The “flange rating” (or Class) indicates the maximum pressure, measured in psi or bars, that a flange can endure at rising temperatures. Higher-rated flanges exhibit greater strength, i.e. are capable of withstanding more pressure, than lower-rated flanges (at the same temperature). The pressure-temperature performance (max allowed pressure at a given temperature) varies across flanges made of different materials. The article explains the concept of flange pressure rating, and shows the ASME B16.5/B16.34 pressure rating charts for flanges in different material groups (carbon, low-alloy, stainless/duplex/superduplex steel).

FLANGE PRESSURE RATING

WHAT MEANS FLANGE PRESSURE RATING?

The flange pressure rating, often referred to as the “Class,” signifies the maximum pressure (measured in bars or psi) that a flange can safely handle at specified (increasing) temperatures (measured in Fahrenheit or Celsius). This rating is crucial for ensuring that the flange, and therefore the piping system to which it is attached, can operate safely under the expected service conditions without the risk of failure.

Pressure ratings are standardized and categorized into various classes, each representing a maximum pressure capacity measured in pounds per square inch (psi) or bars by temperature. The most common rating classes defined by the American National Standards Institute (ANSI/ASME B16.5) and the American Society of Mechanical Engineers (ASME) include Class 150, 300, 600, 900, 1500, and 2500, with the number roughly indicating the maximum pressure the flange can withstand at the temperature of 100°F (38°C).

Class, #, Lb: Synonyms for Pressure Class!

The terms “pressure rating”, “Class”, “#”, “Lb” or “Lbs” are interchangeable, i.e. they all refer to the same exact concept of pressure/temperature performance of a flange (and other equipment like valves, fittings, etc). Note that the designations 150 to 2500 do not refer to any specific measurement and that these values are just conventional and dimensionless (they do not indicate any specific, measurable, pressure value like psi/bar).

It’s important to note that as the temperature increases, the maximum pressure that a flange can handle typically decreases. Therefore, the selection of a flange with an appropriate pressure rating requires consideration of both the operating pressure and temperature of the system. This ensures the integrity and safety of the piping network in various industrial applications, such as chemical processing, oil and gas, and power generation.

A PRACTICAL EXAMPLE

Let’s make the concept of flange pressure rating clear with a practical example:

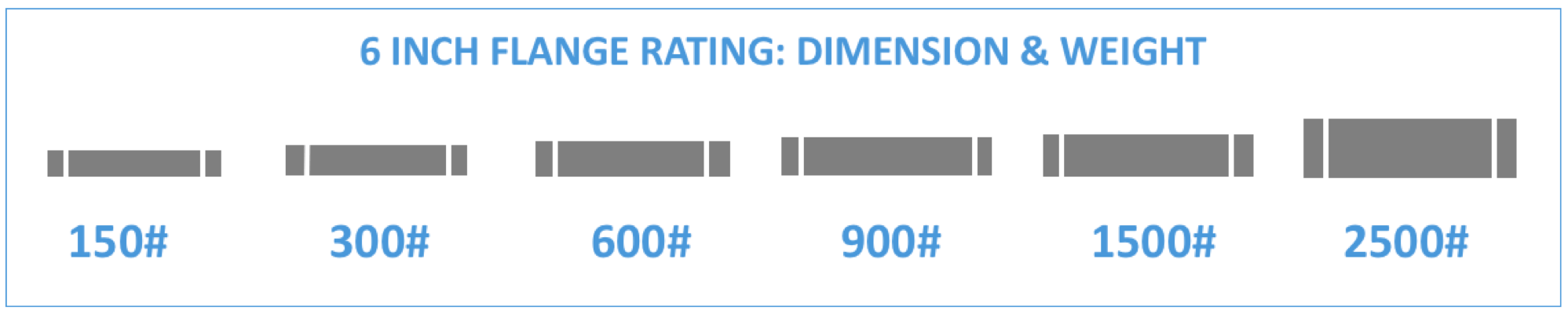

When comparing two flanges with identical bore sizes (for instance, 6 inches) and the same material composition (such as ASTM A105), but differing in pressure ratings—one being Class 150 and the other Class 300—the flange with the lower rating (Class 150) will exhibit a smaller, lighter, and less sturdy construction compared to the flange with the higher rating (Class 300) and will withstand a lower pressure at a given temperature.

