated with a “Schedule” value (the most common are Sch. 40, Sch. STD., Sch. XS/XH, Sch. XXS). Two pipes of different NPS and same schedule have different wall thicknesses in inches or millimeters. | The wall thickness of a steel tube is expressed in inches or millimeters. For tubing, the wall thickness is measured also with a gage nomenclature (BWG, SWG). |

| 3 | Types of Pipes and Tubes (Shapes) | Round only | Round, rectangular, square, oval |

| 4 | Production range | Extensive (up to 80 inches and above) | A narrower range for tubing (up to 5 inches), larger for steel tubes for mechanical applications |

| 5 | Tolerances (straightness, dimensions, roundness, etc) and Pipe vs. Tube strength | Tolerances are set, but rather loose. Strength is not the major concern. | Steel tubes are produced to very strict tolerances. Tubulars undergo several dimensional quality checks, such as straightness, roundness, wall thickness, and surface, during the manufacturing process. Mechanical strength is a major concern for tubes. |

| 6 | Production Process | Pipes are generally made to stock with highly automated and efficient processes, i.e. pipe mills produce on a continuous basis and feed distributors stock around the world. | Tube manufacturing is more lengthy and laborious |

| 7 | Delivery time | Can be short | Generally longer |

| 8 | Market price | Relatively lower price per ton than steel tubes | Higher due to lower mill productivity per hour, and due to the stricter requirements in terms of tolerances and inspections |

| 9 | Materials | A wide range of materials is available | Tubing is available in carbon steel, low alloy, stainless steel, and nickel alloys; steel tubes for mechanical applications are mostly of carbon steel |

| 10 | End Connections | The most common are beveled and plain ends | Threaded and grooved ends are available for quicker connections on-site |

Difference between pipe and tube.pdf

Conclusion

Pipes and tubes are both cylindrical hollow structures used for conveying fluids, gases, and solids in various industries and applications. While they share some similarities, there are distinct differences between pipes and tubes in terms of their manufacturing, dimensions, tolerances, and applications. Here’s a comparison of pipes and tubes:

Manufacturing Process:

- Pipes: Pipes are typically manufactured using processes such as seamless extrusion, welding (ERW, LSAW, etc.), or casting. These processes involve forming a solid cylindrical shape and then shaping it into a hollow tube by removing material (seamless) or welding together steel plates or coils (welded).

- Tubes: Tubes are manufactured using similar processes as pipes, including seamless extrusion and welding. However, tubes may also be produced by drawing, where a solid metal billet or hollow shell is pulled through a die to achieve the desired dimensions and tolerances.

2. Dimensions:

- Pipes: Pipes are characterized by their nominal pipe size (NPS), which refers to the approximate inside diameter (ID) of the pipe. Pipe sizes are standardized based on the NPS system, with common sizes ranging from 1/8 inch to 36 inches or larger.

- Tubes: Tubes are measured based on their outside diameter (OD) and wall thickness. Tube sizes are specified in terms of OD and wall thickness, with dimensions typically expressed in inches or millimeters. Tubes may have thinner walls compared to pipes of similar diameter.

3. Tolerances:

- Pipes: Pipes have tighter dimensional tolerances compared to tubes, particularly in terms of roundness, straightness, and wall thickness. This is because pipes are designed for specific applications where precise dimensions are critical, such as fluid flow and pressure containment.

- Tubes: Tubes may have looser tolerances compared to pipes, allowing for greater variation in dimensions. This is because tubes are often used in applications where dimensional accuracy is less critical, such as structural components, mechanical tubing, and heat exchangers.

4. Applications:

- Pipes: Pipes are primarily used for conveying fluids, gases, and solids in various industries and applications, including oil and gas, water distribution, plumbing, HVAC (heating, ventilation, and air conditioning), and process piping. Pipes are designed to withstand high-pressure and corrosive environments, making them suitable for critical applications.

- Tubes: Tubes have a wider range of applications compared to pipes and are used in industries such as construction, manufacturing, automotive, aerospace, and instrumentation. Tubes are commonly used for structural components, mechanical tubing, heat exchangers, hydraulic systems, and architectural elements.

In summary, while pipes and tubes serve similar purposes as conduits for conveying fluids and materials, they differ in terms of their manufacturing, dimensions, tolerances, and applications. Pipes are characterized by their nominal pipe size and tighter dimensional tolerances, while tubes are measured based on their outside diameter and may have looser tolerances. Both pipes and tubes play essential roles in various industries and applications, offering versatile solutions for fluid handling, structural support, and mechanical systems.

2 Responses

Well written article! also visit our page:Stainless steel pipes supplier

With the help of this article I have clearly understood the difference between a Stainless Steel Pipe and a Stainless Steel Tube