This distinction is vividly illustrated in the accompanying image, demonstrating that as the Class (or pressure rating) of a flange escalates, so does its overall size and robustness.

Now, let’s look at what this means in terms of pressure rating:

- a 6″ Class 150 flange in carbon steel withstands just 140 psi at a temperature of 600 degrees F°

- the 6″ Class 300 flange in carbon steel (bigger and stronger, but with the same bore size) withstands 570 psi at the same temperature of 600 degrees F°

- finally, a 6″ Class 2500 flange in carbon steel bears 34 times more pressure a the 6″ Class 150 flange in carbon steel, reaching a whopping 4730 psi rating at 600 F°!

- a 6″ Class 150 stainless steel flange withstands more pressure than a 6″ Class 150 carbon steel flange (as stainless steel is a “stronger” material than carbon steel), and the same is true for higher material grades (for example Nickel-Alloys, such as Monel, Hastelloy, Inconel, and Incoloy)

In conclusion:

- the flange rating is a measure of the strength (capacity to withstand pressure) of a flange at specified temperatures: a class 600 flange can handle more pressure than a class 300 flange, and a class 300 flange can handle more pressure than a class 150 flange.

- a stainless steel flange class 150 can handle more pressure than a class 150 carbon steel flange at a given temperature

FLANGE RATING CHARTS (ASME B16.5/B16.34)

CARBON STEEL

ASTM A105, A350 Gr. LF2/LF6 Class 1 (High-Temp. CS)

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI.

Note: For intermediate temperatures, linear interpolation of the pressure value is allowed.

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature (in F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test Pressure (in Psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in bars

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature in C° | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -29 / 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

Notes:

- ASTM A105: An extended exposure to temperatures above 425°C, converts the carbide phase of steel to graphite (therefore this material is not recommended for constant temperatures above this value.

- ASTM A350 LF6: shall not be used for temperatures above 260 C°

ASTM A350 Gr. LF3, A350 LF6, Class 2 (Low-Temp. CS)

The flange rating chart shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature in °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 290 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

| 200 | 260 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

| 300 | 230 | 730 | 970 | 1455 | 2185 | 3640 | 6070 |

| 400 | 200 | 705 | 940 | 1410 | 2115 | 3530 | 5880 |

| 500 | 170 | 665 | 885 | 1330 | 1995 | 3325 | 5540 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 505 | 670 | 1010 | 1510 | 2520 | 4200 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2060 | 3430 |

| 850 | 65 | 270 | 355 | 535 | 805 | 1340 | 2230 |

| 900 | 50 | 170 | 230 | 345 | 515 | 860 | 1430 |

| 950 | 35 | 105 | 140 | 205 | 310 | 515 | 860 |

| 1000 | 20 | 50 | 70 | 105 | 155 | 260 | 430 |

ASTM A350 Gr. LF1 (Low-Temp. CS)

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) — in PSI

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 235 | 620 | 825 | 1235 | 1850 | 3085 | 1545 |

| 200 | 215 | 560 | 750 | 1125 | 1685 | 2810 | 4680 |

| 300 | 210 | 550 | 730 | 1095 | 1640 | 2735 | 4560 |

| 400 | 200 | 530 | 705 | 1060 | 1585 | 2645 | 4405 |

| 500 | 170 | 500 | 665 | 995 | 1495 | 2490 | 4150 |

| 600 | 140 | 455 | 610 | 915 | 1370 | 2285 | 3805 |

| 650 | 125 | 450 | 600 | 895 | 1345 | 2245 | 3740 |

| 700 | 110 | 450 | 600 | 895 | 1345 | 2245 | 3740 |

| 750 | 95 | 445 | 590 | 885 | 1325 | 2210 | 3685 |

| 800 | 80 | 370 | 495 | 740 | 1110 | 1850 | 3085 |

| 850 | 65 | 270 | 355 | 535 | 805 | 1340 | 2230 |

| 900 | 50 | 170 | 230 | 345 | 515 | 860 | 1430 |

| 950 | 35 | 105 | 140 | 205 | 310 | 515 | 860 |

| 1000 | 20 | 50 | 70 | 105 | 155 | 260 | 430 |

ASTM A694 F42 (High-Yield CS)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ASTM A694 F42 Flanges | Pressure Rating Chart | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A694 F52 (High-Yield CS)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ASTM A694 F52 Flanges | Pressure Rating Chart | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A694 F65 (High-Yield CS)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ASTM A694 F65 Flanges | Pressure Rating Chart | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

LOW-ALLOY STEEL

ASTM A182 Gr. F1 (Chrome-Moly)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 265 | 695 | 925 | 1390 | 2085 | 3470 | 5785 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5660 |

| 300 | 230 | 655 | 870 | 1305 | 1955 | 3260 | 5435 |

| 400 | 200 | 640 | 855 | 1280 | 1920 | 3200 | 5330 |

| 500 | 170 | 620 | 830 | 1245 | 1865 | 3105 | 5180 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | 50 | 450 | 600 | 900 | 1350 | 2245 | 3745 |

| 950 | 35 | 280 | 375 | 560 | 845 | 1405 | 2345 |

| 1000 | 20 | 165 | 220 | 330 | 495 | 825 | 1370 |

ASTM A182 Gr. F5 (Chrome-Moly)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 265 | 695 | 925 | 1390 | 2085 | 3470 | 5785 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5660 |

| 300 | 230 | 655 | 870 | 1305 | 1955 | 3260 | 5435 |

| 400 | 200 | 640 | 855 | 1280 | 1920 | 3200 | 5330 |

| 500 | 170 | 620 | 830 | 1245 | 1865 | 3105 | 5180 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | 50 | 450 | 600 | 900 | 1350 | 2245 | 3745 |

| 950 | 35 | 280 | 375 | 560 | 845 | 1405 | 2345 |

| 1000 | 20 | 165 | 220 | 330 | 495 | 825 | 1370 |

ASTM A182 Gr. F9 (Chrome-Moly)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| Flanges | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A182 Gr. F11 (Chrome-Moly)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ASTM A182 F11 Flanges | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A182 Gr. F22 (Chrome-Moly)

The flange rating table below shows the maximum pressure for flanges of classes 150 to 2500 at increasing temperatures (Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 265 | 695 | 925 | 1390 | 2085 | 3470 | 5785 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5660 |

| 300 | 230 | 655 | 870 | 1305 | 1955 | 3260 | 5435 |

| 400 | 200 | 640 | 855 | 1280 | 1920 | 3200 | 5330 |

| 500 | 170 | 620 | 830 | 1245 | 1865 | 3105 | 5180 |

| 600 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | 50 | 450 | 600 | 900 | 1350 | 2245 | 3745 |

| 950 | 35 | 280 | 375 | 560 | 845 | 1405 | 2345 |

| 1000 | 20 | 165 | 220 | 330 | 495 | 825 | 1370 |

STAINLESS STEEL / DUPLEX

ASTM A182 Gr. F304/304L

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A182 Gr. F316/316L

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 235 | 620 | 825 | 1240 | 1860 | 3095 | 5160 |

| 300 | 215 | 560 | 745 | 1120 | 1680 | 2795 | 4660 |

| 400 | 195 | 515 | 685 | 1025 | 1540 | 2570 | 4280 |

| 500 | 170 | 480 | 635 | 955 | 1435 | 2390 | 3980 |

| 600 | 140 | 450 | 600 | 900 | 1355 | 2255 | 3760 |

| 650 | 125 | 445 | 590 | 890 | 1330 | 2220 | 3700 |

| 700 | 110 | 430 | 580 | 870 | 1305 | 2170 | 3620 |

| 750 | 95 | 425 | 570 | 855 | 1280 | 2135 | 3560 |

| 800 | 80 | 420 | 565 | 845 | 1265 | 2110 | 3520 |

| 850 | 65 | 420 | 555 | 835 | 1255 | 2090 | 3480 |

| 900 | 50 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 950 | 35 | 385 | 515 | 775 | 1160 | 1930 | 3220 |

| 1000 | 20 | 350 | 465 | 700 | 1050 | 1750 | 2915 |

| 1050 | 20 | 345 | 460 | 685 | 1030 | 1720 | 2865 |

| 1100 | 20 | 305 | 405 | 610 | 915 | 1525 | 2545 |

| 1150 | 20 | 235 | 315 | 475 | 710 | 1185 | 1970 |

| 1200 | 20 | 185 | 245 | 370 | 555 | 925 | 1545 |

| 1250 | 20 | 145 | 195 | 295 | 440 | 735 | 1230 |

| 1300 | 20 | 115 | 155 | 235 | 350 | 585 | 970 |

| 1350 | 20 | 95 | 130 | 190 | 290 | 480 | 800 |

| 1400 | 20 | 75 | 100 | 150 | 225 | 380 | 630 |

| 1450 | 20 | 60 | 80 | 115 | 175 | 290 | 485 |

| 1500 | 20 | 40 | 55 | 85 | 125 | 205 | 345 |

ASTM A182 Gr. F321/321L

The flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI

| Temperature In °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A182 Gr. F347/347L

flange rating table shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius or Fahrenheit) – in PSI

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

ASTM A182 Gr. F51 (Duplex Stainless Steel)

The flange rating table below shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Celsius) – in bars

| Temp, ℃ | Pressure-temperature rating for ASME B16.5 by class, bar | ||||||

| 150# | 300# | 400# | 600# | 900# | 1500# | 2500# | |

| -29 to 38 | 20.0 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

| 50 | 19.5 | 51.7 | 68.9 | 103.4 | 155.1 | 258.6 | 430.9 |

| 100 | 17.7 | 50.7 | 67.5 | 101.3 | 152.0 | 253.3 | 422.2 |

| 150 | 15.8 | 45.9 | 61.2 | 91.9 | 137.8 | 229.6 | 382.7 |

| 200 | 13.8 | 42.7 | 56.9 | 85.3 | 128.0 | 213.3 | 355.4 |

| 250 | 12.1 | 40.5 | 53.9 | 80.9 | 121.4 | 202.3 | 337.2 |

| 300 | 10.2 | 38.9 | 51.8 | 77.7 | 116.6 | 194.3 | 323.8 |

ASTM A182 Gr. F513/F55 (SuperDuplex Stainless Steel)

The flange rating table below shows the maximum pressure for flanges of classes 150/300/400/600/900/1500/2500 at increasing temperatures (Fahrenheit) – in PSI

| ANSI/ASME B16.34 | ANSI/ASME PRESSURE RATING | ||||||

| Temperature °F | 150 Class | 300 Class | 400 Class | 600 Class | 900 Class | 1500 Class | 2500 Class |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |

FLANGE RATING SELECTION

Selecting the proper flange class is crucial to ensuring the safety, efficiency, and longevity of your piping system. The flange class, often referred to as the pressure class, dictates the maximum pressure and temperature that a flange can withstand.

Here’s a guide to help you choose the appropriate flange class for your application, in line with ASME B16.5 and ASME B16.34 recommendations:

1. Understand Your System’s Requirements

- Operating Pressure: Determine the maximum operating pressure of your system, including any potential pressure surges or fluctuations.

- Operating Temperature: Identify the maximum temperature your system will reach during operation. Remember, the material’s strength can decrease at higher temperatures, affecting the flange’s pressure capacity.

- Fluid Characteristics: Consider the type of fluid being transported (e.g., water, oil, gas, chemicals) and its properties, including corrosiveness, toxicity, and viscosity.

2. Know the Flange Materials & Select a Proper Grade

Different materials have varying capabilities for withstanding pressure (psi, bar) at given temperatures. Common flange materials include carbon steel (e.g., A105), stainless steel (e.g., A182), and alloy steel: each grade has different strengths (max. allowed withstandable pressure) at the same temperature.

You should choose the material of the flange from the 44 listed materials in the ASME B16.5 standard. Pay close attention to any qualifying notes regarding maximum operating temperatures for each material, as this can impact the final material selection.

The material choice is the most critical decision as it will impact the flange’s ability and safety to handle the system’s requirements (pressure and temperature).

ASME B16.5 MATERIAL GROUPS

ASME B16.5 categorizes materials into different groups for the purpose of pressure rating selection. This standard provides dimensions, tolerances, materials, pressure-temperature ratings, marking, and testing for flanges in sizes from NPS 1/2 through NPS 24 and in ratings from Class 150 to Class 2500.

Material Groups in ASME B16.5:

The material groups in ASME B16.5 are primarily based on the chemical composition and mechanical properties of the materials. These groups help in determining the appropriate pressure-temperature ratings for flanges made from different materials. Some of the common material groups mentioned in ASME B16.5 include:

Carbon Steel: This is one of the most common materials used for manufacturing flanges and is categorized into several groups based on the carbon content and mechanical properties. Examples include ASTM A105 for standard carbon steel flanges.

Alloy Steel: Alloy steels with varying compositions for improved strength, hardness, or resistance to wear and corrosion. This includes materials like ASTM A182 F1, F5, F9, F11, and F22, which are alloy steels suited for high-temperature or high-pressure service.

Stainless Steel: Stainless steel flanges are categorized into different groups based on their crystalline structure (austenitic, ferritic, martensitic) and composition, offering varying levels of corrosion resistance and strength at high temperatures. Common examples include ASTM A182 F304/L and F316/L.

Nickel Alloys: These materials are used for flanges in highly corrosive environments or where high-temperature resistance is needed. Examples include materials like Inconel, Monel, and Hastelloy, which are not explicitly categorized in ASME B16.5 but are recognized for special applications.

| ASTM Group 2-1.1 Materials | |||

| Nominal Designation | Forgings | Castings | Plates |

| C-Si | ASTM A105 | ASTM A216 Gr.WCB | ASTM A515 Gr.70 |

| C Mn Si | ASTM A350 Gr.LF2 | ASTM A516 Gr.70 | |

| C Mn Si V | ASTM A350 Gr.LF6 Cl 1 | ASTM A537 Cl.1 | |

| 3.1/2Ni | ASTM A350 Gr.LF3 | ||

| ASTM Group 2-2.3 Materials | |||

| Nominal Designation | Forgings | Castings | Plates |

| 16Cr 12Ni 2Mo | ASTM A182 Gr.F316L | ASTM A240 Gr.316L | |

| 18Cr 13Ni 3Mo | ASTM A182 Gr.F317L | ||

| 18Cr 8Ni | ASTM A182 Gr.F304L | ASTM A240 Gr.304L | |

Selection Based on Pressure Ratings:

The pressure-temperature ratings for each material group in ASME B16.5 are determined based on the material’s mechanical properties and its behavior under different temperature conditions. The standard provides tables that list the maximum allowable working pressure for flanges at various temperatures, allowing engineers to select the appropriate flange class and material for their specific application requirements.

It’s important to note that the selection of a flange material and its pressure rating must also consider factors like the type of fluid being handled, potential corrosive conditions, and any specific industry or regulatory requirements. The comprehensive approach to categorizing materials and specifying their pressure-temperature ratings in ASME B16.5 ensures that flanges are chosen that will provide reliable performance and safety in their intended applications.

3. Refer to Pressure-Temperature Ratings

Each flange class has a specific pressure-temperature rating defined in standards such as ASME B16.5 or ASME B16.34. These ratings provide a guideline for what each flange class can handle. For instance, a Class 150 flange may operate safely at a certain pressure at 100°F but at a lower pressure at 500°F. As explained, these values change depending on the specific material grade of the flange.

4. Consider System Upgrades and Changes

Anticipate any future modifications or upgrades that might increase the system’s pressure or temperature requirements. Selecting a flange class that accommodates potential future changes can prevent the need for costly system modifications.

5. Account for Safety Factors

Implement a safety factor by choosing a flange class that exceeds your system’s maximum anticipated pressure and temperature. This factor provides a buffer for unexpected spikes in pressure or temperature, ensuring the system’s safety and reliability.

6. Consultation and Standards

- Consult with Experts: When in doubt, consult with experienced engineers or piping specialists. Their expertise can guide you in selecting the most appropriate flange class for your application.

- Follow Industry Standards: Ensure compliance with relevant industry standards and regulations, which may dictate specific requirements for flange selection based on the application.

By carefully considering these aspects, you can confidently select the proper flange class that meets your system’s demands, ensuring optimal performance and safety. Remember, the right flange not only secures connections within your piping system but also plays a crucial role in maintaining operational integrity and preventing leaks or failures.

Still unsure about choosing the right pressure rating for the flanges in your piping network? Watch the video below for further insights into this essential subject:

11 Responses

Can i use a 150lbs rating flange with pipe of NPS 8″, schedule 80? The max working pressure in system is only 100psig.

Thank you for sharing this information. I can get flange rating data quickly by using this chart. I recommend you to make a flange pressure rating calculator instead of only chart. Calculators will be more easier to use.

Hi.

Please suggest flange dimension for T= 1200K and Pressure=100 bar. Also provide reference if possible.

thanks in advance

Useful information but not complete.

You didn’t mention size. Let’s assume if I select for 10″ 300# flange will this hold the same pressure as 6″ 300# flange of the same material.

I don’t think so.

By the way great website, and well maintained to know even more from other articles.

I have to flange 24 inch diameter mild steel pipes for a water pressure as low as 10 psi. I am concerned why should I use #150 flanges which are over strong for my need? I am desperately looking for some other flange standards which deal with very low pressures. I will be much obliged if some one can help.

Good day,

I have a 200mm T/10 BS4504 galvanized carbon steel flange. I want to multi drill it to T/1600. What will the pressure rating be on the flange after drilling?

How you calc max pressure testing of flang A105 900#

in google search it was 3350psi

Hi

If my pipe is SS 316L. My Backing Flange is #150 lb forged Steel, lap joint (Galvanized) should the Flange pressure rating be based on a Carbon Steel #150 Flange?

Hi,

I have a question about pressure-temperature rating. For which fittings the standard define class rating?

Specifically i want to know why “insulating joints” has class rating?

Thanks

{08/28/19 @ 15:12 EDT}

I found this site to contain much useful information but not exactly what I need. I hope you can help regarding the correct

ASME flange to use for methane service @ 1000°C and 0.2 MPa. I think 900# RF or RTJ? Please, where could I find that information?

Thanks for any help.

Ps. Information not found in “Flange Pressure Rating Explained (and Charts)” article. Charts end at 1500 F (815°C)

The bolts in flanges will relax so flange over 1500F are troublesome. Typical the connect would be internally insulated so the flange and bolts would operate at a lower temperature.